Professional Documents

Culture Documents

Microstructure and Mechanical Properties of TRIP-TWIP Steels

Microstructure and Mechanical Properties of TRIP-TWIP Steels

Uploaded by

Omar Al-AbriCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Factors Affecting PhotosynthesisDocument15 pagesThe Factors Affecting PhotosynthesisAqua PulzeNo ratings yet

- Commissioning and Qualification ASTM ApproachDocument0 pagesCommissioning and Qualification ASTM Approachvenki_beeNo ratings yet

- White Paper - Blow Molding TPOs With High Melt Strength Polyolefin ElastomersDocument4 pagesWhite Paper - Blow Molding TPOs With High Melt Strength Polyolefin Elastomersharshpatel18No ratings yet

- SF6 Gas Handling Gov EPA RegulationDocument10 pagesSF6 Gas Handling Gov EPA RegulationferiNo ratings yet

- Hipertensi KomplikasiDocument15 pagesHipertensi KomplikasiGhea RofifahNo ratings yet

- Foamed Concrete: Potential Application in Thermal InsulationDocument6 pagesFoamed Concrete: Potential Application in Thermal InsulationJr Rameez RajaNo ratings yet

- Coercivity and Remanence in Permanent MagnetsDocument3 pagesCoercivity and Remanence in Permanent Magnetsteddy18No ratings yet

- IFFCODocument36 pagesIFFCOTarun DixitNo ratings yet

- Company Profile - RNDDocument13 pagesCompany Profile - RNDyayat supriatnaNo ratings yet

- Biorefinery of Waste Orange PeelDocument8 pagesBiorefinery of Waste Orange PeelIlireaNo ratings yet

- Grit ClassifierDocument109 pagesGrit ClassifierNguyen Phuc PhamNo ratings yet

- TDS Celvolit 1326 (SG)Document2 pagesTDS Celvolit 1326 (SG)Duc Nguyen100% (1)

- Uses and Advantages of CementDocument3 pagesUses and Advantages of CementdominationanalyticsNo ratings yet

- Automated Sensing of Hydroponic Macronutrients Using Acomputer-Controlled System With An Array of Ion-Selective ElectrodesDocument9 pagesAutomated Sensing of Hydroponic Macronutrients Using Acomputer-Controlled System With An Array of Ion-Selective ElectrodesFolkes EduwardNo ratings yet

- Material Selection in Oil and Gas 1684649857Document15 pagesMaterial Selection in Oil and Gas 1684649857Sh MNNo ratings yet

- LD5655.V855 1966.C4Document106 pagesLD5655.V855 1966.C4Naufal Maliki Rahmat K.JNo ratings yet

- Summary For Antibiotic For USMLE Exam - USMLE MaterialsDocument6 pagesSummary For Antibiotic For USMLE Exam - USMLE MaterialsAshik ThapaNo ratings yet

- Frog Rectus AbdominisDocument76 pagesFrog Rectus AbdominisAdhiraj KakkarNo ratings yet

- PSD200912 Meter PG 46 PDFDocument84 pagesPSD200912 Meter PG 46 PDFosamamae100% (1)

- This Study Resource WasDocument9 pagesThis Study Resource WasNurul izzatiNo ratings yet

- Electron Transfer at Different Electrode MatDocument13 pagesElectron Transfer at Different Electrode MatAbeerNo ratings yet

- Long Test As Level Nucleic AcidDocument9 pagesLong Test As Level Nucleic AcidPrisky Jofan SimbarNo ratings yet

- ISO - ISO - TC 34 - SC 11 - Animal and Vegetable Fats and OilsDocument10 pagesISO - ISO - TC 34 - SC 11 - Animal and Vegetable Fats and OilsZahid Mahmood0% (1)

- Chapter 11 NotesDocument9 pagesChapter 11 NotesJohnnyMoyaNo ratings yet

- Bis (Triethoxysilylpropyl) Polysulfide: Technical DataDocument2 pagesBis (Triethoxysilylpropyl) Polysulfide: Technical DataDaniel MartinsNo ratings yet

- Concrete Technology - 2 Lecture - 4-1Document17 pagesConcrete Technology - 2 Lecture - 4-1Muhammad Ahmad JamilNo ratings yet

- MSDS Auramix 300 PDFDocument3 pagesMSDS Auramix 300 PDFkk mishra0% (1)

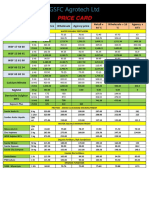

- Price CardDocument2 pagesPrice Cardvim patelNo ratings yet

- Drugs Education and Vice Control: C. TetrahyrocannabinolDocument5 pagesDrugs Education and Vice Control: C. TetrahyrocannabinolHEROWIN EDUARDO100% (1)

- Filtro Aceite SPORLAN OF-303Document2 pagesFiltro Aceite SPORLAN OF-303IDEA RefrisolICENo ratings yet

Microstructure and Mechanical Properties of TRIP-TWIP Steels

Microstructure and Mechanical Properties of TRIP-TWIP Steels

Uploaded by

Omar Al-AbriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Microstructure and Mechanical Properties of TRIP-TWIP Steels

Microstructure and Mechanical Properties of TRIP-TWIP Steels

Uploaded by

Omar Al-AbriCopyright:

Available Formats

Available online at www.sciencedirect.

com

SCIENCE

DIRECT

JOURNAL OF IRON AND STEEL RESEARCH, INTERNATIONAL. 2006, 13(6) : 66-70

Microstructures and Mechanical Properties of

Fe-Mn-(A1 Si) TRIP/TWIP Steels

DING Hua ,

TANG Zheng-You

LI Wei ,

WANG Me?,

SONG Dan

(1. College of Materials and Metallurgy, Northeastern University, Shenyang 110004, Liaoning, China;

2. Continuous Casting Center, Central Iron and Steel Research Institute, Beijing 100081, China)

Abstract: The mechanical properties and microstructure of two low carbon high manganese steels with 23.8%

(No. 1) and 33% (No. 2) (mass percent) of manganese were investigated. The results showed that No. 1 steel possesses high strength and high plasticity, and No. 2 steel has a relatively high strength and extraordinary plasticity.

The NO. 1 steel exhibits both TRIP (transformation induced plasticity) and TWIP (twin induced plasticity) effects

during the deformation; while only TWIP effect appeared under the same deformation condition for No. 2 steel. The

comparison between the microstructures and mechanical properties of two steels was made, and the strengthening

mechanisms were also analyzed.

Key words: manganese; TRIP; TWIP; microstructure; mechanical property

Recently, low carbon high manganese austenitic

steels have aroused interests due to their extraordinary mechanical properties. These engineering highstrength steels are called TRIP (transformation induced plasticity) and TWIP (twin induced plasticity) steels, and they are mostly devoted to automotive bodies. Research work has been done in alloy

development, microstructure analysis and mechanical properties for these steels-31. Steel companies

are also trying to do some pioneer work in applications in auto-industries.

Grassel 0 et a1 have done systematic work in

high manganese TRIP/TWIP steels. They investigated the effects of alloying elernents on the mechanical properties of austenitic Fe-( 15% - 30%)

Mn (mass percent) steels with additions of aluminium and silicon, and also made some comparisons

between TRIP and TWIP steels. I t was stated that

the alloy would mainly reveal TRIP effect when

manganese content was lower than 2 0 % ; while

TWIP effect would be dominant when manganese

content is higher than 25%.

In theoretical aspects, there has been much

work concerning the formation of deformation

twins, and interaction between dislocations moveBiography: DING Hua(1958-1, Female, Doctor, Professor;

ments and twinning in high manganese steels.

Bouaziz 0 conducted modeling work on TWIP effect

to describe the interaction between dislocation gliding and deformation twinningC4. Allain S et a1 investigated the formation of microtwins and proposed

a physical model to highlight the link between the

mechanical properties and the microstructure properties (TWIP e f f e ~ t ) ~ Karaman

~~.

I et a1 studied

the deformation of single M n l 3 steel by twinning

and slip, and analyzed the effects of original orientation on the deformation processC7J.

Up till now, most work related high manganese

steels has been concentrated on the alloy, which either

has TRIP or TWIP effect. In the present work, an alloy

was designed with manganese content between 20% and

25% to see if both TRIP and TWLP effects could coexist, and another alloy with manganese content much

higher than 25% was chosen to make some comparisons

between the mechanical properties and deformed microstructures of different steels. Meanwhile, the strengthening mechanisms were also analyzed.

Experimental Procedure

T h e steels were smelt in a 50 kg vacuum induction furnace, and the chemical composition ( mass

E-mail: hdingB263. net;

Revised Date: June 2 , 2006

67

Microstructures and Mechanical Properties of Fe-Mn-( Al, Si) TRIP/TWIP Steels

No. 6

percent, %) was shown in Table 1.

The ingots were first forged, and then hot

rolled to the plate with thickness of 1 6 mm. T h e

materials were heated up to 1 100 " C , kept at this

temperature for 1 h , then water quenched. T h e tensile testing was carried out in an Instron machine at

s-'.

room temperature and with a strain rate of

T h e gauge area of the tensile specimens is $5 mmX

25 mm. Microhardness of deformed specimens were

measured by FM-700 Vickers microhardness tester.

The microstructures before and after deformation

were observed at a Leicaq 550IW optical microscope

and Tecnai 20 (TEM). X-ray analysis was used to identify the phase structure of the materials.

Table 2

Mechanical properties of tested steels

Steel

R,L/MPa

No. 1

339

666

67

No. 2

223

540

97

R,/MPa

A/%

700

f:

5oo

-.- 300

P

c.

100

Table 1

Chemical compositions of tested steels

Steel

Mn

A1

Si

Fe

No. 1

No. 2

23. 8

2. 7

2. 93

3.0

6X10K4

Balance

3. 0

6X

33. 0

lo-'

Balance

20

40

60

Tensile strai~~%

80

100

Fig. 1 Engineering stress and strain curves

(room temperature,

s-' )

Results

2. 1 Mechanical properties

Table 2 shows the mechanical properties (room

s - ' ) of tested steels. It can be

temperature,

seen that No. 1 steel has a higher strength and No. 2

steel has a higher elongation at the same deformation

condition. The engineering stress and strain curves

of two steels are shown in Fig. 1.

2.2

Microstructural observation

Fig. 2 shows the microstructures of the as-received materials, which show that the initial microstructures contain some annealing twins. XRD indicated both steels contain only single austenite phase. The

(a) No. 1 steel;

Fig. 2

microstructures after deformation of the tested

steels were shown in Fig. 3 . In No. 1 steel, it is

found that there are some islands [ a s shown in arrow in Fig. 3 ( a ) ] , and testing result reveals that

their hardness is 280 HV, which is similar to the

matrix (265 HV). This result indicates that these

islands must be retained austenite remaining after

deformation. It is difficult to identify if phase transformation or twinning took place in No. 1 steel during deformation by optical microscope. For No. 2

steel, deformation twins are clearly seen in Fig. 3 (b).

Both bcc and fcc phase have been identified by

XRD in deformed No. 1 steel [shown in Fig. 4 (b)].

Since the initial state of t h e material w a s single y

( b ) No. 2 steel

Initial microstructures (OM)

Vol. 13

Journal of Iron and Steel Research, International

68 *

(a)

Fig. 3

NO. 1 steel;

( b ) No. 2 steel

Microstructures of deformed specimens (OM)

8 000

6 000

4000

b

.-

2000

0

40

60

80

(a)

Fig. 4

100

120

40

14

26/(")

Undeformed specimen;

60

80

100

120

140

( b ) Deformed specimen

XRD of undeformed and deformed specimens (No. 1 steel)

phase [shown in Fig. 4 (a)], the bcc phase could be

martensite transformed during the deformation

process. This is proven by T E M studies. Fig. 5 ( a >

shows the morphology of deformed specimen under

TEM, and some lath like grains can be found, as

shown in arrows. Fig. 5 ( b ) gives the diffraction

pattern of selected area, and the diffraction analysis

[Fig. 5 (c)] indicates that the microstructure of bcc

phase is martensite formed during deformation.

Fig. 6 (a> shows the morphology of twins in deformed specimen under T E M , and Fig. 6 ( b ) gives

the diffraction pattern of selected area. T h e diffraction analysis indicates that the twinning plane is

(111) and the twinning direction is [ 1131. Therefore, it can be concluded that both T R I P and T W I P

effects existed in the deformation of No. 1 steel. In

the XRD of deformed No. 2 steel, only fcc phase was

detected, so only TWIP effect existed during the deformation of later material.

Discussion

T h e experimental results in the present study

proves that low carbon high manganese austenitic

steels have very good mechanical properties, both

high strength and good plasticity. Also, it can be

found out that both steels have continuous yielding

characteristics and high strain hardening exponent,

which is very good for automobile industry.

In the present work, TRIP and TWIP effects

coexisted in No. 1 steel with manganese content of

23. 8 % ; while only TWIP effect appeared when the

manganese content was 3 3 % (No. 2 steel) in the

tensile testing at a strain rate of

s-l at room

temperature. This means that when manganese content is relatively low, T R I P effect would be dominant in the deformation; whereas only TWIP effect

would appear when manganese content reaches a

certain value.

No. 6

Microstructures and Mechanical Properties of Fe-Mn-C Al, Si)

( a ) Morphology;

Fig. 5

( a ) Morphology;

Fig. 6

TRIP/TWIP Steels

69 *

(b) Diffraction pattern of martensite;

(c) Diffraction analysis

Microstructures of deformed No. 1 steel (TEM)

(b) Diffraction pattern of twins;

(c) Diffraction analysis

Microstructures of deformed No. 1 steel (TEM)

From Table 2 , it can be found that No. 1 steel

possesses high strength and high plasticity, and

No. 2 steel has a relatively high strength and extraordinary plasticity. In TRIP steels, phase transformation would take place preferentially in 7 matrix

in the area where local necking tends to occur.

Therefore, the necking would be restrained and the

uniform elongation could be enhanced. Simultaneously, the strength of the material also increases due

to the intensive local strain hardening. For TWIP

steels, the reason for achieving enhanced elongation

is principally the same as that for the TRIP-effect.

The strain-induced deformation twins will be preferentially formed in a local deformation region, and

the dislocation motion will be retarded since these

twin boundaries could act as strong barriers, which

makes the strength of the materials Increase. Comparing the mechanical properties of two alloys, it

can be found that the No. 1 steel with both T R I P

and T W I P effects has a higher strength; while the

No. 2 steel with only TWIP effect has a higher plasticity. This implies that TRIP effect can obviously

increase the strength of high manganese steel, and

TWIP effect is beneficial to the increase of plasticity

of the material.

Generally, the main strengthening mechanisms

are solid solution strengthening, grain boundary

strengthening, strain hardening and hardening from

phase transformation for structural steels. In the

present case, the steel with a higher manganese content has a lower strength, which means that solid

solution strengthening is not a major strengthening

mechanism. But the strain induced phase transformation or twinning makes the most important contribution t o the increase of the materials strength.

For practical applications, it is not good for

steels t o have a very high manganese content.

Therefore, TRIP and TWIP coexisting effects could

be utilized to obtain balance mechanical properties

with a lower manganese content in this kind of

steels. Also, quantitative descriptions of the effects

of T R I P or T W I P on strength and plasticity of materials need to be investigated further. This part of

work is under research.

Conclusions

(1) For low carbon high manganese austenitic

steel with manganese content of 23.8% ( N o . 1

steel), TRIP and TWIP effects coexist; while only

TWIP effect appears when manganese content is

33% (No. 2 steel) in the tensile testing at a strain

rate of 1 0 - ~

s-* at room temperature.

(2) T h e strength of No.1 steel is higher than

that of No. 2 steel, and the plasticity of No. 1 steel is

70

Journal of Iron and Steel Research, International

lower than that of No. 2 steel under the same testing

condition, which indicates that TRIP effect may

make more contribution to the strength of the materials, while TWIP effect is beneficial to the increase

of plasticity of the materials.

( 3 ) As manganese content increases, the strength

of the high manganese austenitic steel decreases,

while the plasticity of the material increases, which

indicate that solid solution strengthening is not a

major strengthening mechanism, but the strain induced phase transformation or twinning makes a very important contribution to the strength of these

steels.

References :

c11

Grassel 0. High Strength Fe-Mn-CAl, Si) TRIP/TWIP Steel

C2l

c3i

C41

c51

C61

c71

Vol. 13

Development-Properties-Application [J]. International J Plasticity, 2000, 16: 1391-1409.

MI Zhen-li, TANG Di, YAN Ling, et al. Study of High

Strength and High Plasticity TWIP Steel [J]. Iron and Steel,

2005, 40(1): 58-60 (in Chinese).

MI Zhen-li, TANG Di, YAN Ling, et al. High Strength and

High Plasticity TWIP Steel for Modern Vehicle [J]. Mater Sci

Technol, 2005, 21(4): 451-454.

Bouaziz 0, Guelton N. Modeling on TWIP Effect on WorkHardening [I]. Mater Sci Eng, 2001, 319-321A: 246-249.

Allain S. Modeling of Mechanical Twinning in a High Manganese Content Austenitic Steel [J]. Mater Sci Eng, 2004, 387389A: 272-276.

Allain S. A Physical Model of the Twinning-Induced Plasticity

Effect in a High Manganese Austenitic Steel [J]. Mater Sci

Eng, 2004, 387-389A: 143-147.

Karaman I , Sehitoglu H , Gall K , et al. Deformation of Single

Crystal Hadfield Steel by Twinning and Slip [J]. Acta Mater,

2000, 48: 1345-1359.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Factors Affecting PhotosynthesisDocument15 pagesThe Factors Affecting PhotosynthesisAqua PulzeNo ratings yet

- Commissioning and Qualification ASTM ApproachDocument0 pagesCommissioning and Qualification ASTM Approachvenki_beeNo ratings yet

- White Paper - Blow Molding TPOs With High Melt Strength Polyolefin ElastomersDocument4 pagesWhite Paper - Blow Molding TPOs With High Melt Strength Polyolefin Elastomersharshpatel18No ratings yet

- SF6 Gas Handling Gov EPA RegulationDocument10 pagesSF6 Gas Handling Gov EPA RegulationferiNo ratings yet

- Hipertensi KomplikasiDocument15 pagesHipertensi KomplikasiGhea RofifahNo ratings yet

- Foamed Concrete: Potential Application in Thermal InsulationDocument6 pagesFoamed Concrete: Potential Application in Thermal InsulationJr Rameez RajaNo ratings yet

- Coercivity and Remanence in Permanent MagnetsDocument3 pagesCoercivity and Remanence in Permanent Magnetsteddy18No ratings yet

- IFFCODocument36 pagesIFFCOTarun DixitNo ratings yet

- Company Profile - RNDDocument13 pagesCompany Profile - RNDyayat supriatnaNo ratings yet

- Biorefinery of Waste Orange PeelDocument8 pagesBiorefinery of Waste Orange PeelIlireaNo ratings yet

- Grit ClassifierDocument109 pagesGrit ClassifierNguyen Phuc PhamNo ratings yet

- TDS Celvolit 1326 (SG)Document2 pagesTDS Celvolit 1326 (SG)Duc Nguyen100% (1)

- Uses and Advantages of CementDocument3 pagesUses and Advantages of CementdominationanalyticsNo ratings yet

- Automated Sensing of Hydroponic Macronutrients Using Acomputer-Controlled System With An Array of Ion-Selective ElectrodesDocument9 pagesAutomated Sensing of Hydroponic Macronutrients Using Acomputer-Controlled System With An Array of Ion-Selective ElectrodesFolkes EduwardNo ratings yet

- Material Selection in Oil and Gas 1684649857Document15 pagesMaterial Selection in Oil and Gas 1684649857Sh MNNo ratings yet

- LD5655.V855 1966.C4Document106 pagesLD5655.V855 1966.C4Naufal Maliki Rahmat K.JNo ratings yet

- Summary For Antibiotic For USMLE Exam - USMLE MaterialsDocument6 pagesSummary For Antibiotic For USMLE Exam - USMLE MaterialsAshik ThapaNo ratings yet

- Frog Rectus AbdominisDocument76 pagesFrog Rectus AbdominisAdhiraj KakkarNo ratings yet

- PSD200912 Meter PG 46 PDFDocument84 pagesPSD200912 Meter PG 46 PDFosamamae100% (1)

- This Study Resource WasDocument9 pagesThis Study Resource WasNurul izzatiNo ratings yet

- Electron Transfer at Different Electrode MatDocument13 pagesElectron Transfer at Different Electrode MatAbeerNo ratings yet

- Long Test As Level Nucleic AcidDocument9 pagesLong Test As Level Nucleic AcidPrisky Jofan SimbarNo ratings yet

- ISO - ISO - TC 34 - SC 11 - Animal and Vegetable Fats and OilsDocument10 pagesISO - ISO - TC 34 - SC 11 - Animal and Vegetable Fats and OilsZahid Mahmood0% (1)

- Chapter 11 NotesDocument9 pagesChapter 11 NotesJohnnyMoyaNo ratings yet

- Bis (Triethoxysilylpropyl) Polysulfide: Technical DataDocument2 pagesBis (Triethoxysilylpropyl) Polysulfide: Technical DataDaniel MartinsNo ratings yet

- Concrete Technology - 2 Lecture - 4-1Document17 pagesConcrete Technology - 2 Lecture - 4-1Muhammad Ahmad JamilNo ratings yet

- MSDS Auramix 300 PDFDocument3 pagesMSDS Auramix 300 PDFkk mishra0% (1)

- Price CardDocument2 pagesPrice Cardvim patelNo ratings yet

- Drugs Education and Vice Control: C. TetrahyrocannabinolDocument5 pagesDrugs Education and Vice Control: C. TetrahyrocannabinolHEROWIN EDUARDO100% (1)

- Filtro Aceite SPORLAN OF-303Document2 pagesFiltro Aceite SPORLAN OF-303IDEA RefrisolICENo ratings yet