Professional Documents

Culture Documents

Ipes-Ir3 R08

Ipes-Ir3 R08

Uploaded by

naveedfndCopyright:

Available Formats

You might also like

- Air Blowing ProcedureDocument5 pagesAir Blowing ProcedureArslan Nisar100% (2)

- Detector SelectionDocument149 pagesDetector Selectionssriram2003No ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Chimedza W: Boiler Blowdown Heat Recovery ProjectDocument34 pagesChimedza W: Boiler Blowdown Heat Recovery ProjectBlessed ZiyambeNo ratings yet

- LENNOX HS29 - 3phaseDocument20 pagesLENNOX HS29 - 3phasedmoros100% (1)

- Architectural Specifications PlycemDocument4 pagesArchitectural Specifications PlycemZenon PruszaNo ratings yet

- Fire Sentry FS24X Flame DetectorsDocument4 pagesFire Sentry FS24X Flame DetectorshdrNo ratings yet

- The Flamegard Series of Flame Detectors: Fast, Reliable Flame DetectionDocument4 pagesThe Flamegard Series of Flame Detectors: Fast, Reliable Flame DetectionSandika JayaputraNo ratings yet

- Depliant Iris Enea Inim 1.10 ENGDocument4 pagesDepliant Iris Enea Inim 1.10 ENGKnjigescribdNo ratings yet

- Fl4000h DataDocument2 pagesFl4000h Datadarkchess76No ratings yet

- RF 360 Advanced Ceiling Mount PIR Installation Manual-1Document2 pagesRF 360 Advanced Ceiling Mount PIR Installation Manual-1Imi Michał SmulskiNo ratings yet

- Apollo Marinecatalogue2013 All Mr-LockedDocument0 pagesApollo Marinecatalogue2013 All Mr-LockedVictor ChuaNo ratings yet

- IR3 Data Sheet enUS 11803977227Document3 pagesIR3 Data Sheet enUS 11803977227Charles DublinNo ratings yet

- Monitor and Control Equipment 24/7/365: Smoke & TemperatureDocument2 pagesMonitor and Control Equipment 24/7/365: Smoke & TemperaturePushpendra SinghNo ratings yet

- MSA UV - IR Flame Detector PDFDocument2 pagesMSA UV - IR Flame Detector PDFwe202No ratings yet

- Fire Detection SystemDocument38 pagesFire Detection Systemkhalid najjarNo ratings yet

- Simtronics TV7-TDocument2 pagesSimtronics TV7-TNoel Federer SarkarNo ratings yet

- Fire & Flame DetectorDocument4 pagesFire & Flame DetectorAhmed El Sayed SalamaNo ratings yet

- Cirrus 200D Issue 4Document2 pagesCirrus 200D Issue 4Byron RieraNo ratings yet

- Prix N°2.2 Détecteur Optique de FuméeDocument7 pagesPrix N°2.2 Détecteur Optique de Fuméemohammed alsaidiNo ratings yet

- Nikon ManualDocument8 pagesNikon Manualdipayankr40No ratings yet

- In The Name of " The Most Gracious The Most Merciful, Whose Help We SolicitDocument63 pagesIn The Name of " The Most Gracious The Most Merciful, Whose Help We SolicitMuhammad Abdul Rauf100% (1)

- IR400 Data SheetDocument2 pagesIR400 Data Sheetdarkchess76No ratings yet

- Eagle PIR-018H / PIR-045H / PIR-100H Outdoor Passive Infrared DetectorsDocument7 pagesEagle PIR-018H / PIR-045H / PIR-100H Outdoor Passive Infrared DetectorsgjaftelecomNo ratings yet

- Gsti 9104Document2 pagesGsti 9104aditgroupNo ratings yet

- FINAL SimplexFireProducts TrueAlarmAnalogueAddressableDetectorsDataSheet 2aug05Document4 pagesFINAL SimplexFireProducts TrueAlarmAnalogueAddressableDetectorsDataSheet 2aug05darkchess76No ratings yet

- Multispectrum Infrared Flame Detector Autroflame X33Document2 pagesMultispectrum Infrared Flame Detector Autroflame X33Angela FasuyiNo ratings yet

- Main Features: Triple IR (IR3) Flame DetectorDocument2 pagesMain Features: Triple IR (IR3) Flame Detectorykresna1631No ratings yet

- Detronics UV-IR Flame Detector Model X5200Document2 pagesDetronics UV-IR Flame Detector Model X5200selvajanarNo ratings yet

- Fluke Temperatura NotaDocument12 pagesFluke Temperatura Notalopablito24No ratings yet

- Detector Flama IPES-IRUVDocument2 pagesDetector Flama IPES-IRUVPio Wilde Quispe GarciaNo ratings yet

- ProReact Digital LHD Installation InstructionsDocument11 pagesProReact Digital LHD Installation InstructionsAlexandru CraiovanNo ratings yet

- Fire Detection & Alarm SystemDocument30 pagesFire Detection & Alarm SystemmohideenNo ratings yet

- Photoelectric Smoke Detector P.1.18.01-4Document2 pagesPhotoelectric Smoke Detector P.1.18.01-4Pedro Caminos BolanosNo ratings yet

- Flame Detector SpectrexDocument2 pagesFlame Detector Spectrexengmohamedmoheb0No ratings yet

- P.1.52.01 Intelligent Low Profile Plug in DetectorsDocument2 pagesP.1.52.01 Intelligent Low Profile Plug in DetectorsamilcarmbNo ratings yet

- SD365Document2 pagesSD365Jesús Morales IretaNo ratings yet

- 2013 Esser CatalogDocument364 pages2013 Esser CatalogArman Ul Nasar100% (2)

- 5753 LDocument7 pages5753 LYousuf IbrahimNo ratings yet

- 40-40I Flame DetectorDocument2 pages40-40I Flame DetectorSumeet Sisir SarkarNo ratings yet

- Detector UVIR X5200Document2 pagesDetector UVIR X5200chicle60No ratings yet

- 10 - EQP OverviewDocument51 pages10 - EQP OverviewdadyjoshNo ratings yet

- Thermocouple Multiplexer2Document16 pagesThermocouple Multiplexer2Saamir JassimNo ratings yet

- ApolloFire XP95 MultisensorDocument2 pagesApolloFire XP95 MultisensorfasiwiNo ratings yet

- 74-5070 TC840C1000 CoptirDocument2 pages74-5070 TC840C1000 Coptirlopez.garyjavierNo ratings yet

- SPECTREX 4040iDocument2 pagesSPECTREX 4040iLupiNo ratings yet

- PSD DatasheetDocument2 pagesPSD Datasheetmetal_dung2No ratings yet

- AUTOCHIM PRESENTATION Rev 1Document30 pagesAUTOCHIM PRESENTATION Rev 1MGHIRBI HAYKELNo ratings yet

- IR3 Exd Data Sheet EnUS 11803981579Document3 pagesIR3 Exd Data Sheet EnUS 11803981579ionutenacheNo ratings yet

- Dew Point Meter XentourDocument4 pagesDew Point Meter XentourBhaskar KumarNo ratings yet

- Intrusion Detector: Selection GuideDocument28 pagesIntrusion Detector: Selection GuidemoidutNo ratings yet

- Multi-Criteria Sensor - Co, Cohb, Smoke, Heat: Standard FeaturesDocument2 pagesMulti-Criteria Sensor - Co, Cohb, Smoke, Heat: Standard FeaturesJoe Bou NaderNo ratings yet

- Intelligent Addressable Sensors: UL Listed Product RangeDocument2 pagesIntelligent Addressable Sensors: UL Listed Product RangeKalpa Helitha SilvaNo ratings yet

- Product Data Sheet: VIBRO Condition Monitoring 3 (VCM-3 and VCM-3 Ex)Document7 pagesProduct Data Sheet: VIBRO Condition Monitoring 3 (VCM-3 and VCM-3 Ex)Amir HabibNo ratings yet

- 700 Series ENDocument2 pages700 Series ENKen LaszloNo ratings yet

- Honeywell Hbs Fire System Options BrochureDocument8 pagesHoneywell Hbs Fire System Options Brochurerahu2260100% (1)

- 40-40 L4BDocument2 pages40-40 L4Brafael medinaNo ratings yet

- Univario Tech Data CombinedDocument10 pagesUnivario Tech Data CombineddbrodarNo ratings yet

- IR5500 Data SheetDocument2 pagesIR5500 Data SheetsirballesterosNo ratings yet

- VESDA LaserPLUS Data SheetDocument4 pagesVESDA LaserPLUS Data SheetalvarochavezzNo ratings yet

- Fireray 3000 DatasheetDocument2 pagesFireray 3000 DatasheetRahul DevaNo ratings yet

- The Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsFrom EverandThe Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsSylvain ClercNo ratings yet

- CoatingDocument1 pageCoatingnaveedfndNo ratings yet

- Attachment To Test Report Iec 62471 European Group Differences and National DifferencesDocument3 pagesAttachment To Test Report Iec 62471 European Group Differences and National DifferencesnaveedfndNo ratings yet

- T02 - Audiovisual Systems 2022Document23 pagesT02 - Audiovisual Systems 2022naveedfndNo ratings yet

- Electricity Supply & TariffDocument6 pagesElectricity Supply & TariffnaveedfndNo ratings yet

- Voltage Problems in Industrial SystemsDocument9 pagesVoltage Problems in Industrial SystemsnaveedfndNo ratings yet

- Lighting The Electronic Glare Problems With VdusDocument13 pagesLighting The Electronic Glare Problems With VdusnaveedfndNo ratings yet

- Cable Tray With Cable CleatDocument1 pageCable Tray With Cable CleatnaveedfndNo ratings yet

- Page 101Document1 pagePage 101naveedfndNo ratings yet

- Elevators in High Rise BuildingsDocument8 pagesElevators in High Rise BuildingsnaveedfndNo ratings yet

- Earth Leakage ProtectionDocument6 pagesEarth Leakage ProtectionnaveedfndNo ratings yet

- Importance of Electrical & MechDocument2 pagesImportance of Electrical & MechnaveedfndNo ratings yet

- Distribution Generation Aluminium CablesDocument11 pagesDistribution Generation Aluminium CablesnaveedfndNo ratings yet

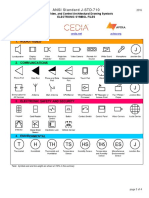

- Summary ANSI J STD 710 Symbols Aug2018Document2 pagesSummary ANSI J STD 710 Symbols Aug2018naveedfndNo ratings yet

- Direct On Line or Star DeltaDocument6 pagesDirect On Line or Star DeltanaveedfndNo ratings yet

- A New Control System For High Rise ElevatorsDocument12 pagesA New Control System For High Rise ElevatorsnaveedfndNo ratings yet

- Spec 222Document5 pagesSpec 222naveedfndNo ratings yet

- Does Your Earthing System Provide SafetyDocument8 pagesDoes Your Earthing System Provide SafetynaveedfndNo ratings yet

- Electrical Equipment Floor Space: Application Paper AP083007ENDocument8 pagesElectrical Equipment Floor Space: Application Paper AP083007ENnaveedfndNo ratings yet

- Electrical Works Technical Specifications (General) : Sr. No.D E S C R I P T I O N Page NoDocument17 pagesElectrical Works Technical Specifications (General) : Sr. No.D E S C R I P T I O N Page NonaveedfndNo ratings yet

- Request For Tender: For The Provision of Passenger LiftDocument40 pagesRequest For Tender: For The Provision of Passenger LiftnaveedfndNo ratings yet

- Lighting With EconomyDocument6 pagesLighting With EconomynaveedfndNo ratings yet

- SBA5.7Document5 pagesSBA5.7naveedfndNo ratings yet

- WavePro LT. Busway SystemDocument44 pagesWavePro LT. Busway SystemnaveedfndNo ratings yet

- 209 Guide To Security TurnstilesDocument13 pages209 Guide To Security TurnstilesnaveedfndNo ratings yet

- X618 BrochureDocument8 pagesX618 BrochurenaveedfndNo ratings yet

- Abloy: Europrofile Handle Controlled LocksDocument6 pagesAbloy: Europrofile Handle Controlled LocksnaveedfndNo ratings yet

- World Class: Electric LocksDocument32 pagesWorld Class: Electric LocksnaveedfndNo ratings yet

- Polymers 13 03697Document17 pagesPolymers 13 03697hykiNo ratings yet

- Armor FlexDocument2 pagesArmor FlexFrancoisKrigeNo ratings yet

- 6721 Amd1Document7 pages6721 Amd1Avinash MishraNo ratings yet

- Chapter 1: Introduction To Company Background 1.1 Background of Company or IndustryDocument4 pagesChapter 1: Introduction To Company Background 1.1 Background of Company or IndustryIzzatyNabihah Zainudin100% (1)

- Racetrack Raiders MNIT, JaipurDocument13 pagesRacetrack Raiders MNIT, JaipurKartikey SharmaNo ratings yet

- 18SP655 PDFDocument19 pages18SP655 PDFJoseGarzaNo ratings yet

- Ilinox Atex LineDocument13 pagesIlinox Atex LineDidit AndiatmokoNo ratings yet

- 17-07-23-Catalog of STEEL WORLDDocument4 pages17-07-23-Catalog of STEEL WORLDRajan BhardwajNo ratings yet

- Kota Stone Flooring: Group Members-Nishtha Dhamija Ankita Pilaniya Shivnashi Aggarwal SimranDocument10 pagesKota Stone Flooring: Group Members-Nishtha Dhamija Ankita Pilaniya Shivnashi Aggarwal SimranAnkitaNo ratings yet

- Tai Lieu Cam Bien MucDocument312 pagesTai Lieu Cam Bien MucTrần Văn PhúcNo ratings yet

- Distribution of Shear Stresses in Circular ShaftsDocument5 pagesDistribution of Shear Stresses in Circular ShaftsSnehasish IsharNo ratings yet

- Assignment Shhet (Testing and Performance of IC Engines)Document2 pagesAssignment Shhet (Testing and Performance of IC Engines)srishashankNo ratings yet

- Dimensional Changes After Heat TreatmentDocument8 pagesDimensional Changes After Heat TreatmentRahul garjeNo ratings yet

- Medium Foam Pod Nozzle - NPB Series Fountain NozzleDocument2 pagesMedium Foam Pod Nozzle - NPB Series Fountain NozzleFachrul Rozi SuriyanaNo ratings yet

- Normas Iec - AstmDocument3 pagesNormas Iec - AstmGregorio Mendoza PolaresNo ratings yet

- CourtCare Squash Court Specification 2011 Web VersionDocument26 pagesCourtCare Squash Court Specification 2011 Web Versionhassan_smss69No ratings yet

- Rocks and Minerals Unit PlanDocument16 pagesRocks and Minerals Unit Planapi-250800467No ratings yet

- LMW CNCDocument5 pagesLMW CNClionlionsherNo ratings yet

- R 8200 Series Uk 180827Document2 pagesR 8200 Series Uk 180827Patrycja RadzichowskaNo ratings yet

- CH2 - Is Matter Around Us Pure - (MCQS)Document8 pagesCH2 - Is Matter Around Us Pure - (MCQS)Abinash NayakNo ratings yet

- Motor's Bearing DetailsDocument9 pagesMotor's Bearing DetailsValipireddy NagarjunNo ratings yet

- Bamboo Space Frame Structures - Aug2012Document4 pagesBamboo Space Frame Structures - Aug2012Shriti DasNo ratings yet

- Settlement: Consolidation of SoilDocument34 pagesSettlement: Consolidation of SoilRyan A. RamirezNo ratings yet

- Push in Fittings Catalogue PDFDocument12 pagesPush in Fittings Catalogue PDFKamitkumar PatelNo ratings yet

- Bearings: Heart of The MachineDocument51 pagesBearings: Heart of The MachinevarunNo ratings yet

- Aluminium Techno PDFDocument134 pagesAluminium Techno PDFsan htet aungNo ratings yet

Ipes-Ir3 R08

Ipes-Ir3 R08

Uploaded by

naveedfndOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ipes-Ir3 R08

Ipes-Ir3 R08

Uploaded by

naveedfndCopyright:

Available Formats

SPECIFICATION SHEET

Technology of the Future

Protection for Today

The state-of-the-art multi-spectral infrared technology of ESP Safetys Model IPES-IR3 Flame

Detector affords the highest sensitivity in detecting flames from combustible vapors gases

within a wide field of view. It is preferred where UV in other detectors may be a problem with

false signal triggers.

SIL3

IPES-IR3s advanced detection technology ensures rapid flame recognition and alarm

signaling. In addition, IPES-IR3s selective, multi-spectral technology virtually eliminates false

alarms. It ignores false triggers from sources such as direct or indirect sunlight, arc welder

flash, resistive heaters, fluorescent, halogen, and incandescent light.

RATED

IPES-IR3 sends an alarm only when data from three different IR wavelengths agree that a

flame or fire is present in the field of view. Upon confirmation of flame or fire, the IPES-IR3

transfers alarm signals to receiving control devices located in control and operations rooms

and to fire alarms and burglar/fire alarm systems. While operating, the IPES-IR3 transmits

detector-status information via:

4-20 mA analog output

A standard RS-485 communication channel under protocol Modbus RTU

Relay outputs

The IPES-IR3 Flame Detector is constructed with an explosion-proof housing for use in

hazardous (classified) locations. It meets the certifications and requirements of Class I,

Division 1, Group B, C & D, T4.

IPES IR3

FLAME DETECTOR

Applications

Features and Benefits

Drilling and production platforms

Multi-spectral IR detection provides the highest level of flame and fire sensitivity.

Shipping tankers, freighters, and other vessels

Fuel loading facilities

Refineries, bulk terminals, and tank farms

LNG/LPG processing and storage facilities

Compressor stations and pipeline facilities

Petrochemical, paint, and fertilizer plants

Power plants and gas turbine facilities

Transportation facilities (airports and subways)

Oil and gas fired boilers / furnaces

Aircraft hangars

Multi-spectral IR detection provides optimal rejection of false alarms.

Power-on self-test and frequent sensor self-test ensure system integrity and correct operation.

Heated optics, secondary heater function helps to prevent condensation problems.

Explosion-proof package allows for hazardous environment operation.

Tri-color status LED on the device is easily viewable for a visual report of the

devices operating status.

Continuous monitoring of the optical path for obstruction or reduced transmission

affords maximum reliability.

Power consumption of <3W means low power costs, protection against surges.

Digital, analog and relay outputs provide reliable status information across a

range of communication formats.

Industry standard for remote alarm and fault indication ensure reliability and consistency.

Extended detection range provides a greater area of protection.

5-year warranty long, reliable product life; low cost to operate over time.

CONTACT

www.espsafetyinc.com

info@espsafetyinc.com

CALIFORNIA

555 N. First Street | San Jose, CA 95112

Ph: +1-408-886-9746 | Fx: +1-408-886-9757

TEXAS

4001 W. Sam Houston Parkway N. Ste #150 | Houston, TX 77043

Ph: +1-713-999-1050 | Fx: +1-713-999-1060

SPECIFICATIONS

info@espsafetyinc.com

Response Time

Certifications

Ex d IIC T4

-40F to +185F

(-40C to +85C)

CE Mark for EMC (TUV)

CE Mark for IECEx

IP66

Class I, Division 1

Groups B, C & D

T4 Ta = -40F to +167F

(-40C to +75C)

IP66

Fuel

Size

Distance

Feet (M)

Typical Response

Time (Sec.)

n-Heptane

1 ft x 1 ft

210 (64.0)

6.0

Methanol

1 ft x 1 ft

150 (45.7)

7.0

JP5

2 ft x 2 ft

210 (64.0)

4.5

Field of View

Horizontal

(right)

50

50

50

56.1 (17.1)

3 sec.

50

50

50

50

41.0 (12.5)

3 sec.

JP5

50

50

50

50

82.0 (25.0)

3 sec.

30

Operating Voltage 18 to 32 VDC

- normally closed relay

- open on fault detection

Operating Temperature -40F to +185F (-40C to +85C)

Extended Operating -75F to +255F (-60C to +125C)

Temperature (By Request)

15

30

150

45

45

120

90

60

50

30

20

10

Digital Outputs RS 485, Modbus RTU, Profibus

Fault:

0

210

180

Current

2 mA 0.1 mA

4 mA 0.1 mA

18 mA 0.1 mA

8 mA 0.1 mA

- normally open relay

- closed on fire detection

- latching or non-latching

y = feet

x = degrees

Dimensions

in inches (millimeters)

The IR3 can be adjusted

to cover a wide angular range

5.96

(151.30mm)

Storage Temperature -76F to +185F (-60C to +85C)

Adjustable

Pivot

Humidity Up to 95 % Relative humidity, non-condensing

(withstands up to 100% RH for short periods)

8.39

(213.16mm)

Wiring 14 AWG (2.08 mm2) or 16 AWG (1.31 mm2)

Shielded cable is recommended

AT THIS ORIENTATION

SIL Rating SIL 3

Ingress Protection IP66

5.45

(138.43mm)

3.94

(100mm)

Mechanical Characteristics

Material 316 Stainless Steel

Avg

Time

50

15

Relay Contact Fire Alarm:

Min. Distance

Feet (down)

Methanol

Viewing Angle

Analog Outputs 4-20mA

Analog signal

Fault signal

Ready signal

Fire signal

Test Mode

Vertical

(down)

n-Heptane

Electrical Characteristics

Power consumption <2 W, standby

<3 W, during alarm

<7.5 W, with heater on maximum

Vertical

(up)

FLAME DETECTOR

Ex d IIC T4

-40F to +185F

(-40C to +85C)

IP66

Horizontal

(left)

IPES IR3

Fuel

Class I, Division 1

Groups B, C & D

T4 Ta = -40F to +167F

(-40C to +75C)

IP66

3.78

(93.98mm)

Cable Entry 3/4 NPT

Weight 11 lbs (5.0 kg)

Warranty 5 years

80013-001

R08

You might also like

- Air Blowing ProcedureDocument5 pagesAir Blowing ProcedureArslan Nisar100% (2)

- Detector SelectionDocument149 pagesDetector Selectionssriram2003No ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Chimedza W: Boiler Blowdown Heat Recovery ProjectDocument34 pagesChimedza W: Boiler Blowdown Heat Recovery ProjectBlessed ZiyambeNo ratings yet

- LENNOX HS29 - 3phaseDocument20 pagesLENNOX HS29 - 3phasedmoros100% (1)

- Architectural Specifications PlycemDocument4 pagesArchitectural Specifications PlycemZenon PruszaNo ratings yet

- Fire Sentry FS24X Flame DetectorsDocument4 pagesFire Sentry FS24X Flame DetectorshdrNo ratings yet

- The Flamegard Series of Flame Detectors: Fast, Reliable Flame DetectionDocument4 pagesThe Flamegard Series of Flame Detectors: Fast, Reliable Flame DetectionSandika JayaputraNo ratings yet

- Depliant Iris Enea Inim 1.10 ENGDocument4 pagesDepliant Iris Enea Inim 1.10 ENGKnjigescribdNo ratings yet

- Fl4000h DataDocument2 pagesFl4000h Datadarkchess76No ratings yet

- RF 360 Advanced Ceiling Mount PIR Installation Manual-1Document2 pagesRF 360 Advanced Ceiling Mount PIR Installation Manual-1Imi Michał SmulskiNo ratings yet

- Apollo Marinecatalogue2013 All Mr-LockedDocument0 pagesApollo Marinecatalogue2013 All Mr-LockedVictor ChuaNo ratings yet

- IR3 Data Sheet enUS 11803977227Document3 pagesIR3 Data Sheet enUS 11803977227Charles DublinNo ratings yet

- Monitor and Control Equipment 24/7/365: Smoke & TemperatureDocument2 pagesMonitor and Control Equipment 24/7/365: Smoke & TemperaturePushpendra SinghNo ratings yet

- MSA UV - IR Flame Detector PDFDocument2 pagesMSA UV - IR Flame Detector PDFwe202No ratings yet

- Fire Detection SystemDocument38 pagesFire Detection Systemkhalid najjarNo ratings yet

- Simtronics TV7-TDocument2 pagesSimtronics TV7-TNoel Federer SarkarNo ratings yet

- Fire & Flame DetectorDocument4 pagesFire & Flame DetectorAhmed El Sayed SalamaNo ratings yet

- Cirrus 200D Issue 4Document2 pagesCirrus 200D Issue 4Byron RieraNo ratings yet

- Prix N°2.2 Détecteur Optique de FuméeDocument7 pagesPrix N°2.2 Détecteur Optique de Fuméemohammed alsaidiNo ratings yet

- Nikon ManualDocument8 pagesNikon Manualdipayankr40No ratings yet

- In The Name of " The Most Gracious The Most Merciful, Whose Help We SolicitDocument63 pagesIn The Name of " The Most Gracious The Most Merciful, Whose Help We SolicitMuhammad Abdul Rauf100% (1)

- IR400 Data SheetDocument2 pagesIR400 Data Sheetdarkchess76No ratings yet

- Eagle PIR-018H / PIR-045H / PIR-100H Outdoor Passive Infrared DetectorsDocument7 pagesEagle PIR-018H / PIR-045H / PIR-100H Outdoor Passive Infrared DetectorsgjaftelecomNo ratings yet

- Gsti 9104Document2 pagesGsti 9104aditgroupNo ratings yet

- FINAL SimplexFireProducts TrueAlarmAnalogueAddressableDetectorsDataSheet 2aug05Document4 pagesFINAL SimplexFireProducts TrueAlarmAnalogueAddressableDetectorsDataSheet 2aug05darkchess76No ratings yet

- Multispectrum Infrared Flame Detector Autroflame X33Document2 pagesMultispectrum Infrared Flame Detector Autroflame X33Angela FasuyiNo ratings yet

- Main Features: Triple IR (IR3) Flame DetectorDocument2 pagesMain Features: Triple IR (IR3) Flame Detectorykresna1631No ratings yet

- Detronics UV-IR Flame Detector Model X5200Document2 pagesDetronics UV-IR Flame Detector Model X5200selvajanarNo ratings yet

- Fluke Temperatura NotaDocument12 pagesFluke Temperatura Notalopablito24No ratings yet

- Detector Flama IPES-IRUVDocument2 pagesDetector Flama IPES-IRUVPio Wilde Quispe GarciaNo ratings yet

- ProReact Digital LHD Installation InstructionsDocument11 pagesProReact Digital LHD Installation InstructionsAlexandru CraiovanNo ratings yet

- Fire Detection & Alarm SystemDocument30 pagesFire Detection & Alarm SystemmohideenNo ratings yet

- Photoelectric Smoke Detector P.1.18.01-4Document2 pagesPhotoelectric Smoke Detector P.1.18.01-4Pedro Caminos BolanosNo ratings yet

- Flame Detector SpectrexDocument2 pagesFlame Detector Spectrexengmohamedmoheb0No ratings yet

- P.1.52.01 Intelligent Low Profile Plug in DetectorsDocument2 pagesP.1.52.01 Intelligent Low Profile Plug in DetectorsamilcarmbNo ratings yet

- SD365Document2 pagesSD365Jesús Morales IretaNo ratings yet

- 2013 Esser CatalogDocument364 pages2013 Esser CatalogArman Ul Nasar100% (2)

- 5753 LDocument7 pages5753 LYousuf IbrahimNo ratings yet

- 40-40I Flame DetectorDocument2 pages40-40I Flame DetectorSumeet Sisir SarkarNo ratings yet

- Detector UVIR X5200Document2 pagesDetector UVIR X5200chicle60No ratings yet

- 10 - EQP OverviewDocument51 pages10 - EQP OverviewdadyjoshNo ratings yet

- Thermocouple Multiplexer2Document16 pagesThermocouple Multiplexer2Saamir JassimNo ratings yet

- ApolloFire XP95 MultisensorDocument2 pagesApolloFire XP95 MultisensorfasiwiNo ratings yet

- 74-5070 TC840C1000 CoptirDocument2 pages74-5070 TC840C1000 Coptirlopez.garyjavierNo ratings yet

- SPECTREX 4040iDocument2 pagesSPECTREX 4040iLupiNo ratings yet

- PSD DatasheetDocument2 pagesPSD Datasheetmetal_dung2No ratings yet

- AUTOCHIM PRESENTATION Rev 1Document30 pagesAUTOCHIM PRESENTATION Rev 1MGHIRBI HAYKELNo ratings yet

- IR3 Exd Data Sheet EnUS 11803981579Document3 pagesIR3 Exd Data Sheet EnUS 11803981579ionutenacheNo ratings yet

- Dew Point Meter XentourDocument4 pagesDew Point Meter XentourBhaskar KumarNo ratings yet

- Intrusion Detector: Selection GuideDocument28 pagesIntrusion Detector: Selection GuidemoidutNo ratings yet

- Multi-Criteria Sensor - Co, Cohb, Smoke, Heat: Standard FeaturesDocument2 pagesMulti-Criteria Sensor - Co, Cohb, Smoke, Heat: Standard FeaturesJoe Bou NaderNo ratings yet

- Intelligent Addressable Sensors: UL Listed Product RangeDocument2 pagesIntelligent Addressable Sensors: UL Listed Product RangeKalpa Helitha SilvaNo ratings yet

- Product Data Sheet: VIBRO Condition Monitoring 3 (VCM-3 and VCM-3 Ex)Document7 pagesProduct Data Sheet: VIBRO Condition Monitoring 3 (VCM-3 and VCM-3 Ex)Amir HabibNo ratings yet

- 700 Series ENDocument2 pages700 Series ENKen LaszloNo ratings yet

- Honeywell Hbs Fire System Options BrochureDocument8 pagesHoneywell Hbs Fire System Options Brochurerahu2260100% (1)

- 40-40 L4BDocument2 pages40-40 L4Brafael medinaNo ratings yet

- Univario Tech Data CombinedDocument10 pagesUnivario Tech Data CombineddbrodarNo ratings yet

- IR5500 Data SheetDocument2 pagesIR5500 Data SheetsirballesterosNo ratings yet

- VESDA LaserPLUS Data SheetDocument4 pagesVESDA LaserPLUS Data SheetalvarochavezzNo ratings yet

- Fireray 3000 DatasheetDocument2 pagesFireray 3000 DatasheetRahul DevaNo ratings yet

- The Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsFrom EverandThe Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsSylvain ClercNo ratings yet

- CoatingDocument1 pageCoatingnaveedfndNo ratings yet

- Attachment To Test Report Iec 62471 European Group Differences and National DifferencesDocument3 pagesAttachment To Test Report Iec 62471 European Group Differences and National DifferencesnaveedfndNo ratings yet

- T02 - Audiovisual Systems 2022Document23 pagesT02 - Audiovisual Systems 2022naveedfndNo ratings yet

- Electricity Supply & TariffDocument6 pagesElectricity Supply & TariffnaveedfndNo ratings yet

- Voltage Problems in Industrial SystemsDocument9 pagesVoltage Problems in Industrial SystemsnaveedfndNo ratings yet

- Lighting The Electronic Glare Problems With VdusDocument13 pagesLighting The Electronic Glare Problems With VdusnaveedfndNo ratings yet

- Cable Tray With Cable CleatDocument1 pageCable Tray With Cable CleatnaveedfndNo ratings yet

- Page 101Document1 pagePage 101naveedfndNo ratings yet

- Elevators in High Rise BuildingsDocument8 pagesElevators in High Rise BuildingsnaveedfndNo ratings yet

- Earth Leakage ProtectionDocument6 pagesEarth Leakage ProtectionnaveedfndNo ratings yet

- Importance of Electrical & MechDocument2 pagesImportance of Electrical & MechnaveedfndNo ratings yet

- Distribution Generation Aluminium CablesDocument11 pagesDistribution Generation Aluminium CablesnaveedfndNo ratings yet

- Summary ANSI J STD 710 Symbols Aug2018Document2 pagesSummary ANSI J STD 710 Symbols Aug2018naveedfndNo ratings yet

- Direct On Line or Star DeltaDocument6 pagesDirect On Line or Star DeltanaveedfndNo ratings yet

- A New Control System For High Rise ElevatorsDocument12 pagesA New Control System For High Rise ElevatorsnaveedfndNo ratings yet

- Spec 222Document5 pagesSpec 222naveedfndNo ratings yet

- Does Your Earthing System Provide SafetyDocument8 pagesDoes Your Earthing System Provide SafetynaveedfndNo ratings yet

- Electrical Equipment Floor Space: Application Paper AP083007ENDocument8 pagesElectrical Equipment Floor Space: Application Paper AP083007ENnaveedfndNo ratings yet

- Electrical Works Technical Specifications (General) : Sr. No.D E S C R I P T I O N Page NoDocument17 pagesElectrical Works Technical Specifications (General) : Sr. No.D E S C R I P T I O N Page NonaveedfndNo ratings yet

- Request For Tender: For The Provision of Passenger LiftDocument40 pagesRequest For Tender: For The Provision of Passenger LiftnaveedfndNo ratings yet

- Lighting With EconomyDocument6 pagesLighting With EconomynaveedfndNo ratings yet

- SBA5.7Document5 pagesSBA5.7naveedfndNo ratings yet

- WavePro LT. Busway SystemDocument44 pagesWavePro LT. Busway SystemnaveedfndNo ratings yet

- 209 Guide To Security TurnstilesDocument13 pages209 Guide To Security TurnstilesnaveedfndNo ratings yet

- X618 BrochureDocument8 pagesX618 BrochurenaveedfndNo ratings yet

- Abloy: Europrofile Handle Controlled LocksDocument6 pagesAbloy: Europrofile Handle Controlled LocksnaveedfndNo ratings yet

- World Class: Electric LocksDocument32 pagesWorld Class: Electric LocksnaveedfndNo ratings yet

- Polymers 13 03697Document17 pagesPolymers 13 03697hykiNo ratings yet

- Armor FlexDocument2 pagesArmor FlexFrancoisKrigeNo ratings yet

- 6721 Amd1Document7 pages6721 Amd1Avinash MishraNo ratings yet

- Chapter 1: Introduction To Company Background 1.1 Background of Company or IndustryDocument4 pagesChapter 1: Introduction To Company Background 1.1 Background of Company or IndustryIzzatyNabihah Zainudin100% (1)

- Racetrack Raiders MNIT, JaipurDocument13 pagesRacetrack Raiders MNIT, JaipurKartikey SharmaNo ratings yet

- 18SP655 PDFDocument19 pages18SP655 PDFJoseGarzaNo ratings yet

- Ilinox Atex LineDocument13 pagesIlinox Atex LineDidit AndiatmokoNo ratings yet

- 17-07-23-Catalog of STEEL WORLDDocument4 pages17-07-23-Catalog of STEEL WORLDRajan BhardwajNo ratings yet

- Kota Stone Flooring: Group Members-Nishtha Dhamija Ankita Pilaniya Shivnashi Aggarwal SimranDocument10 pagesKota Stone Flooring: Group Members-Nishtha Dhamija Ankita Pilaniya Shivnashi Aggarwal SimranAnkitaNo ratings yet

- Tai Lieu Cam Bien MucDocument312 pagesTai Lieu Cam Bien MucTrần Văn PhúcNo ratings yet

- Distribution of Shear Stresses in Circular ShaftsDocument5 pagesDistribution of Shear Stresses in Circular ShaftsSnehasish IsharNo ratings yet

- Assignment Shhet (Testing and Performance of IC Engines)Document2 pagesAssignment Shhet (Testing and Performance of IC Engines)srishashankNo ratings yet

- Dimensional Changes After Heat TreatmentDocument8 pagesDimensional Changes After Heat TreatmentRahul garjeNo ratings yet

- Medium Foam Pod Nozzle - NPB Series Fountain NozzleDocument2 pagesMedium Foam Pod Nozzle - NPB Series Fountain NozzleFachrul Rozi SuriyanaNo ratings yet

- Normas Iec - AstmDocument3 pagesNormas Iec - AstmGregorio Mendoza PolaresNo ratings yet

- CourtCare Squash Court Specification 2011 Web VersionDocument26 pagesCourtCare Squash Court Specification 2011 Web Versionhassan_smss69No ratings yet

- Rocks and Minerals Unit PlanDocument16 pagesRocks and Minerals Unit Planapi-250800467No ratings yet

- LMW CNCDocument5 pagesLMW CNClionlionsherNo ratings yet

- R 8200 Series Uk 180827Document2 pagesR 8200 Series Uk 180827Patrycja RadzichowskaNo ratings yet

- CH2 - Is Matter Around Us Pure - (MCQS)Document8 pagesCH2 - Is Matter Around Us Pure - (MCQS)Abinash NayakNo ratings yet

- Motor's Bearing DetailsDocument9 pagesMotor's Bearing DetailsValipireddy NagarjunNo ratings yet

- Bamboo Space Frame Structures - Aug2012Document4 pagesBamboo Space Frame Structures - Aug2012Shriti DasNo ratings yet

- Settlement: Consolidation of SoilDocument34 pagesSettlement: Consolidation of SoilRyan A. RamirezNo ratings yet

- Push in Fittings Catalogue PDFDocument12 pagesPush in Fittings Catalogue PDFKamitkumar PatelNo ratings yet

- Bearings: Heart of The MachineDocument51 pagesBearings: Heart of The MachinevarunNo ratings yet

- Aluminium Techno PDFDocument134 pagesAluminium Techno PDFsan htet aungNo ratings yet