Professional Documents

Culture Documents

Attachment - 1 Onshore Rigs Required Safety Equipment - August 2015

Attachment - 1 Onshore Rigs Required Safety Equipment - August 2015

Uploaded by

Andrei OlteanuCopyright:

Available Formats

You might also like

- Precision Drilling International Task Risk Assessment WorksheetDocument1 pagePrecision Drilling International Task Risk Assessment WorksheetAbdul Hameed OmarNo ratings yet

- Inspection - Rig AcceptanceDocument40 pagesInspection - Rig AcceptanceSrikanth Bammidi100% (6)

- Preparation For Running CasingDocument3 pagesPreparation For Running CasingYougchu LuanNo ratings yet

- MC Case PDFDocument20 pagesMC Case PDFShivani KarkeraNo ratings yet

- Tutorial Chapter 1 - 0 ThermodynamicDocument2 pagesTutorial Chapter 1 - 0 ThermodynamicSufferedMuchNo ratings yet

- Yamaha CLP 170 Service ManualDocument122 pagesYamaha CLP 170 Service ManualicaroheartNo ratings yet

- Arabian Drilling Company Rig Specific Procedure AD - 32 Manriding OperationDocument5 pagesArabian Drilling Company Rig Specific Procedure AD - 32 Manriding OperationinfonexusNo ratings yet

- ACS-RIG MOVE-MWS-TECHNICAL v1.0Document6 pagesACS-RIG MOVE-MWS-TECHNICAL v1.0saeed ghafooriNo ratings yet

- Arabian Drilling Company Rig Specific Procedure AD - 32 Prepare CasingDocument6 pagesArabian Drilling Company Rig Specific Procedure AD - 32 Prepare CasinginfonexusNo ratings yet

- Scope of Wok As Per Cat IV Rig InspectionDocument1 pageScope of Wok As Per Cat IV Rig InspectionAsia BelmontNo ratings yet

- Parker Drilling HSE IADC Rig CoursesDocument8 pagesParker Drilling HSE IADC Rig CoursesDanciulescu Mircea GabrielNo ratings yet

- Responsibilities During Drilling OperationsDocument1 pageResponsibilities During Drilling OperationsYougchu LuanNo ratings yet

- Scope of Rig AuditsDocument2 pagesScope of Rig AuditsKhurram S. MuzammilNo ratings yet

- Responsibilities During Offshore Rig MovesDocument2 pagesResponsibilities During Offshore Rig MovesYougchu LuanNo ratings yet

- Derrickman Rescuing Device Service Manual 44022.66.000 REDocument24 pagesDerrickman Rescuing Device Service Manual 44022.66.000 REKhedr HamoudNo ratings yet

- 9.1.4 Admasco Rig Move Procedure PDFDocument52 pages9.1.4 Admasco Rig Move Procedure PDFkhaled100% (2)

- WC-SLR Rig Move: Checklist Date: Auditor NameDocument4 pagesWC-SLR Rig Move: Checklist Date: Auditor NameMarko BravoNo ratings yet

- Rig ComponentsDocument66 pagesRig Componentshardik khandelwalNo ratings yet

- OIl Rig Safety ChecklistDocument10 pagesOIl Rig Safety ChecklistTom TaoNo ratings yet

- Weatherford TRSDocument4 pagesWeatherford TRSspydaman4uNo ratings yet

- 5-Guidelines For The Content of Rig Move ProceduresDocument8 pages5-Guidelines For The Content of Rig Move ProceduresRidamrutNo ratings yet

- Drilling Rig Technical Audit ChecklistDocument113 pagesDrilling Rig Technical Audit Checklistmarwan khalilNo ratings yet

- BOP Nipple Down 17-May-2010Document1 pageBOP Nipple Down 17-May-2010HAMDI RAFIEK100% (2)

- Onshore Oil & Gas Rig Move Logistics MTLNextGen SoftwareDocument13 pagesOnshore Oil & Gas Rig Move Logistics MTLNextGen SoftwareSanjeev MadaviNo ratings yet

- A Cost-Effective Rig MoveDocument4 pagesA Cost-Effective Rig MoveNA NANo ratings yet

- F0810 - Pre-Post Rig Move Meetings FormsDocument18 pagesF0810 - Pre-Post Rig Move Meetings FormsPaulNo ratings yet

- Sms Gap Analysis Implementation Planning ToolDocument13 pagesSms Gap Analysis Implementation Planning ToolsmallhausenNo ratings yet

- Land Rig Functional RequirementsDocument23 pagesLand Rig Functional RequirementsAboozar FathinejadNo ratings yet

- Handrill - Training Matrix - Drilling CrewsDocument2 pagesHandrill - Training Matrix - Drilling Crewsnashrul_izzuanNo ratings yet

- ZaneGrey Well Completion Report - Basic Data Rev B GovDocument1,018 pagesZaneGrey Well Completion Report - Basic Data Rev B GovHtetAungMoeNo ratings yet

- Tomax AST Tool User ManualDocument4 pagesTomax AST Tool User ManualChinyere NkereNo ratings yet

- DOP 206 - Rev 4Document12 pagesDOP 206 - Rev 4Fernando AybarNo ratings yet

- Monthly Drilling ReportDocument46 pagesMonthly Drilling ReportAsif KhanzadaNo ratings yet

- 2-07 1. Tools and Equipment: Changing LinersDocument2 pages2-07 1. Tools and Equipment: Changing LinersAbdul Hameed OmarNo ratings yet

- Guidance Checklist WebDocument5 pagesGuidance Checklist WebmeidiansyahNo ratings yet

- Pre-Spud InspectionDocument6 pagesPre-Spud InspectionHany100% (2)

- Nipple Up Nipple Down BOP Using BOP Hoist - RA-R9-01-025-01Document1 pageNipple Up Nipple Down BOP Using BOP Hoist - RA-R9-01-025-01cmrig74No ratings yet

- IDC SOP # 13 POOH With DP, DC's and BitDocument4 pagesIDC SOP # 13 POOH With DP, DC's and BitkareemNo ratings yet

- ZJ70D111╫Ω╗·╬¼╗ñ▒ú╤°╩╓OK engDocument55 pagesZJ70D111╫Ω╗·╬¼╗ñ▒ú╤°╩╓OK engGabriel IbarraNo ratings yet

- Break Out and Laying Down BhaDocument3 pagesBreak Out and Laying Down BhakhurramNo ratings yet

- IADC Gin Pole Guidelines Rig Pass.75140439Document22 pagesIADC Gin Pole Guidelines Rig Pass.75140439Hashimi Juni100% (1)

- Rig Handling and Installation Procedure DALIADocument269 pagesRig Handling and Installation Procedure DALIACarlos Gloogh100% (1)

- Introduction To Oil and Gas Drilling: BY Engr. Jam Muhammad KashifDocument27 pagesIntroduction To Oil and Gas Drilling: BY Engr. Jam Muhammad Kashifhasan sabahNo ratings yet

- Man-Riding Checklist - OHSE-PR-010-FM-01-03 (002) 1Document1 pageMan-Riding Checklist - OHSE-PR-010-FM-01-03 (002) 1cmrig7450% (2)

- Shah Ali Hussain-CvDocument3 pagesShah Ali Hussain-Cvdr_shaikhfaisalNo ratings yet

- RM-001 Rig Move TRADocument7 pagesRM-001 Rig Move TRAcenim2004No ratings yet

- BSEE Test ProcedureDocument35 pagesBSEE Test ProcedureNatraji100% (2)

- Low Profile Spider Elevator 400 PDFDocument2 pagesLow Profile Spider Elevator 400 PDFMohamed AbozeimaNo ratings yet

- SIMOPS-Drilling Rigs CostsDocument4 pagesSIMOPS-Drilling Rigs CostsMarkyNo ratings yet

- Curriculum Vitae: Availability: Immediately Professional QualificationDocument5 pagesCurriculum Vitae: Availability: Immediately Professional QualificationAchraf Ben DhifallahNo ratings yet

- Install 500 Ton Slips & ElevatorDocument1 pageInstall 500 Ton Slips & ElevatorAbdul Hameed OmarNo ratings yet

- Jib Crane & Over Head BeamDocument5 pagesJib Crane & Over Head BeamRanjithNo ratings yet

- D&Wo Lifting Equipment Matrix - January-14-2020Document2 pagesD&Wo Lifting Equipment Matrix - January-14-2020Mohammed Nabil AVNo ratings yet

- Ohsar PDFDocument40 pagesOhsar PDFMohammed Ali YoussefNo ratings yet

- Rig Acceptance Check ListDocument2 pagesRig Acceptance Check ListAhmedNo ratings yet

- Pre Spud Checklist 1Document2 pagesPre Spud Checklist 1Ali AlakariNo ratings yet

- h2s OperationsDocument27 pagesh2s OperationsRaMy AdelNo ratings yet

- CAD Product Brouchure 2010Document11 pagesCAD Product Brouchure 2010jlmunozvNo ratings yet

- Hd26000 Casing TongDocument121 pagesHd26000 Casing TongTerry Smith100% (1)

- AmmoniaDocument7 pagesAmmoniaital1961No ratings yet

- Tender22 8Document38 pagesTender22 8er_bhavin3119100% (1)

- Item H2S Detection Equipment and Services Specifications Contractor'S Response 1 PersonnelDocument4 pagesItem H2S Detection Equipment and Services Specifications Contractor'S Response 1 PersonnelMaskur SukhemiNo ratings yet

- Emergency Flare Design Features System-Some Practical: A The TheDocument3 pagesEmergency Flare Design Features System-Some Practical: A The Thekumar_chemicalNo ratings yet

- Mouser TestsectionDocument33 pagesMouser TestsectionalltheloveintheworldNo ratings yet

- (12942) Sheet Chemical Bonding 4 Theory eDocument8 pages(12942) Sheet Chemical Bonding 4 Theory eAnurag SinghNo ratings yet

- A. Title of Experiment B. Date and Time of Experiment: Wednesday, 10Document15 pagesA. Title of Experiment B. Date and Time of Experiment: Wednesday, 10LichaNo ratings yet

- Abb Reg615 Ansi Appl 859072 EndDocument124 pagesAbb Reg615 Ansi Appl 859072 EndjppreciadomNo ratings yet

- Solution Manual For Fundamentals of Semiconductor Fabrication Gary S May Simon M Sze Isbn 0471232793 Isbn 978-0-471 23279 7 Isbn 9780471232797Document16 pagesSolution Manual For Fundamentals of Semiconductor Fabrication Gary S May Simon M Sze Isbn 0471232793 Isbn 978-0-471 23279 7 Isbn 9780471232797warepneumomxkhf100% (17)

- Therapeutic Diet Manual: DIRECTIVE #4311Document27 pagesTherapeutic Diet Manual: DIRECTIVE #4311DuNo ratings yet

- Jack and The Beanstalk Treatment-2Document10 pagesJack and The Beanstalk Treatment-2api-668257195No ratings yet

- The Harrod-Domar Growth ModelDocument6 pagesThe Harrod-Domar Growth ModelSimeonNo ratings yet

- Koch - Control ChartsDocument40 pagesKoch - Control ChartsAkash MarathakamNo ratings yet

- UVU Jungle Marathon 2012 BookDocument41 pagesUVU Jungle Marathon 2012 BookGerhard FlatzNo ratings yet

- 130-87 InstructionsDocument7 pages130-87 InstructionsAlex GarciaNo ratings yet

- Gear Trains: 8.1. Angular Velocity RatioDocument16 pagesGear Trains: 8.1. Angular Velocity RatioaddisudagneNo ratings yet

- Masterglenium Ace: Solutions For The Pre-Cast IndustryDocument7 pagesMasterglenium Ace: Solutions For The Pre-Cast IndustryAlanNo ratings yet

- Likedislikedon't LikeDocument3 pagesLikedislikedon't LikeBriza PaolaNo ratings yet

- A Clinical Audit Into The Success Rate of Inferior Alveolar Nerve Block Analgesia in General Dental PracticeDocument4 pagesA Clinical Audit Into The Success Rate of Inferior Alveolar Nerve Block Analgesia in General Dental PracticeGina CastilloNo ratings yet

- Regulator InfoDocument6 pagesRegulator InfoAguilar AlexNo ratings yet

- 5 - Introduction Q-Series Vs2 Customer Version2Document49 pages5 - Introduction Q-Series Vs2 Customer Version2mahreza189100% (1)

- Stages of SleepDocument2 pagesStages of SleepCamilia Hilmy FaidahNo ratings yet

- Synchronous Generators: Instructional ObjectivesDocument18 pagesSynchronous Generators: Instructional Objectivessanthosh2009No ratings yet

- Intensifying AdjectivesDocument2 pagesIntensifying AdjectivesReena JimmyNo ratings yet

- Chapter 20 Practice TestDocument19 pagesChapter 20 Practice TestCorei'Ana Conrad0% (1)

- S900 Inverter User Manualv1.5 PDFDocument86 pagesS900 Inverter User Manualv1.5 PDFOmar ShadyNo ratings yet

- Process SequenceDocument2 pagesProcess SequenceUmesh SakhareliyaNo ratings yet

- Fetomaternal Hemorrhage (FMH), An Update Review of LiteratureDocument35 pagesFetomaternal Hemorrhage (FMH), An Update Review of LiteratureEugenia Jeniffer JNo ratings yet

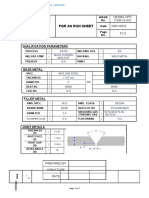

- PQR As Run SheetDocument2 pagesPQR As Run SheetAhmed ElsharkawNo ratings yet

- (A) Design - Introduction To Transformer DesignDocument16 pages(A) Design - Introduction To Transformer DesignZineddine BENOUADAHNo ratings yet

- Structural Engineering Professor Step III: Ucsd Academic Biography/Bibliography FormDocument30 pagesStructural Engineering Professor Step III: Ucsd Academic Biography/Bibliography FormCesar Paul Purihuaman MoraNo ratings yet

Attachment - 1 Onshore Rigs Required Safety Equipment - August 2015

Attachment - 1 Onshore Rigs Required Safety Equipment - August 2015

Uploaded by

Andrei OlteanuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Attachment - 1 Onshore Rigs Required Safety Equipment - August 2015

Attachment - 1 Onshore Rigs Required Safety Equipment - August 2015

Uploaded by

Andrei OlteanuCopyright:

Available Formats

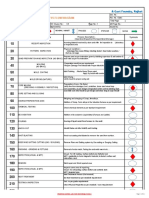

D&WO (ONSHORE) Rigs Assessment Program/Checklist

Attachment #1

Rig Safety Equipment Requirements for Onshore Rigs

1. Hydrogen Sulfide (H2S) Monitoring and Alarm Systems (Fixed Sensors, Monitors and

Alarms):

All rig drawings accurately reflect the location of all gas detectors and LEL safety

systems.

All land drilling rigs operating in known or suspected H2S locations are required to have

installed and fully operational two 4-channel H2S monitoring systems with two

visual-audio alarm systems:

One of the two systems must have four (4) H2S sensors, located as follows:

The top of the bell nipple

The flowline opening to the shale shaker

The Drillers position and about 18-24 inches above the floor

The cellar this sensor should be easily movable so that it can be used around the

BOP Stack or at the well testing equipment, when necessary

The second of the two systems must have four (4) H2S sensors, located as follows:

Two sensors on the perimeter of the camp site, on the side closest to the rig

One sensor at the Camp Muster Station

One sensor outside the Drilling Rig Military Post

A minimum of two (2) spare H2S sensors are required.

Two (2) H2S Monitors are required, located as follows:

Rig site in the Doghouse

Rig site in the Supervisors or Toolpushers office

Two (2) H2S Alarm Systems (one for each of the two H2S monitoring systems noted

above) with Amber Strobe Lights and Horns. First (low) alarm (visible) shall be set for

10 ppm. Second (high) alarm (visible and audible) shall be set for 20 ppm. The alarm

systems shall be located in clearly visible locations so that personnel in any work area

can see and/or hear at least one of the two alarm systems. Audible alarms shall be

included inside the rig site living quarters. H2S alarms shall be positioned at the rig

camp so that all personnel can see and hear the alarm.

2. Combustible Gas Monitoring and Alarm System (Fixed Sensors, Monitors and

Alarms):

A continuous Combustible Gas Monitoring and Alarm System, with Two (2) Lower

Explosive Limit (LEL) sensors, audible and visible alarms, and Two (2) continuous

LEL monitors are required.

The Two (2) LEL sensors must be located as follows:

Rig site one at the top of the bell nipple

Rig site one at the flowline opening to the shale shaker

A minimum of one (1) spare LEL sensor is required.

Onshore Rigs Assessment Program/Checklist

Attachment#1

GBS May 2015

Page 1 of 7

D&WO (ONSHORE) Rigs Assessment Program/Checklist

Attachment #1

Rig Safety Equipment Requirements for Onshore Rigs

Two (2) Combustible Gas Monitors are required, located as follows:

Rig site in the Doghouse

Rig site in the Supervisors or Toolpushers office

LEL Alarm System with Red Strobe Lights and Horns: First (low) alarm (visible) shall

be set for 20% of the LEL. Second (high) alarm (visible and audible) shall be set for

50% of the LEL. At the rig site, the LEL Alarm System shall be clearly visible from all

work areas. The LEL Alarm System shall be located on the Rig Floor, above the

Doghouse. At the camp site, the LEL Alarm System shall be located in a central area

clearly visible from all areas of the camp.

3. Portable Hydrogen Sulfide (H2S) Monitors

Six (6) Personal Portable H2S Monitors (each with the alarm set at 10 ppm) are

required, as follows:

One to the Shakerman

One to the Derrickman

One to the Driller

One to the Aramco Rig Foreman

One to the Contractor Rig Manager

One to the Rescue Team Leader

Portable Hydrogen Sulfide (H2S) Gas Detectors (Hand Pump Suction Type)

Two (2) Portable H2S Detectors are required, with an adequate supply of low, medium,

And high level H2S and SO2 tubes. The range of detection tubes shall be able to

Accurately measure from 0 ppm to a high percentage H2S and SO2.

Portable Combustible Gas or Vapor Monitors

Two (2) Portable Monitors are required.

Test Kit for Checking H2S Concentration in Mud (Water and Oil Base)

One (1) Test Kit is required.

Note: All portable gas monitoring equipment must be calibrated monthly, and log books

with maintenance and calibration records must be maintained for each gas detector.

Each gas detector must be labeled with the date of the last calibration and the name of

the person who performed the last calibration.

Test a sample of H2S/LEL sensors to ensure that readings and response times are

accurate and within manufacturers specifications.

4. Required Breathing Apparatus (all breathing apparatus must be positive pressure,

open circuit SCBA)

A. Open-circuit positive pressure design.

B. Integrated Face Mask Voice Communication Device (Specified Locations).

C. Minimum 10/15-Minute Escape Cylinder/Minimum 30-Minute Emergency Operations

Cylinder.

Onshore Rigs Assessment Program/Checklist

Attachment#1

GBS May 2015

Page 2 of 7

D&WO (ONSHORE) Rigs Assessment Program/Checklist

Attachment #1

Rig Safety Equipment Requirements for Onshore Rigs

D. Integrated OEM Cylinder Quick Fill Connection (Emergency Packs Only 10/15 minute).

E. Cascade BA System Manifold Hose Connection.

F. Equivalent Harness Quality to the SA G.I.-1780 specified units (NFPA-1500 compliant for

all fire and rescue team members).

Hose-line work units, with 15-minute minimum emergency escape cylinders, shall be

provided as follows:

Six (6) at the Rig Floor

Two (2) at the Shale Shaker

Two (2) at the Mud Mixing Area

Two (2) at the Choke Manifold

Two (2) in the Derrick (at the Monkey Board)

Four (4) at the Logging Unit

Two (2) at the Mud Pits

Two (2) at the Cement Unit (when in use

(Total above = 22)

Self-Contained Breathing Apparatus with integrated face mask voice

communication Devices (30-minute SCBAs) shall be provided as follows:

Two (2) at the Toolpushers office/quarters

Two (2) at the Company Mans office/quarters

Two (2) at the SCR room

Three (3) at the Rig Floor

Eight (8) at the Primary Safe Briefing Area

Eight (8) at the Secondary Safe Briefing Area

(Total above = 25)

Minimum 10/15-Minute SCBA Escape Units with integrated Cascade BA Manifold

Connections and Cylinder Quick Fill Connections shall be positioned as follows:

Rig floor - six (6).

Shale shaker - two (2).

Mud mixing area - two (2).

Choke manifold - two (2). (With Retractable Air Line Reel)

In derrick for Derrickman (at monkey board) - two (2).

Logging unit - four (4).

Mud Pits - two (2).

Cement Mixing Tank (when in use) - two (2).

All Rig Site Accommodation Cabins Escape Only units such as ELSA Scott/Sabre

will be acceptable in lieu of the above.

All Rig camp Accommodation Cabins when located within the well site perimeter

Escape Only units such as ELSA Scott/Sabre will be acceptable in lieu of the above.

During the walk-about, select a sample and make sure that the SCBAs clean & dry

inside in the cases (no mud, sand or dirt) and that the tanks are fully charged.

Onshore Rigs Assessment Program/Checklist

Attachment#1

GBS May 2015

Page 3 of 7

D&WO (ONSHORE) Rigs Assessment Program/Checklist

Attachment #1

Rig Safety Equipment Requirements for Onshore Rigs

At least one fully-charged Spare Cylinder is required for each 30 minute SCBA at

designated safe briefing areas.

One 15-minute Emergency Escape Breathing Apparatus for each person on location

these units shall be stored in the rig accommodation and rig camp.

A Cascade Storage System with sufficient capacity to provide breathing air to all

working crew members for not less than 60 minutes at a consumption rate of 3.5 cubic

feet of air per man per minute. The Cascade System shall be pressure tested to + 10%

of the operating pressure and purged before commissioning.

Two (2) Breathing Air Compressors (one diesel powered, one electric powered) each

capable of producing a minimum of 11 cfm, to allow filling the Cascade Storage System

cylinders in a reasonable amount of time and to maintain them full. The compressors

shall be permanent installations allowing for the immediate recharging of any storage

cylinder. Both compressors shall have an ambient operating temperature of no less than

50 degrees C.

A Looped Tubing/Hose Distribution System which will supply air in either direction (in

case of tubing/hose failure) to work manifolds placed around the rig as necessary.

One (1) set of green, yellow and red flags to signal H2S danger status.

Minimum Cascade BA Manifold & OEM RV

Compressor Relief Valves shall be OEM RV Shop set at a maximum of 105% of

Cascade BA Cylinder MAWP, but no less than 3,780 psi and included in the Rig RV

Registry and RV Inspection Process.

A separate and distinct minimum 3,600 psi SCBA Cylinder Recharging Rack shall be

provided if the Rig Operator wishes to operate the required integrated high pressure loop

at less than 3,600 psi. Recharging SCBA cylinders directly from the BA compressors

specifically prohibited.

A competent person shall conduct weekly air purity testing utilizing a compliant air purity

test kit for CO2, H2O and Oil Mist prior to recharging the cascade air cylinders.

All components of the Integrated Cascade BA System shall have both OEM Certification

and traceability for the applicable MAWP and Breathing Air Service and shall be included

in a comprehensive Cascade BA and SCBA Unit Registry

5. Emergency Safety Equipment:

5.1 Bug Blowers (Fans) (should be at least 40,000 CFM)

Three (3) Bug Blowers are required. They must be explosion proof, high volume

(40,000 cfm), and moveable.

Onshore Rigs Assessment Program/Checklist

Attachment#1

GBS May 2015

Page 4 of 7

D&WO (ONSHORE) Rigs Assessment Program/Checklist

Attachment #1

Rig Safety Equipment Requirements for Onshore Rigs

5.2 Wind Socks

Three (3) Wind Socks, two (2) in service, plus Streamers, to be located so all

personnel will know the wind direction. One Wind Sock to be held as a spare.

5.3 Flare Line Ignition System

With a back-up Flare Gun and a supply of 20 long-shelf-life Flare Gun Cartridges.

5.4 Portable Oxygen Resuscitator Units

Two (2) portable units, each with a spare oxygen cylinder or a minimum of two

bag Valve mask (BVM also known as an AMBU bag) with the capability of

providing 100% 02.

5.5 First Aid Kits

Two (2) 25-man First Aid Kits one at the Rig Site and one at the Camp Site.

5.6 Eye Wash Stations

As a minimum and based on risk, eye wash only stations will be positioned as follows,

(water must be potable and between 15 degrees and 38 degrees C):

On the Rig Floor or (Inside Dog house / Drillers console)

All workshops (Welders, Mechanics etc.)

All Fuel Transfer stations.

Shower and eye wash units will be positioned as follows

Mixing areas

Mud Pits

Shale Shaker Area

Chemical storage areas

5.7 Safety Harnesses

Two (2) Safety Harnesses with two (2) 250-foot Retrieval Ropes to be worn by

Search Team for search and rescue operations under limited visibility.

5.8 Basket-type Stretchers

Two (2) Basket-type Stretchers with blankets, securing straps, and lifting harnesses.

5.9 Quick-Air Splint Kits

Two (2)

5.10 Portable Bull Horn

One (1), with extra battery pack

5.11 Chalk Boards

Six (6) small Chalk Boards (or Dry Eraser Boards)

5.12 Flashlights

Explosion-proof and with an extra set of batteries and an extra lamp for each

flashlight. Number must be at least one flashlight for every two persons in the

operation, but not less than five.

Onshore Rigs Assessment Program/Checklist

Attachment#1

GBS May 2015

Page 5 of 7

D&WO (ONSHORE) Rigs Assessment Program/Checklist

Attachment #1

Rig Safety Equipment Requirements for Onshore Rigs

5.13 Fixed Fire Water Pumps (NFPA 20 A.4.12.1.1)

Ensure that fixed fire water pumps have clear operating instructions posted on/near

the pumps.

6. Onshore Rig Hand / Portable Fire Extinguishers:

The specified CO2 and Dry Chemical Hand / Portable Fire Extinguishers shall be of the

specified manufacturers and models and deployed as follows:

Carbon Dioxide (CO2) (10 pound size) shall be either Badger 10V or Kidde Pro

10CD.

Dry Chemical (150 pound and 30 pound sizes) shall be Ansul Red Line.

Dry Chemical (10 pound size) shall be Ansul Sentry 10.

Big Fire Extinguishers:

Three (3) Big Fire Extinguishers (150 pound Wheeled Ansul Red Line Dry Chemical Fire

Extinguishers) located as follows:

One at the Diesel Fuel Storage/Generator Area (Purple K Powder Dry Chemical)

One at the Tool Pushers Office (Purple K Powder Dry Chemical)

One at the Rig Camp (Foray ABC Powder Dry Chemical)

Note: The Rig must maintain either one (1) spare 150 pound Fire Extinguisher, or spare

parts and extinguishing agent required to recharge one (1) of the 150 pound Fire

Extinguishers.

Small Fire Extinguishers:

Required

Size

2

10 lb

1

10 lb

2

30 lb

1

30 lb

1

30 lb

1

30 lb

1

30 lb

1

30 lb

1

30 lb

2

30 lb

1

30 lb

1

30 lb

1

30 lb

1

30 lb

Cabins

10 lb

Onshore Rigs Assessment Program/Checklist

Attachment#1

Location

SCR

Each Camp Kitchen

Rig Floor

Each Mud Tank

Each Generator

Accumulator

Each Mud Pump

Gasoline Storage Tank

Diesel Storage Tank

Toolpushers Office

Camp Generator

Utility House

Warehouse

SA Material House

Accommodation Cabins

GBS May 2015

Extinguishing Agent

CO2

CO2

Purple K Powder

Purple K Powder

Purple K Powder

Purple K Powder

Purple K Powder

Purple K Powder

Purple K Powder

Foray (ABC) Powder

Purple K Powder

Purple K Powder

Foray (ABC) Powder

Foray (ABC) Powder

Foray (ABC) Powder

Page 6 of 7

D&WO (ONSHORE) Rigs Assessment Program/Checklist

Attachment #1

Rig Safety Equipment Requirements for Onshore Rigs

Note: The requirements listed above are taken from the Saudi Aramco Drilling & Health,

Safety and Environmental Requirements Manual / SWIM & HSERM / 1st Edition (July

2015) Section B-5 & B-7 (Hydrogen Sulfide Safety (Onshore Rig Fire Fighting

Equipment).

Onshore Rigs Assessment Program/Checklist

Attachment#1

GBS May 2015

Page 7 of 7

You might also like

- Precision Drilling International Task Risk Assessment WorksheetDocument1 pagePrecision Drilling International Task Risk Assessment WorksheetAbdul Hameed OmarNo ratings yet

- Inspection - Rig AcceptanceDocument40 pagesInspection - Rig AcceptanceSrikanth Bammidi100% (6)

- Preparation For Running CasingDocument3 pagesPreparation For Running CasingYougchu LuanNo ratings yet

- MC Case PDFDocument20 pagesMC Case PDFShivani KarkeraNo ratings yet

- Tutorial Chapter 1 - 0 ThermodynamicDocument2 pagesTutorial Chapter 1 - 0 ThermodynamicSufferedMuchNo ratings yet

- Yamaha CLP 170 Service ManualDocument122 pagesYamaha CLP 170 Service ManualicaroheartNo ratings yet

- Arabian Drilling Company Rig Specific Procedure AD - 32 Manriding OperationDocument5 pagesArabian Drilling Company Rig Specific Procedure AD - 32 Manriding OperationinfonexusNo ratings yet

- ACS-RIG MOVE-MWS-TECHNICAL v1.0Document6 pagesACS-RIG MOVE-MWS-TECHNICAL v1.0saeed ghafooriNo ratings yet

- Arabian Drilling Company Rig Specific Procedure AD - 32 Prepare CasingDocument6 pagesArabian Drilling Company Rig Specific Procedure AD - 32 Prepare CasinginfonexusNo ratings yet

- Scope of Wok As Per Cat IV Rig InspectionDocument1 pageScope of Wok As Per Cat IV Rig InspectionAsia BelmontNo ratings yet

- Parker Drilling HSE IADC Rig CoursesDocument8 pagesParker Drilling HSE IADC Rig CoursesDanciulescu Mircea GabrielNo ratings yet

- Responsibilities During Drilling OperationsDocument1 pageResponsibilities During Drilling OperationsYougchu LuanNo ratings yet

- Scope of Rig AuditsDocument2 pagesScope of Rig AuditsKhurram S. MuzammilNo ratings yet

- Responsibilities During Offshore Rig MovesDocument2 pagesResponsibilities During Offshore Rig MovesYougchu LuanNo ratings yet

- Derrickman Rescuing Device Service Manual 44022.66.000 REDocument24 pagesDerrickman Rescuing Device Service Manual 44022.66.000 REKhedr HamoudNo ratings yet

- 9.1.4 Admasco Rig Move Procedure PDFDocument52 pages9.1.4 Admasco Rig Move Procedure PDFkhaled100% (2)

- WC-SLR Rig Move: Checklist Date: Auditor NameDocument4 pagesWC-SLR Rig Move: Checklist Date: Auditor NameMarko BravoNo ratings yet

- Rig ComponentsDocument66 pagesRig Componentshardik khandelwalNo ratings yet

- OIl Rig Safety ChecklistDocument10 pagesOIl Rig Safety ChecklistTom TaoNo ratings yet

- Weatherford TRSDocument4 pagesWeatherford TRSspydaman4uNo ratings yet

- 5-Guidelines For The Content of Rig Move ProceduresDocument8 pages5-Guidelines For The Content of Rig Move ProceduresRidamrutNo ratings yet

- Drilling Rig Technical Audit ChecklistDocument113 pagesDrilling Rig Technical Audit Checklistmarwan khalilNo ratings yet

- BOP Nipple Down 17-May-2010Document1 pageBOP Nipple Down 17-May-2010HAMDI RAFIEK100% (2)

- Onshore Oil & Gas Rig Move Logistics MTLNextGen SoftwareDocument13 pagesOnshore Oil & Gas Rig Move Logistics MTLNextGen SoftwareSanjeev MadaviNo ratings yet

- A Cost-Effective Rig MoveDocument4 pagesA Cost-Effective Rig MoveNA NANo ratings yet

- F0810 - Pre-Post Rig Move Meetings FormsDocument18 pagesF0810 - Pre-Post Rig Move Meetings FormsPaulNo ratings yet

- Sms Gap Analysis Implementation Planning ToolDocument13 pagesSms Gap Analysis Implementation Planning ToolsmallhausenNo ratings yet

- Land Rig Functional RequirementsDocument23 pagesLand Rig Functional RequirementsAboozar FathinejadNo ratings yet

- Handrill - Training Matrix - Drilling CrewsDocument2 pagesHandrill - Training Matrix - Drilling Crewsnashrul_izzuanNo ratings yet

- ZaneGrey Well Completion Report - Basic Data Rev B GovDocument1,018 pagesZaneGrey Well Completion Report - Basic Data Rev B GovHtetAungMoeNo ratings yet

- Tomax AST Tool User ManualDocument4 pagesTomax AST Tool User ManualChinyere NkereNo ratings yet

- DOP 206 - Rev 4Document12 pagesDOP 206 - Rev 4Fernando AybarNo ratings yet

- Monthly Drilling ReportDocument46 pagesMonthly Drilling ReportAsif KhanzadaNo ratings yet

- 2-07 1. Tools and Equipment: Changing LinersDocument2 pages2-07 1. Tools and Equipment: Changing LinersAbdul Hameed OmarNo ratings yet

- Guidance Checklist WebDocument5 pagesGuidance Checklist WebmeidiansyahNo ratings yet

- Pre-Spud InspectionDocument6 pagesPre-Spud InspectionHany100% (2)

- Nipple Up Nipple Down BOP Using BOP Hoist - RA-R9-01-025-01Document1 pageNipple Up Nipple Down BOP Using BOP Hoist - RA-R9-01-025-01cmrig74No ratings yet

- IDC SOP # 13 POOH With DP, DC's and BitDocument4 pagesIDC SOP # 13 POOH With DP, DC's and BitkareemNo ratings yet

- ZJ70D111╫Ω╗·╬¼╗ñ▒ú╤°╩╓OK engDocument55 pagesZJ70D111╫Ω╗·╬¼╗ñ▒ú╤°╩╓OK engGabriel IbarraNo ratings yet

- Break Out and Laying Down BhaDocument3 pagesBreak Out and Laying Down BhakhurramNo ratings yet

- IADC Gin Pole Guidelines Rig Pass.75140439Document22 pagesIADC Gin Pole Guidelines Rig Pass.75140439Hashimi Juni100% (1)

- Rig Handling and Installation Procedure DALIADocument269 pagesRig Handling and Installation Procedure DALIACarlos Gloogh100% (1)

- Introduction To Oil and Gas Drilling: BY Engr. Jam Muhammad KashifDocument27 pagesIntroduction To Oil and Gas Drilling: BY Engr. Jam Muhammad Kashifhasan sabahNo ratings yet

- Man-Riding Checklist - OHSE-PR-010-FM-01-03 (002) 1Document1 pageMan-Riding Checklist - OHSE-PR-010-FM-01-03 (002) 1cmrig7450% (2)

- Shah Ali Hussain-CvDocument3 pagesShah Ali Hussain-Cvdr_shaikhfaisalNo ratings yet

- RM-001 Rig Move TRADocument7 pagesRM-001 Rig Move TRAcenim2004No ratings yet

- BSEE Test ProcedureDocument35 pagesBSEE Test ProcedureNatraji100% (2)

- Low Profile Spider Elevator 400 PDFDocument2 pagesLow Profile Spider Elevator 400 PDFMohamed AbozeimaNo ratings yet

- SIMOPS-Drilling Rigs CostsDocument4 pagesSIMOPS-Drilling Rigs CostsMarkyNo ratings yet

- Curriculum Vitae: Availability: Immediately Professional QualificationDocument5 pagesCurriculum Vitae: Availability: Immediately Professional QualificationAchraf Ben DhifallahNo ratings yet

- Install 500 Ton Slips & ElevatorDocument1 pageInstall 500 Ton Slips & ElevatorAbdul Hameed OmarNo ratings yet

- Jib Crane & Over Head BeamDocument5 pagesJib Crane & Over Head BeamRanjithNo ratings yet

- D&Wo Lifting Equipment Matrix - January-14-2020Document2 pagesD&Wo Lifting Equipment Matrix - January-14-2020Mohammed Nabil AVNo ratings yet

- Ohsar PDFDocument40 pagesOhsar PDFMohammed Ali YoussefNo ratings yet

- Rig Acceptance Check ListDocument2 pagesRig Acceptance Check ListAhmedNo ratings yet

- Pre Spud Checklist 1Document2 pagesPre Spud Checklist 1Ali AlakariNo ratings yet

- h2s OperationsDocument27 pagesh2s OperationsRaMy AdelNo ratings yet

- CAD Product Brouchure 2010Document11 pagesCAD Product Brouchure 2010jlmunozvNo ratings yet

- Hd26000 Casing TongDocument121 pagesHd26000 Casing TongTerry Smith100% (1)

- AmmoniaDocument7 pagesAmmoniaital1961No ratings yet

- Tender22 8Document38 pagesTender22 8er_bhavin3119100% (1)

- Item H2S Detection Equipment and Services Specifications Contractor'S Response 1 PersonnelDocument4 pagesItem H2S Detection Equipment and Services Specifications Contractor'S Response 1 PersonnelMaskur SukhemiNo ratings yet

- Emergency Flare Design Features System-Some Practical: A The TheDocument3 pagesEmergency Flare Design Features System-Some Practical: A The Thekumar_chemicalNo ratings yet

- Mouser TestsectionDocument33 pagesMouser TestsectionalltheloveintheworldNo ratings yet

- (12942) Sheet Chemical Bonding 4 Theory eDocument8 pages(12942) Sheet Chemical Bonding 4 Theory eAnurag SinghNo ratings yet

- A. Title of Experiment B. Date and Time of Experiment: Wednesday, 10Document15 pagesA. Title of Experiment B. Date and Time of Experiment: Wednesday, 10LichaNo ratings yet

- Abb Reg615 Ansi Appl 859072 EndDocument124 pagesAbb Reg615 Ansi Appl 859072 EndjppreciadomNo ratings yet

- Solution Manual For Fundamentals of Semiconductor Fabrication Gary S May Simon M Sze Isbn 0471232793 Isbn 978-0-471 23279 7 Isbn 9780471232797Document16 pagesSolution Manual For Fundamentals of Semiconductor Fabrication Gary S May Simon M Sze Isbn 0471232793 Isbn 978-0-471 23279 7 Isbn 9780471232797warepneumomxkhf100% (17)

- Therapeutic Diet Manual: DIRECTIVE #4311Document27 pagesTherapeutic Diet Manual: DIRECTIVE #4311DuNo ratings yet

- Jack and The Beanstalk Treatment-2Document10 pagesJack and The Beanstalk Treatment-2api-668257195No ratings yet

- The Harrod-Domar Growth ModelDocument6 pagesThe Harrod-Domar Growth ModelSimeonNo ratings yet

- Koch - Control ChartsDocument40 pagesKoch - Control ChartsAkash MarathakamNo ratings yet

- UVU Jungle Marathon 2012 BookDocument41 pagesUVU Jungle Marathon 2012 BookGerhard FlatzNo ratings yet

- 130-87 InstructionsDocument7 pages130-87 InstructionsAlex GarciaNo ratings yet

- Gear Trains: 8.1. Angular Velocity RatioDocument16 pagesGear Trains: 8.1. Angular Velocity RatioaddisudagneNo ratings yet

- Masterglenium Ace: Solutions For The Pre-Cast IndustryDocument7 pagesMasterglenium Ace: Solutions For The Pre-Cast IndustryAlanNo ratings yet

- Likedislikedon't LikeDocument3 pagesLikedislikedon't LikeBriza PaolaNo ratings yet

- A Clinical Audit Into The Success Rate of Inferior Alveolar Nerve Block Analgesia in General Dental PracticeDocument4 pagesA Clinical Audit Into The Success Rate of Inferior Alveolar Nerve Block Analgesia in General Dental PracticeGina CastilloNo ratings yet

- Regulator InfoDocument6 pagesRegulator InfoAguilar AlexNo ratings yet

- 5 - Introduction Q-Series Vs2 Customer Version2Document49 pages5 - Introduction Q-Series Vs2 Customer Version2mahreza189100% (1)

- Stages of SleepDocument2 pagesStages of SleepCamilia Hilmy FaidahNo ratings yet

- Synchronous Generators: Instructional ObjectivesDocument18 pagesSynchronous Generators: Instructional Objectivessanthosh2009No ratings yet

- Intensifying AdjectivesDocument2 pagesIntensifying AdjectivesReena JimmyNo ratings yet

- Chapter 20 Practice TestDocument19 pagesChapter 20 Practice TestCorei'Ana Conrad0% (1)

- S900 Inverter User Manualv1.5 PDFDocument86 pagesS900 Inverter User Manualv1.5 PDFOmar ShadyNo ratings yet

- Process SequenceDocument2 pagesProcess SequenceUmesh SakhareliyaNo ratings yet

- Fetomaternal Hemorrhage (FMH), An Update Review of LiteratureDocument35 pagesFetomaternal Hemorrhage (FMH), An Update Review of LiteratureEugenia Jeniffer JNo ratings yet

- PQR As Run SheetDocument2 pagesPQR As Run SheetAhmed ElsharkawNo ratings yet

- (A) Design - Introduction To Transformer DesignDocument16 pages(A) Design - Introduction To Transformer DesignZineddine BENOUADAHNo ratings yet

- Structural Engineering Professor Step III: Ucsd Academic Biography/Bibliography FormDocument30 pagesStructural Engineering Professor Step III: Ucsd Academic Biography/Bibliography FormCesar Paul Purihuaman MoraNo ratings yet