Professional Documents

Culture Documents

50 Kva Distibution Transformer Design

50 Kva Distibution Transformer Design

Uploaded by

Jemal MusaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

50 Kva Distibution Transformer Design

50 Kva Distibution Transformer Design

Uploaded by

Jemal MusaCopyright:

Available Formats

Design of Distribution Transformer

Design a Transformer to meet the following Specification:

Type of Distribution: CORE

Output in KVA

: 50kVA

Primary (HT) Volts : 2400 V

Secondary (LT) Volts

Frequency

: 480/240 V (multi-tap)

: 60 Cycle

Efficiency at Unity Power Factor

Full Load

: 98.4 %

Load

: 97.8 %

Temperature rise not to exceed to 55c

CALCULATIONS:

Guaranteed Losses:

Total Loss @ Full Load

10.984

x 50000=813 watts

0.984

Total Loss @ Full Load

10.978 50000

x

=281.186 watts

0.978

4

Full Load Copper Loss

813567.268=245.73 watts

Core Loss

Item 1.

Vt

813281

=567.268 watts

1

1

16

Volts Per Turn

=

5 0000

60

(assume c = 60)

= 3.73 volts

Item 2 to 4. Primary and Secondary Turns. It is desirable to use Two coils on

the High Tension Side

and Four coils of the Low Tension Side.

Total Secondary Turns

Turns per Secondary coils

480

3.73

=

= 128.686 (say) 132 turns

132

4

= 33 turn/coil

Total Primary Turns

Turns per Primary coils =

Item 5.

@ Low Tension

50000

I p=

=20.83 amp.

2400

2( 132 x 104.167)

=59.3313 sq .inch

1500 x 0.309

4.11 inch

H=14.41 inch

108 x 480

By formula, the flux in the iron is = 4.44 x 132 x 60 =1365001.365 maxwells

From art 130. We select 70000 lines per sq. in as a trial density in the limbs

under windings. Hence the proportion S = 2L and stacking factor of 0.9

assume S = 1.5L.

1365001.365

0.9 L x 1.5 L=

L=3.8 inch

70000

M =L=3.8

= 330 turn/coil

H

=3.5 inch

D

=660 turns

Item 6 to 15. Before deciding upon the sizes of wire in the windings, it would

be advisable to

the probable dimensions of the opening or window, which must

accommodate both primary and secondary windings. (assume Current

Density = 1500 amp/sq. inch)

10

Space factor = 30+ 2.4 =0.309

H x D=

660

2

2400

3.73

Full Load Current

@ High Tension

50000

Is

=104.167 amp .

480

inch

S=1.5 ( 3.8 ) =5.7 inch

Assuming M=L, the same cross section of iron and the same flux density in

the end of the core as in the limbs under windings M= 3.8 inch

0.28 ( SF x L x S ) 2( H+ S+ L+ M )

Weight of iron

0.28 ( 0.9 x 3.8 x 5.7 ) x 2 ( 14.41+5.7+3.8+3.8 )

W iron=302.5 lb.

Total core loss watts per pound of B= 70000 be 0.75 from fig. 154

Total Core Loss=W iron ( 0.75 ) =302.5 ( 0.75 )=226.875 watts

The total Core Loss needs to be increased to meet the guaranteed Core Loss of

245.73.

By making slight changes in the design and decreasing the number of turns in

the windings, it will now be possible to proceed with the final calculations and

approxiamate the losses required to give the specified efficiencies.

Recalculation of Core Loss

The total flux is:

132

=1,365,001.365 x

116

= 1,553,277.415 maxwells

Calculating the losses in the limbs under the windings and in the end sections

must be calculated separately.

For the losses of the 2 limbs under windings:

1,553,277.415

=

=

CSA=0.9 x 3.8 x 5.7

CSA

19.494

19.494

sq. in

79679.769

(say) 80,000 lines per sq. In.

We read watts loss per pound be: 0.95

Weight of 2 limbs under windings 0.28 x 19.494 x 14.41 x 2

157.3lbs .

Core Loss of 2 limbs under windings

157.3 x 0.95=149.44 watts

For the losses of the 2 end sections, it will also be calculated in the same

manner.

Henc, adjusting M=5.

CSA=0.9 x 5 x 5.7

25.65 sq .

sq. In.

We read Watts loss per pound be: 0.57

1,553,277.415

25.65

60,556.62 (say) 61,000 lines per

2 x 0.28 x 25.65 x (4.11+ (2 x 3.8 ))

Weight of 2 end sections

168.2lbs .

168.2 x 0.57

Core Loss of 2 end sections

149.314+95.874=245.314 watts

Total Core Loss

Loss of

95.874 watts

which is practically the specified

245. 75 watts

Core Dimensions:

L= 3.8 in.

S= 5.7 in.

M= 5 in.

H= 14.41 in.

D= 4.11 in.

Size of Wires And Winding Particulars

Thickness CSA / Width

I s 104.167

=

=0. 6933 sq .inch.

1500

Length of winding space in the Layer = 13.91 (from fig.)

13.91

=0.4797

Width of one Conductor including insulation =

29

Cotton Coverings = 0.02 in (20 mils)

Width of Copper = 0.46 inch

0.06933

Thickness =

= 0.15175 inch

0.46

For rectangular conductor

0.46 by 0.1575=0.07245 sq .inch .

For high tension side select the size of wire at the table n page 431 use size #7

DCC wire

Current Density=

20.83

amp

=1 223.24

0.01635

sq . inch

Length of winding Layer = 13.66 (assumption)

Number of Wires per Layer = 13.66 x 6.35 = 86.74 (say) 87

where 6.35 is obtained from the wire table on page 431.

580

=6.67 7 layer

Total Number of Layers of Wire

87

(for each 2 limbs)

Volts (RMS)

1200 x

2 x 87

=360 volts (rms value)

580

It is usual to limit the potential

difference between layers which can

generally be accomplish the number

of windings in the sufficient number

of separate coils providing adequate

insulation between coils with core

dimension.

Thickness of copper and insulation

is computed as follows.

Item 16 to 23.

Materials

Radial Thickness

Cotton tape binding assembled laminations

0.018

Varnished cambric

0.010

Pressboard

0.030

Clearance

0.067

Inner L.T. coil (one layer) including cotton on wire

0.190

Parchment paper (0.010) between coils; allow

0.015

Outer L.T. coil (one layer)

0.190

Pressboard around outer L.T. coil

0.020

Spacers of treated wood to form oil ducts

0.125

Pressboard

0.020

Two layers cotton tape

0.018

Parchment paper w/ crimped edges on w/c primary and

secondary coil will be wound

0.005

18 layers of No. 13 dcc round wire

1.092

Two thickness of 0.005 papers between layers

0.080

Cotton tape, half lapped

0.018

Allowance for bulging (0.02 x 3.05)

0.114

Total

2.012

t = 0.125

s = 0.395

g = 0.188

p = 1.304

Space available to accomodate this total thickness of copper and insulation =

4.11

=2.055 in.

2

CALCULATION OF COPPER LOSS

The mean length per turn (MLT) of the windings

2 ( 3.8+5.7 )+ ( 0.25+ 0.395 )

Secondary MLT =

=1.75 ft

12

Primary MLT =

2 ( 3.8+5.7 ) + (0.25+0.79+0.304)

=1.72 ft

12

Total Length of Wire

Primary Winding = 580 x 1.72 = 997.6 ft

Secondary Winding = 116 x 1.75 = 203 ft

Weight of Copper Loss

Primary Coils (No.7), 63 x 0.9976 = 62.85 lb

Secondary Coils = 0.32(0.46 x 0.151) x 203 x 12 = 54.145 lb

Since the resistance of No.7 DCC wire is 0.5790 ,

234.5+75

0.5790 x

= 0.61

234.5+60

Total Resistance

(Primary)

RT = 0.61 x 0.9976 = 0.61

IR = 20.83 x 0.61 = 12.68 volts

I 2 R=20.83 2 x 0.61=264.67 watts

(Secondary)

0.0635

203

RT= 0.61 x 0.0726 x 1000 =0.02789

IR = 104.167 x 0.02789 = 2.9 volts

I 2 R=104.167 2 x 0.02789=302.63 watts

Total Copper Loss = 264.67 + 302.63 = 567.3 watts

Items 24 32.

Items 33.

Core and Copper Losses 245.31 + 567.3= 812.61 watts

Efficiency at unity power factor

1

4

Full Load

50,000

4

1

=98.77

567.3

50,000

120+

16

4

@ Full load

245.31+567.3

1

=98.4

50000+812.61

@ Half Full load

245.31+141.825

=98.5

25000+203.1525

@ Three quarter full load :

0.75

( 2 x 567)+120+( 0.75 x 50,000)=98.42

0.75 x 50,000

@ 25% over load

1.25

( 2 x 567.3)+ 120+(1.25 x 50,000)=98.42

1.25 x 50,000

Maximum Efficiency:

245.31

50000

=32.88 KVA

567.3

Items 34.

245.31+245.31

= 94.5%

8439.3+490.62

Basis of 4 hour full load and 20 hour no load.

All Day Efficiency:

50000 x 4

=96.7

( 50000 x 4 ) + ( 145.31 x 24 )+(812.4 x 4)

Item 35.

For the two limbs under the winding with mean length

B = 80,000

Mean Length = 2 x (3.8 + 5.7 + 4.11) = 27.22

T x I = [ 27.22 ] x [ 0.8 ] =21.78

Mean Length=2 x ( 5+5.7+ 4.11 )=50.22

T x I =50.22 x 3.5=175.77

Total (T x I) = 21.78 + 175.77 = 197.55 amp. turns

2

Np

total I x T

Ic=

197.55

=0.2408

580 ( 2)

Energy Component=I w =

core loss

245.31

=

=0.1022 amp .

H . T . volts 2400

I = I c 2 + I w2 =(0.1022)2+(0.2408)2=0.2616 amp .

Item 36 to 39.

IR Drop=

Regulation

812.61

x 100=1.7087

50000

length=12 x

%IX Drop=

1.75+1.72

=18.06

2

2 f T s Isl

n h E s 10

x g+

5

p+ s 2 x 60 x 116 2 x 104.167 x 18.06

1.304+0.395

=

x 0.188+

=1.656

5

3

3

2 x 14.41 x 480 x 10

Equivalent Reactive Drop=2400 x 0.01656=43.24 volts

% Regulation @ 0.80 power factor

%IR cos+%IX sin

1.6252 ( 0.80 )+1.656 ( 0.60 )=2.49

Item 40 to 42.

The temperature rise of the windings as measured by

the resistance method must not exceed the specified 55 .

For the dimension of tank total area

S=

245.48

=861 sq . inch

50 x 0.0057

Dimension are 15 x 12 x 24 in high

1

20 [ (15 x 2 )+(12 x 2) ] + ( 24 x 15 )=1440 sq . inch.

2

Cooling Effective Surface

For Watts

861

=0.6

1070

For temperature

Item

No.

1

245.48

=42

0.0041 x 1440

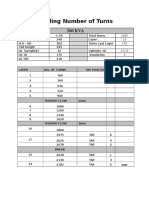

SUMMARY OF CALCULATIONS

Volts per turn : From formula = 3.73 v

Windings

; actual = 4.138 v

High

Tension

Low

Tensi

on

2

3

4

5

6

Total numbers of turns

Numbers of coils

Turns per coil

Full Load Current (Amp)

2

Current Density( amp ./inch )

580

2

290

20.83

1223.24

116

4

29

104.167

1500

7

8

9

10

11

12

13

14

Cross Section of Conductor

Dimension of Conductors

# of Turns per Layer per Coil

# of Layer per Coil

# of Taps

Volts per Coil

Volts Between Layers

Length of Winding Layers

0.01635

No. 7

87

7

None

1200

360

13.68

0.07245

0.46 x 0.1575

29

1

2

120

15

Length of Layer Including Insulation

16

17

18

19

20

21

22

Insulation Between Layers

Insulation on Wire

Length per Turn

Total Length, all Turn in series, ft

Weight in Copper(lbs)

Resistance a 75 c All Coils

IR Drop Volts

14.41

0.02

dcc

1.72

997.6

62.85

0.61

12.68

13.91

14.41

dcc

1.75

203

54.145

0.02789

2.9

23

Full Load Copper Loss(Compare to

Guaranteed)

246.67

302.63

THE MAGNETIC CIRCUIT

24

25

26

27

28

29

30

31

32

Dimension of Windows

Total Flux, Maxwells

Flux Density in Core Under Windings

Cross Section of Iron in Core Under Windings

Width of Stampings in Core Under Windings

Gross Thickness of Core

Total Weight or Iron in Core, lbs.

Watts Loss in Iron (compare to guaranteed)

Total Full Load Losses, watts

14.41 x 4.11

1553277.415

80000

19.494

3.8

5.7

325.5

245.31

812.61

EFFICIENCY AND EXCITING CURRENT

33

34

35

Efficiency at Unity Power Factor

At Full Load

At Load

At Load

At Load

At 25% Over Load

All Day Efficiency (4Hr Full Load)

Primary Exciting Current, Amp.

98.4%

98.5%

98.77%

98.84%

98.42%

96.7%

0.2408

REGULATION

36

37

38

39

Total Equivalent IR Drop Percent

Total Reactive Drop Percent

Regulation on Unity Power Factor

Regulation on 0.80 Power Factor

1.6252

1.656

1.6252

2.29376

DESIGN OF TANK TEMPERATURE RISE

40

41

Effective Cooling Surface of Tank, sq. inch.

Watts per square inch of Tank

3020

0.269

42

Approximate Temperature Rise,

47.2

You might also like

- 1 KV 250 A 3150 Din 42530 67 3370221Document2 pages1 KV 250 A 3150 Din 42530 67 3370221Yigit SarıkayaNo ratings yet

- Derivation of Formula For Calculation of Turns Per Volts of Transformer DesignDocument15 pagesDerivation of Formula For Calculation of Turns Per Volts of Transformer DesignJemal Musa100% (1)

- 1.6 MVA Dry Transformer DesignDocument21 pages1.6 MVA Dry Transformer DesignJemal MusaNo ratings yet

- Principles of Acc. II Lecture NoteDocument54 pagesPrinciples of Acc. II Lecture NoteJemal Musa83% (6)

- Objective:: Voltage Per Turn: EDocument19 pagesObjective:: Voltage Per Turn: EMohammed Rubayet Sharif100% (1)

- RewindingDocument9 pagesRewindingBlack StarNo ratings yet

- Current Transformer Design GuideDocument3 pagesCurrent Transformer Design Guidedeepthik27No ratings yet

- DESIGNDocument7 pagesDESIGNjaythakar8887No ratings yet

- Transformer Manufacturer EnquiryDocument26 pagesTransformer Manufacturer EnquiryblaagicaNo ratings yet

- 2.01.1 Wire ENDocument20 pages2.01.1 Wire ENNoname_user989No ratings yet

- 1000 KVA Type Test From ERDA, IndiaDocument9 pages1000 KVA Type Test From ERDA, IndiasaikatNo ratings yet

- CRGODocument15 pagesCRGOipraoNo ratings yet

- Distribution Transformer TestingDocument2 pagesDistribution Transformer TestingjamilsoriaNo ratings yet

- Calculations For Design Parameters of Transformer - Engineer ExperiencesDocument40 pagesCalculations For Design Parameters of Transformer - Engineer ExperiencesSamit DasNo ratings yet

- Design of Single and Three Phase Transformer Using MATLABDocument6 pagesDesign of Single and Three Phase Transformer Using MATLABDevesh JayaswalNo ratings yet

- Over Reach of Distance RelayDocument2 pagesOver Reach of Distance Relayimcoolmailme2No ratings yet

- Design 3-Phase Core Type of Transformer and Modification of Symmetrical Star Shaped Core-IJAERDV04I0183936Document8 pagesDesign 3-Phase Core Type of Transformer and Modification of Symmetrical Star Shaped Core-IJAERDV04I0183936Editor IJAERDNo ratings yet

- Introduction of Electric Power SystemDocument17 pagesIntroduction of Electric Power SystemsohaibNo ratings yet

- IEEMA-Basics of Dual Ratio TransformersDocument3 pagesIEEMA-Basics of Dual Ratio TransformersHari Krishna.MNo ratings yet

- Aditya Design of Transformers CD PDFDocument84 pagesAditya Design of Transformers CD PDFAkshay Kumar DadhichNo ratings yet

- Introduction To Instrument TransformersDocument20 pagesIntroduction To Instrument TransformersAbdul'Azeez Stanley IgweNo ratings yet

- Operacion Recloser RoclwillDocument54 pagesOperacion Recloser RoclwillChristian Vasquez MedranoNo ratings yet

- Transformer Winding PracticesDocument7 pagesTransformer Winding PracticeskshgunawardenaNo ratings yet

- Vertical Step Lap CoreDocument6 pagesVertical Step Lap CoreMohit Sharma100% (1)

- Design & Optimization of Power Transformers With Source CodesDocument75 pagesDesign & Optimization of Power Transformers With Source CodesN. T. DadlaniNo ratings yet

- 074bel348 EMD AssignmentDocument11 pages074bel348 EMD Assignmentkeshav raj sharma100% (1)

- Calculate IDMT Over Current Relay Setting (50 - 51) - Electrical Notes & ArticlesDocument3 pagesCalculate IDMT Over Current Relay Setting (50 - 51) - Electrical Notes & ArticlesSheraz KhanNo ratings yet

- Siemens 3af 01Document24 pagesSiemens 3af 01Nhat Nguyen VanNo ratings yet

- Product Manual For New Insulating Oils ACCORDING TO IS 335:2018Document8 pagesProduct Manual For New Insulating Oils ACCORDING TO IS 335:2018Ajay KumarNo ratings yet

- 21-06-2017 16-45-31 - MCOMP - Protection Relays - Manual PDFDocument249 pages21-06-2017 16-45-31 - MCOMP - Protection Relays - Manual PDFmehtaabhi99_27916695No ratings yet

- Transformer Design NotesDocument15 pagesTransformer Design Notesrishabh100% (2)

- Pwer TransformerDocument17 pagesPwer Transformerrossikada100% (2)

- Transformer Solved Examples of Basic Electrical Eng by Nagrath and KothariDocument4 pagesTransformer Solved Examples of Basic Electrical Eng by Nagrath and KothariAnurag ZwNo ratings yet

- Specification For Polymer Pin InsulatorDocument9 pagesSpecification For Polymer Pin InsulatorBinay PaudyalNo ratings yet

- Transformer Design (Version 1)Document19 pagesTransformer Design (Version 1)Divya AravindNo ratings yet

- Insulation ResistanceDocument2 pagesInsulation ResistanceDEADMAN0% (1)

- Final Report Transformer Design Section A PDFDocument68 pagesFinal Report Transformer Design Section A PDFThabiso Kyle100% (1)

- Roth Method of Force CalculationDocument8 pagesRoth Method of Force CalculationKavish JainNo ratings yet

- ELE 2117 - Lesson 9Document36 pagesELE 2117 - Lesson 9elioNo ratings yet

- Indian Institute of Engineering Science and Technology, Shibpur Department of Electrical EngineeringDocument4 pagesIndian Institute of Engineering Science and Technology, Shibpur Department of Electrical EngineeringKool PrashantNo ratings yet

- Drying Time For Transformer Core and Winding AssemblyDocument4 pagesDrying Time For Transformer Core and Winding AssemblyPasan Heshara LiyanageNo ratings yet

- IS 2026-2 (2010) - Power Transformers, Part 2 - Temperature-RiseDocument17 pagesIS 2026-2 (2010) - Power Transformers, Part 2 - Temperature-Riserajiv71No ratings yet

- Ccum 21Document4 pagesCcum 21Hari Krishna.MNo ratings yet

- unit-II TransformersDocument19 pagesunit-II Transformersc.naresh9727100% (1)

- Brochure - Electrical Insulating PapersDocument28 pagesBrochure - Electrical Insulating PapersEko SusantoNo ratings yet

- ITI Basics - 2-09Document66 pagesITI Basics - 2-09peloquin1349391No ratings yet

- Books RefrenceDocument13 pagesBooks RefrencePradith SaiNo ratings yet

- Transformer Design DifferencesDocument22 pagesTransformer Design DifferencesSurabhi KatochNo ratings yet

- SBG (Nilai), German, Oil Distribution TransformerDocument12 pagesSBG (Nilai), German, Oil Distribution TransformerpeakfortuneNo ratings yet

- Transformer Losses & EfficencyDocument8 pagesTransformer Losses & EfficencyMuhammad ZumyNo ratings yet

- Combine TRDocument8 pagesCombine TRAchmad ZulkifliNo ratings yet

- Comp Insulator PDFDocument10 pagesComp Insulator PDFryan_jay55No ratings yet

- Inductance of 3 Phase LineDocument50 pagesInductance of 3 Phase LineFemi PrinceNo ratings yet

- RISHMaster 6100Document5 pagesRISHMaster 6100Aarif Patel0% (1)

- Product Data Sheet: Circuit Breaker Compact NS400N - STR23SE - 400 A - 3 Poles 3dDocument2 pagesProduct Data Sheet: Circuit Breaker Compact NS400N - STR23SE - 400 A - 3 Poles 3dGabriel ZorattiNo ratings yet

- Surge - Protection For Sync MachDocument8 pagesSurge - Protection For Sync MachpwmvsiNo ratings yet

- 12.testing of High Voltage Equipment and Insulation CoordinationDocument53 pages12.testing of High Voltage Equipment and Insulation CoordinationumeshNo ratings yet

- Voizecom - Brochure V836Document1 pageVoizecom - Brochure V836EHS Engineer0% (1)

- Chapter - 1 Transformer: 1.1introduction OftransformerDocument30 pagesChapter - 1 Transformer: 1.1introduction OftransformerpraneethNo ratings yet

- CDTTSDocument2 pagesCDTTSAnonymous m65TTcfOT100% (1)

- Designing of Amorphous Core Distribution Transformer and Comparison With CRGO Core Distribution TransformerDocument5 pagesDesigning of Amorphous Core Distribution Transformer and Comparison With CRGO Core Distribution TransformerIJMERNo ratings yet

- Power Transformer Online Monitoring Using Electromagnetic WavesFrom EverandPower Transformer Online Monitoring Using Electromagnetic WavesNo ratings yet

- Design of 100 KVA 380 by 220 V Transformer: HV WindingDocument4 pagesDesign of 100 KVA 380 by 220 V Transformer: HV WindingJemal MusaNo ratings yet

- Star Delta WiringDocument15 pagesStar Delta WiringJemal MusaNo ratings yet

- Winding Number of TurnsDocument1 pageWinding Number of TurnsJemal MusaNo ratings yet

- Electrical DesignDocument39 pagesElectrical DesignJemal Musa100% (1)

- Motivation LetterDocument2 pagesMotivation LetterJemal Musa100% (1)

- What Is The Definition of ZeroDocument1 pageWhat Is The Definition of ZeroJemal MusaNo ratings yet

- 200 KvaDocument1 page200 KvaJemal MusaNo ratings yet

- Winding Number of TurnsDocument1 pageWinding Number of TurnsJemal MusaNo ratings yet

- Presentation1 TransformerDocument16 pagesPresentation1 TransformerJemal MusaNo ratings yet

- 400 Kva, 15 & 0.4 KV PDF - Docx TsDocument8 pages400 Kva, 15 & 0.4 KV PDF - Docx TsJemal MusaNo ratings yet

- Mechanical Part Dry Type TransformerDocument21 pagesMechanical Part Dry Type TransformerJemal MusaNo ratings yet

- An Example of A Protection CTDocument1 pageAn Example of A Protection CTJemal MusaNo ratings yet

- An Example of A Protection CTDocument1 pageAn Example of A Protection CTJemal MusaNo ratings yet

- Mechanical Part Dry Type TransformerDocument21 pagesMechanical Part Dry Type TransformerJemal MusaNo ratings yet

- CAN NetworkDocument18 pagesCAN NetworkAM76No ratings yet

- Calibrating The ADE7753 For Watt, VAR, RMS and VA MeasurementsDocument40 pagesCalibrating The ADE7753 For Watt, VAR, RMS and VA MeasurementsOoal GonNo ratings yet

- W7751 Smart VAV InstallationDocument12 pagesW7751 Smart VAV InstallationAnwar LatiffNo ratings yet

- Power Electronics and Drives U4Document58 pagesPower Electronics and Drives U4Idiots Idiotss100% (1)

- XMH3-30RT-E series Integrator Fast reference manual 【 】: Performance Performance Performance PerformanceDocument2 pagesXMH3-30RT-E series Integrator Fast reference manual 【 】: Performance Performance Performance PerformanceMarcos Luiz AlvesNo ratings yet

- Uas Owners Manual Smog Hog SHNDocument28 pagesUas Owners Manual Smog Hog SHNbcsf01No ratings yet

- Electra 329Document135 pagesElectra 329Clotilde RodinoNo ratings yet

- Family Health Center Kenichira, Poothadi: A Mini Project ReportDocument58 pagesFamily Health Center Kenichira, Poothadi: A Mini Project ReportAnanthu vijayanNo ratings yet

- Riya Katiyar-1712910Document131 pagesRiya Katiyar-1712910Ram SinghNo ratings yet

- 40-Gb/s Transimpedance Amplifier in 0.18 - M CMOS Technology: Jun-De Jin and Shawn S. H. HsuDocument4 pages40-Gb/s Transimpedance Amplifier in 0.18 - M CMOS Technology: Jun-De Jin and Shawn S. H. HsuTshering Sangmo SherpaNo ratings yet

- Homework Assignment No. 1: MOSFET Parameter N-Channel P-Channel UnitsDocument4 pagesHomework Assignment No. 1: MOSFET Parameter N-Channel P-Channel UnitsThippeswamy LNo ratings yet

- 1st Summative Test EIMDocument1 page1st Summative Test EIMHyuk Jin Joson100% (3)

- Synchronization, Speed Control & Load SharingDocument20 pagesSynchronization, Speed Control & Load Sharingshakil100% (1)

- Main Single LineDocument1 pageMain Single LinesswahyudiNo ratings yet

- Modicon X80 Modules - BMXCPS4002Document3 pagesModicon X80 Modules - BMXCPS4002Boris MoreiraNo ratings yet

- Digital Storage Oscilloscope (DSO) Presentation Based On The TDS210/TDS1002 Series User ManualDocument19 pagesDigital Storage Oscilloscope (DSO) Presentation Based On The TDS210/TDS1002 Series User ManualAtharva TambatNo ratings yet

- RC Coupled Amplifier - DC Operation - EXERCISE 7Document15 pagesRC Coupled Amplifier - DC Operation - EXERCISE 7Debbie ComissionNo ratings yet

- Portable Power 1150: Operator'SDocument15 pagesPortable Power 1150: Operator'SDarren HoffmanNo ratings yet

- Asco PV Emxx Solenoid Valve Operator II 2 G Ex MB II t6..t3 II 2 D Ex MD 21 Ip67Document2 pagesAsco PV Emxx Solenoid Valve Operator II 2 G Ex MB II t6..t3 II 2 D Ex MD 21 Ip67Mustafa TemelNo ratings yet

- Chapter I Review of Basics of Digital ElectronicsDocument21 pagesChapter I Review of Basics of Digital ElectronicsMia LateNo ratings yet

- What Is Voltage Stabilizer & How It Works? Types of StabilizersDocument15 pagesWhat Is Voltage Stabilizer & How It Works? Types of StabilizersCHakornNo ratings yet

- Spare Parts List: Arc 151i, Arc 201iDocument8 pagesSpare Parts List: Arc 151i, Arc 201iGurkan ÇetinkayaNo ratings yet

- CP 265x Cpu ModuleDocument40 pagesCP 265x Cpu Modulededy250591No ratings yet

- Amplifiers ElectionDocument58 pagesAmplifiers Electionqiuye123123No ratings yet

- 132kv Malana Ekd-Section-Rev01 ModifiedDocument1 page132kv Malana Ekd-Section-Rev01 ModifiedannuvyasNo ratings yet

- Kokam Battery: 48V SolutionDocument2 pagesKokam Battery: 48V SolutionLucian A MUșaNo ratings yet

- Polarity in Arc WeldingDocument3 pagesPolarity in Arc WeldingBabuli KumarNo ratings yet

- Results and Discussion: 4.1 Data GatheringDocument16 pagesResults and Discussion: 4.1 Data Gatheringraymond baliteNo ratings yet

- A Case For The Separated Double Tie: Main A Main B Tie N.C. N.CDocument4 pagesA Case For The Separated Double Tie: Main A Main B Tie N.C. N.CcokicisneNo ratings yet

- Automation 2012Document222 pagesAutomation 2012Franco FranchiNo ratings yet