Professional Documents

Culture Documents

PM Day 2 June 2016

PM Day 2 June 2016

Uploaded by

Andreas SetiawanCopyright:

Available Formats

You might also like

- Ethical Hacking AgreementDocument4 pagesEthical Hacking AgreementVijay Sundar0% (2)

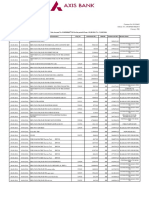

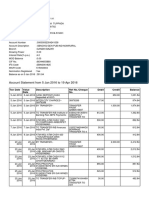

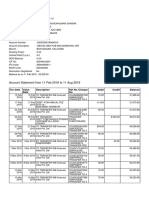

- AGICL Axis Bank Statement Aug 2016 PDFDocument7 pagesAGICL Axis Bank Statement Aug 2016 PDFSagar Asati100% (1)

- Transformers Companies ListDocument6 pagesTransformers Companies ListnehaNo ratings yet

- Attachments-Ordinary Council Meeting 17 May-2021Document259 pagesAttachments-Ordinary Council Meeting 17 May-2021Oliver TNo ratings yet

- ReportDocument19 pagesReportAbhinav BhardwajNo ratings yet

- Network Provider: BBNLONT Report For Zone SOUTH ZONEDocument12 pagesNetwork Provider: BBNLONT Report For Zone SOUTH ZONEZaheerAhmedAhmedNo ratings yet

- Listado de CorrectivosDocument13 pagesListado de CorrectivosJulio TapiaNo ratings yet

- Switch OverDocument22 pagesSwitch OverCatherine RyanNo ratings yet

- Material On Site: Pembangunan Pipa Transmisi Intake Ke WTP Waduk Paya Seunara Di Kota Sabang Lokasi: Kota SabangDocument2 pagesMaterial On Site: Pembangunan Pipa Transmisi Intake Ke WTP Waduk Paya Seunara Di Kota Sabang Lokasi: Kota SabangMuhammad FauzanNo ratings yet

- HDFC BB Upto29042016Document98 pagesHDFC BB Upto29042016Sridhar GandikotaNo ratings yet

- HP PumpDocument90 pagesHP PumpInsannulNo ratings yet

- Av LWClih QOo ZN N5 WDocument6 pagesAv LWClih QOo ZN N5 WSowjanya MulakaluriNo ratings yet

- 2016 OldDocument44 pages2016 OldPradipta Kumar MohantyNo ratings yet

- Status - Berkas Alasan - BLM - Terima Do - Nomor Do - TGLDocument6 pagesStatus - Berkas Alasan - BLM - Terima Do - Nomor Do - TGLnana supriyatnaNo ratings yet

- Report List - Gap Analysis - Status - DBDocument146 pagesReport List - Gap Analysis - Status - DBvaraNo ratings yet

- Stock Ragister-ELECTRICALDocument71 pagesStock Ragister-ELECTRICALMAZHAR ALINo ratings yet

- CRANE SewaDocument55 pagesCRANE SewaYa ZidNo ratings yet

- 29Th FebDocument10 pages29Th FebMangeshRudrawarNo ratings yet

- New Calibration DataDocument23 pagesNew Calibration DataAnkurNo ratings yet

- Record Do SampleDocument23 pagesRecord Do Samplemawar putihNo ratings yet

- Bank Statement - 0ct To March17 PDFDocument4 pagesBank Statement - 0ct To March17 PDFasphak ansariNo ratings yet

- Laporan PN SC 2018Document127 pagesLaporan PN SC 2018Bismi Fajaria DestiantiNo ratings yet

- Name of Work: No. DB/Tender 6/15-16 Date: 16/01/2016 District Panchayat, Kottayam Notice Inviting E-TenderDocument8 pagesName of Work: No. DB/Tender 6/15-16 Date: 16/01/2016 District Panchayat, Kottayam Notice Inviting E-Tenderanu_hkumarNo ratings yet

- REPORTING PERIOD (15th February To 15th March 2016) : Field Density Test (FDT)Document11 pagesREPORTING PERIOD (15th February To 15th March 2016) : Field Density Test (FDT)Red FolderNo ratings yet

- Date Company Name1 Contact NumberDocument5 pagesDate Company Name1 Contact NumberMangeshRudrawarNo ratings yet

- Clase4 - San Lorenzo EBDocument84 pagesClase4 - San Lorenzo EBnicoNo ratings yet

- Nomor SK ApkDocument4 pagesNomor SK ApkAgunk ArtNo ratings yet

- 6th Feb MDocument22 pages6th Feb MMangeshRudrawarNo ratings yet

- F6 NJG 2 Sixm Eig 77 TDocument5 pagesF6 NJG 2 Sixm Eig 77 TSandeep SharmaNo ratings yet

- Asistencia Operativa Semanal: A N G E LDocument108 pagesAsistencia Operativa Semanal: A N G E LJHAKELIN VICTORIA ALENDEZ LOAIZANo ratings yet

- Tlla DekDocument20 pagesTlla DekJeegar RojasaraNo ratings yet

- Waktu Ganti Ban No. Kupon No. PolisiDocument2 pagesWaktu Ganti Ban No. Kupon No. PolisiFarfis 22No ratings yet

- Contacto Ciudadano 31AGO2023Document18 pagesContacto Ciudadano 31AGO2023eugeniosalas221210No ratings yet

- Chaitanya Bharathi Institute of Technology Training and Placement Cell Placements 2013-14 BatchDocument8 pagesChaitanya Bharathi Institute of Technology Training and Placement Cell Placements 2013-14 BatchAnvesh AnuNo ratings yet

- Modern Construction and Cleaning Services Pte .LTD - Timesheet FormDocument2 pagesModern Construction and Cleaning Services Pte .LTD - Timesheet FormtilamisuNo ratings yet

- Realisasi Produksi Project 33 Kereta Bagasi: PT. Industri Kereta Api (PerseroDocument3 pagesRealisasi Produksi Project 33 Kereta Bagasi: PT. Industri Kereta Api (PerseroMangBedjoNo ratings yet

- Po 2016Document27 pagesPo 2016AdeImanudinNo ratings yet

- GabonDocument15 pagesGabonnshefeekNo ratings yet

- Arabian Fal Holding Approval To Receive The Rpo Contract # 6600026589Document8 pagesArabian Fal Holding Approval To Receive The Rpo Contract # 6600026589Shams TabrezNo ratings yet

- D, Duty Sept OctDocument405 pagesD, Duty Sept OctAnonymous l5D7kSlRrNo ratings yet

- June 2023 Local Tour Format UpdatedDocument6 pagesJune 2023 Local Tour Format UpdatedVishal PaswanNo ratings yet

- Yard Inventory Updated 20.2.13Document8 pagesYard Inventory Updated 20.2.13Syahir IsmailNo ratings yet

- Absen Campur BengkelDocument6 pagesAbsen Campur BengkelM IqbalNo ratings yet

- Daily Manpower in - Out StatusDocument2 pagesDaily Manpower in - Out StatusEnamul HaqueNo ratings yet

- Laporan Bulanan MH + K3 SeptemberDocument6 pagesLaporan Bulanan MH + K3 SeptemberNizar FatchurrochmanNo ratings yet

- Laporan Kegiatan Kia KB 01052023-043059Document26 pagesLaporan Kegiatan Kia KB 01052023-043059pkm pelindung hewanNo ratings yet

- BBH - Report - 4 JAN-15Document56 pagesBBH - Report - 4 JAN-15Raju SutradharNo ratings yet

- Date Integrity Cell Availabilty 3G (%)Document9 pagesDate Integrity Cell Availabilty 3G (%)telecomNo ratings yet

- Formulir LHRDocument13 pagesFormulir LHREdi SupriyonoNo ratings yet

- Activity Report For June 2020 - Pravin AwalkondeDocument6 pagesActivity Report For June 2020 - Pravin AwalkondePravin AwalkondeNo ratings yet

- Sureshkumar TN 5Document32 pagesSureshkumar TN 5PrashanthNo ratings yet

- Geotechnical Investigation Proposed Mixed-Use Development 484 - 490 Plains Road East, Burlington, OntarioDocument52 pagesGeotechnical Investigation Proposed Mixed-Use Development 484 - 490 Plains Road East, Burlington, OntarioKhalil FanousNo ratings yet

- Calibration Maintenence AbstractDocument5 pagesCalibration Maintenence AbstractSundara NayakanNo ratings yet

- PT Diletto Julio 2016Document568 pagesPT Diletto Julio 2016yanpNo ratings yet

- Form Inspeksi (1-33)Document6 pagesForm Inspeksi (1-33)Juli adiSHENo ratings yet

- Fastrust ServicesDocument2 pagesFastrust ServicesPeralta Cabil VinzNo ratings yet

- Stock Ragister-FIRE FIGHTINGDocument70 pagesStock Ragister-FIRE FIGHTINGMAZHAR ALINo ratings yet

- Draft: Restoration of Landslide Jhika Gali, Murree Completion of ProjectDocument2 pagesDraft: Restoration of Landslide Jhika Gali, Murree Completion of ProjectMudassar KhanNo ratings yet

- GabonIncident BasedRNADocument29 pagesGabonIncident BasedRNAnshefeekNo ratings yet

- No EMR. Number Model Branch Customer SN Code Unit Delivery Date Trouble DateDocument5 pagesNo EMR. Number Model Branch Customer SN Code Unit Delivery Date Trouble Datenuraida hakikiNo ratings yet

- Gulf County Sheriff's Office Law Enforcement Weekly SummaryDocument3 pagesGulf County Sheriff's Office Law Enforcement Weekly SummaryMichael AllenNo ratings yet

- Course Module Course Unit Week: Bachelor of Science in Nursing NCMB 311 (Nursing Research 1)Document8 pagesCourse Module Course Unit Week: Bachelor of Science in Nursing NCMB 311 (Nursing Research 1)Jordz PlaciNo ratings yet

- Performance Management Form Planning and Evaluation Form: Partially MetDocument2 pagesPerformance Management Form Planning and Evaluation Form: Partially MetSeth BautistaNo ratings yet

- Indian Coal AnalysisDocument3 pagesIndian Coal AnalysisK.S.MAYILVAGHANAN100% (1)

- Definitive Guide To Security Awareness SuccessDocument19 pagesDefinitive Guide To Security Awareness SuccessRicardo RodríguezNo ratings yet

- Oil-Degassing:: 1-SeparationDocument34 pagesOil-Degassing:: 1-SeparationAhmed AbdullaNo ratings yet

- Chemical Applications of Group TheoryDocument468 pagesChemical Applications of Group TheoryBrunoRamosdeLima80% (5)

- The Structure of The Long BoneDocument3 pagesThe Structure of The Long BonesharneNo ratings yet

- Nist Fips 201-2Document87 pagesNist Fips 201-2Mohammad Reza NazariNo ratings yet

- Etching of CarbidesDocument6 pagesEtching of CarbidesSmilindNo ratings yet

- Steps of Transportation and AssignmentDocument16 pagesSteps of Transportation and AssignmentSubir ChakrabartyNo ratings yet

- Subject Availability - IalDocument11 pagesSubject Availability - IalDaianna PeirisNo ratings yet

- Icn ApiDocument172 pagesIcn ApiNaveen SemwalNo ratings yet

- CMF and CRF Series: Addressable Control and Relay ModulesDocument4 pagesCMF and CRF Series: Addressable Control and Relay ModulesZaira LorenaNo ratings yet

- My Adorable Girlfriend (Shouxing Laogong Ye Ye Liao) - 1ST KISS MANGADocument1 pageMy Adorable Girlfriend (Shouxing Laogong Ye Ye Liao) - 1ST KISS MANGACyreen TomammanNo ratings yet

- Validation and Dissoiution Enhacement of Loratadine and Desloratadine Tablets by Various Spctrophotometric MethodsDocument40 pagesValidation and Dissoiution Enhacement of Loratadine and Desloratadine Tablets by Various Spctrophotometric MethodsDr. Vishal BabarNo ratings yet

- Volume 69 PDFDocument84 pagesVolume 69 PDFShobit Sharma100% (3)

- Bathroom Suites by Ideal Standard - International Brochure 2011Document94 pagesBathroom Suites by Ideal Standard - International Brochure 2011BathroomsNINo ratings yet

- TLS and DTLS (Notes Materials) : Mr. S P Maniraj Dr. S Suresh Mr. M PrabuDocument14 pagesTLS and DTLS (Notes Materials) : Mr. S P Maniraj Dr. S Suresh Mr. M PrabuSuresh SNo ratings yet

- Evaluation of First Seizure and Newly Diagnosed.4Document31 pagesEvaluation of First Seizure and Newly Diagnosed.4veerraju tvNo ratings yet

- Welfare Economics and Public FinanceDocument5 pagesWelfare Economics and Public FinanceVedastus Timothy100% (1)

- Chapter 5,6 Regression AnalysisDocument44 pagesChapter 5,6 Regression AnalysisSumeshNo ratings yet

- Legal Hurdle in Gaming PaymentDocument9 pagesLegal Hurdle in Gaming Paymentanurag kumarNo ratings yet

- Interpreting Self-Directed Search Profiles: Validity of The "Rule of Eight"Document6 pagesInterpreting Self-Directed Search Profiles: Validity of The "Rule of Eight"AAYUSHI PARMARNo ratings yet

- Awaring Presentation On Ethiopian Standards ES 3961 2 June 2017Document36 pagesAwaring Presentation On Ethiopian Standards ES 3961 2 June 2017berekajimma100% (4)

- Acknowledgement AbstractDocument6 pagesAcknowledgement AbstractNarendra ReddyNo ratings yet

- APPLICATION SECURITY ASSESSMENT - Draft - Ver01Document42 pagesAPPLICATION SECURITY ASSESSMENT - Draft - Ver01An LeNo ratings yet

- ExcelAssignment1 21062022Document10 pagesExcelAssignment1 21062022Neeraj PatelNo ratings yet

PM Day 2 June 2016

PM Day 2 June 2016

Uploaded by

Andreas SetiawanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PM Day 2 June 2016

PM Day 2 June 2016

Uploaded by

Andreas SetiawanCopyright:

Available Formats

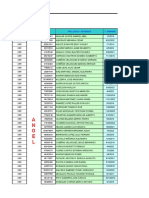

Date

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

Name

Scope

AgusAliy

Andre

Andre

Andre

Anto

Anto

Anto

Anto

Anto

Anto

Anto

Anto

Anto

Anto

Anto

Anto

Aris

Aris

Area 3

TP

TP

Area 3

TL

TL

TL

TL

TL

TL

TL

TL

TL

TL

TL

TL

Area 2

Area 2

Aris

Area 2

Aris

Aris

Aris

Asep

Area 2

Area 2

Area 3

Asep

Area 3

Asep

Asep

Asep

Area 3

Area 3

Area 3

Asep

Area 3

Dayat

PCIS

Diesa

Area 3

Diesa

EAO3

Diesa,Agus

Area 3

Problem Statement

action

45 degree bar contami

RCO

Tucker plate Bearing BD

Turner head headplay big

5S

TBM

TBM

TBM

TBM

TBM

TBM

TBM

TBM

TBM

TBM

TBM

CIL

RTT

ABH#2135. There is leakage sound from

Manipulator

Hilangkan contami yang nyumbat|

Plan untuk SWAT team qualification

cek bearing movement use dial gage

replace #5|

Team Leader Organisir Team untuk 5S sebelum line start setelah pitstop

L71 Tummy Lamination Gun Filter replace

L71 Tummy/E Glue GunFilter replace

L71 W/E FR DR GunFilter TBM

L71 W/E Back OP GunFilter TBM

L71 W/E Back OP Nozzle Replacement

L71 W/E FR DR Nozzle Replacement

L71 Pump3 AQL & Patch Tank Filter TBM

L71 Chassis Bead DR GunFilter TBM

L71 B/S Lami Glue GunFilter replace

TE solenoid replace (dari tummy buttock kebelakang udah, ke OS nya belum)

B/S lam nozzle replace

NWBS & Cuff splicer box cleaning: cover box, knife, anvil, rail cylinder, nip

RTT MONTHLY/WEEKLY CPE on your area (input Proficy + record CPE Book)

Find source of leakage, if there is hole => measure the dimension/diameter, if there is

leakage hose => plan to replace hose

ABH#2188. Cipratan glue dibawah Tank 751

ABH#2228 bolt 3Roll Coupling

ABH#2298 oiler roll lower 3Roll

RLS

Bersihkan

install bolt|

replace oiler roll|

put back seamer number to original position, match with padcode

TBM

RTT

TBM

TBM

ABH#2333 Idler diatas combining roll DLP

contami

1. Check breakout elastic sensor tension

offset

ABH#2255. Glue buttock elastic patternya

tipis/keluaran gluenya tipis

seamer hot airflow meter

FK all compliance roll inspection (any damaged roll or not) -prepare spare (Andre)

RTT MONTHLY/WEEKLY CPE on your area (input Proficy + record CPE Book)

L71 Belt Slitter Anvil TBM|

L71 Belt Slitter Blade TBM|

Duration (mins)

Result, Comment, and Critique

10

10

tanya asep

10

10

10

done

online/offline

online

online

online

online

online

online

online

online

online

online

online

online

online

online

online

online

online

online

Online

offline

online

online

online

5

30

online

online

online

online

10

Cleaning

online

1. Check breakout elastic sensor tension offset|

online

Cek apakah berpengaruh terhadap quality, decide need to replace soon or later?

ganti regulator. |

cek centering web area 2|

replace nozzle

tanya cara kalibrasi ke dayat (site lain)

Offline

online

melihat data webguide (Kavin)

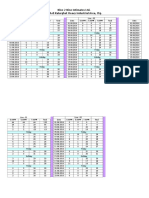

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

02/06/2016

Endang

Fikri

Area 1

Fikri

Area 1

Fikri

Fikri

Mina

Mina

Navrita

Navrita

Navrita

Navrita

Navrita

Area 1

Area 1

Area 4

Area 4

EAO4

EAO4

EAO4

EAO4

EAO4

Navrita, Mina

Area 4

Navrita, Mina

Navrita, Mina

Navrita, Mina

Navrita, Mina

Area 3

Ramanda

Area 2

Ramanda

Area 1

02/06/2016

02/06/2016

Ramanda

Area 4

Ramanda

Area 4

02/06/2016

02/06/2016

02/06/2016

02/06/2016

Rizky

Area 1

Udha

Yan

Yan

PCIS

Area 3

Area 3

02/06/2016

02/06/2016

02/06/2016

02/06/2016

Yan

Area 3

Yan

Yan

Yan

Area 3

Area 3

Area 3

YAN

SPL

02/06/2016

02/06/2016

02/06/2016

02/06/2016

bikin VC dengan gravier (ukiran) dan ditambahkan warna spidol

cek record perubahan guider offset

kenapa lotion omega roll dibuat miring dengan shim??? --> cek actual angle

chassis missing karena web ga center antara

area 2 dan 3

ABH#2328. MSDS Panel DLP Slek

ABH#2081. Oil spillage under PK

ABH#2264. Ada kebocoran di sambungan

gauge Filter Blow Off Receiver 009 di AGM

receiver

TBM

RTT

prevent seam weak

RTT

CIL

2. Fix guard door RP

3. Quick release Bag brush slack

4. Quick release SAD O/S slack

5. Lamp on S-Shape

ABH#2149. Mounting spool collector NG,

missing bolt

ABH#2356. Bolt bracket Side Folder

additional OS/DS slack

pakai laser sebagai VC

Check, decide need replace or can fix

Check source of oil leakage/Check all possibility that causing this leakage

online

online

online

Find source of leakage, close it properly

Cleaning tensioner calender lower

RTT MONTHLY/WEEKLY CPE on your area (input Proficy + record CPE Book)

tracking every 4HRS for seam strength (input to proficy)

RTT MONTHLY/WEEKLY CPE on your area (input Proficy + record CPE Book)

Wicket OS inspection: chain

2. Fix guard door RP |

3. Quick release Bag brush slack |

4. Quick release SAD O/S slack|

5. Lamp on S-Shape|

Check actual condition, if just missing bolt, put new one, if bend or broke, please do the

best to repair

online

online

online

online

online

online

online

online

online

online

20

10

~

10

15

online

Replace

offline

ABH#2357. Bolt OS bag Assist additional slack Replace

ABH#2358. MC Bolt slack

Replace

offline

offline

ABH#2256. Bolt of Bar Conveyor many defect Replace bolt with new one

ABH#2298. Oiler roll lower 3 roll jelek

ABH#2229. Pintu DLP seret kalau dibuka

ABH#2137. Missing front cover for OS/OS

Case Sealer Conveyor

ABH#2036. OHP DS thread hole worn out

online

replace oiler roll\offline

Cek which engsel yang bikin seret, kasih pelumas

Jika dallam 2 minggu masih seret, need to bongkar engsel|

Make new one

Drill new hole, insert helicoil

Check condition of rusty, how big for line performance

ABH#1502. Rusty mark in DLP feed wedge

Decide need special clean or not? When?

2. Replace horn in ADP

2. Replace horn in ADP|

chassis conv belt issue

cleaning inside vacuum chamber|

ABH#2140. Combining Roll contami

Replace

Cek apakah gauge masih berfungsi? Cek apakah jarum menunjukkan nilai pressure yang

ABH#2310. CtB Gauge showing wrong value benar (sesuai GCL)? Konsul ke EAO need to adjust or not?

TBM

L71 Elastic Combinig Drum TBM|

TBM

L71 Folding Board Waist inspection|

TBM

L71 DT C/S Anvil OilerRoll Felt Replacement |

ABH#1343. Lube bank Area 1 & 2 banyak

yang gak bisa dipompa

SHA for lubrication system in Area 1 & Area 2|

Task

Glue related replacement

Conv Belt replace / adjust

DT blade repalce/adjust/phasing

seamer unit replacement

Offline activity

Watchout

check pressure ketika glue purging

pastikan vacuum hidup ketika single axis

special tucker infeed: cek selama 3hari ke depan untuk tension dijaga di target

cek ulang phasing (anvil, oiler, blade)

hati-hati part yang mudah bertabrakan, instal terakhir setelah unit terpasang

cek ulang vaccum sebelum running

feedback to EO (done)

replace oiler tgl 2jun

offline

cek lagi tanggal 2

online

offline

online

Done?

need shutdown

Online

online

online

online

gage nya rusak harus diganti

Online

online

online

online

area 2done, area 1 belum

online

You might also like

- Ethical Hacking AgreementDocument4 pagesEthical Hacking AgreementVijay Sundar0% (2)

- AGICL Axis Bank Statement Aug 2016 PDFDocument7 pagesAGICL Axis Bank Statement Aug 2016 PDFSagar Asati100% (1)

- Transformers Companies ListDocument6 pagesTransformers Companies ListnehaNo ratings yet

- Attachments-Ordinary Council Meeting 17 May-2021Document259 pagesAttachments-Ordinary Council Meeting 17 May-2021Oliver TNo ratings yet

- ReportDocument19 pagesReportAbhinav BhardwajNo ratings yet

- Network Provider: BBNLONT Report For Zone SOUTH ZONEDocument12 pagesNetwork Provider: BBNLONT Report For Zone SOUTH ZONEZaheerAhmedAhmedNo ratings yet

- Listado de CorrectivosDocument13 pagesListado de CorrectivosJulio TapiaNo ratings yet

- Switch OverDocument22 pagesSwitch OverCatherine RyanNo ratings yet

- Material On Site: Pembangunan Pipa Transmisi Intake Ke WTP Waduk Paya Seunara Di Kota Sabang Lokasi: Kota SabangDocument2 pagesMaterial On Site: Pembangunan Pipa Transmisi Intake Ke WTP Waduk Paya Seunara Di Kota Sabang Lokasi: Kota SabangMuhammad FauzanNo ratings yet

- HDFC BB Upto29042016Document98 pagesHDFC BB Upto29042016Sridhar GandikotaNo ratings yet

- HP PumpDocument90 pagesHP PumpInsannulNo ratings yet

- Av LWClih QOo ZN N5 WDocument6 pagesAv LWClih QOo ZN N5 WSowjanya MulakaluriNo ratings yet

- 2016 OldDocument44 pages2016 OldPradipta Kumar MohantyNo ratings yet

- Status - Berkas Alasan - BLM - Terima Do - Nomor Do - TGLDocument6 pagesStatus - Berkas Alasan - BLM - Terima Do - Nomor Do - TGLnana supriyatnaNo ratings yet

- Report List - Gap Analysis - Status - DBDocument146 pagesReport List - Gap Analysis - Status - DBvaraNo ratings yet

- Stock Ragister-ELECTRICALDocument71 pagesStock Ragister-ELECTRICALMAZHAR ALINo ratings yet

- CRANE SewaDocument55 pagesCRANE SewaYa ZidNo ratings yet

- 29Th FebDocument10 pages29Th FebMangeshRudrawarNo ratings yet

- New Calibration DataDocument23 pagesNew Calibration DataAnkurNo ratings yet

- Record Do SampleDocument23 pagesRecord Do Samplemawar putihNo ratings yet

- Bank Statement - 0ct To March17 PDFDocument4 pagesBank Statement - 0ct To March17 PDFasphak ansariNo ratings yet

- Laporan PN SC 2018Document127 pagesLaporan PN SC 2018Bismi Fajaria DestiantiNo ratings yet

- Name of Work: No. DB/Tender 6/15-16 Date: 16/01/2016 District Panchayat, Kottayam Notice Inviting E-TenderDocument8 pagesName of Work: No. DB/Tender 6/15-16 Date: 16/01/2016 District Panchayat, Kottayam Notice Inviting E-Tenderanu_hkumarNo ratings yet

- REPORTING PERIOD (15th February To 15th March 2016) : Field Density Test (FDT)Document11 pagesREPORTING PERIOD (15th February To 15th March 2016) : Field Density Test (FDT)Red FolderNo ratings yet

- Date Company Name1 Contact NumberDocument5 pagesDate Company Name1 Contact NumberMangeshRudrawarNo ratings yet

- Clase4 - San Lorenzo EBDocument84 pagesClase4 - San Lorenzo EBnicoNo ratings yet

- Nomor SK ApkDocument4 pagesNomor SK ApkAgunk ArtNo ratings yet

- 6th Feb MDocument22 pages6th Feb MMangeshRudrawarNo ratings yet

- F6 NJG 2 Sixm Eig 77 TDocument5 pagesF6 NJG 2 Sixm Eig 77 TSandeep SharmaNo ratings yet

- Asistencia Operativa Semanal: A N G E LDocument108 pagesAsistencia Operativa Semanal: A N G E LJHAKELIN VICTORIA ALENDEZ LOAIZANo ratings yet

- Tlla DekDocument20 pagesTlla DekJeegar RojasaraNo ratings yet

- Waktu Ganti Ban No. Kupon No. PolisiDocument2 pagesWaktu Ganti Ban No. Kupon No. PolisiFarfis 22No ratings yet

- Contacto Ciudadano 31AGO2023Document18 pagesContacto Ciudadano 31AGO2023eugeniosalas221210No ratings yet

- Chaitanya Bharathi Institute of Technology Training and Placement Cell Placements 2013-14 BatchDocument8 pagesChaitanya Bharathi Institute of Technology Training and Placement Cell Placements 2013-14 BatchAnvesh AnuNo ratings yet

- Modern Construction and Cleaning Services Pte .LTD - Timesheet FormDocument2 pagesModern Construction and Cleaning Services Pte .LTD - Timesheet FormtilamisuNo ratings yet

- Realisasi Produksi Project 33 Kereta Bagasi: PT. Industri Kereta Api (PerseroDocument3 pagesRealisasi Produksi Project 33 Kereta Bagasi: PT. Industri Kereta Api (PerseroMangBedjoNo ratings yet

- Po 2016Document27 pagesPo 2016AdeImanudinNo ratings yet

- GabonDocument15 pagesGabonnshefeekNo ratings yet

- Arabian Fal Holding Approval To Receive The Rpo Contract # 6600026589Document8 pagesArabian Fal Holding Approval To Receive The Rpo Contract # 6600026589Shams TabrezNo ratings yet

- D, Duty Sept OctDocument405 pagesD, Duty Sept OctAnonymous l5D7kSlRrNo ratings yet

- June 2023 Local Tour Format UpdatedDocument6 pagesJune 2023 Local Tour Format UpdatedVishal PaswanNo ratings yet

- Yard Inventory Updated 20.2.13Document8 pagesYard Inventory Updated 20.2.13Syahir IsmailNo ratings yet

- Absen Campur BengkelDocument6 pagesAbsen Campur BengkelM IqbalNo ratings yet

- Daily Manpower in - Out StatusDocument2 pagesDaily Manpower in - Out StatusEnamul HaqueNo ratings yet

- Laporan Bulanan MH + K3 SeptemberDocument6 pagesLaporan Bulanan MH + K3 SeptemberNizar FatchurrochmanNo ratings yet

- Laporan Kegiatan Kia KB 01052023-043059Document26 pagesLaporan Kegiatan Kia KB 01052023-043059pkm pelindung hewanNo ratings yet

- BBH - Report - 4 JAN-15Document56 pagesBBH - Report - 4 JAN-15Raju SutradharNo ratings yet

- Date Integrity Cell Availabilty 3G (%)Document9 pagesDate Integrity Cell Availabilty 3G (%)telecomNo ratings yet

- Formulir LHRDocument13 pagesFormulir LHREdi SupriyonoNo ratings yet

- Activity Report For June 2020 - Pravin AwalkondeDocument6 pagesActivity Report For June 2020 - Pravin AwalkondePravin AwalkondeNo ratings yet

- Sureshkumar TN 5Document32 pagesSureshkumar TN 5PrashanthNo ratings yet

- Geotechnical Investigation Proposed Mixed-Use Development 484 - 490 Plains Road East, Burlington, OntarioDocument52 pagesGeotechnical Investigation Proposed Mixed-Use Development 484 - 490 Plains Road East, Burlington, OntarioKhalil FanousNo ratings yet

- Calibration Maintenence AbstractDocument5 pagesCalibration Maintenence AbstractSundara NayakanNo ratings yet

- PT Diletto Julio 2016Document568 pagesPT Diletto Julio 2016yanpNo ratings yet

- Form Inspeksi (1-33)Document6 pagesForm Inspeksi (1-33)Juli adiSHENo ratings yet

- Fastrust ServicesDocument2 pagesFastrust ServicesPeralta Cabil VinzNo ratings yet

- Stock Ragister-FIRE FIGHTINGDocument70 pagesStock Ragister-FIRE FIGHTINGMAZHAR ALINo ratings yet

- Draft: Restoration of Landslide Jhika Gali, Murree Completion of ProjectDocument2 pagesDraft: Restoration of Landslide Jhika Gali, Murree Completion of ProjectMudassar KhanNo ratings yet

- GabonIncident BasedRNADocument29 pagesGabonIncident BasedRNAnshefeekNo ratings yet

- No EMR. Number Model Branch Customer SN Code Unit Delivery Date Trouble DateDocument5 pagesNo EMR. Number Model Branch Customer SN Code Unit Delivery Date Trouble Datenuraida hakikiNo ratings yet

- Gulf County Sheriff's Office Law Enforcement Weekly SummaryDocument3 pagesGulf County Sheriff's Office Law Enforcement Weekly SummaryMichael AllenNo ratings yet

- Course Module Course Unit Week: Bachelor of Science in Nursing NCMB 311 (Nursing Research 1)Document8 pagesCourse Module Course Unit Week: Bachelor of Science in Nursing NCMB 311 (Nursing Research 1)Jordz PlaciNo ratings yet

- Performance Management Form Planning and Evaluation Form: Partially MetDocument2 pagesPerformance Management Form Planning and Evaluation Form: Partially MetSeth BautistaNo ratings yet

- Indian Coal AnalysisDocument3 pagesIndian Coal AnalysisK.S.MAYILVAGHANAN100% (1)

- Definitive Guide To Security Awareness SuccessDocument19 pagesDefinitive Guide To Security Awareness SuccessRicardo RodríguezNo ratings yet

- Oil-Degassing:: 1-SeparationDocument34 pagesOil-Degassing:: 1-SeparationAhmed AbdullaNo ratings yet

- Chemical Applications of Group TheoryDocument468 pagesChemical Applications of Group TheoryBrunoRamosdeLima80% (5)

- The Structure of The Long BoneDocument3 pagesThe Structure of The Long BonesharneNo ratings yet

- Nist Fips 201-2Document87 pagesNist Fips 201-2Mohammad Reza NazariNo ratings yet

- Etching of CarbidesDocument6 pagesEtching of CarbidesSmilindNo ratings yet

- Steps of Transportation and AssignmentDocument16 pagesSteps of Transportation and AssignmentSubir ChakrabartyNo ratings yet

- Subject Availability - IalDocument11 pagesSubject Availability - IalDaianna PeirisNo ratings yet

- Icn ApiDocument172 pagesIcn ApiNaveen SemwalNo ratings yet

- CMF and CRF Series: Addressable Control and Relay ModulesDocument4 pagesCMF and CRF Series: Addressable Control and Relay ModulesZaira LorenaNo ratings yet

- My Adorable Girlfriend (Shouxing Laogong Ye Ye Liao) - 1ST KISS MANGADocument1 pageMy Adorable Girlfriend (Shouxing Laogong Ye Ye Liao) - 1ST KISS MANGACyreen TomammanNo ratings yet

- Validation and Dissoiution Enhacement of Loratadine and Desloratadine Tablets by Various Spctrophotometric MethodsDocument40 pagesValidation and Dissoiution Enhacement of Loratadine and Desloratadine Tablets by Various Spctrophotometric MethodsDr. Vishal BabarNo ratings yet

- Volume 69 PDFDocument84 pagesVolume 69 PDFShobit Sharma100% (3)

- Bathroom Suites by Ideal Standard - International Brochure 2011Document94 pagesBathroom Suites by Ideal Standard - International Brochure 2011BathroomsNINo ratings yet

- TLS and DTLS (Notes Materials) : Mr. S P Maniraj Dr. S Suresh Mr. M PrabuDocument14 pagesTLS and DTLS (Notes Materials) : Mr. S P Maniraj Dr. S Suresh Mr. M PrabuSuresh SNo ratings yet

- Evaluation of First Seizure and Newly Diagnosed.4Document31 pagesEvaluation of First Seizure and Newly Diagnosed.4veerraju tvNo ratings yet

- Welfare Economics and Public FinanceDocument5 pagesWelfare Economics and Public FinanceVedastus Timothy100% (1)

- Chapter 5,6 Regression AnalysisDocument44 pagesChapter 5,6 Regression AnalysisSumeshNo ratings yet

- Legal Hurdle in Gaming PaymentDocument9 pagesLegal Hurdle in Gaming Paymentanurag kumarNo ratings yet

- Interpreting Self-Directed Search Profiles: Validity of The "Rule of Eight"Document6 pagesInterpreting Self-Directed Search Profiles: Validity of The "Rule of Eight"AAYUSHI PARMARNo ratings yet

- Awaring Presentation On Ethiopian Standards ES 3961 2 June 2017Document36 pagesAwaring Presentation On Ethiopian Standards ES 3961 2 June 2017berekajimma100% (4)

- Acknowledgement AbstractDocument6 pagesAcknowledgement AbstractNarendra ReddyNo ratings yet

- APPLICATION SECURITY ASSESSMENT - Draft - Ver01Document42 pagesAPPLICATION SECURITY ASSESSMENT - Draft - Ver01An LeNo ratings yet

- ExcelAssignment1 21062022Document10 pagesExcelAssignment1 21062022Neeraj PatelNo ratings yet