Professional Documents

Culture Documents

2853-Simple Drilling Jigs

2853-Simple Drilling Jigs

Uploaded by

syllavethyjimCopyright:

Available Formats

You might also like

- The Table Leg Typewriter (Practical Scrap Metal Small Arms Vol.10)Document37 pagesThe Table Leg Typewriter (Practical Scrap Metal Small Arms Vol.10)xan94% (18)

- IMP Workshop ManualDocument336 pagesIMP Workshop Manualsyllavethyjim67% (3)

- 《桥梁工程Bridge Engineering》设计试卷 (A)Document8 pages《桥梁工程Bridge Engineering》设计试卷 (A)Mashrique AdnanNo ratings yet

- WC5 Parts Fabrication: Author: J. RandleDocument48 pagesWC5 Parts Fabrication: Author: J. RandleCristian Silva100% (1)

- Table Saw JigsDocument16 pagesTable Saw Jigscyclonium100% (9)

- Hydraulic Turbine Classification and SelectionDocument57 pagesHydraulic Turbine Classification and SelectionNarayan ShresthaNo ratings yet

- 149-Workshop Hints & Tips PDFDocument1 page149-Workshop Hints & Tips PDFsyllavethyjimNo ratings yet

- Saw HandleDocument7 pagesSaw Handleانغي رحمنيNo ratings yet

- WC5 Parts Fabrication: Author: J. RandleDocument48 pagesWC5 Parts Fabrication: Author: J. RandleCarlos Gabriel Estergaard100% (1)

- Pocket-Hole PointersDocument9 pagesPocket-Hole PointersLee BannisterNo ratings yet

- Hack SawingDocument15 pagesHack SawingVergara KoyNo ratings yet

- BHManual Fuselage46 79rev1Document34 pagesBHManual Fuselage46 79rev1viorelu99No ratings yet

- Lathe Modelling 2Document2 pagesLathe Modelling 2cesargramcko100% (1)

- Purpose-Built Chucks.: Wooden Pad Glued To WorkpieceDocument2 pagesPurpose-Built Chucks.: Wooden Pad Glued To Workpieceneko222No ratings yet

- Unimat Pages 26-30Document5 pagesUnimat Pages 26-30remendabNo ratings yet

- Make A Wheel Marking GaugeDocument6 pagesMake A Wheel Marking Gaugeserkan ünlü100% (1)

- Foam Core Construction: Tools Tips and TricksDocument12 pagesFoam Core Construction: Tools Tips and TricksRohan KulkarniNo ratings yet

- Hand ProcessesDocument14 pagesHand Processeschandajustin526No ratings yet

- 2 ToolsDocument83 pages2 ToolsKileta KafusiNo ratings yet

- How To Make Your Own Six Yard Bell Target Mechanism: Glossary of TermsDocument24 pagesHow To Make Your Own Six Yard Bell Target Mechanism: Glossary of TermsJose German Ojeda CruzNo ratings yet

- Workshop Equipment: How To Make 12 Woodworking ToolsDocument110 pagesWorkshop Equipment: How To Make 12 Woodworking ToolsSean100% (1)

- Wooden SouthDocument27 pagesWooden Southİbrahim Anıl Balkan100% (1)

- 3184-Piston Patterns & Core BoxesDocument1 page3184-Piston Patterns & Core Boxesmn_9013No ratings yet

- Recoil PadsDocument3 pagesRecoil PadsAnonymous jbeHFUNo ratings yet

- Bensen b8 PDFDocument8 pagesBensen b8 PDFmaxNo ratings yet

- Hand Taps and Proper Threading TechniquesDocument3 pagesHand Taps and Proper Threading TechniquesCiobanu Constantin-DoruNo ratings yet

- Batangas State UniversityDocument6 pagesBatangas State UniversityEnchanting BerryNo ratings yet

- All About Drill BitsDocument10 pagesAll About Drill BitsjunarNo ratings yet

- Chapter 7Document25 pagesChapter 7Timothy MartinezNo ratings yet

- Mod 7 Book 2 ToolsDocument83 pagesMod 7 Book 2 Toolsranjit prasad100% (1)

- Dead Drop DeviceDocument7 pagesDead Drop DeviceAgino MottoNo ratings yet

- Shop Practice No. 1: Dust PanDocument8 pagesShop Practice No. 1: Dust Pankmds23No ratings yet

- Lamination TrickeryDocument6 pagesLamination TrickeryFlyingrasta100% (1)

- 2886-Stud Fitting & Removal PDFDocument1 page2886-Stud Fitting & Removal PDFsyllavethyjimNo ratings yet

- Cutter Making David CreedDocument19 pagesCutter Making David CreedBruno Delsupexhe100% (1)

- Mapúa University: Shop Exercise No. 1Document15 pagesMapúa University: Shop Exercise No. 1Eriane GarciaNo ratings yet

- ME137L-2 Exercise1Document7 pagesME137L-2 Exercise1Andrew PantaleonNo ratings yet

- YEET22 V2 Manual Updated 2022 12 05Document18 pagesYEET22 V2 Manual Updated 2022 12 05hans landa100% (1)

- Acoustic Guitar PlansDocument7 pagesAcoustic Guitar PlansFrançesko Astroza80% (5)

- 2837-Screws & How To Fit ThemDocument1 page2837-Screws & How To Fit ThemSandra Barnett CrossanNo ratings yet

- Manufacturing Process of StaplerDocument9 pagesManufacturing Process of StaplerThoriq AliNo ratings yet

- Tips For Hollowing End Grain: Wood TurningDocument4 pagesTips For Hollowing End Grain: Wood TurningAdrian Cocis100% (1)

- SE1Document5 pagesSE1AlexisNo ratings yet

- Jewelry Box: Woodworks: Beginner Project 2009-2010Document7 pagesJewelry Box: Woodworks: Beginner Project 2009-2010Sal GNo ratings yet

- Traditional Bookcase: Woodworks: Intermediate ProjectDocument6 pagesTraditional Bookcase: Woodworks: Intermediate ProjectDúctil De La Gran Raza de YithNo ratings yet

- .Au Agnet Make Piston RingsDocument6 pages.Au Agnet Make Piston Ringsashishgoel102No ratings yet

- Nut Bolt Installation PracticesDocument8 pagesNut Bolt Installation PracticesArjun SharmaNo ratings yet

- General DrillingDocument3 pagesGeneral DrillingAndrew GoslingNo ratings yet

- Sheet Metal DesignDocument33 pagesSheet Metal DesignNanda Sagar100% (3)

- Design of DieDocument41 pagesDesign of DieKarthik ACNo ratings yet

- Family Handyman Trade Secrets: Fix Your Home Like a Pro!From EverandFamily Handyman Trade Secrets: Fix Your Home Like a Pro!Rating: 4 out of 5 stars4/5 (1)

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- Elementary Course in Woodwork: Designed for use in high and technical schools, with one hundred and thirty-four illustrations: First EditionFrom EverandElementary Course in Woodwork: Designed for use in high and technical schools, with one hundred and thirty-four illustrations: First EditionNo ratings yet

- Family Handyman Ultimate 1 Day ProjectsFrom EverandFamily Handyman Ultimate 1 Day ProjectsRating: 5 out of 5 stars5/5 (1)

- Elementary Course in Woodwork: Designed for use in high and technical schools, with illustrationsFrom EverandElementary Course in Woodwork: Designed for use in high and technical schools, with illustrationsNo ratings yet

- Cabinet Making for Beginners - Tools, Joints, Cabinet Construction, Veneering and Inlaying, Drawing, Cutting Lists, Etc., Timber, Fittings, Typical DesignsFrom EverandCabinet Making for Beginners - Tools, Joints, Cabinet Construction, Veneering and Inlaying, Drawing, Cutting Lists, Etc., Timber, Fittings, Typical DesignsRating: 5 out of 5 stars5/5 (2)

- 2886-Stud Fitting & Removal PDFDocument1 page2886-Stud Fitting & Removal PDFsyllavethyjimNo ratings yet

- 2888-Oblique Drilling PDFDocument1 page2888-Oblique Drilling PDFsyllavethyjimNo ratings yet

- 2884-Panel Beating PDFDocument1 page2884-Panel Beating PDFsyllavethyjim100% (1)

- 2878-Chains & Sprockets PDFDocument1 page2878-Chains & Sprockets PDFsyllavethyjimNo ratings yet

- Contours 1: Hile It CannotDocument1 pageContours 1: Hile It CannotsyllavethyjimNo ratings yet

- 2873-Cotters & Wedges PDFDocument1 page2873-Cotters & Wedges PDFsyllavethyjimNo ratings yet

- 2877-Roller Chain & Sprockets PDFDocument1 page2877-Roller Chain & Sprockets PDFsyllavethyjimNo ratings yet

- 2864-Poppet Valves & Seating PDFDocument1 page2864-Poppet Valves & Seating PDFsyllavethyjimNo ratings yet

- 2858-How To Use Scrapers PDFDocument1 page2858-How To Use Scrapers PDFsyllavethyjimNo ratings yet

- 2852-Polishing Metal SurfacesDocument1 page2852-Polishing Metal SurfacessyllavethyjimNo ratings yet

- 2847-Keys & Driving PinsDocument1 page2847-Keys & Driving PinssyllavethyjimNo ratings yet

- Temperature Distribution in Concrete Bridges by E C Hambly PDFDocument6 pagesTemperature Distribution in Concrete Bridges by E C Hambly PDFAnonymous dxsNnL6S8hNo ratings yet

- Wax DepositionDocument35 pagesWax DepositionArjit KumarNo ratings yet

- Improvement of A Multiphase Flow Model For Wellhead Chokes Under Critical and Subcritical Conditions Using Field DataDocument17 pagesImprovement of A Multiphase Flow Model For Wellhead Chokes Under Critical and Subcritical Conditions Using Field DataBEHNAM FALLAHNo ratings yet

- HGA CatDocument31 pagesHGA CatPetroMan CMNo ratings yet

- Chapter 16: Reducing Valves: What Is in This Article?Document21 pagesChapter 16: Reducing Valves: What Is in This Article?AmitabhaNo ratings yet

- Kuorma AutohydrauliikkaaDocument40 pagesKuorma AutohydrauliikkaaSAMNo ratings yet

- Are The Voigt Transformations Consistent With Experiments?Document11 pagesAre The Voigt Transformations Consistent With Experiments?pic2007No ratings yet

- Advanced Sgt6-5000F Development: 09-IAGT-202Document18 pagesAdvanced Sgt6-5000F Development: 09-IAGT-202Ronald ChavezNo ratings yet

- Electric Arc Welding: Version 3.0, Last Updated: November 1, 2011 YS, JA, & ZIDocument24 pagesElectric Arc Welding: Version 3.0, Last Updated: November 1, 2011 YS, JA, & ZIErick AlvarezNo ratings yet

- Multipurpose Valves For Liquid Withdrawal of LP-Gas and NH Containers A8017D & A8020DDocument1 pageMultipurpose Valves For Liquid Withdrawal of LP-Gas and NH Containers A8017D & A8020DLPG Equipment Consulting and ServicesNo ratings yet

- NTPC Gas Power PlantDocument32 pagesNTPC Gas Power PlantBlack PantherNo ratings yet

- Helios Uk ElsDocument22 pagesHelios Uk ElssanitermNo ratings yet

- Embedment Design Examples: ACI 349.2R-97Document26 pagesEmbedment Design Examples: ACI 349.2R-97guillermoNo ratings yet

- 25a Tyre Wear ChartDocument3 pages25a Tyre Wear ChartVickyNo ratings yet

- Fluid Mechanics Chapter2Document26 pagesFluid Mechanics Chapter2Ricky MakNo ratings yet

- Goulds Pumps 3175Document15 pagesGoulds Pumps 3175Mohamed KishkNo ratings yet

- Completepartslist 1366885931Document16 pagesCompletepartslist 1366885931joaofavioNo ratings yet

- Quantum Condensed Matter Past PapersDocument3 pagesQuantum Condensed Matter Past PapersChung Chee YuenNo ratings yet

- Designing For Metal 3D PrintingDocument4 pagesDesigning For Metal 3D PrintingthisisjineshNo ratings yet

- Chapter 6Document109 pagesChapter 6gutom alldayNo ratings yet

- Product Overview: in Row & in Rack Cooling SystemsDocument26 pagesProduct Overview: in Row & in Rack Cooling SystemsJose Navarro NavarroNo ratings yet

- TugasDocument18 pagesTugasWicaksana try YudhantoNo ratings yet

- Acs Segmentfolder 2020 en 88183Document20 pagesAcs Segmentfolder 2020 en 88183William Rincon ReyesNo ratings yet

- 6685 PDFDocument2 pages6685 PDFZewduErkyhun100% (2)

- CC 305 / CC 335 / CC 355: Lightweight - Low Noise - PowerfulDocument4 pagesCC 305 / CC 335 / CC 355: Lightweight - Low Noise - PowerfulAnkush khuranaNo ratings yet

- C330 Torque Converter SpecDocument2 pagesC330 Torque Converter SpecTamer Elsebaei EbarhimNo ratings yet

- Practical Exercise: Putting Seawater Cooling System To ServiceDocument1 pagePractical Exercise: Putting Seawater Cooling System To ServiceJohnarey Galve PantuaNo ratings yet

- Activity No. 3 Study of Pump Units - Positive and Non-Positive Displacement IDocument19 pagesActivity No. 3 Study of Pump Units - Positive and Non-Positive Displacement ILeonito Ypon FulgadoNo ratings yet

2853-Simple Drilling Jigs

2853-Simple Drilling Jigs

Uploaded by

syllavethyjimOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2853-Simple Drilling Jigs

2853-Simple Drilling Jigs

Uploaded by

syllavethyjimCopyright:

Available Formats

CUTTING and

FITTING GASKETS

GEOMETER gives some advice on an operation

which is needed in the workshop from ti

in sheets

permits the cutting of various

types of washers and gaskets

which are unobtainable or not to

hand when required. Not so many

years ago, in fact, it was common

practice to do this, except in the

case of car cylinder head joints.

Nowadays, there are gasket sets,

but they do not neccssarily contain

all joints, and on occasion it is

necessary to cut ones own.

Ordinary thick note paper or brown

paper is suitable in many instances,

apart from the available special

materials-toughened papers, fibre,

cork sheeting and-to resist heatasbestos-base sheeting such as Hallite.

OINTING MATERIAL

Holes and perimeters

First thing with sheeting, having

obtained a piece of suitable size, is

to mark the shape of the joint, which

is best done on the component

containing the holes, not on that

with the studs. The material is held

flat on the face, or a piece of board is

placed on top one end. If the material

is thin, pressure of the fingers will

reveal the position of holes, but if

thick so finger pressure is inadequate,

a small hammer is necessary-one

with a flat and a ball end.

On a small joint, all holes and the

perimeter can be marked, and the

sheeting removed for cuttmg. On a

complicated joint, two opposite holes

can be marked, these punched, then

the material located with bolts,

while the remainder of the holes are

marked. Where there is a spigot or

protruding diameter, the sheeting is

marked and cut first to locate on it.

There are various ways of cutting

holes. For small ones? from about

3/32 in:, there is the plier-punch, A,

producing six different sizes. Tubular

punches, B, can be bought in all

standard sizes, or made from steel

pipe or rod-by drilling the centre.

They can be chamfered on a grinding

9 FEBRUARY 1956

wheel to keep sharp. The punching

block can be hardwood on the end

grain, or a lump of cast lead-kept

flat by hammering. In cutting round

washers, the bores must be punched,

then the outsides; if done the other

way, they often split. Large holes can

be cut with the compass-type cutter,

C, this having a blade or sharp disc

set to required radius from a rule.

The material should be on a flat

board, and the spike of the tool well

pressed in.

Subject to there being no damage

to components, holes can be cut in

thin material using the ball end of the

hammer, and outside perimeters with

the flat, D. If the material is thick,

it is depressed at the end, made

ragged or broken, so punching is

advisable.

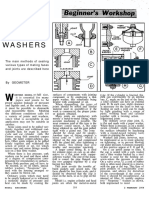

Above: Tools used in cutting gaskets

Below: E and F are typical four-stud

and six-stud joints. G, side valve

motorcycle cylinder head and H, small

car cylinder head

Cutting and securing

The inside perimeter of narrow

joints should be cut first, and often

the outside can be trimmed when the

components are assembled, using a

sharp knife or scraper. Thm material

can be cut with straight and curvedblade scissors, thick mateiial with

flat and half-round wood chisels on

a board or block.

Where dismantling without difficulty

is necessary., joints may be fitted dry

or lightly oiled. If there is the possibility of leakage, jointing compound

should be used, but on manifolds

where there is heat, jointing compound

should not be used. On cylinder head

gaskets, jointing compound is used,

or ordinary grease-this helping the

joint to slip during tightening.

In assembling, it is very important

to employ a suitable order of nut

tightening, and to tighten gradually

which means going over the nuts

in the given order, tightening each a

little at a time until secure.

The general principle is to provide

balanced tightening, or on multistud joints like car cylinder heads to

tighten from the centre outwards. q

225

MODEL

ENGINEER

. r:.

You might also like

- The Table Leg Typewriter (Practical Scrap Metal Small Arms Vol.10)Document37 pagesThe Table Leg Typewriter (Practical Scrap Metal Small Arms Vol.10)xan94% (18)

- IMP Workshop ManualDocument336 pagesIMP Workshop Manualsyllavethyjim67% (3)

- 《桥梁工程Bridge Engineering》设计试卷 (A)Document8 pages《桥梁工程Bridge Engineering》设计试卷 (A)Mashrique AdnanNo ratings yet

- WC5 Parts Fabrication: Author: J. RandleDocument48 pagesWC5 Parts Fabrication: Author: J. RandleCristian Silva100% (1)

- Table Saw JigsDocument16 pagesTable Saw Jigscyclonium100% (9)

- Hydraulic Turbine Classification and SelectionDocument57 pagesHydraulic Turbine Classification and SelectionNarayan ShresthaNo ratings yet

- 149-Workshop Hints & Tips PDFDocument1 page149-Workshop Hints & Tips PDFsyllavethyjimNo ratings yet

- Saw HandleDocument7 pagesSaw Handleانغي رحمنيNo ratings yet

- WC5 Parts Fabrication: Author: J. RandleDocument48 pagesWC5 Parts Fabrication: Author: J. RandleCarlos Gabriel Estergaard100% (1)

- Pocket-Hole PointersDocument9 pagesPocket-Hole PointersLee BannisterNo ratings yet

- Hack SawingDocument15 pagesHack SawingVergara KoyNo ratings yet

- BHManual Fuselage46 79rev1Document34 pagesBHManual Fuselage46 79rev1viorelu99No ratings yet

- Lathe Modelling 2Document2 pagesLathe Modelling 2cesargramcko100% (1)

- Purpose-Built Chucks.: Wooden Pad Glued To WorkpieceDocument2 pagesPurpose-Built Chucks.: Wooden Pad Glued To Workpieceneko222No ratings yet

- Unimat Pages 26-30Document5 pagesUnimat Pages 26-30remendabNo ratings yet

- Make A Wheel Marking GaugeDocument6 pagesMake A Wheel Marking Gaugeserkan ünlü100% (1)

- Foam Core Construction: Tools Tips and TricksDocument12 pagesFoam Core Construction: Tools Tips and TricksRohan KulkarniNo ratings yet

- Hand ProcessesDocument14 pagesHand Processeschandajustin526No ratings yet

- 2 ToolsDocument83 pages2 ToolsKileta KafusiNo ratings yet

- How To Make Your Own Six Yard Bell Target Mechanism: Glossary of TermsDocument24 pagesHow To Make Your Own Six Yard Bell Target Mechanism: Glossary of TermsJose German Ojeda CruzNo ratings yet

- Workshop Equipment: How To Make 12 Woodworking ToolsDocument110 pagesWorkshop Equipment: How To Make 12 Woodworking ToolsSean100% (1)

- Wooden SouthDocument27 pagesWooden Southİbrahim Anıl Balkan100% (1)

- 3184-Piston Patterns & Core BoxesDocument1 page3184-Piston Patterns & Core Boxesmn_9013No ratings yet

- Recoil PadsDocument3 pagesRecoil PadsAnonymous jbeHFUNo ratings yet

- Bensen b8 PDFDocument8 pagesBensen b8 PDFmaxNo ratings yet

- Hand Taps and Proper Threading TechniquesDocument3 pagesHand Taps and Proper Threading TechniquesCiobanu Constantin-DoruNo ratings yet

- Batangas State UniversityDocument6 pagesBatangas State UniversityEnchanting BerryNo ratings yet

- All About Drill BitsDocument10 pagesAll About Drill BitsjunarNo ratings yet

- Chapter 7Document25 pagesChapter 7Timothy MartinezNo ratings yet

- Mod 7 Book 2 ToolsDocument83 pagesMod 7 Book 2 Toolsranjit prasad100% (1)

- Dead Drop DeviceDocument7 pagesDead Drop DeviceAgino MottoNo ratings yet

- Shop Practice No. 1: Dust PanDocument8 pagesShop Practice No. 1: Dust Pankmds23No ratings yet

- Lamination TrickeryDocument6 pagesLamination TrickeryFlyingrasta100% (1)

- 2886-Stud Fitting & Removal PDFDocument1 page2886-Stud Fitting & Removal PDFsyllavethyjimNo ratings yet

- Cutter Making David CreedDocument19 pagesCutter Making David CreedBruno Delsupexhe100% (1)

- Mapúa University: Shop Exercise No. 1Document15 pagesMapúa University: Shop Exercise No. 1Eriane GarciaNo ratings yet

- ME137L-2 Exercise1Document7 pagesME137L-2 Exercise1Andrew PantaleonNo ratings yet

- YEET22 V2 Manual Updated 2022 12 05Document18 pagesYEET22 V2 Manual Updated 2022 12 05hans landa100% (1)

- Acoustic Guitar PlansDocument7 pagesAcoustic Guitar PlansFrançesko Astroza80% (5)

- 2837-Screws & How To Fit ThemDocument1 page2837-Screws & How To Fit ThemSandra Barnett CrossanNo ratings yet

- Manufacturing Process of StaplerDocument9 pagesManufacturing Process of StaplerThoriq AliNo ratings yet

- Tips For Hollowing End Grain: Wood TurningDocument4 pagesTips For Hollowing End Grain: Wood TurningAdrian Cocis100% (1)

- SE1Document5 pagesSE1AlexisNo ratings yet

- Jewelry Box: Woodworks: Beginner Project 2009-2010Document7 pagesJewelry Box: Woodworks: Beginner Project 2009-2010Sal GNo ratings yet

- Traditional Bookcase: Woodworks: Intermediate ProjectDocument6 pagesTraditional Bookcase: Woodworks: Intermediate ProjectDúctil De La Gran Raza de YithNo ratings yet

- .Au Agnet Make Piston RingsDocument6 pages.Au Agnet Make Piston Ringsashishgoel102No ratings yet

- Nut Bolt Installation PracticesDocument8 pagesNut Bolt Installation PracticesArjun SharmaNo ratings yet

- General DrillingDocument3 pagesGeneral DrillingAndrew GoslingNo ratings yet

- Sheet Metal DesignDocument33 pagesSheet Metal DesignNanda Sagar100% (3)

- Design of DieDocument41 pagesDesign of DieKarthik ACNo ratings yet

- Family Handyman Trade Secrets: Fix Your Home Like a Pro!From EverandFamily Handyman Trade Secrets: Fix Your Home Like a Pro!Rating: 4 out of 5 stars4/5 (1)

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- Elementary Course in Woodwork: Designed for use in high and technical schools, with one hundred and thirty-four illustrations: First EditionFrom EverandElementary Course in Woodwork: Designed for use in high and technical schools, with one hundred and thirty-four illustrations: First EditionNo ratings yet

- Family Handyman Ultimate 1 Day ProjectsFrom EverandFamily Handyman Ultimate 1 Day ProjectsRating: 5 out of 5 stars5/5 (1)

- Elementary Course in Woodwork: Designed for use in high and technical schools, with illustrationsFrom EverandElementary Course in Woodwork: Designed for use in high and technical schools, with illustrationsNo ratings yet

- Cabinet Making for Beginners - Tools, Joints, Cabinet Construction, Veneering and Inlaying, Drawing, Cutting Lists, Etc., Timber, Fittings, Typical DesignsFrom EverandCabinet Making for Beginners - Tools, Joints, Cabinet Construction, Veneering and Inlaying, Drawing, Cutting Lists, Etc., Timber, Fittings, Typical DesignsRating: 5 out of 5 stars5/5 (2)

- 2886-Stud Fitting & Removal PDFDocument1 page2886-Stud Fitting & Removal PDFsyllavethyjimNo ratings yet

- 2888-Oblique Drilling PDFDocument1 page2888-Oblique Drilling PDFsyllavethyjimNo ratings yet

- 2884-Panel Beating PDFDocument1 page2884-Panel Beating PDFsyllavethyjim100% (1)

- 2878-Chains & Sprockets PDFDocument1 page2878-Chains & Sprockets PDFsyllavethyjimNo ratings yet

- Contours 1: Hile It CannotDocument1 pageContours 1: Hile It CannotsyllavethyjimNo ratings yet

- 2873-Cotters & Wedges PDFDocument1 page2873-Cotters & Wedges PDFsyllavethyjimNo ratings yet

- 2877-Roller Chain & Sprockets PDFDocument1 page2877-Roller Chain & Sprockets PDFsyllavethyjimNo ratings yet

- 2864-Poppet Valves & Seating PDFDocument1 page2864-Poppet Valves & Seating PDFsyllavethyjimNo ratings yet

- 2858-How To Use Scrapers PDFDocument1 page2858-How To Use Scrapers PDFsyllavethyjimNo ratings yet

- 2852-Polishing Metal SurfacesDocument1 page2852-Polishing Metal SurfacessyllavethyjimNo ratings yet

- 2847-Keys & Driving PinsDocument1 page2847-Keys & Driving PinssyllavethyjimNo ratings yet

- Temperature Distribution in Concrete Bridges by E C Hambly PDFDocument6 pagesTemperature Distribution in Concrete Bridges by E C Hambly PDFAnonymous dxsNnL6S8hNo ratings yet

- Wax DepositionDocument35 pagesWax DepositionArjit KumarNo ratings yet

- Improvement of A Multiphase Flow Model For Wellhead Chokes Under Critical and Subcritical Conditions Using Field DataDocument17 pagesImprovement of A Multiphase Flow Model For Wellhead Chokes Under Critical and Subcritical Conditions Using Field DataBEHNAM FALLAHNo ratings yet

- HGA CatDocument31 pagesHGA CatPetroMan CMNo ratings yet

- Chapter 16: Reducing Valves: What Is in This Article?Document21 pagesChapter 16: Reducing Valves: What Is in This Article?AmitabhaNo ratings yet

- Kuorma AutohydrauliikkaaDocument40 pagesKuorma AutohydrauliikkaaSAMNo ratings yet

- Are The Voigt Transformations Consistent With Experiments?Document11 pagesAre The Voigt Transformations Consistent With Experiments?pic2007No ratings yet

- Advanced Sgt6-5000F Development: 09-IAGT-202Document18 pagesAdvanced Sgt6-5000F Development: 09-IAGT-202Ronald ChavezNo ratings yet

- Electric Arc Welding: Version 3.0, Last Updated: November 1, 2011 YS, JA, & ZIDocument24 pagesElectric Arc Welding: Version 3.0, Last Updated: November 1, 2011 YS, JA, & ZIErick AlvarezNo ratings yet

- Multipurpose Valves For Liquid Withdrawal of LP-Gas and NH Containers A8017D & A8020DDocument1 pageMultipurpose Valves For Liquid Withdrawal of LP-Gas and NH Containers A8017D & A8020DLPG Equipment Consulting and ServicesNo ratings yet

- NTPC Gas Power PlantDocument32 pagesNTPC Gas Power PlantBlack PantherNo ratings yet

- Helios Uk ElsDocument22 pagesHelios Uk ElssanitermNo ratings yet

- Embedment Design Examples: ACI 349.2R-97Document26 pagesEmbedment Design Examples: ACI 349.2R-97guillermoNo ratings yet

- 25a Tyre Wear ChartDocument3 pages25a Tyre Wear ChartVickyNo ratings yet

- Fluid Mechanics Chapter2Document26 pagesFluid Mechanics Chapter2Ricky MakNo ratings yet

- Goulds Pumps 3175Document15 pagesGoulds Pumps 3175Mohamed KishkNo ratings yet

- Completepartslist 1366885931Document16 pagesCompletepartslist 1366885931joaofavioNo ratings yet

- Quantum Condensed Matter Past PapersDocument3 pagesQuantum Condensed Matter Past PapersChung Chee YuenNo ratings yet

- Designing For Metal 3D PrintingDocument4 pagesDesigning For Metal 3D PrintingthisisjineshNo ratings yet

- Chapter 6Document109 pagesChapter 6gutom alldayNo ratings yet

- Product Overview: in Row & in Rack Cooling SystemsDocument26 pagesProduct Overview: in Row & in Rack Cooling SystemsJose Navarro NavarroNo ratings yet

- TugasDocument18 pagesTugasWicaksana try YudhantoNo ratings yet

- Acs Segmentfolder 2020 en 88183Document20 pagesAcs Segmentfolder 2020 en 88183William Rincon ReyesNo ratings yet

- 6685 PDFDocument2 pages6685 PDFZewduErkyhun100% (2)

- CC 305 / CC 335 / CC 355: Lightweight - Low Noise - PowerfulDocument4 pagesCC 305 / CC 335 / CC 355: Lightweight - Low Noise - PowerfulAnkush khuranaNo ratings yet

- C330 Torque Converter SpecDocument2 pagesC330 Torque Converter SpecTamer Elsebaei EbarhimNo ratings yet

- Practical Exercise: Putting Seawater Cooling System To ServiceDocument1 pagePractical Exercise: Putting Seawater Cooling System To ServiceJohnarey Galve PantuaNo ratings yet

- Activity No. 3 Study of Pump Units - Positive and Non-Positive Displacement IDocument19 pagesActivity No. 3 Study of Pump Units - Positive and Non-Positive Displacement ILeonito Ypon FulgadoNo ratings yet