Professional Documents

Culture Documents

TAM - Single Set Brochure

TAM - Single Set Brochure

Uploaded by

Anonymous rey6aU3ZCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TAM - Single Set Brochure

TAM - Single Set Brochure

Uploaded by

Anonymous rey6aU3ZCopyright:

Available Formats

TAM

Single SeT

inflATAble

ReTRievAble

PAckeRS

Sets with pressure only

Releases with straight pull

or rotate

Ideal for horizontal applications

Sets in casing or open hole

Runs on tubing, coiled tubing,

drill pipe, or SlikPak

Packer, bridge plug, scab

liner applications

ISO 9001:2008 Certified Company

General Descriptions

Simple Setting Procedure

The TAM Single Set product line enhances

the advantages of the inflatable packer

element with a positive sealing mechanism

that requires only hydraulic pressure to

set the packer. As pipe movement is not

required to set the tool, it is ideal for running

on slickline/electric line with SlikPak, or

with coiled tubing. It is also widely utilized

for work string applications in highly

deviated and horizontal wells.

Once the tool has been run to the desired

depth, a ball or dart is pumped to a seat in

the tool, diverting pressure applied to the

work string into the inflation chamber. Shear

pin settings, determined prior to running into

the well, define the pressure at which the tool

is locked in the set position.

The product line consists of the Single Set,

Full Bore/Setting Head, Retrievable Plug

and Retrievable Scab Liner tools as well as

a variety of accessories to release from the

packer, control flow through the tool and

re-latch for retrieval.

All Single Set products are capable of a

single set when run into the well and can

be released for retrieval.

Superior Setting Mechanism Field

Proven Reliability

Unlike traditional inflatable packer setting

mechanisms, TAM Single Set tools do not

rely on a check valve to retain inflation

pressure. Oftentimes, debris can be caught

in a check valve impairing the seal, causing

the packer to deflate.

The TAM Single Set tools utilize a pressure

actuated sliding sleeve with redundant

seals that wipe any debris from the sealing

surfaces when setting the packer. When

the setting sleeve slides over the packer

inflation ports, pressure is locked in the

packer element. The setting superiority of

the TAM Single Set product line has been

proven in over 20 years of field applications.

The 7-1/2 OD Single Set Tools utilize

TAMs Safelok Valve System. For more

information refer to the TAM 7-1/2 Single

Set Brochure.

Inflation Elements

TAM offers four (4) types of inflatable

elements to satisfy the wide range of

application requirements, in vertical,

horizontal, cased or open hole, 3:1

expansion capability and up to 300 F

operating temperature. For specific

element data and application analysis refer

to the TAM Element Selection Brochure.

Once the desired setting pressure is

achieved by applying pressure to the work

string, the set sleeve shifts down, closing

the tool bypass and locking the tool in the

inflated position. Differential pressure can be

applied from either side of the packer without

releasing the tool.

Flexible Configuration for

Varying Applications

TAM Single Set products are our work

horse tool line and can be easily configured

for use in a wide variety of applications from

single packers for Production, Treating or

Squeezing to temporary or permanent Bridge

Plugs. Multiple packers can be configured as

scab liners for selective production control.

Optional Element

Reinforcement Styles

Weave Type Element (IE)

Multiple-set applications

Sets in perforations, slots,

fractures, or open hole

Seldom leaves rubber

in the hole

Weave Type Element (HE)

Combination of Slat element

for extrusion resistance, and

Weave element for multi-set

capabilities

Each product provides various features that

optimize the success of each application.

The Full Bore/Setting Head (FB-SH) tool

provides the largest ID of any comparable tool

OD in the industry and therefore is the typical

selection for use in Scab Liner applications to

modify a wells production flow profile.

The Setting Head can be adapted to a

releasable/retrievable Casing Annulus Packer.

Slat Type Element (TE & SE)

Single and multi-set applications

Exposed slats function as slips

The Retrievable Plug (RP) tool is specifically

designed as a through-tubing Bridge Plug.

The RP can be run on work string, slickline/

electric line with SlikPak, or with coiled

tubing in highly deviated wells.

The Retrievable Scab (RS) tool provides a

large ID and can be run in sections to allow

installation of a long length assembly into a

well with surface tubing pressure. This tool is

also configured to run and/or retrieve on work

string, slickline/electric line with SlikPak,

or with coiled tubing.

Canted Slat Dual Layer (VE)

Single and multi-set applications

Cased or open hole

Benefit of Slat type for HPHT

Sets in perforations, slots,

fractures, or open hole

Single Set ApplicationsVertical

Problem:

Problem:

Lower perforations producing

excess water

Collapsed casing

Solution:

Run Inflatable Bridge Plug on

SlickPak set above lower zone

Dump bail cement on top of plug

Well requires production packer

Solution:

Run Inflatable Single Set production

packer and set below damaged or

collapsed casing

Single Set ApplicationsVertical

Problem:

Problem:

L

ower perforations producing

excess water

S

hoe requires squeeze in large OD

or odd sized casing in deep water

drilling program

Requires squeezing

Solution:

R

un Infl atable Single Set packer

on coiled tubing and set above

lower perforations

Squeeze as required

Solution:

R

un Infl atable Single Set on drill

pipe and set near casing shoe

Squeeze cement as required

Single Set ApplicationsHorizontal

Problem:

Solution:

Excess water production from middle

of horizontal well

Run Inflatable Scab Liner and set

across water producing section

Problem:

Solution:

Need to protect first lateral while

drilling additional lateral

Run Inflatable Single Set as Bridge Plug

and set near exit point of first lateral

Retrieve packer after drilling additional lateral

Single Set ApplicationsHorizontal

Problem:

Excess water production from toe

of horizontal well

Solution:

Run Inflatable Bridge Plug and set above

toe of lateral, or run Inflatable Packer and

squeeze cement if desired.

Problem:

Solution:

Heel of lateral requires isolation

due to excessive gas (or water) production

Run Inflatable Full Bore Single Set below

hydraulic set production packer

Single Set Inflatable Packers and Release Options

Single Set

Workstring Pull Release

(rotate release optional)

Set Sleeve Shear Pin

Hydraulic Release (HR)

Rotationally locked can transmit torque

thru the tool.

Adjustable activation pressure via shear

pin quantity.

Two release options:

Set Sleeve

Packer Inflation Port

Setting Ball

Choke Shear Pin

No ball release, which is achieved by

pressuring the workstring.

Ball release, which requires a ball to be

dropped through the workstring to land

on internal seat in tool.

Bypass ports are opened when the tool is

released, allowing circulation of workstring

being retrieved.

Choke

TAMCON (CN)

Can be used to latch onto & retrieve

an inflatable packer.

Inflation Element

Once the overshot with seal assembly is

released, a fishable profile with latching lugs/

pins is left above the set packer (for latching

& retrieving at a later date).

Set down weight and left-hand torque to

release.

Re-latching is automatic via J-track profile and

latching lugs. The seal stack is engaged on

O.D. of stem allowing pressure to be applied

in tool string.

Tool can be shear pinned to prevent

accidental disconnect when running.

TAMCONs have an optional hydraulic

release profile cut in the top of the stem to

allow running the tool in horizontal or deep

water wells, without requiring left-hand

rotation to release.

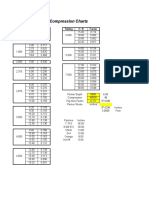

Tool Sizes and Configurations

Tool Type:

SS Single Set

RP Retrievable Plug

RS Retrievable Scab Liner

SH

Setting

Tool

SizesHead

and Configurations

(in)

Tool OD

1.69

2.13

2.13

2.13

2.56

2.63

3.44

3.50

3.53

3.63

3.88

(mm)

Tool Type

0.88

22.4

0.48

54.1

RP

0.53

65.0

RS

54.1

54.1

66.8

87.4

SS

RS

RP

92.2

SH

98.6

SS

190.5

1.21

0.53

0.53

1.99

SS

117.6

117.6

0.94

RP

4.63

108.0

1.25

SS

88.9

89.7

0.88

SS

SH

7.50

(mm)

SS

104.9

4.63

(in)

42.9

4.13

4.25

Minimum ID

1.88

2.45

SS

1.82

2.28

SH

2.95

SS

2.25

Deflation Mechanisms

Rotate

12.2

13.5

Pull

Ball

Work String

X

X

22.4

31.8

23.9

30.7

13.5

13.5

50.5

62.2

47.8

46.2

57.9

74.9

57.2

Run On

X

X

X

X

X

X

Wireline

X

X

X

X

X

X

X

X

X

X

X

X

X

X

*5.50 RS is available. Consult TAM for more information

*Element Range; 111/16 up to 141/2

Multiple-Release Options

TAM Single Set tools can be released in a

variety of methods depending

Multiple-Release

Options on tool size.

Releasing Mechanisms include rotation,

TAM

Single

Setand

tools

can

be released

in aabove

variety of methods depending on

straight

pull

ball

seat.

The chart

tool

size.the

Releasing

Mechanisms

include rotation, straight pull and ball seat.

defines

optional

release mechanism

available

by tool

size. the optional release mechanism available by tool size.

The

chart above

defines

800.462.7617

713.462.7617

713.462.1536 Fax

info@tamintl.com

Worldwide sales and service contacts at www.tamintl.com

The information and/or data in this publication is supplied solely for informational purposes

and TAM International makes no guarantees or warranties, either expressed or implied, with

respect to its accuracy, completeness or use.

2011, TAM International Inc. 9/11

You might also like

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Grove G9 Wafer Gate ValveDocument9 pagesGrove G9 Wafer Gate Valvetxlucky80No ratings yet

- Excel Test - CISD - SolutionNishantDocument494 pagesExcel Test - CISD - SolutionNishantnehaNo ratings yet

- Superconducting MagnetsDocument10 pagesSuperconducting Magnetsee05d008No ratings yet

- Compsim PDFDocument40 pagesCompsim PDFciucalata88No ratings yet

- Halliburton Packer Information PDFDocument76 pagesHalliburton Packer Information PDFrlk2806100% (5)

- Crane Engineering Data 1Document56 pagesCrane Engineering Data 1jerry666aNo ratings yet

- Petroleum DictionaryDocument360 pagesPetroleum DictionaryAnonymous rey6aU3ZNo ratings yet

- Formation Fluid Migration After CementingDocument40 pagesFormation Fluid Migration After CementingAnonymous rey6aU3ZNo ratings yet

- Internship ReportDocument34 pagesInternship ReportFaisal Sandhu67% (3)

- Culinary Arts Prep Cook Level 1Document5 pagesCulinary Arts Prep Cook Level 1zoltan2014100% (1)

- Permanent PKR Eline/Hydraulic Setting Tool Signature: AdvantagesDocument18 pagesPermanent PKR Eline/Hydraulic Setting Tool Signature: Advantagesjulio RDLRNo ratings yet

- 3FlowControlEquipment PDFDocument20 pages3FlowControlEquipment PDFAnonymous gZOzOtaqQqNo ratings yet

- DST Tools CatalogDocument103 pagesDST Tools CatalogSikander Mushtaq100% (1)

- Circulating Packer Gets Casing To Bottom FasterDocument4 pagesCirculating Packer Gets Casing To Bottom FastercuervohijoguachoNo ratings yet

- Manual Texproil Empaque Inflable TAMDocument8 pagesManual Texproil Empaque Inflable TAMOviedoJorgeNo ratings yet

- VAC Spring Balancer Hose ReelsDocument14 pagesVAC Spring Balancer Hose ReelsSathishNo ratings yet

- Pressure Control EquipmentDocument169 pagesPressure Control EquipmentAshok SureshNo ratings yet

- Worcester Controls 10, 15, 20 ACCESS I and 10-40 ACCESS M 39 Actuators Intrinsically SafeDocument16 pagesWorcester Controls 10, 15, 20 ACCESS I and 10-40 ACCESS M 39 Actuators Intrinsically SafeMijin28No ratings yet

- H 04437Document4 pagesH 04437E_Amr_SorourNo ratings yet

- Bridge PlugsDocument19 pagesBridge Plugsparag padoleNo ratings yet

- 007045200iss9 MW 3 DatasheetDocument4 pages007045200iss9 MW 3 DatasheetahamedkyanaNo ratings yet

- CT WKM Gate Saf T Seal 01 PDFDocument36 pagesCT WKM Gate Saf T Seal 01 PDFchonubobbyNo ratings yet

- Forbes Marshall Turbine Bypass ValvesDocument28 pagesForbes Marshall Turbine Bypass Valveser_sanjaypatelNo ratings yet

- Cement RetainerDocument2 pagesCement RetainerahmedNo ratings yet

- Muller Tapping MachineDocument8 pagesMuller Tapping MachineKUMAARRRNo ratings yet

- Pressure Seal Valves-GateDocument24 pagesPressure Seal Valves-GateHieu NguyenNo ratings yet

- PackerDocument76 pagesPackerRafael100% (1)

- EurOpal VariOpal enDocument20 pagesEurOpal VariOpal endanboimpexNo ratings yet

- Model E Hydraulic Setting ToolDocument1 pageModel E Hydraulic Setting ToolrezaNo ratings yet

- Forbes Marshall Turbine Bypass Valves PDFDocument28 pagesForbes Marshall Turbine Bypass Valves PDFAnonymous lmCR3SkPrKNo ratings yet

- Valve Solutions For Pipelines PDFDocument8 pagesValve Solutions For Pipelines PDFCristhian Niño MartinezNo ratings yet

- Chapter 9Document22 pagesChapter 9m90abdelwahabNo ratings yet

- PRDocument27 pagesPRdon121don121No ratings yet

- Old Otis Pump Through Plug SubsDocument6 pagesOld Otis Pump Through Plug SubsincasuminstrosNo ratings yet

- DAN-EX Brochure WebDocument12 pagesDAN-EX Brochure Webzakkyf6455No ratings yet

- Valvulas de Seguridad Maxon 6100Document14 pagesValvulas de Seguridad Maxon 6100liusdhgNo ratings yet

- On Site Machining ServicesDocument3 pagesOn Site Machining ServicesMeriam KetataNo ratings yet

- Eds Efs Pushbutton Control StationsDocument7 pagesEds Efs Pushbutton Control StationsginursamadNo ratings yet

- Válvula de Presión y Vacío para TransformadoresDocument2 pagesVálvula de Presión y Vacío para Transformadoreslaime_floresNo ratings yet

- 02 Sand ManagementDocument4 pages02 Sand ManagementEjaz ul Haq kakarNo ratings yet

- Lecture 2 2023Document29 pagesLecture 2 2023kelvinmsemo33No ratings yet

- Packer PDFDocument76 pagesPacker PDFMansur Ermila100% (1)

- Butterfly Valve BrochureDocument6 pagesButterfly Valve BrochureRohiNo ratings yet

- Perar Trunnion Ball ValvesDocument54 pagesPerar Trunnion Ball ValvesUday GokhaleNo ratings yet

- PPE I PR 005Document11 pagesPPE I PR 005MahanderOadNo ratings yet

- Y-Pattern Globe Valves PDFDocument11 pagesY-Pattern Globe Valves PDFcristhianNo ratings yet

- Basic Slickline Rig Up EquipmentsDocument41 pagesBasic Slickline Rig Up EquipmentsAKOMOLAFE ABAYOMI100% (5)

- PVC & CPVC True Union 2000 Valves: One of The Most Versatile, Compact Valve Designs AvailableDocument4 pagesPVC & CPVC True Union 2000 Valves: One of The Most Versatile, Compact Valve Designs AvailableKarthick VenkateshNo ratings yet

- Autoclave Engineers - Valves Fittings and Tubing - Condensed CatalogDocument16 pagesAutoclave Engineers - Valves Fittings and Tubing - Condensed Catalogchristophedepaepe100% (1)

- (FCENBR0003AQ) - Natural Gas Industry LRDocument12 pages(FCENBR0003AQ) - Natural Gas Industry LRkamy001No ratings yet

- SU-90 Series Unitized Surface Wellhead SystemDocument16 pagesSU-90 Series Unitized Surface Wellhead SystemAderobaki Gbenga100% (1)

- Hot Tapping On Operating LinesDocument20 pagesHot Tapping On Operating LinesCelestine Ozokechi100% (1)

- MLS SysDocument37 pagesMLS Syshshobeyri100% (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.From EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.No ratings yet

- Handloader's Digest: The World's Greatest Handloading BookFrom EverandHandloader's Digest: The World's Greatest Handloading BookRating: 2 out of 5 stars2/5 (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualFrom EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualNo ratings yet

- RolesDocument1 pageRolesAnonymous rey6aU3ZNo ratings yet

- SOWDocument7 pagesSOWAnonymous rey6aU3ZNo ratings yet

- Work Over Systems KnowledgeDocument7 pagesWork Over Systems KnowledgeAnonymous rey6aU3ZNo ratings yet

- Loan Details: Loan Amount Eligibility CalculatorDocument2 pagesLoan Details: Loan Amount Eligibility CalculatorAnonymous rey6aU3ZNo ratings yet

- Buoyancy CalcDocument1 pageBuoyancy CalcAnonymous rey6aU3ZNo ratings yet

- Future Plans: Just in Time Mill ManufacturingDocument1 pageFuture Plans: Just in Time Mill ManufacturingAnonymous rey6aU3ZNo ratings yet

- Compression CalculatorDocument1 pageCompression CalculatorAnonymous rey6aU3ZNo ratings yet

- Cement CalculatorDocument1 pageCement CalculatorAnonymous rey6aU3ZNo ratings yet

- Hassan Dars - PoetryDocument1 pageHassan Dars - PoetryAnonymous rey6aU3Z100% (2)

- Hydraulic Fracturing StudyDocument158 pagesHydraulic Fracturing StudyAnonymous rey6aU3ZNo ratings yet

- Well Control PrinciplesDocument196 pagesWell Control PrinciplesAnonymous rey6aU3ZNo ratings yet

- Packer Failure PDFDocument23 pagesPacker Failure PDFAnonymous rey6aU3ZNo ratings yet

- Well Integrity IntroDocument154 pagesWell Integrity IntroAnonymous rey6aU3ZNo ratings yet

- Work Over Systems KnowledgeDocument92 pagesWork Over Systems KnowledgeAnonymous rey6aU3Z100% (1)

- Well Stimulation TechDocument149 pagesWell Stimulation Techscupid81No ratings yet

- Rock Mechanics in Wellbore ConstructionDocument65 pagesRock Mechanics in Wellbore ConstructionAnonymous rey6aU3ZNo ratings yet

- Watson - Packer CatalogDocument60 pagesWatson - Packer CatalogAnonymous rey6aU3ZNo ratings yet

- MWD LWD GeosteeringDocument57 pagesMWD LWD GeosteeringAnonymous rey6aU3ZNo ratings yet

- Sewerage DesignDocument6 pagesSewerage DesignAsmatSalSabila100% (2)

- Demand Factor-Diversity Factor-Utilization Factor-Load Factor - Electrical Notes & ArticlesDocument29 pagesDemand Factor-Diversity Factor-Utilization Factor-Load Factor - Electrical Notes & ArticlessujingthetNo ratings yet

- Ashrae-2011-Hvac-Applications-swimming PoolDocument3 pagesAshrae-2011-Hvac-Applications-swimming Poolmhmdjdgmailcom100% (1)

- Insulation Coordination PresentationDocument42 pagesInsulation Coordination PresentationAyanangshu ChakrabartyNo ratings yet

- JLG 450 Series - DieselDocument2 pagesJLG 450 Series - Dieselluiggi lanciottiNo ratings yet

- Dynamic, Absolute and Kinematic ViscosityDocument5 pagesDynamic, Absolute and Kinematic ViscosityDeidra CadeNo ratings yet

- Basic Hydraulic and Components (Pub. ES-100-2) PDFDocument97 pagesBasic Hydraulic and Components (Pub. ES-100-2) PDFjayath100% (2)

- Theoretical Push Cylinder SelectionDocument1 pageTheoretical Push Cylinder Selectionjsrplc7952No ratings yet

- Final Project PSODocument31 pagesFinal Project PSOadeel80% (5)

- Flammable Facts PDFDocument1 pageFlammable Facts PDFverat81No ratings yet

- Torque ShiftDocument43 pagesTorque ShiftDavid Rosado100% (1)

- Seismic Stag 6343Document67 pagesSeismic Stag 6343akujeeNo ratings yet

- Isa Cba 1000 ManualDocument29 pagesIsa Cba 1000 ManualYugie OktavianaNo ratings yet

- The Periodic Table and Bonding - Introducing A Free Online Resource For Middle School ChemistryDocument47 pagesThe Periodic Table and Bonding - Introducing A Free Online Resource For Middle School ChemistryVan GenetioNo ratings yet

- Solar Ppa 16Document11 pagesSolar Ppa 16GILLHARVINDERNo ratings yet

- FIS123 Support Reservoir Install - 1Document8 pagesFIS123 Support Reservoir Install - 1DumitrescuNo ratings yet

- Viscous FlowDocument2 pagesViscous FlowAamir Qutub Alig0% (1)

- Drone TechnologyDocument26 pagesDrone TechnologyAlexNo ratings yet

- 25 3 Solutn Using Sepratn VariablsDocument16 pages25 3 Solutn Using Sepratn Variablstarek mahmoudNo ratings yet

- E105 - AgustinDocument25 pagesE105 - AgustinSeth Jarl G. AgustinNo ratings yet

- Chapter 2 - DC Motor - SlidesDocument16 pagesChapter 2 - DC Motor - SlidesNurul ShathirahNo ratings yet

- MechanicsDocument523 pagesMechanicsJuiced-IN it80% (10)

- TJ40-G1 Turbojet Engine: Designed For UAV Systems, Such As Target Drones, Decoy Drones, or Small Reconnaissance DronesDocument2 pagesTJ40-G1 Turbojet Engine: Designed For UAV Systems, Such As Target Drones, Decoy Drones, or Small Reconnaissance DronesMorgen GumpNo ratings yet

- Knock Control System (For Type 6 Engines) - Commissioning: Technical InstructionDocument24 pagesKnock Control System (For Type 6 Engines) - Commissioning: Technical InstructionRahimNo ratings yet

- Low Power RF GuideDocument45 pagesLow Power RF Guidedormevu0% (1)

- Fire HydrantsDocument5 pagesFire HydrantsBoy Alfredo PangaribuanNo ratings yet