Professional Documents

Culture Documents

A New Landmark Arch Bridge in Milan: The Twelfth East Asia-Pacific Conference On Structural Engineering and Construction

A New Landmark Arch Bridge in Milan: The Twelfth East Asia-Pacific Conference On Structural Engineering and Construction

Uploaded by

Vijay KumarCopyright:

Available Formats

You might also like

- Design Spreadsheet Gusset Plate Connection For TrussDocument4 pagesDesign Spreadsheet Gusset Plate Connection For TrussMatumbi Naito100% (1)

- Diaphragm Wall Construction SequenceDocument10 pagesDiaphragm Wall Construction Sequencedanzy89100% (2)

- Lecture 6 Cable Structures Wolfgang Schueller PDFDocument420 pagesLecture 6 Cable Structures Wolfgang Schueller PDFMike100% (1)

- The Messeturm in Rostock - A Tensegrity Tower by SchlaichDocument7 pagesThe Messeturm in Rostock - A Tensegrity Tower by SchlaichTensegrity Wiki0% (1)

- Design of Highly Curved Concrete Ramp BridgesDocument10 pagesDesign of Highly Curved Concrete Ramp BridgesyhszaNo ratings yet

- Guy AnchorDocument1 pageGuy AnchorVijay KumarNo ratings yet

- Global Transmission Report January 2016 PDFDocument62 pagesGlobal Transmission Report January 2016 PDFVijay KumarNo ratings yet

- Global Transmission Report January 2016 PDFDocument62 pagesGlobal Transmission Report January 2016 PDFVijay KumarNo ratings yet

- Mceeratc 49Document186 pagesMceeratc 49E44D44E44R 4444No ratings yet

- "Ponte Del Mare" - Conceptual Design and Realization of A Long Span Pedestrian BridgeDocument5 pages"Ponte Del Mare" - Conceptual Design and Realization of A Long Span Pedestrian BridgeJames ClaytonNo ratings yet

- Damage Analysis and Seismic Retrofitting of A Continuous Prestressed Reinforced Concrete Bridge (Caterino, Et Al. 2014)Document7 pagesDamage Analysis and Seismic Retrofitting of A Continuous Prestressed Reinforced Concrete Bridge (Caterino, Et Al. 2014)Jose ManuelNo ratings yet

- Akashi Kaikyo Bridge 1Document29 pagesAkashi Kaikyo Bridge 1Ssiddhartha VemuriNo ratings yet

- Darío Galante Bardín, Miguel A. Astiz Suárez. School of Civil Engineering, Technical University of Madrid (UPM) Dario - Galante@idiingenieros - EsDocument33 pagesDarío Galante Bardín, Miguel A. Astiz Suárez. School of Civil Engineering, Technical University of Madrid (UPM) Dario - Galante@idiingenieros - EsDarío Galante BardínNo ratings yet

- Seismic Design of Cable-Stayed Bridges. The South Crossing Bridge in Guayaquil, EcuadorDocument10 pagesSeismic Design of Cable-Stayed Bridges. The South Crossing Bridge in Guayaquil, EcuadorSanjay SinghNo ratings yet

- ANALYSIS AND DESIGN OF Cable Stayed BridgeDocument31 pagesANALYSIS AND DESIGN OF Cable Stayed Bridgeshrikantharle100% (1)

- Diagrid Structures For Tall Buildings: Case Studies and Design ConsiderationsDocument22 pagesDiagrid Structures For Tall Buildings: Case Studies and Design ConsiderationstarunkumarsharmaNo ratings yet

- An Innovative Tall Building Conception: The Sphere: Nicola Longarini Mauro Nicoletti Pietro CRESPIDocument8 pagesAn Innovative Tall Building Conception: The Sphere: Nicola Longarini Mauro Nicoletti Pietro CRESPIDan TomoiagaNo ratings yet

- Alfredo Camara Casado ApendicesaDocument149 pagesAlfredo Camara Casado ApendicesaBorna DasovićNo ratings yet

- Steel Lattice Telecommunication MastsDocument7 pagesSteel Lattice Telecommunication MastsjojogarciaNo ratings yet

- Comparison of The Seismic and Wind Analyses of Two Tower CranesDocument20 pagesComparison of The Seismic and Wind Analyses of Two Tower Cranessuresh_501No ratings yet

- Stress-Ribbon Bridges Stiffened by Arches or CablesDocument8 pagesStress-Ribbon Bridges Stiffened by Arches or Cablessure vineethNo ratings yet

- Pedestrian-Induced Torsional Vibrations of Suspended FootbridgesDocument11 pagesPedestrian-Induced Torsional Vibrations of Suspended FootbridgesSarwo Edhi zu UbitNo ratings yet

- Capping Beam Design 1Document8 pagesCapping Beam Design 1massive85No ratings yet

- Q1.What Are Cable Structures? What Are Their Different Types, and Principle of DesignDocument20 pagesQ1.What Are Cable Structures? What Are Their Different Types, and Principle of DesignTEHREEM ZAHRANo ratings yet

- Study On The Design of Chirajara BridgeDocument8 pagesStudy On The Design of Chirajara Bridgepaul ostepNo ratings yet

- Composite Truss BridgesDocument6 pagesComposite Truss Bridgeszepedro_fernandes100% (1)

- Seismic Design and Performance of Two Isolation Systems Used For Reinforced Concrete Bridge ConstructionDocument10 pagesSeismic Design and Performance of Two Isolation Systems Used For Reinforced Concrete Bridge ConstructionGourab GhoshNo ratings yet

- Dynamic Behaviour of Steel-Concrete Composite Under-Deck Cable-Stayed Bridges Under The Action of Moving LoadsDocument33 pagesDynamic Behaviour of Steel-Concrete Composite Under-Deck Cable-Stayed Bridges Under The Action of Moving LoadsRicardo PimentelNo ratings yet

- Wind Loads Talavera de La ReinaDocument5 pagesWind Loads Talavera de La ReinaAlexandru IonescuNo ratings yet

- The Evolution of Arches As Lightweight Structures - Cottbus - 22.11.08Document8 pagesThe Evolution of Arches As Lightweight Structures - Cottbus - 22.11.08spiff9999No ratings yet

- Caleng TPDocument10 pagesCaleng TPJose Miguel Sta. CruzNo ratings yet

- Integral Bridge Concept Applied To Rehabilitate An Existing Bridge and Construct A Dual-Use BridgeDocument8 pagesIntegral Bridge Concept Applied To Rehabilitate An Existing Bridge and Construct A Dual-Use BridgeMuhammad AbdullahNo ratings yet

- Footbridge 2005: Design and Construction Method of The New Coimbra FootbridgeDocument9 pagesFootbridge 2005: Design and Construction Method of The New Coimbra FootbridgeVijay KumarNo ratings yet

- Camara Et Al Mode Estimation CSB JBE OpenaccessDocument36 pagesCamara Et Al Mode Estimation CSB JBE OpenaccessCristian Camilo Londoño PiedrahítaNo ratings yet

- Behaviour of A Steel Bridge Equipped With Seismic Isolation DevicesDocument10 pagesBehaviour of A Steel Bridge Equipped With Seismic Isolation DevicesbulbucataNo ratings yet

- 25501322032 Arindam Mukherje ADocument7 pages25501322032 Arindam Mukherje Aarindam_925024954No ratings yet

- Arch206 - Lecture2 - Işık Ülkün PDFDocument71 pagesArch206 - Lecture2 - Işık Ülkün PDFRAJ AGRAWALNo ratings yet

- Elongation of The Fundamental Periods of Highway Bridges During Nonlinear Seismic Response - A Case StudyDocument12 pagesElongation of The Fundamental Periods of Highway Bridges During Nonlinear Seismic Response - A Case StudycorderovNo ratings yet

- Case Study 1Document7 pagesCase Study 1harishma hsNo ratings yet

- Base Isolation of Railway Bridges-2Document8 pagesBase Isolation of Railway Bridges-2Marco FigueiredoNo ratings yet

- [17344492 - International Journal of Applied Mechanics and Engineering] Cable-Stayed Cantilever Structures As An Expat Of Unique Application In The Construction Of A Building Located In Seismic Area – An Author’s Proje.pdfDocument12 pages[17344492 - International Journal of Applied Mechanics and Engineering] Cable-Stayed Cantilever Structures As An Expat Of Unique Application In The Construction Of A Building Located In Seismic Area – An Author’s Proje.pdfArtjom SamsonovNo ratings yet

- Gatwick Air BridgeDocument7 pagesGatwick Air BridgemrasdanNo ratings yet

- Numerical Analysis of The Axial-Flexural BehaviorDocument26 pagesNumerical Analysis of The Axial-Flexural BehaviorvNo ratings yet

- Design of Self - Supporting Dome RoofsDocument6 pagesDesign of Self - Supporting Dome RoofszatenneNo ratings yet

- Weak Beam-Strong ColumnDocument7 pagesWeak Beam-Strong Columnarun_angshuNo ratings yet

- Optimization of Hanger Inclination in A Tied Arch BridgeDocument8 pagesOptimization of Hanger Inclination in A Tied Arch Bridgecerbu_bass_cdcNo ratings yet

- Steel Cable Creates Novel Structural Space SystemsDocument11 pagesSteel Cable Creates Novel Structural Space Systemsuhu_plus6482No ratings yet

- Multi Storey Steel Building 01Document19 pagesMulti Storey Steel Building 01Dan AlexandrescuNo ratings yet

- Structural Analysis of BridgesDocument16 pagesStructural Analysis of BridgesKato EmmanuelNo ratings yet

- 2019the Effect of Slenderness On The Design of Diagrid StructuresDocument12 pages2019the Effect of Slenderness On The Design of Diagrid Structuresmaikol cantorNo ratings yet

- (Asce) Be 1943-5592 0001807Document13 pages(Asce) Be 1943-5592 0001807Adriano De SortisNo ratings yet

- A Deployable Mast For Adaptable TextileDocument12 pagesA Deployable Mast For Adaptable TextileWeifeng HeNo ratings yet

- A Review On Shapes of Pylon For Cable-Stayed Bridge.: Mr. Ajinkya D. Raut, Prof. R.A. DubalDocument2 pagesA Review On Shapes of Pylon For Cable-Stayed Bridge.: Mr. Ajinkya D. Raut, Prof. R.A. DubalMohammad Salman MananNo ratings yet

- Upgrading of Transmission Towers Using A Diaphragm Bracing SystemDocument26 pagesUpgrading of Transmission Towers Using A Diaphragm Bracing SystemthoriqNo ratings yet

- An Overview On Diagrid Structures For Tall BuildingsDocument10 pagesAn Overview On Diagrid Structures For Tall BuildingsLopamudra SenguptaNo ratings yet

- Atmaca, Yurdakul, & Ates - The Effect of Seismic Isolation On The Dynamic Behavior of Cable-StayedDocument7 pagesAtmaca, Yurdakul, & Ates - The Effect of Seismic Isolation On The Dynamic Behavior of Cable-StayedPhan TumNo ratings yet

- Shake Table Test of Cable-Stayed Bridge Subjected To Non-Uniform ExcitationDocument8 pagesShake Table Test of Cable-Stayed Bridge Subjected To Non-Uniform ExcitationSantos Daza VallejosNo ratings yet

- Parametric Study of Double Layer Steel Dome With Reference To Span To Height RatioDocument9 pagesParametric Study of Double Layer Steel Dome With Reference To Span To Height RatioIjsrnet EditorialNo ratings yet

- Transverse Seismic Behaviour of CompositDocument10 pagesTransverse Seismic Behaviour of CompositYohannes TesfayeNo ratings yet

- Malm2010 - Time Dependent Analyses of Segmentally Constructed Balanced Cantilever BridgesDocument8 pagesMalm2010 - Time Dependent Analyses of Segmentally Constructed Balanced Cantilever BridgesHuber MezaNo ratings yet

- Modern Solution For The Foundation of Poland'S Largest Arch BridgeDocument10 pagesModern Solution For The Foundation of Poland'S Largest Arch Bridgemalves56No ratings yet

- Limit Analysis of The External Wall of ColosseumDocument6 pagesLimit Analysis of The External Wall of ColosseumOana PopaNo ratings yet

- Response of Cable Stayed Bridge Under Ground MotionsDocument8 pagesResponse of Cable Stayed Bridge Under Ground MotionsPhan TumNo ratings yet

- Bridges Spanish HSRLDocument13 pagesBridges Spanish HSRLVelugoti VijayachandNo ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- A Guide to Some of the Equations used in Constructing a Suspension BridgeFrom EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeNo ratings yet

- Rock AnchorDocument2 pagesRock AnchorVijay Kumar100% (1)

- No - of Bolts Required 0.66 No.s No - of Bolts Provided No.sDocument1 pageNo - of Bolts Required 0.66 No.s No - of Bolts Provided No.sVijay KumarNo ratings yet

- (Lef/ry) 2 (Lef Te) 2Document1 page(Lef/ry) 2 (Lef Te) 2Vijay KumarNo ratings yet

- Input Parameters For Foundation DesignDocument1 pageInput Parameters For Foundation DesignVijay KumarNo ratings yet

- Check For Uplift (Refer Figure - 2)Document1 pageCheck For Uplift (Refer Figure - 2)Vijay KumarNo ratings yet

- Structural Design of FoundationDocument1 pageStructural Design of FoundationVijay KumarNo ratings yet

- Bending Moment About Section Y-YDocument1 pageBending Moment About Section Y-YVijay KumarNo ratings yet

- Hence The Spcacing Between Rod Is (MM) 105 O.KDocument1 pageHence The Spcacing Between Rod Is (MM) 105 O.KVijay KumarNo ratings yet

- Hence The Spcacing Between Rod Is (MM) 202 O.K.: (5) CHECK FOR SLIDING (Refer Figure - 4)Document1 pageHence The Spcacing Between Rod Is (MM) 202 O.K.: (5) CHECK FOR SLIDING (Refer Figure - 4)Vijay KumarNo ratings yet

- Check For OverturningDocument1 pageCheck For OverturningVijay KumarNo ratings yet

- 20-F201007-SC-010 R0 - Design Calculation of Foam Tank and Fire Pump ShedDocument187 pages20-F201007-SC-010 R0 - Design Calculation of Foam Tank and Fire Pump ShedSaravan KumarNo ratings yet

- Structural Masonry SyllabusDocument1 pageStructural Masonry SyllabusPrashant Sunagar0% (1)

- 1 2 MergedDocument37 pages1 2 MergedCarjez LoveNo ratings yet

- Retrofitting of Columns by Steel Jackets-8cccDocument7 pagesRetrofitting of Columns by Steel Jackets-8cccsecond2nonnNo ratings yet

- ETABS Concrete Frame Design: Eurocode 2-2004 Column Section DesignDocument2 pagesETABS Concrete Frame Design: Eurocode 2-2004 Column Section DesignTith ReaksmeyNo ratings yet

- Content RCC Fanella PDFDocument4 pagesContent RCC Fanella PDFJulio Cesar ValdiviesoNo ratings yet

- Shear Wall Design-ACI-318-14Document30 pagesShear Wall Design-ACI-318-14Christian ReedNo ratings yet

- Design of 75Kl Zinc Alume (Znal) Elevated Water Storage TankDocument26 pagesDesign of 75Kl Zinc Alume (Znal) Elevated Water Storage TankSmit PatelNo ratings yet

- Seismic Analysis of Steel Frames With Different TypesDocument27 pagesSeismic Analysis of Steel Frames With Different Typesdushyant choudharyNo ratings yet

- Tension MemberDocument35 pagesTension MemberLUGHANO NGAJILONo ratings yet

- Learning From Failures: Case StudiesDocument71 pagesLearning From Failures: Case Studiesyedida v r aviswanadhNo ratings yet

- Beton Precomprimat Post-TensionatDocument48 pagesBeton Precomprimat Post-TensionatCocis MirceaNo ratings yet

- Internship Report 17l-4621 2020Document33 pagesInternship Report 17l-4621 2020Mirza TalhaNo ratings yet

- 2 - Productivity RatesDocument3 pages2 - Productivity RatesfadymagedNo ratings yet

- Al Rostamani Mix Design Compliance SheetDocument6 pagesAl Rostamani Mix Design Compliance SheetOMAR MUKTHAR JAMAL MOHAMEDNo ratings yet

- Pier Cap Plan: Project:-Client: - ConsultantsDocument1 pagePier Cap Plan: Project:-Client: - ConsultantsShaileshRastogiNo ratings yet

- Trowel Brick Set or Blocking Chisel Hammer Jointer Square: Name Illustration UsesDocument3 pagesTrowel Brick Set or Blocking Chisel Hammer Jointer Square: Name Illustration UsesjjjjjNo ratings yet

- ETABS Concrete Frame Design: ETABS 19.0.0 License # 1WCT4F2SJUY5KH2Document1 pageETABS Concrete Frame Design: ETABS 19.0.0 License # 1WCT4F2SJUY5KH2Melissa MartinezNo ratings yet

- Structural Analysis of 1 Pervious Concrete Pavement PDFDocument18 pagesStructural Analysis of 1 Pervious Concrete Pavement PDFCarlosACuadroCausilNo ratings yet

- Sa-I QP PDFDocument19 pagesSa-I QP PDFmythilispd_355305156No ratings yet

- Cad DrawingDocument53 pagesCad DrawingAvish Gunnuck100% (3)

- AASHTO Standard Specifications For Highway Bridge 16thDocument412 pagesAASHTO Standard Specifications For Highway Bridge 16thJuzonguyen100% (1)

- Department of Civil Engineering: BE (Civil) Syllabus StructureDocument80 pagesDepartment of Civil Engineering: BE (Civil) Syllabus StructureELEVATED KnowledgeNo ratings yet

- Ass 1Document3 pagesAss 1Yonas BelaynehNo ratings yet

- StructDesign (GFSST - LRFD - TIA222G) 3GT-40-280C-Z-320CDocument63 pagesStructDesign (GFSST - LRFD - TIA222G) 3GT-40-280C-Z-320CMIHDI PALAPUZNo ratings yet

- Btech 413 Activity No. 01Document3 pagesBtech 413 Activity No. 01Joshua DizonNo ratings yet

A New Landmark Arch Bridge in Milan: The Twelfth East Asia-Pacific Conference On Structural Engineering and Construction

A New Landmark Arch Bridge in Milan: The Twelfth East Asia-Pacific Conference On Structural Engineering and Construction

Uploaded by

Vijay KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A New Landmark Arch Bridge in Milan: The Twelfth East Asia-Pacific Conference On Structural Engineering and Construction

A New Landmark Arch Bridge in Milan: The Twelfth East Asia-Pacific Conference On Structural Engineering and Construction

Uploaded by

Vijay KumarCopyright:

Available Formats

Available online at www.sciencedirect.

com

Procedia Engineering 14 (2011) 10511058

The Twelfth East Asia-Pacific Conference on Structural Engineering and Construction

A New Landmark Arch Bridge in Milan

P. G. MALERBAa*, M. DI DOMIZIOb, P. GALLIb

a

Politecnico di Milano, Department of Structural Engineering, Milan, Italy

b

Studio Malerba, Milan, Italy

Abstract

The search for new architectural shapes may lead to schemes of bridges which cannot be traced back to known and

tested typologies. In these cases, a new aesthetics requires new static views. The novelty of the De Gasperi Bridge,

located in Milan, consists of two steel arches diverging towards the lateral sides of the deck. Such a choice involved

particular structural problems as regards to both the vertical loads and the lateral ones due to wind and earthquake.

Another delicate issue was posed by the array of joints connecting the tubular hangers and the arches, for which

cardan joints have been employed in order to avoid any flexural stresses. The paper illustrates the criteria which led

to the conception of a structural system which, while respecting the shape determined by architectural choices,

activates an effective and natural force path. A synthesis of the analyses and of the experimental tests performed on

the cardan joint are presented.

2011 Published by Elsevier Ltd. Open access under CC BY-NC-ND license.

Selection

Keywords: landmark bridge, diverging arches bridge, steel bride, cardan joints

1. Introduction

There are no particular reasons for designing a bridge with arches lying onto planes diverging towards

the lateral sides. On the contrary, there are many good reasons to maintain the arches onto vertical planes

or to have them converging in correspondence with their crown, and to connect them by means of

transverse elements. This latter choice, in particular, makes the arches less sensitive to lateral instability

phenomena, while the whole structure becomes more robust and stiffer.

Corresponding author

Email: malerba@stru.polimi.it

18777058 2011 Published by Elsevier Ltd. Open access under CC BY-NC-ND license.

doi:10.1016/j.proeng.2011.07.132

1052

P.G. MALERBA et al. / Procedia Engineering 14 (2011) 10511058

In the new De Gasperi Bridge, located at Milan Portello, the two bearing arches diverge toward the

lateral sides of the deck: such a characteristic derives from an architectural choice, coherent with the

recent urban requalification project, which led to the introduction of wide green areas and to the erection

of few, refined and innovative tall buildings. The image of the new Portello district has to be caught in its

entirety. In this context, the bridge was conceived mainly from an architectural viewpoint, as an object

which is part of the surrounding landscape but, at the same time, has a character of its own.

Actually, many of the architectural intuitions were confirmed after the completion of the works.

During centuries, the bridges crossing the boundaries of a city were also custom check points and could

be identified as a barrier. On the contrary, the diverging shape of the arches suggests to most people the

idea of opening and reception.

After some obvious and soundly based remonstrance, the structural engineer had to accept the

prevailing of the architectural concept: the engineers job became seeking a static justification to

predefined shapes and giving consistency to an architectural object, thus inverting the equilibriumoriented wisdom which wants the shape justified by the statics.

2. Geometry and Concept of the Bridge

The main structure is composed of two slightly diverging steel arches. The horizontal component of

the thrust conveyed by the arches is held by the deck structure, which works like a tie. With regard to the

global static, the bridge behaves like a simply supported beam, having a hinge at one side and a roller at

the other. The span between the supports is 80m.

The arches are the geometrical elements of greatest significance. The arches have circular axes with

radius R = 73,695m and rise f = 11,600m (Figure 1), and lie onto planes inclined at a 22.5 angle with

respect to a vertical reference. Two sets of hangers, whose axes belong to a bundle of straight lines

radiating from the centre of the arches, lie on the same planes.

Figure 1: The De Gasperi Bridge during loading test.

According to such a geometry, the loads are conveyed to the earth with the following path:

the hangers carry the loads acting on the deck and they convey them to the arches;

P.G. MALERBA et al. / Procedia Engineering 14 (2011) 10511058

along the arches, starting from the crown downward, the forces conveyed by the hangers are

vectorially added to one another and to the arches self-weight, so that the arches can be regarded as

the funiculars of these systems of forces. This progressive build-up of forces is translated into the

axial force which finally arrives at the springings, where the vertical component of this vector sum is

held by the bearing supports, while the horizontal one is born by the deck.

On the whole, the deck can be seen as a cradle, hanging from the two arches: the exercise of

conveying the forces according to a scheme both rational and compatible with the given geometry, has

thus been solved for the vertical loads. It is worth noting that, by means of the forces transmitted by the

hangers to the arches, a ballast action is exerted on these latter, which contributes in stabilizing the out of

plane displacements.

On the other hand, however, with regard to the horizontal loads due to wind and earthquake, there still

remained the problems deriving from the lateral flexibility of arches which are not transversally

connected. The particular overall geometry of the bridge led to exclude the use of rope hangers. In fact, in

addition to supporting the deck, the hangers have to exert a restraining action against the transversal

displacements of the arches. In the transverse section, the elastic restrain is provided by the U-shaped

frames made up of the hanger/deck-crossbeam/hanger system, working in flexure. Such a mechanism

determines the distribution of stiffness and of resistance, resulting in slender tubular hangers connected to

stiffer and more sturdy crossbeams by means of robust nodal joints.

At the end, the volumetric translation of these structural details resulted consistent with the imagine of

the ensemble, succeeding in combining statics with aesthetics.

A delicate issue was posed by the array of joints connecting the tubular hangers and the arches. A

direct connection, tube on tube, would have involved contact lines shaped according to conical sections,

difficult to obtain. The nodes would have been subjected to mainly tensile forces, but accompanied by

relevant secondary flexural components and by local stress peaks whose intensity would have made the

satisfaction of fatigue verifications very demanding. Finally, the welding processes, that should have been

carried out on-site, would have been difficult both to perform and to check. The most natural solution

seemed to adopt a joint capable of conveying axial forces only, without blocking others freedom degrees.

Since no joints compatible with the loads involved were available on the market, a special Cardan

suspension, capable of rotation on two axes, was specifically designed. Negligible torque moments arise

from the remaining rotational degree of freedom, around the longitudinal axis of the hanger, which

remains locked. The use of Cardan joints introduced an element of separation between the bundle of

hangers and the arches, emphasizing the continuity of the arches and, at the same time, marking the

different static roles of the two systems.

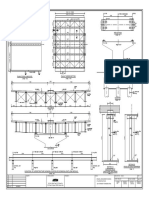

3. General Characteristics and Structural Components

In its entirety, the load-bearing structure is made up of a tied-arch bridge, having a 80 m span between

the springing (Figure 2). The deck, whose overall width is 13.50 m, comprises of three lane, two lateral

shoulders, and a 1.50 m wide sidewalk. The structure lies on two abutments that also serve as retaining

walls for the approaching embankments.

3.1. Foundations and abutments

By means of 17.00 x 9.20 x 1.20 m plinths, the foundations rest on 15 piles, having a diameter of 100

cm, and driven to a depth of 24 m. In elevation, a 1.20 m thick transverse wall rises from the plinth. The

bearing supports rest on the top of such wall. At a 2.40 m distance at the back of it, a second wall, 0.60 m

thick, act as retaining wall for the approaching embankment. The two walls are connected by three 0.80 m

1053

1054

P.G. MALERBA et al. / Procedia Engineering 14 (2011) 10511058

wide buttresses. The space between the two walls was left empty. Together with the lateral diaphragms

which serve as wing walls for the approaching embankments, the two transverse walls form a stiff box

system.

Figure 2: The De Gasperi bridge: front view, plan and transverse section.

P.G. MALERBA et al. / Procedia Engineering 14 (2011) 10511058

3.2. The arches

The steel arches lie on planes with a 22.5 tilt with respect to a vertical reference, and have a mean

radius R = 73,695 m and a rise f = 11,600 m. The opening of the arches at springings is 65.75. The

comprehensive length of the arches is 85 m and the rise/span ratio is f/l = 1/6.9. At design stage, the

arches were conceived as tubular sections with a diameter of 1300 mm and a thickness of 30 mm. The

curvature was to be obtained by calandering arch chunks having an average length of 28.3 m, which

would subsequently be assembled. During construction, however, finding structural sections having the

exact combination of diameter, thickness and steel type considered during the design stages, proved very

difficult. Therefore, the arches were manufactured from straight stretches, having an average length of

2.98 m, shaped into tubular sections by calandering plane slabs of 30 mm thickness. Each arch was thus

obtained by the assembly of three subsets, each one made up of nine straight pieces, jointed by means of

complete penetration butt welds. The segmentation criterion was attentively studied, comparing different

solutions, in order to minimize the perception of angular points. The maximum offset between the arch

circular axis and the axes of the straight segments was about 7 mm. The result confirms the accuracy of

the solution adopted.

3.3. The deck

The deck is a mixed structure, having steel girders and crossbeams, and a concrete slab. The

longitudinal girders are 1340 mm high H-shaped composite sections, made from flat plates. The central

girders have vertical webs, while the webs of the lateral ones are tilted at a 22.5 angle, thus recalling the

inclination of the arches and making the lateral view of the deck less impacting (Figure 2).

The reinforced concrete slab is 250+50 mm thick, and is connected to the steel girders by means of

Nelson studs. The connection between the longitudinal beams and the arches is obtained thanks to nine

transverse box girders, slightly tapered at the two ends (minimum height is 1000 mm, maximum height is

1950 mm), which stretch outside the deck width and are connected to the tubular hangers. Three

manholes were left in the crossbeams, so as to allow internal inspections.

The deck is stiffened at the intrados and at the extrados by two sets of bracing crosses, laid out at a

constant 4 m pitch in the longitudinal direction, and at a 3.25 m pitch in the transverse direction.

The upper bracing system is necessary only in the transient assembling phase, before the casting of the

slab. The lower bracing system is made up of 90x9 L sections: its contribution allows the deck to behave

like a box girder, improving both stiffness and torsional resistance. The slab collaborates with the steel

substructure of the deck in bearing part of the tension which contrasts the thrust conveyed by the arches.

Some areas of the slab, in correspondence with the crossbeams, are also subjected to negative flexural

moments. Finally, in case of asymmetric load conditions, the zones situated at about one quarter of the

span are affected by a further contribution to negative bending moments. In order to reduce tensile

stresses, the usual construction requirements (section and geometry of the reinforcements, concrete of

adequate resistance, cast progressively and possibly enriched with steel fibers in the most sensitive areas)

have been integrated by a prestressing action. To this aim, nine prestressing cables, made of

20/0,6strands, run straight immediately underneath the slab, at a barycentic level inside the contour of

the deck.

3.4. The tubular hangers

The two sets of nine hangers that connect the tips of the crossbeams to the arches, are made up of

tubular profiles, having a diameter of 620 mm and a thickness of 23.8 mm (Figure 2). The connection

1055

1056

P.G. MALERBA et al. / Procedia Engineering 14 (2011) 10511058

between hangers and crossbeams is stiffened internally by plates arranged so as to form a cross, and,

externally, by four triangular fins.

a)

b)

Figure 3: The Cardan joint: a) view and cross-section; b) the lab tests; c) the assembled joint.

c)

P.G. MALERBA et al. / Procedia Engineering 14 (2011) 10511058

The upper connection between hangers and arches is provided by Cardan joints, connected to the

hangers tip by flange joints, which in turn are stiffened by triangular fins (Figure 3). The upper part of the

joint is held by grippers, fitted inside the arches and emerging from especially provided slots, so that all

other parts of the joint are left hidden. Considering its peculiarity, after an attentive theoretical modelling,

lab tests on a 1:1 prototype of the joint were performed, before proceeding with the final stages of the

design process.

3.5. Bearings supports and expansion joints

Pot bearings supports, produced by Alga S.p.A., have been employed. Their bearing capacities are: in

the vertical direction Vmax = 9750 kN; in both transverse directions Hmax = 1500 kN. The maximum

longitudinal movement capability is G = 100 mm. The expansion joints are of the Algaflex T200S type,

with a maximum movement capability of 100 mm.

4. Structural Analyses and Experimental Tests

4.1. Structural Analyses

The bridge has been modelled as a spatial frame having 213 nodes and 472 elements, of which 416

were employed for the modelling of the deck. Each arch was modelled with 20 elements, and the hangers

with a total of 36 elements.

Static analyses were performed in order to evaluate the stress characteristics and for the verification of

the main structural elements. Stability analyses for the evaluation of the critical Eulerian load of the entire

structure were carried out, with particular attention paid to the behaviour of the arch in a direction normal

to the plane onto which the arch lies.

Dynamic analyses and response spectrum analyses were used to identify the dynamic and seismic

behaviour of the bridge. For the seismic analyses, the structure was considered as comprised in Zone 4,

on an A class soil (according to the Italian building codes), which correspond to a max horizontal

acceleration of 0.156 g, and max acceleration of 0.135 g on a C class soil.

A special study was dedicated to the Cardan joint, whose central plate was modelled by means of

three-dimensional finite elements. A prototype of the same joint was tested at the Material Testing Lab of

the Department of Structural Engineering at the Politecnico di Milano. The tests were coordinated by Prof.

Eng. Carlo Poggi. Electrical strain gauges were applied to the models pin, making it possible to draw

comparisons between actual and theoretical stresses.

5. Workshop Activities. Building. Erection Stages. Load Tests

5.1. Workshop activities. Building and erection stages

All primary works were carried out in the steelwork manufacturer workshop, together with the

assembly of arches and deck substructures of transportable dimensions. The arches were preassembled

into three stretches, approximately 28m long, each composed of nine straight segments. During the

preassembling stages the dimensional characteristics and the effectiveness of the temporary lifting

systems were checked. The nine deck crossbeams were also assembled in the workshop. The two

crossbeams placed in correspondence with the springings, more cumbersome and remarkably heavier

(900kN) than the other parts, were subdivided into two halves. The four half-crossbeams were the only

elements which required special transportations.

1057

1058

P.G. MALERBA et al. / Procedia Engineering 14 (2011) 10511058

The building stages can be summarized as follows: a) construction of foundation piles, plinths and

reinforced concrete abutments; b) assembly of the steel substructures; c) casting of the reinforced

concrete deck slab; d) finishing works. The manufacturing of the steel parts took about six months.

5.2. Controls and Load Tests

Row materials, cutting and working tolerances were systematically controlled at the workshop. All the

welded connections were checked with ultrasonic and X-ray tests. The geometric attitude during

assemblage at the construction site was controlled by topographic surveys. The pre-commissioning load

tests took place on July 15th 2009. The main deflection under the load exerted by six 440kN lorries was

36mm. The expected theoretical value was 44mm.

6. Conclusions

This paper presents the criteria followed in designing the new De Gasperi Bridge, located at Milan

Portello. The main structure is composed of two steel arches, having a 80 m span and laying into planes

which are slightly tilted with respect to the vertical reference. The paper describes the structural concept

and the static role of the different parts composing the bridge. The Cardan joints, which connect the

hangers to the arches, not only mark the different static roles of the two systems, but also provide an

element of peculiarity to the overall image of the bridge.

7. Design Staff

The design staff of the new structure was composed as follows:

z Project managing and general design: Metropolitana Milanese S.p.A., under the supervision of e.

Arini, A. Cavagna, M. Recalcati, Merlanti and M. Chiorboli;

z Urban planning and architectural design: L. Forges Davanzati and F. Colombo;

z Structural project: P. G. Malerba, P. Galli, M. di Domizio.

z Chief site engineer: M. Saibene (MM S.p.A.).

z Engineer in charge of pre-commissioning load testing: P. Piacentini.

z Main Contractor: Claudio Salini Grandi Lavori S.p.A., Rome Milan.

z Steelworks manufacturer: BIT S.p.A, Cordignano, Italy.

z The F.E. structural analyses on the main components of the Cardan joints were performed in

cooperation with M. Sartori.

You might also like

- Design Spreadsheet Gusset Plate Connection For TrussDocument4 pagesDesign Spreadsheet Gusset Plate Connection For TrussMatumbi Naito100% (1)

- Diaphragm Wall Construction SequenceDocument10 pagesDiaphragm Wall Construction Sequencedanzy89100% (2)

- Lecture 6 Cable Structures Wolfgang Schueller PDFDocument420 pagesLecture 6 Cable Structures Wolfgang Schueller PDFMike100% (1)

- The Messeturm in Rostock - A Tensegrity Tower by SchlaichDocument7 pagesThe Messeturm in Rostock - A Tensegrity Tower by SchlaichTensegrity Wiki0% (1)

- Design of Highly Curved Concrete Ramp BridgesDocument10 pagesDesign of Highly Curved Concrete Ramp BridgesyhszaNo ratings yet

- Guy AnchorDocument1 pageGuy AnchorVijay KumarNo ratings yet

- Global Transmission Report January 2016 PDFDocument62 pagesGlobal Transmission Report January 2016 PDFVijay KumarNo ratings yet

- Global Transmission Report January 2016 PDFDocument62 pagesGlobal Transmission Report January 2016 PDFVijay KumarNo ratings yet

- Mceeratc 49Document186 pagesMceeratc 49E44D44E44R 4444No ratings yet

- "Ponte Del Mare" - Conceptual Design and Realization of A Long Span Pedestrian BridgeDocument5 pages"Ponte Del Mare" - Conceptual Design and Realization of A Long Span Pedestrian BridgeJames ClaytonNo ratings yet

- Damage Analysis and Seismic Retrofitting of A Continuous Prestressed Reinforced Concrete Bridge (Caterino, Et Al. 2014)Document7 pagesDamage Analysis and Seismic Retrofitting of A Continuous Prestressed Reinforced Concrete Bridge (Caterino, Et Al. 2014)Jose ManuelNo ratings yet

- Akashi Kaikyo Bridge 1Document29 pagesAkashi Kaikyo Bridge 1Ssiddhartha VemuriNo ratings yet

- Darío Galante Bardín, Miguel A. Astiz Suárez. School of Civil Engineering, Technical University of Madrid (UPM) Dario - Galante@idiingenieros - EsDocument33 pagesDarío Galante Bardín, Miguel A. Astiz Suárez. School of Civil Engineering, Technical University of Madrid (UPM) Dario - Galante@idiingenieros - EsDarío Galante BardínNo ratings yet

- Seismic Design of Cable-Stayed Bridges. The South Crossing Bridge in Guayaquil, EcuadorDocument10 pagesSeismic Design of Cable-Stayed Bridges. The South Crossing Bridge in Guayaquil, EcuadorSanjay SinghNo ratings yet

- ANALYSIS AND DESIGN OF Cable Stayed BridgeDocument31 pagesANALYSIS AND DESIGN OF Cable Stayed Bridgeshrikantharle100% (1)

- Diagrid Structures For Tall Buildings: Case Studies and Design ConsiderationsDocument22 pagesDiagrid Structures For Tall Buildings: Case Studies and Design ConsiderationstarunkumarsharmaNo ratings yet

- An Innovative Tall Building Conception: The Sphere: Nicola Longarini Mauro Nicoletti Pietro CRESPIDocument8 pagesAn Innovative Tall Building Conception: The Sphere: Nicola Longarini Mauro Nicoletti Pietro CRESPIDan TomoiagaNo ratings yet

- Alfredo Camara Casado ApendicesaDocument149 pagesAlfredo Camara Casado ApendicesaBorna DasovićNo ratings yet

- Steel Lattice Telecommunication MastsDocument7 pagesSteel Lattice Telecommunication MastsjojogarciaNo ratings yet

- Comparison of The Seismic and Wind Analyses of Two Tower CranesDocument20 pagesComparison of The Seismic and Wind Analyses of Two Tower Cranessuresh_501No ratings yet

- Stress-Ribbon Bridges Stiffened by Arches or CablesDocument8 pagesStress-Ribbon Bridges Stiffened by Arches or Cablessure vineethNo ratings yet

- Pedestrian-Induced Torsional Vibrations of Suspended FootbridgesDocument11 pagesPedestrian-Induced Torsional Vibrations of Suspended FootbridgesSarwo Edhi zu UbitNo ratings yet

- Capping Beam Design 1Document8 pagesCapping Beam Design 1massive85No ratings yet

- Q1.What Are Cable Structures? What Are Their Different Types, and Principle of DesignDocument20 pagesQ1.What Are Cable Structures? What Are Their Different Types, and Principle of DesignTEHREEM ZAHRANo ratings yet

- Study On The Design of Chirajara BridgeDocument8 pagesStudy On The Design of Chirajara Bridgepaul ostepNo ratings yet

- Composite Truss BridgesDocument6 pagesComposite Truss Bridgeszepedro_fernandes100% (1)

- Seismic Design and Performance of Two Isolation Systems Used For Reinforced Concrete Bridge ConstructionDocument10 pagesSeismic Design and Performance of Two Isolation Systems Used For Reinforced Concrete Bridge ConstructionGourab GhoshNo ratings yet

- Dynamic Behaviour of Steel-Concrete Composite Under-Deck Cable-Stayed Bridges Under The Action of Moving LoadsDocument33 pagesDynamic Behaviour of Steel-Concrete Composite Under-Deck Cable-Stayed Bridges Under The Action of Moving LoadsRicardo PimentelNo ratings yet

- Wind Loads Talavera de La ReinaDocument5 pagesWind Loads Talavera de La ReinaAlexandru IonescuNo ratings yet

- The Evolution of Arches As Lightweight Structures - Cottbus - 22.11.08Document8 pagesThe Evolution of Arches As Lightweight Structures - Cottbus - 22.11.08spiff9999No ratings yet

- Caleng TPDocument10 pagesCaleng TPJose Miguel Sta. CruzNo ratings yet

- Integral Bridge Concept Applied To Rehabilitate An Existing Bridge and Construct A Dual-Use BridgeDocument8 pagesIntegral Bridge Concept Applied To Rehabilitate An Existing Bridge and Construct A Dual-Use BridgeMuhammad AbdullahNo ratings yet

- Footbridge 2005: Design and Construction Method of The New Coimbra FootbridgeDocument9 pagesFootbridge 2005: Design and Construction Method of The New Coimbra FootbridgeVijay KumarNo ratings yet

- Camara Et Al Mode Estimation CSB JBE OpenaccessDocument36 pagesCamara Et Al Mode Estimation CSB JBE OpenaccessCristian Camilo Londoño PiedrahítaNo ratings yet

- Behaviour of A Steel Bridge Equipped With Seismic Isolation DevicesDocument10 pagesBehaviour of A Steel Bridge Equipped With Seismic Isolation DevicesbulbucataNo ratings yet

- 25501322032 Arindam Mukherje ADocument7 pages25501322032 Arindam Mukherje Aarindam_925024954No ratings yet

- Arch206 - Lecture2 - Işık Ülkün PDFDocument71 pagesArch206 - Lecture2 - Işık Ülkün PDFRAJ AGRAWALNo ratings yet

- Elongation of The Fundamental Periods of Highway Bridges During Nonlinear Seismic Response - A Case StudyDocument12 pagesElongation of The Fundamental Periods of Highway Bridges During Nonlinear Seismic Response - A Case StudycorderovNo ratings yet

- Case Study 1Document7 pagesCase Study 1harishma hsNo ratings yet

- Base Isolation of Railway Bridges-2Document8 pagesBase Isolation of Railway Bridges-2Marco FigueiredoNo ratings yet

- [17344492 - International Journal of Applied Mechanics and Engineering] Cable-Stayed Cantilever Structures As An Expat Of Unique Application In The Construction Of A Building Located In Seismic Area – An Author’s Proje.pdfDocument12 pages[17344492 - International Journal of Applied Mechanics and Engineering] Cable-Stayed Cantilever Structures As An Expat Of Unique Application In The Construction Of A Building Located In Seismic Area – An Author’s Proje.pdfArtjom SamsonovNo ratings yet

- Gatwick Air BridgeDocument7 pagesGatwick Air BridgemrasdanNo ratings yet

- Numerical Analysis of The Axial-Flexural BehaviorDocument26 pagesNumerical Analysis of The Axial-Flexural BehaviorvNo ratings yet

- Design of Self - Supporting Dome RoofsDocument6 pagesDesign of Self - Supporting Dome RoofszatenneNo ratings yet

- Weak Beam-Strong ColumnDocument7 pagesWeak Beam-Strong Columnarun_angshuNo ratings yet

- Optimization of Hanger Inclination in A Tied Arch BridgeDocument8 pagesOptimization of Hanger Inclination in A Tied Arch Bridgecerbu_bass_cdcNo ratings yet

- Steel Cable Creates Novel Structural Space SystemsDocument11 pagesSteel Cable Creates Novel Structural Space Systemsuhu_plus6482No ratings yet

- Multi Storey Steel Building 01Document19 pagesMulti Storey Steel Building 01Dan AlexandrescuNo ratings yet

- Structural Analysis of BridgesDocument16 pagesStructural Analysis of BridgesKato EmmanuelNo ratings yet

- 2019the Effect of Slenderness On The Design of Diagrid StructuresDocument12 pages2019the Effect of Slenderness On The Design of Diagrid Structuresmaikol cantorNo ratings yet

- (Asce) Be 1943-5592 0001807Document13 pages(Asce) Be 1943-5592 0001807Adriano De SortisNo ratings yet

- A Deployable Mast For Adaptable TextileDocument12 pagesA Deployable Mast For Adaptable TextileWeifeng HeNo ratings yet

- A Review On Shapes of Pylon For Cable-Stayed Bridge.: Mr. Ajinkya D. Raut, Prof. R.A. DubalDocument2 pagesA Review On Shapes of Pylon For Cable-Stayed Bridge.: Mr. Ajinkya D. Raut, Prof. R.A. DubalMohammad Salman MananNo ratings yet

- Upgrading of Transmission Towers Using A Diaphragm Bracing SystemDocument26 pagesUpgrading of Transmission Towers Using A Diaphragm Bracing SystemthoriqNo ratings yet

- An Overview On Diagrid Structures For Tall BuildingsDocument10 pagesAn Overview On Diagrid Structures For Tall BuildingsLopamudra SenguptaNo ratings yet

- Atmaca, Yurdakul, & Ates - The Effect of Seismic Isolation On The Dynamic Behavior of Cable-StayedDocument7 pagesAtmaca, Yurdakul, & Ates - The Effect of Seismic Isolation On The Dynamic Behavior of Cable-StayedPhan TumNo ratings yet

- Shake Table Test of Cable-Stayed Bridge Subjected To Non-Uniform ExcitationDocument8 pagesShake Table Test of Cable-Stayed Bridge Subjected To Non-Uniform ExcitationSantos Daza VallejosNo ratings yet

- Parametric Study of Double Layer Steel Dome With Reference To Span To Height RatioDocument9 pagesParametric Study of Double Layer Steel Dome With Reference To Span To Height RatioIjsrnet EditorialNo ratings yet

- Transverse Seismic Behaviour of CompositDocument10 pagesTransverse Seismic Behaviour of CompositYohannes TesfayeNo ratings yet

- Malm2010 - Time Dependent Analyses of Segmentally Constructed Balanced Cantilever BridgesDocument8 pagesMalm2010 - Time Dependent Analyses of Segmentally Constructed Balanced Cantilever BridgesHuber MezaNo ratings yet

- Modern Solution For The Foundation of Poland'S Largest Arch BridgeDocument10 pagesModern Solution For The Foundation of Poland'S Largest Arch Bridgemalves56No ratings yet

- Limit Analysis of The External Wall of ColosseumDocument6 pagesLimit Analysis of The External Wall of ColosseumOana PopaNo ratings yet

- Response of Cable Stayed Bridge Under Ground MotionsDocument8 pagesResponse of Cable Stayed Bridge Under Ground MotionsPhan TumNo ratings yet

- Bridges Spanish HSRLDocument13 pagesBridges Spanish HSRLVelugoti VijayachandNo ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- A Guide to Some of the Equations used in Constructing a Suspension BridgeFrom EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeNo ratings yet

- Rock AnchorDocument2 pagesRock AnchorVijay Kumar100% (1)

- No - of Bolts Required 0.66 No.s No - of Bolts Provided No.sDocument1 pageNo - of Bolts Required 0.66 No.s No - of Bolts Provided No.sVijay KumarNo ratings yet

- (Lef/ry) 2 (Lef Te) 2Document1 page(Lef/ry) 2 (Lef Te) 2Vijay KumarNo ratings yet

- Input Parameters For Foundation DesignDocument1 pageInput Parameters For Foundation DesignVijay KumarNo ratings yet

- Check For Uplift (Refer Figure - 2)Document1 pageCheck For Uplift (Refer Figure - 2)Vijay KumarNo ratings yet

- Structural Design of FoundationDocument1 pageStructural Design of FoundationVijay KumarNo ratings yet

- Bending Moment About Section Y-YDocument1 pageBending Moment About Section Y-YVijay KumarNo ratings yet

- Hence The Spcacing Between Rod Is (MM) 105 O.KDocument1 pageHence The Spcacing Between Rod Is (MM) 105 O.KVijay KumarNo ratings yet

- Hence The Spcacing Between Rod Is (MM) 202 O.K.: (5) CHECK FOR SLIDING (Refer Figure - 4)Document1 pageHence The Spcacing Between Rod Is (MM) 202 O.K.: (5) CHECK FOR SLIDING (Refer Figure - 4)Vijay KumarNo ratings yet

- Check For OverturningDocument1 pageCheck For OverturningVijay KumarNo ratings yet

- 20-F201007-SC-010 R0 - Design Calculation of Foam Tank and Fire Pump ShedDocument187 pages20-F201007-SC-010 R0 - Design Calculation of Foam Tank and Fire Pump ShedSaravan KumarNo ratings yet

- Structural Masonry SyllabusDocument1 pageStructural Masonry SyllabusPrashant Sunagar0% (1)

- 1 2 MergedDocument37 pages1 2 MergedCarjez LoveNo ratings yet

- Retrofitting of Columns by Steel Jackets-8cccDocument7 pagesRetrofitting of Columns by Steel Jackets-8cccsecond2nonnNo ratings yet

- ETABS Concrete Frame Design: Eurocode 2-2004 Column Section DesignDocument2 pagesETABS Concrete Frame Design: Eurocode 2-2004 Column Section DesignTith ReaksmeyNo ratings yet

- Content RCC Fanella PDFDocument4 pagesContent RCC Fanella PDFJulio Cesar ValdiviesoNo ratings yet

- Shear Wall Design-ACI-318-14Document30 pagesShear Wall Design-ACI-318-14Christian ReedNo ratings yet

- Design of 75Kl Zinc Alume (Znal) Elevated Water Storage TankDocument26 pagesDesign of 75Kl Zinc Alume (Znal) Elevated Water Storage TankSmit PatelNo ratings yet

- Seismic Analysis of Steel Frames With Different TypesDocument27 pagesSeismic Analysis of Steel Frames With Different Typesdushyant choudharyNo ratings yet

- Tension MemberDocument35 pagesTension MemberLUGHANO NGAJILONo ratings yet

- Learning From Failures: Case StudiesDocument71 pagesLearning From Failures: Case Studiesyedida v r aviswanadhNo ratings yet

- Beton Precomprimat Post-TensionatDocument48 pagesBeton Precomprimat Post-TensionatCocis MirceaNo ratings yet

- Internship Report 17l-4621 2020Document33 pagesInternship Report 17l-4621 2020Mirza TalhaNo ratings yet

- 2 - Productivity RatesDocument3 pages2 - Productivity RatesfadymagedNo ratings yet

- Al Rostamani Mix Design Compliance SheetDocument6 pagesAl Rostamani Mix Design Compliance SheetOMAR MUKTHAR JAMAL MOHAMEDNo ratings yet

- Pier Cap Plan: Project:-Client: - ConsultantsDocument1 pagePier Cap Plan: Project:-Client: - ConsultantsShaileshRastogiNo ratings yet

- Trowel Brick Set or Blocking Chisel Hammer Jointer Square: Name Illustration UsesDocument3 pagesTrowel Brick Set or Blocking Chisel Hammer Jointer Square: Name Illustration UsesjjjjjNo ratings yet

- ETABS Concrete Frame Design: ETABS 19.0.0 License # 1WCT4F2SJUY5KH2Document1 pageETABS Concrete Frame Design: ETABS 19.0.0 License # 1WCT4F2SJUY5KH2Melissa MartinezNo ratings yet

- Structural Analysis of 1 Pervious Concrete Pavement PDFDocument18 pagesStructural Analysis of 1 Pervious Concrete Pavement PDFCarlosACuadroCausilNo ratings yet

- Sa-I QP PDFDocument19 pagesSa-I QP PDFmythilispd_355305156No ratings yet

- Cad DrawingDocument53 pagesCad DrawingAvish Gunnuck100% (3)

- AASHTO Standard Specifications For Highway Bridge 16thDocument412 pagesAASHTO Standard Specifications For Highway Bridge 16thJuzonguyen100% (1)

- Department of Civil Engineering: BE (Civil) Syllabus StructureDocument80 pagesDepartment of Civil Engineering: BE (Civil) Syllabus StructureELEVATED KnowledgeNo ratings yet

- Ass 1Document3 pagesAss 1Yonas BelaynehNo ratings yet

- StructDesign (GFSST - LRFD - TIA222G) 3GT-40-280C-Z-320CDocument63 pagesStructDesign (GFSST - LRFD - TIA222G) 3GT-40-280C-Z-320CMIHDI PALAPUZNo ratings yet

- Btech 413 Activity No. 01Document3 pagesBtech 413 Activity No. 01Joshua DizonNo ratings yet

![[17344492 - International Journal of Applied Mechanics and Engineering] Cable-Stayed Cantilever Structures As An Expat Of Unique Application In The Construction Of A Building Located In Seismic Area – An Author’s Proje.pdf](https://imgv2-2-f.scribdassets.com/img/document/475872256/149x198/32a58394c6/1600032013?v=1)