Professional Documents

Culture Documents

B 84567 SB MM1 DSR ST 67 0011 - 4 - AOC - Air Compressor and Air Dryer Package

B 84567 SB MM1 DSR ST 67 0011 - 4 - AOC - Air Compressor and Air Dryer Package

Uploaded by

pragatheeskOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B 84567 SB MM1 DSR ST 67 0011 - 4 - AOC - Air Compressor and Air Dryer Package

B 84567 SB MM1 DSR ST 67 0011 - 4 - AOC - Air Compressor and Air Dryer Package

Uploaded by

pragatheeskCopyright:

Available Formats

Data Sheet

Air Compressors & Air Dryer Package

ConocoPhillips (Grissik) Ltd.

B-84567-SB-MM1-DSR-ST-67-0011 Rev 4

Page 2 of 11

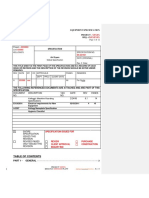

Revision Sheet

ConocoPhillips (Grissik) Ltd.

REVISION

DATE

DESCRIPTION OF CHANGE

1A

22-Apr-15

First Issuance

1B

08-July-15

Issued For Approval (With Incorporated Client Comment)

20-July-15

Issued For Use (With Incorporated Client Comment)

31-July-15

Re-Issued For Use (With Incorporated Client Comment)

28-Aug-15

Re-Issued For Use (With Incorporated Client Comment)

Additional Approvers (If Applicable)

Name

Designation

Signature

Date

MECHANICAL DATA SHEET

DOC. NO. :

B-84567-SB-MM1-DSR-ST-67-0011

AIR COMPRESSOR AND AIR DRYER PACKAGE

Page : 3 of 11

ConocoPhillips (Grissik) Ltd.

Rev : 4

GENERAL INFORMATION

1

2

APPLICABLE TO :

FEED

LOCATION

SUBAN GAS PLANT

MANUFACTURER

NOTE-24

EQUIPMENT NAME

AIR COMPRESSOR AND AIR DRYER PACKAGE

MODEL NO.

(*)

ITEM NO.

67SAE-301

NO OF UNIT

ONE SKID (SINGLE SKID) (*)

BID

AS BUILT

EXTENT PACKAGE

6

7

PURCHASE

INSTRUMENT AIR COMPRESSOR & AIR DRYER PACKAGE (67SAE-301) CONSIST OF :

2X100% AIR COMPRESSORS PACKAGE SKID (COMPLETE WITH ELETRIC MOTOR DRIVEN, AIR COOLER, OIL SEPARATORS, WATER SEPARATORS AND AUXILLIARIES)

ONE SKID MOUNTED AIR DRYER PACKAGE CONSIST OF:

10

4X100% AIR PRE FILTERS (TWO PER TRAIN)

11

2X100% AIR DRYER (DUAL TOWER) INCLUDING 2 (TWO) DEW POINT ANALYZER

12

4X100% AIR POST FILTERS (TWO PER TRAIN)

13

INTERCONNECTING PIPE, VALVE, PITTING, INSTRUMENTATION,ETC ON DRYER PACKAGE SKID AS PER P&ID (B-84567-SB-PP0-PID-ST-67-0005)

14

ALL INTERCONNECTING PIPE, VALVE, FITTING,ETC BEETWEEN SKID AS PER P&ID (B-84567-SB-PP0-PID-ST-67-0005)

ELECTRICAL INFORMATION

15

16

ELECTRICAL AREA CLASSIFICATION :

NON HAZARDOUS AREA (ELECTRIC MOTOR SHALL BE CLASS 1 DIV.2 GROUP D)

17

PACKAGE DESIGN INFORMATION

18

19

DRY AIR FLOW RATE AT EDGE OF SKID PER TRAIN, (SCFM)

450

20

PRESSURE AT PACKAGE OUTLET, (PSIG)

120

21

WATER PRESSURE DEW POINT (F)

- 40

22

BAROMETIC PRESSURE (PSIA)

14.696

23

WIND VELOCITY (FT/S)

72.9

24

INSPECTION AND TESTING

PER SPEC, CODE AND MIGAS

25

LIFTING PROVISIONS

YES, BY VENDOR

26

VIBRATION / DAMPING REQUIREMENTS

ANTI - VIBRATION MOUNT

27

ELEVATION ( FT )

179.8 (PLANT AREA)

28

LOCATION

OUTDOOR, INSTALLED UNDER SHELTER

AIR COMPRESSOR (67-CAE-301 A/B) : OPERATING DATA (EACH)

29

30

GAS HANDLED

AIR

NO. OF DUTY COMPRESSOR

31

OPERATION

INTERMITTENT (LEAD -LAG SYTEM)

NO. OF STAND - BY COMPRESSOR

32

OPERATING CONDITIONS (PER UNIT COMPRESSOR)

33

AIR DRYER PACKAGE REQUIRED INLET FLOW RATE

MIN

34

lb/hr

(*)

scfm

(*)

MAX

NORMAL

INLET MASS FLOW RATE

lb/hr

(*)

INLET FLOW RATE

scfm

(*)

37

INLET ACTUAL FLOW RATE @ P,T

acfm

(*)

(*)

(*)

38

INLET PRESSURE

psig

ATM

psig

(*)

NOTE-11

NOTE-11

F / RH%

65/60

100/100

(*)

(*)

DISCHARGE PRESSURE

INLET CONDITION

41

AFTERCOOLER OUTLET TEMPERATURE

42

MOL. WEIGHT AT INLET

43

Cp/Cv AT INLET

44

DENSITY @STD AT INLET

45

VISCOSITY AT INLET

46

Z (COMPRESSIBILITY FACTOR) AT INLET

47

ESTIMATED SHAFT POWER / COMPRESSOR

hp

48

DISCHARGE PARTICLE SIZE (MAX)

49

DISCHARGE OIL CONTENT (MAX)

(*)

NOTE-11 & 23 NOTE-11 & 23

28.95

1.421

lb/ft

Cp

0.996

VTA

micron

NOTE -14

ppm

NOTE -14

COMPRESSOR DRIVER

OIL INJECTED LUBRICATED SCREW

51

TYPE

52

MANUFACT'R/MODEL

53

NO. OF STAGES

54

CASING DESIGN TEMP. (MIN/MAX.)

55

CASING DESIGN PRESSURE. (MIN/MAX.)

56

VOL. EFFICIENCY (%)

57

MECH. EFFICIENCY (%)

(*)

58

TOTAL POWER (kW)

(*)

59

PRESSURE RATIO

(*)

60

PRODUCT QUALITY

(*)

SUCTION

61

LIQUID (ppm)

(*)

DISCHARGE

62

SOLID (micron)

(*)

VENT

DRAIN

63

(*)

COMPRESSOR

50

COMMENTS

OTHER

(*)

36

40

OFFERED

NOTE-11 & 23 NOTE-11 & 23

35

39

NOTE-24

SINGLE STAGE

o

psig

ELECTRIC MOTOR

TYPE

(*)

DIRECTION OF ROTATION (FACING DRIVING END)

(*)

SPEED

(*) HP

(*)

NOMINAL POWER

(*)

VOLTAGE

(*)

DRIVE (FLUID COUPLING/DIRECT/GEAR)

400 V / 50 Hz / 3 phase

DIRECT

PROCESS/UTILITY CONNECTION

SIZE

ANSI

FACING

CLASS

1 1/2" (*)

150

RF

(*)

150

RF

(*)

150

RF

ORIENTATION

MECHANICAL DATA SHEET

DOC. NO. :

B-84567-SB-MM1-DSR-ST-67-0011

AIR COMPRESSOR AND AIR DRYER PACKAGE

Page : 4 of 11

ConocoPhillips (Grissik) Ltd.

Rev : 4

AIR COMPRESSOR : CONSTRUCTION FEATURES *

1

SPEED

BEARING HOUSING CONSTRUCTION

NORMAL OPERATING SPEED :

(*)

TYPE (SEPARATE/INTEGRAL) :

(*)

MAX.ALLOWABLE SPEED :

(*)

MATERIAL :

(*)

RADIAL BEARING

CASING

CASING SPLIT :

(*)

MATERIAL :

(*)

TYPE :

ROTOR

DIAMETER (mm) :

(*)

MATERIAL :

(*)

NO. OF LOBES :

(*)

FEMALE :

(*)

10

TYPE :

11

TYPE OF FABRICATION :

LOCATION :

(*)

MATERIAL :

(*)

TYPE :

(*)

SHAFT

SHAFT SEAL

12

MATERIAL :

(*)

AIR COMPRESSOR : CONSTRUCTION

13

14

(*)

THRUST BEARING

AIR INTAKE FILTER :

15

ITEMS TO BE SUPPLIED BY PACKAGE MANUFACTURER :

ALL PIPING TO EDGE OF SKID

DRIVER :

MODEL

SPEED REDUCING GEAR

SHAFT COUPLING

RATING (MICRON)

COUPLING GUARD

SEPARATOR

EFFICIENCY (%)

CONTROL STATION

AIR INTAKE FILTER

FLANGED OUTLET CONNECTION

INLET SILINCER

EXHAUST SILINCER

BY:

PACKAGE MFR.

16

TO API 619

17

MFR.

18

TYPE

19

20

PURCHASER

MANUFACTURER'S STD.

21

INLET PIPING :

22

SILINCER :

23

BY:

PACKAGE MFR.

PURCHASER

ELECTRIC MOTOR

STAINLESS STEEL

CARBON STEEL INTERNALLY LINED

24

TO API 619

MANUFACTURER'S STD.

ORIFICED BLEED

INLET

EXHAUST

THERMAL RELIEF VALVE (COOLANT)

26

MFR.

MODEL

TORSIONAL ANALYSIS (GEARED UNITS ONLY)

27

TYPE

P(psi)

ANALOG STUDY

28

INLET/OUTLET CONNECTION

32

AIR/OIL SEPARATOR :

31

BY:

PACKAGE MFR.

TO API 619

33

DESIGN CODE :

34

MFR

35

DES. PRESS (psig)

36

DES. TEMP

37

INLET/OUTLET CONNECTION

PURCHASER

MANUFACTURER'S STD.

ASME SECT. VIII DIV.1

MODEL

CAPACITY

CLASS

(*)

GRP

COOLING SYSTEM :

29

30

PVC

DISCHARGE CHECK VALVE

25

PSV

OIL /AIR COOLERS

CLOSED SYSTEM

PRESSURE TRANDUCER CONNECTION

SPECIAL TOOLS

AUTO CONDENSATE TRAP

LATERAL CRITICAL ANALYSIS

EXTERNAL SUPPLY

(*)

INSTRUMENT SUPPLIERS

38

39

PRESSURE GAUGE :

(*)

MFR.

(*)

SIZE / TYPE

(*)

40

TEMPERATURE GAUGES :

(*)

MFR.

(*)

SIZE / TYPE

(*)

41

LEVEL GAUGES :

(*)

MFR.

(*)

SIZE / TYPE

(*)

42

DIFF. PRESSURE GAUGE :

(*)

MFR.

(*)

SIZE / TYPE

(*)

43

PRESSURE SWITCHES :

(*)

MFR.

(*)

SIZE / TYPE

(*)

44

DIFF. PRESSURE SWITCHES :

(*)

MFR.

(*)

SIZE / TYPE

(*)

45

TEMPERATURE SWITCHES :

(*)

MFR.

(*)

SIZE / TYPE

(*)

46

LEVEL SWITCHES :

(*)

MFR.

(*)

SIZE / TYPE

(*)

47

CONTROL VALVES :

(*)

MFR.

(*)

SIZE / TYPE

(*)

48

PRESSURE RELIEF VALVES :

(*)

MFR.

(*)

SIZE / TYPE

(*)

49

THERMAL RELIEF VALVES :

(*)

MFR.

(*)

SIZE / TYPE

(*)

50

SIGHT FLOW INDICATORS :

(*)

MFR.

(*)

SIZE / TYPE

(*)

51

VIBRATION EQUIPMENT :

(*)

MFR.

(*)

SIZE / TYPE

(*)

52

SOLENOID VALVES :

(*)

MFR.

(*)

SIZE / TYPE

(*)

53

ANNUNCIATOR :

(*)

MFR.

(*)

MODEL / NO. POINTS

(*)

54

TACHOMETER

(*)

MFR.

(*)

RANGE / TYPE

(*)

AIR COMPRESSOR : CONTROL PANEL

55

56

TYPE

CONTROL LOGIC

SEQUENTAL PANEL REQUIRED

57

MANUFACTURER

NOTE-24

DIMENSIONS : (L X W X H )

(*)

58

LOCATION

MOUNTED TO COMPRESSOR ENCLOSURE

IP RATING

NEMA 4x

59

CONTROL SUPPLY

60

POWER CONSUMPTION

61

NOTE : - ALLEN BRADLEY CONTROL LOGIX PLC'S REQUIRED TO CONTROL & MONITOR EACH AIR COMPRESSOR, DRYER AND DEW POINT AND COMMUNICATE WITH CUSTOMER DCS VIA

62

FIBER OPTIC (ETHERNET)

YES

120 VAC,1Ph,50Hz (From UPS)

WATT

(*)

MECHANICAL DATA SHEET

DOC. NO. :

B-84567-SB-MM1-DSR-ST-67-0011

AIR COMPRESSOR AND AIR DRYER PACKAGE

Page : 5 of 11

ConocoPhillips (Grissik) Ltd.

Rev : 4

AIR COMPRESSOR : INSTRUMENTATION AND CONTROLS

1

2

UCP

3

FUNCTION

LOCAL INDICATION

DCS

INDICATION

ALARM

REMARKS

TRIP

AIR INTAKE FILTER DIFFERENTIAL PRESSURE

COOLANT FILTER DIFFERENTIAL PRESSURE

AFTER COOLER FAN MOTOR VIBRATION

LEAD/ LAG SELECTOR

LEAD/ LAG STATUS

10

PRESSURE AT DISHARGE LINE --> TO TRIGGER START AND STOP

OF LEAD OR LAG COMPRESSOR

11

COMMON ALARM

12

EMERGENCY STOP BUTTON

13

AUTO / MANUAL SELECTOR

14

AIR COMPRESSOR RUNNING STATUS

REMOTE SHUTDOWN

NO VIBRATION MONITOR

Y

Y

Y

Y

Y

15

RUNNING HOURS INDICATOR

16

HIGH COMPRESSOR DISCHARGE PRESSURE

17

HIGH COMPRESSOR DISCHARGE TEMPERATURE

18

HIGH COMPRESSOR VIBRATION

19

HIGH INLET AIR DIFFERENTIAL PRESSURE

20

HIGH AIR/OIL SEPARATOR DIFFERENTIAL PRESSURE

21

HIGH LUBE OIL FILTER DIFFERENTIAL PRESSURE

22

HIGH LUBE OIL TEMPERATURE

23

LOW LUBE OIL PRESSURE

24

LOW AIR RECEIVER PRESSURE

Y

Y

Y

Y

Y

25

26

NOTES :

- Y = YES REQUIRED

27

- VENDOR TO ADVICE MANUFACTURER'S STANDARD INSTRUMENTATION, INDICATION, ALARM, AND TRIPS.

28

- VENDOR IS REQUIRED TO PROVIDE A ETHERNET TCP/IP FOR THE PURCHASER'S PCS.

29

30

31

AIR COMPRESSOR : AFTER - COOLER

32

PERFORMANCE TUBE SIDE

33

34

FLUID NAME :

COMPRESSED AIR

35

TOTAL FLUD ENTERING (scfm) :

36

RELATIVE HUMIDITY (%) :

37

LATENT HEAT (Btu.lb) :

(*)

38

INLET PRESSURE (psig)

(*)

(*)

(psi)

(*)

(*)

VELOCITY (ALLOW/CALC)

(ft/s)

(*)

(*)

( ft .F/W )

(*)

(*)

( F )

(*)

(*)

INSIDE FOUL RES.

TEMPERATURE IN/OUT

MECHANICAL EQUIPMENT

39

40

PRESSURE DROP. (ALLOW/CALC)

FAN

DRIVER

41

MANUFACTURER :

(*)

TYPE :

42

MODEL NO. :

(*)

RPM :

(*)

MANUFACTURER & MODEL :

ELECTRIC MOTOR

43

DIAMETER :

(*)

NO. OF BLADES :

(*)

DRIVER (kW) :

44

ANGLE :

45

PITCH ADJUSTMENT :

46

BLADE MATERIAL :

(*)

47

kW/FAN @DES. TEMP :

(*)

48

MAX ALLOW/CALC TIP SPEED (ft/s) :

COMPRESSOR DRIVER :

MANUAL

AUTO

HUB MATERIAL

ENCLOSURE :

(*)

VOLT :

(*)

SERFICE FACTOR :

400

SPACE HEATER :

PHASE :

85

120

Volt

STARTING METHOD :

50

FRAME :

(*)

51

MOUNTING :

(*)

COUPLINGS

53

DRIVER - COMPRESSOR OR DRIVER

GEAR

54

55

MANUFACTURER :

NOTE-24

FREQUENCY : 50 Hz

dB @ 3ft

49

52

1.15

TEFC, INSULATION CLASS F, CLASS B TEMP.RISE

FAN NOISE LEVEL :

(*)

NOTE-24

(*)

(FOR 10 HP AND ABOVE)

(*)

DIMENSION AND WEIGHT

LxWxH (ft-inch)

WEIGHT

GEAR - COMPRESSOR

COMPRESSOR UNIT :

(*)

(*)

lb/unit

COMPRESSOR DRIVER :

(*)

(*)

lb/unit

56

MODEL :

SKID :

(*)

(*)

lb

57

LUBRICATION :

CONTROL PANEL :

(*)

(*)

lb

58

MECHANICAL DATA SHEET

DOC. NO. :

Page : 6 of 11

Rev : 4

AIR COMPRESSOR TESTING

1

2

REQUIRED

WITNESS

SHOP INSPECTION

HYDROSTATIC

FUNCTION TEST

MECHANICAL RUN

PERFORMANCE TEST (AIR)

COMPRESSOR WITH DRIVER

PRESSURE COMPRESSOR TO FULL OPERATION PRESSURE

10

NOISE LEVEL TEST

11

VIBRATION LEVEL TEST

PRE - FILTERS (67MAJ-301 A/B & 67 MAJ-303 A/B)

12

13

MANUFACTURER : NOTE-24

14

QUANTITY :

15

B-84567-SB-MM1-DSR-ST-67-0011

AIR COMPRESSOR AND AIR DRYER PACKAGE

ConocoPhillips (Grissik) Ltd.

SERVICE :

TWO PER TRAIN (TOTAL 4 NO'S)

HORIZONTAL

INSTRUMENT AIR

INCLUDE AUTO DRAIN VALVE

VERTICAL

DESIGN DATA

16

17

FILTERED FLUID :

INSTRUMENT AIR

18

INLET PRESSURE :

19

INLET TEMPERATURE :

20

DESIGN PRESSURE (MAX):

NOTE-11

(psig)

120

( F )

NOTE-11

(psig)

21

DESIGN TEMPERATURE :

180

22

DENSITY AT STD :

(*)

(lb/ft )

( F )

23

VISCOSITY :

(*)

(cP)

24

CONTAMINANTS :

25

MASS FLOW

26

FLOW RATE, DESIGN :

27

MAX ALLOWABLE DP CLEAN :

(*)

28

MAX ALLOWABLE DP DIRTY :

(*)

29

MAX PARTICLE SIZE :

30

MAX OIL CONTENT :

31

FILTER RERMOVE :

100% PARTICLES ABOVE SIZE :

(in)

TOTAL VOLUME :

(ft )

(ft )

(*)

SHELL

HEAD

(*)

NOZZLE NECK

(*)

(scfm)

NOZZLE /BLIND FLANGES

(*)

(psi)

SHELL FLANGES

(*)

(psi)

LIFTING LUG

(*)

NOTE-14

(micron)

SKIRT/LEGS

(*)

NOTE-14

(ppm)

BRACKET SUPPORTS

(*)

GASKETS

(*)

NOTE-11 & 23

LIQUID :

COVER THICKNESS :

MATERIAL

(lb/h)

33

(in)

(in)

OPERATING VOLUME :

OIL & SOLID

32

INTERNAL DIA. TOP/BOTTOM :

SHELL THICKNESS :

INTERNAL BOLTS & NUTS

(*)

99% DISPERED LIQUID

EXTERNAL FLANGE BOLTS

(*)

(*)

(*)

(micron)

34

COMPOSITION (MOL%) :

AIR WATER VAPOUR

EXTERNAL FLANGE NUTS

35

RELATIVE HUMIDITY :

60 - 100

INTERNALS

(*)

36

CORROSION ALLOWANCE :

NAMEPLATE

316 SS

%

(*)

(in)

CONSTRUCTION

37

38

ELEMENT TYPE :

(*)

GAUGES DIFF. PRESS READING

39

MATERIAL :

(*)

AUTOMATIC DISCHARGE SYSTEM

YES

NO

40

SCREEN SIZE :

(*)

YES

NO

41

TOTAL FILTER AREA :

(*)

AUTOMATIC WATER DRAIN

YES

NO

42

INITIATED BY :

TIMER

DIFF. PRESSURE

FLOW RATE CONTROL

YES

NO

43

VENT VALVE :

AUTO

MANUAL

PRESSURE RELIEF VALVE

YES

NO

44

DRAIN VALVE :

AUTO

MANUAL

HORIZONTAL

45

DIMENSION :

46

MOUNTING :

(micron) FLOAT OPERATED PILOT

(ft )

N/A

INDIRECT

WEIGHT

(in)

DIRECT

VERTICAL

WEIGHT OF COVER :

(lb)

COMPRESSOR DRIVER

(lb)

47

AIR DRYER (67MBK-301 A/B & 67MBK-302 A/B)

48

SERVICE DESCRIPTION

49

50

UNIT

MAXIMUM

NORMAL

COMPRESSED AIR

FLUID HANDLED

COMPRESSED AIR

51

SOURCE

52

INLET AIR OIL CONTENT

53

INLET AIR TEMPERATURE

(*)

54

INLET AIR RELATIVE HUMIDITY

100

65

55

INLET AIR PRESSURE

psig

NOTE-11

NOTE-11

56

OUTLET AIR FLOWRATE

scfm

NOTE-11 & 23

NOTE-11 & 23

57

INLET AIR FLOWRATE @ STD

scfm

NOTE-11 & 23

NOTE-11 & 23

58

INLET AIR ACTUAL FLOWRATE @ P,T

acfm

(*)

(*)

59

INLET AIR MASS FLOWRATE

lb/h

(*)

(*)

ppm

NOTE -14

120 (*)

OFFERED

COMMENTS

MECHANICAL DATA SHEET

DOC. NO. :

B-84567-SB-MM1-DSR-ST-67-0011

AIR COMPRESSOR AND AIR DRYER PACKAGE

Page : 7 of 11

ConocoPhillips (Grissik) Ltd.

SERVICE DESCRIPTION

UNIT

MAXIMUM

NORMAL

lb/ft

(*)

(*)

OFFERED

INLET AIR DENSITY @ STD

INLET AIR VISCOSITY

Cp

(*)

(*)

OUTLET DRY AIR FLOWRATE @ STD

scfm

NOTE-11 & 23

NOTE-11 & 23

OUTLET DRYER AIR ACTUAL FLOWRATE @ P, T

acfm

(*)

(*)

OUTLET DRY AIR MASS FLOWRATE

lb/h

(*)

(*)

OUTLET DRY AIR DEWPOINT

(*)

-40

OUTLET DRY AIR TEMPERATURE

(*)

120 ( * )

10

PRESSURE DROP

psig

(*)

(*)

11

OUTLET DRY AIR OIL CONTENT

ppm

NOTE-14

(*)

12

OUTLET ABSOLUTE FILTER RATING

micron

NOTE-14

(*)

13

AIR DRYER TYPE

14

NO. OF DRYER PACKAGE/SKID

15

NO. OF DESICCANT VESSEL/UNIT

16

REGENERATION AIR

17

NOTE : DRYER SWITCHING DEW POINT DEPENDENT AND TIME BASED

F

F

2 X 100% (DUAL TOWER)

2 (DUTY / REGENERATION)

scfm

(*)

(*)

INSTRUMENTATION AND CONTROLS

UCP

19

FUNCTION

DCS

LOCAL INDICATION

20

INDICATION

ALARM

21

PRE - FILTER DIFFERENTIAL PRESSURE

22

AFTER- FILTER DIFFERENTIAL PRESSURE

23

AIR DRYER PRESSURE

24

AIR DRYER HIGH MOISTURE CONTENT (DEW

POINT)

25

AIR DRYER FAIL TO SHIFT - SWITCHING FAILURE

26

AIR DRYER RUNNING STATUS

27

DEW POINT ANALYZER

28

NOTES :

REMARKS

TRIP

- Y = YES REQUIRED

29

- VENDOR TO ADVICE MANUFACTURER'S STANDARD INSTRUMENTATION, INDICATION, ALARM, AND TRIPS.

30

- VENDOR IS REQUIRED TO PROVIDE A ETHERNET TCP/IP FOR THE PURCHASER'S PCS.

DRYER CONTROL PANEL

31

TYPE :

VENDOR STANDARD

SEQUENTIAL PANEL REQUIRED :

33

MANUFACTURE :

COMMON ALLEN BRADLEY PLC REQUIRED

FOR COMMUNICATION OF STATUS OF EACH

AIR COMPRESSOR, DRYER, AND DEW POINT

TO CUSTOMER DCS

DIMENSIONS : ( L X W X H)

34

LOCATION :

ON SKID

FACTORY TESTING :

35

POWER SUPPLY

120 VAC,1Ph,50Hz

YES

(*)

FUNCTIONAL TEST

DESICCANT DRYER VESSELS

36

37

COMMENTS

HEATLESS DESICCANT

18

32

Rev : 4

AIR DRYER PACKAGE (CONTINUED)

MANUFACTURER :

QUANTITY :

2 X 100%

DESIGN DATA

38

39

CODE :

40

SPECIFICATIONS :

OPERATING CONDITIONS

ASME VIII Div. 1

CONTENT :

COMPRESSED AIR

SPECIFIC GRAVITY OF CONTENTS :

YES

41

STATUTORY AUTHORITY APPROVAL :

42

DESIGN PRESSURE, INTERNAL :

NO

(*)

(psig)

OPERATING TEMPERATURE :

OPERATING PRESSURE :

43

DESIGN TEMPERATURE AT DESIGN PRESSURE :

(*)

(psig)

OPERATING VOLUME :

44

DESIGN MINIMUM TEMPERATURE AT DESIGN PRESSURE :

(*)

45

INTENDED NUMBER OF OPERATING CYCLES :

(*)

NOTE-11

(psig)

120

TOTAL VOLUME :

( F )

(*)

(ft )

(*)

(ft )

MATERIALS

( F )

46

CORROSION ALLOWANCE :

(*)

(in)

SHELL

(*)

47

INTERNAL DIAMETER :

(*)

(in)

HEADS

(*)

48

SHELL THICKNESS :

(*)

(in)

COMPRESSOR DRIVER

(*)

49

HEAD THICKNESS :

(*)

(in)

NOZZLE / BLIND FLANGES

(*)

50

SUPPORT TYPE :

(*)

SHELL FLANGES

(*)

51

VESSEL SKIRT/LEG

YES

NO

REINFORCING PADS

(*)

52

LIFTING LUG

YES

NO

STIFFENING RINGS

(*)

53

EARTHING LUG

YES

NO

LIFTING LUGS

(*)

54

MANWAY COVER / HANDLE

YES

NO

CLIPS

(*)

SKIRT/LEGS

(*)

FABRICATION & INSPECTION

55

56

RADIOGRAPHY :

YES, 100 %

BASE PLATES

(*)

57

MAGNETIC PARTICLE :

YES

GASKET

(*)

58

DYE PENETRANT :

YES

EXTERNAL FLANGE BOLTS

(*)

59

ULTRASONIC :

YES

EXTERNAL BOLTS & NUTS

(*)

60

HYDROSTATIC TEST :

YES, PER UG - 99 (b)

INTERNAL

61

NAMEPLATE

(*)

316 SS

MECHANICAL DATA SHEET

DOC. NO. :

B-84567-SB-MM1-DSR-ST-67-0011

AIR COMPRESSOR AND AIR DRYER PACKAGE

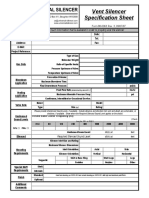

NOISE LIMITATIONS - SOUND PRESSURE LEVELS

1

2

ACCOUSTIC TREATMENT :

YES

SILINCER SCOPE :

SUPPLIER

TYPE :

SILINCER

NOISE LIMIT :

85 @

MATERIAL :

316 SS (*)

3 ft

dB(A)

AFTER FILTERS (67MAJ-302 A/B & 67MAJ-304 A/B)

4

5

MANUFACTURER :

QUANTITY :

Rev : 4

Page : 8 of 11

ConocoPhillips (Grissik) Ltd.

NOTE-24

TWO PER TRAIN (TOTAL 4 NO'S)

HORIZONTAL

VERTICAL

SERVICE :

AIR DRYER AFTER - FILTER

LOCATION :

SUBAN GAS PLANT

INCLUDE AUTO DRAIN VALVE

DESIGN DATA

8

DRY COMPRESSED AIR

FILTERED FLUID

10

INLET PRESSURE

11

INLET TEMPERATURE

12

DESIGN PRESSURE

NOTE-11

13

DESIGN TEMPERATURE

NOTE-11

14

DENSITY AT STD

15

VISCOSITY

16

CONTAMINANTS

NOTE-11

(psig)

120 (*)

INTERNAL DIA. TOP/BOTTOM

(*)

(in)

SHELL THICKNESS

(*)

(in)

(*)

(in)

TOTAL VOLUME

(*)

(ft )

( F ) OPERATING VOLUME

(*)

(ft )

( F ) COVER THICKNESS

(psig)

(*)

(lb/ft )

(*)

(Cp)

DESSICANT DUST & COMP. OIL

(*)

HEAD

(*)

(*)

(lb/h)

NOZZLE NECKS

(*)

NOTE-11 & 23

scfm

NOZZLE/BLIND FLANGES

(*)

MAX ALLOWABLE DP CLEAN

(*)

(psi)

SHELL FLANGES

(*)

21

MAX ALLOWABLE DP DIRTY

(*)

(psi)

LIFTING LUGS

(*)

22

MAX PARTICLE SIZE

NOTE -14

23

MAX OIL CONTENT

NOTE -14

24

FILTER TO REMOVE :

17

CORROSIVE COMPOUND

18

MASS FLOW

19

FLOW RATE, DESIGN

20

N/A

MATERIALS

SHELL

25

100 % PARTICLE ABOVE SIZE

26

100 % DROPLETS ABOVE

27

COMPOSITION (MOL %)

28

RELATIVE HUMIDITY

29

CORROSION ALLOWANCE

(*)

(micron) SKIRT/LEGS

(ppm)

BRACKET SUPPORT

(*)

GASKET

(*)

(*)

(micron) INTERNAL BOLTING

AIR & TRACE WATER VAPOUR

EXTERNAL FLANGE BOLTS

(*)

EXTERNAL FLANGES NUTS

(*)

60 - 100

(%)

INTERNALS

(*)

(*)

(in)

NAMEPLATE

316 SS

CONSTRUCTION

30

31

ELEMENT TYPE :

(*)

GAUGES DIFF. PRESS READING

32

MATERIAL :

(*)

AUTOMATIC DISCHARGE SYSTEM

YES

NO

33

SCREEN SIZE :

(*)

(*)

YES

NO

34

TOTAL FILTER AREA :

(*)

(*)

AUTOMATIC WATER DRAIN

YES

NO

35

INITIATED BY :

TIMER

DIFF. PRESSURE

FLOW RATE CONTROL

YES

NO

36

VENT VALVE :

AUTO

MANUAL

PRESSURE RELIEF VALVE

YES

NO

37

DRAIN VALVE :

AUTO

MANUAL

HORIZONTAL

38

DIMENSION :

39

MOUNTING :

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

(micron) FLOAT OPERATED PILOT

(ft )

N/A

VERTICAL

INDIRECT

WEIGHT

(in)

DIRECT

WEIGHT OF COVER :

(*)

(lb)

WEIGHT OF ELEMENT :

(*)

(lb)

MECHANICAL DATA SHEET

AIR COMPRESSOR AND AIR DRYER PACKAGE

ConocoPhillips (Grissik) Ltd.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

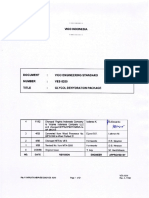

DOC. NO. :

B-84567-SB-MM1-DSR-ST-67-0011

Page : 9 of 11

Rev : 4

SCHEMATIC AIR COMPRESSOR AND AIR DRYER PACKAGE ATTACHMENT (AS PER P&ID B-84567-SB-PP0-PID-ST-67-0005 Rev.4)

MECHANICAL DATA SHEET

AIR COMPRESSOR AND AIR DRYER PACKAGE

ConocoPhillips (Grissik) Ltd.

DOC. NO. :

B-84567-SB-MM1-DSR-ST-67-0011

Page : 10 of 11

Rev : 4

NOTES :

1

2

VTA/ (*) : VENDOR TO ADVISE DATA.

THE EQUIPMENT SHALL BE DESIGNED LIFE SHALL BE MINIMUM 20 YEARS.

AIR COMPRESSOR PACKAGE SHALL BE MINIMUM CONSIST OF SCREW COMPRESSORS WITH ALL ACCESSORIES LIKE SUCTION FILTERS, AIR INTAKE,SILENCERS, AFTER

2 (TWO) X 100% AIR COMPRESSORS WILL BE PROVIDED AND OPERATED IN LEAD-LAG MODE. THE LEAD-LAG OPERATION CONTROL LOGIC TO BE INCLUDED IN AIR

5

6

COOLERS,AND CONTROL PANEL.

COMPRESSOR'S UCP. THE SETTING PRESSURE OF AIR COMPRESSOR (AT THE OUTLET OF INSTRUMENT AIR RECEIVER) IS AS FOLLOWS :

ACTION

PRESSURE (PSIG)

120

LEAD UNLOAD AIR COMPRESSOR

10

110

LEAD LOAD AIR COMPRESSOR

11

120

LAG UNLOAD AIR COMPRESSOR

12

105

LAG LOAD AIR COMPRESSOR

13

EACH AIR COMPRESSOR SHALL BE PROVIDED WITH PRESSURE RELIEF VALVE SIZED FOR FULL FLOW.

14

VENDOR TO CLEARLY STATE THE FOLOWING :

15

I)

16

II) COMPRESSOR TURNDOWN

RATED CAPACITY OF THE COMPRESSOR

17

III) MAXIMUM AIR LOSSES FROM THE PACKAGE

18

IV) POWER AND UTILITY CONSUMPTION.

19

V) SKID WEIGHT AND FOOT PRINTS

20

VENDOR TO FURNISH THE COMPLETE P&ID OF AIR COMPRESSOR PACKAGE.

21

THE COMPRESSOR CAPACITY SHALL INCLUDE AN ALLOWANCE FOR THE AIR DRYER REGENERATION AIR FLOW REQUIREMENT.

22

23

AIR COMPRESSOR DISCHARGE PRESSURE SHALL BE ADEQUATE TO ACHIEVE THE MINIMUM PRESSURE 120 PSIG AT THE AIR DRYER PACKAGE OUTLET (I.E AFTER FILTER

OUTLET) UNDER FILTER CLOGGED CONDITION.

24

10

AIR COMPRESSOR PACKAGE SHALL BE COMPLETE WITH PIPING, VALVES, CABLE WIRING, INSTRUMENTATION AND CONTROL, AND MOTOR STARTER.

25

11

THE DESIGN PRESSURE AND TEMPERATURE OF THE AIR COMPRESSOR DISCHARGE PIPING AND DOWNSTREAM EQUIPMENT IS STATED BELOW :

26

DESIGN PRESSURE

145 psig (*)

27

DESIGN TEMPERATURE MIN/MAX

120 / 180 oF (*)

28

VENDOR SHALL BE SELECTED AIR COMPRESSOR > 450 SCFM DUE THE CAPACITY AT OUTLET AIR DRYER PACKAGE ON SKID ABOUT 450 SCFM (DRY AIR) AND PRESSURE

29

AT OUTLET AIR DRYER PACKAGE ABOUT 120 PSIG.

30

12

DELETED

31

13

FLOWRATE SHALL BE BASED ON TOTAL INSTRUMENT AIR DEMAND AND AIR FOR DRYER REGENERATION CONSUMPTION.

32

14

VENDOR USE ISO STANDARD ISO 8573.1 CLASS 1.2.1. SOLID PARTICLE SIZE OUTLET PACKAGE SHALL BE 0.1 MICRON AND OIL PARTICLE 0.01 mg/m3 (0.008) ppm

33

15

VENDOR TO CLEARLY STATE THE FOLLOWING :

34

I)

35

II) SKID WEIGHT AND FOOT PRINTS.

36

AIR LOSSES IN SCFM DURING REGENERATION.

III) UTILITIES REQUIREMENTS, INCLUDING INSTRUMENT AIR AND POWER CONSUMPTION (IF ANY).

37

16

SURGE PROTECTION DEVICE SHALL BE PROVIDED FOR ALL INPUT/OUTPUT I/O TERMINAL AND POWER SUPPLY.

38

17

DEW POINT ANALYZERS SHALL BE NEMA 4X ENCLOSURE.

39

18

SUITABLE PROVISION SHALL BE MADE TO AVOID VACUUM IN THE DRYER WHEN COMPRESSOR IS TRIPPED / CUTOUT.

40

19

THE CONTROL PANEL SHALL COMPLY TO THE REQUIREMENTS STATED IN THE INSTRUMENT REQUIREMENT FOR PACKAGED EQUIPMENT SPECIFICATION

42

20

ALL ENCLOSURE FOR PLC PANEL AND OTHER ELECTRICAL ACCESSORIES SHALL MEET NON-HAZARDOUS AREA.

43

21

ALL DRAINS SHALL BE PIPED TO A COMMON HEADER TO PURCHASER CONNECTION

44

22

TWO (2) GROUNDING BOSS SS MATERIAL SHALL BE PROVIDED AT CORNER LOCATION

45

23

41

AND OTHER SPECIFICATIONS AND CODES AND STANDARDS REFERENCED IN THE SPECIFICATION.

46

1 (ONE) DRYER WILL BE RUNNING, 1 (ONE) UNIT STAND-BY. SIZING OF EACH DRYER CAPACITY SHALL CONSIDER BOTH COMPRESSOR RUNNING SIMULTANIOUSLY.

VENDOR TO CONFIRM DRYER CAPACITY (EACH).

47

NORMAL OPERATION 1 (ONE) COMPRESSOR + 1 (ONE) DRYER CAN BE HANDLED CAPACITY 450 SCFM (DRY AIR), PRESSURE 120 PSIG AT OUTLET AIR DRYER PACKAGE.

48

24

VENDOR SHALL COMPLY MANUFACTURER AS PER DOC NO. ID-G-BU-GG0-AML-GN-00-0001 (COPI APPROVED VENDOR LIST )

49

25

VEHICLE TONNAGE IS LIMITED BY BRIDGE DIMENSION AND CAPACITY.

50

MAXIMUM TRANSPORTABLE SIZE :

- LENGTH :

12 METERS

- WIDTH :

4.5 METERS

52

- HEIGHT :

5 METERS

53

- MAXIMUM TRANSPORTABLE WEIGHT : 90 TONS (1TON = 2000 LB)

51

54

55

56

57

58

59

26

THE AIR COMPRESSOR PACKAGE SHALL BE PROVIDED WITH SOFT STARTER COMPLETE WITH PROTECTION AND MOUNTED IN PACKAGE ENCLOSURE.

MECHANICAL DATA SHEET

DOC. NO. :

B-84567-SB-MM1-DSR-ST-67-0011

AIR COMPRESSOR AND AIR DRYER PACKAGE

Page : 11 of 11

ConocoPhillips (Grissik) Ltd.

NOTES (CONTINUED):

1

2

27

VENDOR TO COMPLY THE FOLLOWING APPLICABLE THE LATEST CODE, STANDARD & SPECIFICATION

B-84567-SB-MM1-SPC-ST-67-0301

SPECIFICATION - INSTRUMENT AIR COMPRESSOR PACKAGE

B-84567-SB-MM2-SPC-ST-00-0301

UNFIRED PRESSURE VESSEL SPESIFICATION

ID-G-BU-DD3-STS-GN-98-0002

FACILITIES COATING SPECIFICATION FOR OFFSHORE & ONSHORE

ID-G-BU-GG0-AML-GN-00-0001

COPI APPROVED VENDOR LIST

ID-N-BU-LA1-STS-GN-00-0001

TESTING AND INSPECTION OF PIPING SYSTEM

B-84567-SB-LL0-SPC-ST-00-0001

PIPING MATERIAL SPECIFICATION

ID-G-BU-DD1-STS-GN-00-0001

STANDARD SPECIFICATION FOR POSITIVE MATERIAL IDENTIFICATION

10

ID-N-BU-LL2-STS-GN-00-0001

STANDARD SPECIFICATION FOR WELDING

11

ID-G-BU-JJ0-STS-GN-87-0001

STANDARD SPECIFICATION - INSTRUMENT DESIGN

12

ID-N-BU-JJ1-STS-GN-00-0001

PRESSURE INSTRUMENT

13

ID-N-BU-JJ1-STS-GN-00-0002

TEMPERATURE INSTRUMENT

14

ID-N-BU-JJ1-STS-GN-00-0005

ACTUATED BALL VALVES

15

ID-N-BU-JJ1-STS-GN-00-0007

RELIEF VALVES

16

ID-N-BU-CC0-STS-GN-00-0001

STANDARD SPECIFICATION FOR GENERAL CIVIL AND STRUCTURAL DESIGN

17

ID-N-BU-EE0-STS-GN-00-0001

GENERAL ELECTRICAL DESIGN

18

ID-N-BU-EE2-STS-GN-00-0001

CABLE TRAY

19

ID-N-BU-EE1-STS-GN-00-0001

PACKAGE ELECTRICAL EQUIPMENT

20

ID-N-BU-EE1-STS-GN-00-0008

WIRE AND CABLES

21

ID-N-BU-EE1-STS-GN-00-0009

LIGHTNING PROTECTION AND GROUNDING

22

ID-N-BU-EE1-STS-GN-00-0010

SPECIFICATION FOR INDUCTION MOTOR

23

ID-N-BU-JJ0-STS-GN-00-0006

LOCAL CONTROL PANEL

24

API STD 686

MACHINERY INSTALLATION & INSTALLATION DESIGN

25

ASME VIII DIV.1

RULES FOR CONSTRUCTION OF PRESSURE VESSEL

26

NEMA MG-1

MOTORS AND GENERATORS

27

ASME B16.5

PIPE FLANGES AND FLANGED FITTINGS

28

ASME B31.3

PROCESS PIPINGS

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

Rev : 4

You might also like

- Api 618 4th Ed Si DatasheetsDocument17 pagesApi 618 4th Ed Si Datasheetshmshawki100% (5)

- API 674 Pump Data SheetDocument5 pagesAPI 674 Pump Data SheetEason Ng100% (2)

- Design of Oxidation DitchDocument23 pagesDesign of Oxidation Ditchartiraha100% (1)

- BE-WI-248-01-F19 Datasheet Breather ValveDocument3 pagesBE-WI-248-01-F19 Datasheet Breather Valvemika cabelloNo ratings yet

- Ga Comment Response SheetDocument1 pageGa Comment Response SheetHudaFiHayyatNo ratings yet

- Checklist Bypass Line SizingDocument5 pagesChecklist Bypass Line Sizingsrinivas_gowthamNo ratings yet

- Vent Silencer Specification SheetDocument2 pagesVent Silencer Specification Sheethuso100% (1)

- MBR DesignDocument52 pagesMBR Designpragatheesk100% (2)

- Instrument Air Dryer and Instrument Air ReceiverDocument1 pageInstrument Air Dryer and Instrument Air ReceiverAimanNo ratings yet

- 903-10004-SPC-M-001 Piping Material SpecificationDocument15 pages903-10004-SPC-M-001 Piping Material SpecificationChitradeep FalguniyaNo ratings yet

- Plant Air Instrument Air PackageDocument5 pagesPlant Air Instrument Air Packagekumar31052003No ratings yet

- Typical PFD For Centrifugal Compressor SystemsDocument2 pagesTypical PFD For Centrifugal Compressor Systemsandres_old_condeNo ratings yet

- Spring Supports CP Catalog 09VDocument52 pagesSpring Supports CP Catalog 09VNizarHamrouniNo ratings yet

- Gas Dehydration (ENGINEERING DESIGN GUIDELINE)Document23 pagesGas Dehydration (ENGINEERING DESIGN GUIDELINE)Tu Dang TrongNo ratings yet

- BP Variable Catalog 09VDocument52 pagesBP Variable Catalog 09VPetros IosifidisNo ratings yet

- Kolmetz Handbook of Process Equipment Design Flare Systems Safety, Selection, Sizing and Troubleshooting (Engineering Design Guidelines)Document24 pagesKolmetz Handbook of Process Equipment Design Flare Systems Safety, Selection, Sizing and Troubleshooting (Engineering Design Guidelines)ramadan rashadNo ratings yet

- GA Drawing SLOP TankDocument2 pagesGA Drawing SLOP TankMathivanan AnbazhaganNo ratings yet

- Tank Datasheet - CS-8000KL - RADocument1 pageTank Datasheet - CS-8000KL - RASumantrra ChattopadhyayNo ratings yet

- Dokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsDocument28 pagesDokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsCorne SalcedoNo ratings yet

- PMS Rev 0Document36 pagesPMS Rev 0rami ghorbelNo ratings yet

- Column Piping - Study Layout, Nozzle Orientation & Platforms RequirementsDocument37 pagesColumn Piping - Study Layout, Nozzle Orientation & Platforms RequirementsvasuNo ratings yet

- Index - Amendment To TBPDocument4 pagesIndex - Amendment To TBPVineet 01No ratings yet

- Vol II - Assorted Valves PDFDocument125 pagesVol II - Assorted Valves PDFashish.mathur1100% (2)

- 7-12-0026 Rev6 (Earthing Lug)Document1 page7-12-0026 Rev6 (Earthing Lug)sumit kumarNo ratings yet

- Flare Scrubber DSDocument8 pagesFlare Scrubber DSsudjonoNo ratings yet

- Restriction Orifice Final CalculationDocument1 pageRestriction Orifice Final CalculationJasperTanNo ratings yet

- Instrument List: J300 011 405 REV-01Document5 pagesInstrument List: J300 011 405 REV-01hari reddyNo ratings yet

- Pump Hydraulic CalculationsDocument14 pagesPump Hydraulic CalculationsJosue GonzalezNo ratings yet

- HEXPHDocument2 pagesHEXPHMuthuKumar ArunachalamNo ratings yet

- 7-12-0033 Rev 4Document1 page7-12-0033 Rev 4cynideNo ratings yet

- Y-Strainer Spears DatasheetDocument10 pagesY-Strainer Spears Datasheetmanoj_sitecNo ratings yet

- Datasheet For FiltersDocument13 pagesDatasheet For FiltersAntonio MendesNo ratings yet

- 01NU0B01Document4 pages01NU0B01raobabar21No ratings yet

- TA2860 RHI 50 ZZ DR N 2001 P&ID Fire Fighting Generation System CommentDocument1 pageTA2860 RHI 50 ZZ DR N 2001 P&ID Fire Fighting Generation System CommentBack To SumateraNo ratings yet

- Tower-Process-Data-Sheet - Ex (Version 1)Document1 pageTower-Process-Data-Sheet - Ex (Version 1)Abraham Burgos CelisNo ratings yet

- API 650 Storage Tank 2400Document34 pagesAPI 650 Storage Tank 2400PANOLI PROJECTNo ratings yet

- Equipment Specification Project - RFQ - #: Page 1 of 12Document12 pagesEquipment Specification Project - RFQ - #: Page 1 of 12Calin SeraphimNo ratings yet

- 22-DS-R-001 Rev 1 API 617 GTCPsDocument25 pages22-DS-R-001 Rev 1 API 617 GTCPsChike Nwachukwu100% (1)

- Insulation Thickness TableDocument9 pagesInsulation Thickness TableSachin MankameNo ratings yet

- Hierarchy in PDMS - World, Site, ZoneDocument6 pagesHierarchy in PDMS - World, Site, Zones_baishyaNo ratings yet

- Al-Khobar Seawater Reverse Osmosis 2 Desalination PlantDocument4 pagesAl-Khobar Seawater Reverse Osmosis 2 Desalination PlantABAID ULLAHNo ratings yet

- Fisher FB and FBG Control Valves Bulletin PDFDocument24 pagesFisher FB and FBG Control Valves Bulletin PDFWalid FattahNo ratings yet

- PZ D CS Pi SP 015 02Document60 pagesPZ D CS Pi SP 015 02epbamdadNo ratings yet

- GE Oil & Gas Measurement & Control: OutletDocument1 pageGE Oil & Gas Measurement & Control: Outletshakuntla5bankerNo ratings yet

- Engineering Standard - Piping Material Specification - Table of Contents PDFDocument3 pagesEngineering Standard - Piping Material Specification - Table of Contents PDFSoniNo ratings yet

- Ves 5200 R4 RDocument21 pagesVes 5200 R4 RdanikakaNo ratings yet

- MM-ZTK-1A-ZPQ-PIP-DTS-0125 Rev A1Document10 pagesMM-ZTK-1A-ZPQ-PIP-DTS-0125 Rev A1gracemanotocNo ratings yet

- A Demister Pad Is Similar To An Air Filter Except Instead of Removing Dust ParticlesDocument1 pageA Demister Pad Is Similar To An Air Filter Except Instead of Removing Dust ParticlesyogacruiseNo ratings yet

- Restriction Orifice Diamater CalculationDocument1 pageRestriction Orifice Diamater CalculationaytihdaNo ratings yet

- Tds Tcs Tata Krishnapatnam Rev.r0Document46 pagesTds Tcs Tata Krishnapatnam Rev.r0SupriyaRongNo ratings yet

- Unit Plot PlanDocument1 pageUnit Plot PlanSuryakantKolekarNo ratings yet

- Flange Leakage CheckingDocument3 pagesFlange Leakage CheckingKumar RNo ratings yet

- ACFrOgBo1iGqwe3hPVDeso7MlgDOoxXORvOyEPoZX7JH5P r8f w5kQHxIeABvtbWmHyzF8fls6khF BW 5H54Qnr8eSv2XIP8cFF1tq7Bcevn9Kl6UNUgaqVsIwYNgDocument2 pagesACFrOgBo1iGqwe3hPVDeso7MlgDOoxXORvOyEPoZX7JH5P r8f w5kQHxIeABvtbWmHyzF8fls6khF BW 5H54Qnr8eSv2XIP8cFF1tq7Bcevn9Kl6UNUgaqVsIwYNgbaccour bilelNo ratings yet

- 8 AS4041 ASME B31 3 Pipe Wall ThicknessDocument8 pages8 AS4041 ASME B31 3 Pipe Wall ThicknessĐinh Thiện SỹNo ratings yet

- Stim-03.006 - en Control FluidDocument17 pagesStim-03.006 - en Control Fluidbikendiaguirre100% (1)

- Basket FilterDocument1 pageBasket FilterShreya TrikhaNo ratings yet

- P&id SymoblDocument5 pagesP&id Symoblkunallpatill95No ratings yet

- SR Piping Designer/checkerDocument4 pagesSR Piping Designer/checkerapi-78715367No ratings yet

- 015 VA1 BSWS 00100 GE M3 PID 0040 Legend and SymbolsDocument2 pages015 VA1 BSWS 00100 GE M3 PID 0040 Legend and SymbolsScribd_delNo ratings yet

- Reciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)Document17 pagesReciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)tutuionutNo ratings yet

- Reciprocating Compressor (Api 618-4Th) Data Sheet U.S. Customary UnitsDocument17 pagesReciprocating Compressor (Api 618-4Th) Data Sheet U.S. Customary UnitstutuionutNo ratings yet

- (I S 0 Standards) : 'K) Lntermlttent (Starts1Day)Document9 pages(I S 0 Standards) : 'K) Lntermlttent (Starts1Day)Janakiraman MalligaNo ratings yet

- LabDocument12 pagesLabpragatheeskNo ratings yet

- List of Preferred BrandDocument8 pagesList of Preferred BrandpragatheeskNo ratings yet

- RFQ For Pumps-UpdatedDocument3 pagesRFQ For Pumps-UpdatedpragatheeskNo ratings yet

- ComparisonDocument10 pagesComparisonpragatheeskNo ratings yet

- Product Leaflet Seawater ElectrochlorinationDocument1 pageProduct Leaflet Seawater ElectrochlorinationpragatheeskNo ratings yet

- Equipment: Respond To This Bidding DocumentDocument1 pageEquipment: Respond To This Bidding DocumentpragatheeskNo ratings yet

- Kubota-Mbr Technical PDFDocument13 pagesKubota-Mbr Technical PDFpragatheeskNo ratings yet

- MBR System Evaluation Overview: A C E H F MBR TDocument9 pagesMBR System Evaluation Overview: A C E H F MBR TpragatheeskNo ratings yet

- Anoxic TankDocument12 pagesAnoxic TankpragatheeskNo ratings yet

- Equalisation GuideDocument16 pagesEqualisation GuidepragatheeskNo ratings yet