Professional Documents

Culture Documents

Pinholes: Description of Defects: Pinholes Description of Defects: Pinholes

Pinholes: Description of Defects: Pinholes Description of Defects: Pinholes

Uploaded by

metkarthikCopyright:

Available Formats

You might also like

- AFS Effects of Hot SandDocument10 pagesAFS Effects of Hot Sandvivek1312No ratings yet

- AFS Effects of Hot SandDocument10 pagesAFS Effects of Hot Sandvivek1312No ratings yet

- Determination Active Clay Percentage of Moulding Sand by Using Methylene BlueDocument9 pagesDetermination Active Clay Percentage of Moulding Sand by Using Methylene Bluevivek1312100% (2)

- SAT Chem 02 BondingDocument2 pagesSAT Chem 02 Bondingebola123No ratings yet

- GAS PROBLEM in Steel Sand CastingsDocument7 pagesGAS PROBLEM in Steel Sand CastingsVasu RajaNo ratings yet

- 23-IKO Poster Casting DefectsDocument1 page23-IKO Poster Casting DefectsGopal Jetani50% (2)

- Elkem Poster For Ductile Iron PDFDocument1 pageElkem Poster For Ductile Iron PDFvivek1312100% (4)

- White Wax 50 G White Petrolatum 950 G To Make 1000 GDocument3 pagesWhite Wax 50 G White Petrolatum 950 G To Make 1000 GRoseanne Legaspi CasayuranNo ratings yet

- Common Metallurgical Defects in Grey Cast IronDocument9 pagesCommon Metallurgical Defects in Grey Cast IronRolando Nuñez Monrroy100% (1)

- Casting Defect - Fissure DefectsDocument3 pagesCasting Defect - Fissure Defectsvivek1312No ratings yet

- FP 238Document32 pagesFP 238Mahmoud Atia100% (2)

- Filtration of Iron and Steel Castings PDFDocument24 pagesFiltration of Iron and Steel Castings PDFbvphimanshu100% (1)

- Causes and Remedies of Blow Holes in SanDocument33 pagesCauses and Remedies of Blow Holes in SanNikhil KumarNo ratings yet

- Carbon Dioxide Moulding ProcessDocument17 pagesCarbon Dioxide Moulding ProcessqwertyuioNo ratings yet

- Spheriodiser Cored Wire NewDocument6 pagesSpheriodiser Cored Wire NewamitkkambleNo ratings yet

- Positioning Ceramic Foam Filters in Gating System For Casting Alloy FiltrationDocument8 pagesPositioning Ceramic Foam Filters in Gating System For Casting Alloy FiltrationSiddharth GuptaNo ratings yet

- AFS Thermal Analysis of CupsDocument12 pagesAFS Thermal Analysis of Cupsyash_ganatraNo ratings yet

- Shrinkage in Iron CastingsDocument10 pagesShrinkage in Iron CastingskarthikkandaNo ratings yet

- Recovery of Magnesium in A Ductile Iron Process.: AbstractDocument8 pagesRecovery of Magnesium in A Ductile Iron Process.: AbstractJorge Prado DiazNo ratings yet

- Cast IronDocument12 pagesCast IronSurendra SonayeNo ratings yet

- Cast Iron BrochureDocument12 pagesCast Iron BrochureFlamarion BadaroNo ratings yet

- Foundry DefectsDocument12 pagesFoundry DefectsVirendra Gupta100% (1)

- Controlling The Chemistry and The and The Section Size Is Very ImportantDocument2 pagesControlling The Chemistry and The and The Section Size Is Very ImportantHeuzerGomesNo ratings yet

- Surface Graphite Degeneration in Ductile Iron CastDocument8 pagesSurface Graphite Degeneration in Ductile Iron CastKhairul MuzafarNo ratings yet

- Effect of Bismuth in Ductile IronDocument4 pagesEffect of Bismuth in Ductile Ironmarcotulio123100% (2)

- Why Primary Graphite Is Bad!Document4 pagesWhy Primary Graphite Is Bad!qwsx123No ratings yet

- Simulatiing Porosity in Ductile Iron - Etip17Document2 pagesSimulatiing Porosity in Ductile Iron - Etip17yeokbinNo ratings yet

- Common Metal Casting DefectsDocument12 pagesCommon Metal Casting DefectsMACKAY9999No ratings yet

- Partition of Slag Phases in The Treatment and Pouring of Ductile IronDocument2 pagesPartition of Slag Phases in The Treatment and Pouring of Ductile Ironarnaldorcr8646No ratings yet

- Carbidic Austempered Ductile Iron - ADIDocument8 pagesCarbidic Austempered Ductile Iron - ADITayfun TezanlarNo ratings yet

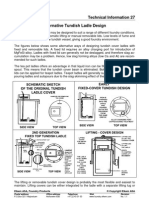

- Alternative Tundish Ladle DesignDocument2 pagesAlternative Tundish Ladle Designarnaldorcr8646No ratings yet

- FP240Document28 pagesFP240igorisakovNo ratings yet

- Casting Defects in SteelsDocument4 pagesCasting Defects in SteelsShamsur Rahman Russell100% (1)

- Nitrogen Fissures Defects in Iron Castings: Back ToDocument2 pagesNitrogen Fissures Defects in Iron Castings: Back ToJustin DixonNo ratings yet

- MAG Design GuideDocument32 pagesMAG Design Guidekarthik_thanguduNo ratings yet

- Niobium in Cast IronDocument13 pagesNiobium in Cast IronTayyab HussainNo ratings yet

- Application Manual Chapter 6 - Feeding & GatingDocument148 pagesApplication Manual Chapter 6 - Feeding & GatingVishal MaliNo ratings yet

- Disamatic GatingDocument7 pagesDisamatic Gatingtanto_deep_15No ratings yet

- Metallurgical Defects of Cast Steel: SeminarDocument26 pagesMetallurgical Defects of Cast Steel: SeminarAndré RibeiroNo ratings yet

- Common Metallurgical Defects in Grey Cast Irons 2Document1 pageCommon Metallurgical Defects in Grey Cast Irons 2Rasool MohammadiNo ratings yet

- Elkem InoculacaoDocument26 pagesElkem InoculacaoeduardolavratiNo ratings yet

- Composition of Grey Cast IronDocument2 pagesComposition of Grey Cast IronPranil GhatageNo ratings yet

- Introduction in Alloys and Influence of Elements: Alloys and Melting 01 - Alloys - and - Melting - EN - Docx 1/13Document13 pagesIntroduction in Alloys and Influence of Elements: Alloys and Melting 01 - Alloys - and - Melting - EN - Docx 1/13luisA1923No ratings yet

- Furane Sand PDFDocument118 pagesFurane Sand PDFOscar SotomayorNo ratings yet

- Gating-Risering Sec2Document35 pagesGating-Risering Sec2jagan_4u100% (1)

- Analysis of Casting DefectsDocument20 pagesAnalysis of Casting DefectsVarun Jain100% (1)

- 256412Document68 pages256412tabibkarim100% (1)

- AntiSegregation HopperDocument5 pagesAntiSegregation Hoppermecaunidos7771No ratings yet

- Casting DefectsDocument39 pagesCasting DefectsAnup Tigga100% (3)

- Effect of Minor and Trace Elements in Cast IronDocument2 pagesEffect of Minor and Trace Elements in Cast IronsachinguptachdNo ratings yet

- Carbide Dissolution in Thin Wall Ductile Iron PDFDocument8 pagesCarbide Dissolution in Thin Wall Ductile Iron PDFsachinguptachdNo ratings yet

- ATAS Metstar Kovis FoundryDocument18 pagesATAS Metstar Kovis FoundryslagmercuryNo ratings yet

- AFS Casting DefectDocument4 pagesAFS Casting Defectdarwin_huaNo ratings yet

- Principles of SolidificationDocument74 pagesPrinciples of SolidificationAnand ShivannaNo ratings yet

- RECHUPEDocument7 pagesRECHUPEmarcotulio123No ratings yet

- Pin HolesDocument4 pagesPin HolesEr WidodoNo ratings yet

- Sintering ProcessDocument4 pagesSintering ProcessNicollas Matheus100% (1)

- 07 Fissure Defects2Document3 pages07 Fissure Defects2Gh AbadiNo ratings yet

- Cacat PinholeDocument12 pagesCacat PinholeMaya Ida SilviaNo ratings yet

- Lectures On CementsDocument32 pagesLectures On CementsKaushik RNo ratings yet

- ZincDocument73 pagesZincAqsa BanoNo ratings yet

- Chemical AttackDocument35 pagesChemical AttackArjun V CivilNo ratings yet

- 5-Hot Tear PDFDocument9 pages5-Hot Tear PDFPeeka Prabhakara RaoNo ratings yet

- 01 Burnt-On SandDocument2 pages01 Burnt-On SandWert DasNo ratings yet

- 16 ScabbingDocument4 pages16 Scabbingvivek13120% (1)

- Sand Testing ProcedureDocument34 pagesSand Testing Procedurevivek1312100% (5)

- ALSTOM Different-Types-of-Mills PDFDocument39 pagesALSTOM Different-Types-of-Mills PDFvivek1312100% (1)

- Influence MN S Properties Cast IronDocument14 pagesInfluence MN S Properties Cast Ironvivek1312No ratings yet

- Common Metallurgical Defects in Ductile IronDocument1 pageCommon Metallurgical Defects in Ductile IronMehdi Koneshlou100% (1)

- The Oolitization Rate Determination of Bentonite Moulding MixturesDocument4 pagesThe Oolitization Rate Determination of Bentonite Moulding Mixturesvivek1312No ratings yet

- Foundry DefectsDocument74 pagesFoundry DefectsdanielsasikumarNo ratings yet

- Toyota PDFDocument8 pagesToyota PDFOHNo ratings yet

- Yogyata VikasDocument11 pagesYogyata Vikasvivek1312No ratings yet

- 4 OEE ExampleDocument8 pages4 OEE Examplevivek1312No ratings yet

- Gating System DesignDocument8 pagesGating System Designvivek1312No ratings yet

- GREEN SAND PREPARATION Manufacturing Lab Foundry PDFDocument21 pagesGREEN SAND PREPARATION Manufacturing Lab Foundry PDFvivek1312100% (1)

- WEAR The Wear Behaviour of Hi ChromiumDocument19 pagesWEAR The Wear Behaviour of Hi Chromiumvivek1312No ratings yet

- Expansion Silica SandDocument2 pagesExpansion Silica Sandvivek1312No ratings yet

- Mold Hardness Vs PermeabilityDocument4 pagesMold Hardness Vs Permeabilityvivek1312No ratings yet

- Mold Hardness Vs PermeabilityDocument4 pagesMold Hardness Vs Permeabilityvivek1312No ratings yet

- MM Daily - Monthly - Yearly Performance - DASH BOARD: Dispatch GCT Sales Value Rs. LacsDocument6 pagesMM Daily - Monthly - Yearly Performance - DASH BOARD: Dispatch GCT Sales Value Rs. Lacsvivek1312No ratings yet

- Green Sand For HPMLDocument2 pagesGreen Sand For HPMLvivek1312No ratings yet

- Kaizeninstitutemexico2013 130903094330Document13 pagesKaizeninstitutemexico2013 130903094330vivek1312No ratings yet

- Oxidation-Reduction by Mahima WaldiaDocument20 pagesOxidation-Reduction by Mahima WaldiaRahul Waldia100% (1)

- Qdoc - Tips - Chemistry Project On Factors Responsible For Tea XDocument21 pagesQdoc - Tips - Chemistry Project On Factors Responsible For Tea XKartikeya MishraNo ratings yet

- 1st Module - PointersDocument2 pages1st Module - PointersMariejoy Vargas Adlawan-SartigaNo ratings yet

- Product Veritas Health Science PVT LTD-1Document8 pagesProduct Veritas Health Science PVT LTD-1DRIVECURENo ratings yet

- Senza TitoloDocument28 pagesSenza TitoloGMSNo ratings yet

- Methyl Isocyanate - WikipediaDocument28 pagesMethyl Isocyanate - WikipediaABDulNafeNo ratings yet

- Anti-Fungal Activity of Carica Papaya Leaf ExtractDocument12 pagesAnti-Fungal Activity of Carica Papaya Leaf ExtractDaniel BartoloNo ratings yet

- 10 Science Notes 03 Metals and Non Metals 1Document10 pages10 Science Notes 03 Metals and Non Metals 1Rishu KaulNo ratings yet

- General BiochemistryDocument85 pagesGeneral BiochemistryHafrizDanielNo ratings yet

- Activated Carbons Produced by Pyrolysis of Waste Potato Peels Cobalt Ions Removal by AdsorptionDocument10 pagesActivated Carbons Produced by Pyrolysis of Waste Potato Peels Cobalt Ions Removal by AdsorptionLaura LambreaNo ratings yet

- Masterseal TC 242: Description Typical PropertiesDocument2 pagesMasterseal TC 242: Description Typical PropertiesGavriel NgNo ratings yet

- Periodic Table - Study NotesDocument19 pagesPeriodic Table - Study NotesTamoghna DeyNo ratings yet

- Chem 26.1 Practicals ReviewerDocument2 pagesChem 26.1 Practicals ReviewerKyla JavierNo ratings yet

- Worley Parsons - Balikpapan Project Overview - 2020Document4 pagesWorley Parsons - Balikpapan Project Overview - 2020Vraja DasiNo ratings yet

- Mark Scheme Jan 1996 Unit-1Document10 pagesMark Scheme Jan 1996 Unit-1Samira MahmoodNo ratings yet

- Enhanced Thermal Destruction of Toxic Microalgal Biomass by Using CO2Document9 pagesEnhanced Thermal Destruction of Toxic Microalgal Biomass by Using CO2Julian De BedoutNo ratings yet

- AVIS - Brucellosis - OIE Laboratory Techniques Antigen Production RBTDocument1 pageAVIS - Brucellosis - OIE Laboratory Techniques Antigen Production RBTRofiqul AlaNo ratings yet

- Application of Low Fouling RO Membrane Elements For Reclamation of Municipal WastewaterDocument17 pagesApplication of Low Fouling RO Membrane Elements For Reclamation of Municipal Wastewaterzerocool86No ratings yet

- Application Note Vapor Recovery Units PDFDocument4 pagesApplication Note Vapor Recovery Units PDFNicolae VisanNo ratings yet

- Electronegativity and The Bond TriangleDocument9 pagesElectronegativity and The Bond TriangleKSmklNo ratings yet

- Crystal Field Theory of Coordination ComplexesDocument2 pagesCrystal Field Theory of Coordination ComplexesMohammed ZiyadNo ratings yet

- PhEd-Some Basic Concepts of Chemistry-W.SDocument18 pagesPhEd-Some Basic Concepts of Chemistry-W.SSubharna ChauhanNo ratings yet

- I. Chaouki, L. Mouhir, M. Fekhaoui, A. El Abidi, A. Bellaouchou, M. El MorhitDocument10 pagesI. Chaouki, L. Mouhir, M. Fekhaoui, A. El Abidi, A. Bellaouchou, M. El MorhitBenjelloun MehdiNo ratings yet

- Name Reaction by Ashish SirDocument10 pagesName Reaction by Ashish SirSrishant KumarNo ratings yet

- Assecheur D'air COMEM-EnDocument7 pagesAssecheur D'air COMEM-EnTarek FawzyNo ratings yet

- Cloud PointDocument1 pageCloud PointRavi ShankarNo ratings yet

- Molecular Mechanism of Fluoride Induced Oxidative Stress and Its Possible Reversal by Chelation TherapyDocument27 pagesMolecular Mechanism of Fluoride Induced Oxidative Stress and Its Possible Reversal by Chelation TherapyAshitosh KumarNo ratings yet

- Alcohol Phenol Ethers Solved QuestionsDocument21 pagesAlcohol Phenol Ethers Solved QuestionssauravNo ratings yet

Pinholes: Description of Defects: Pinholes Description of Defects: Pinholes

Pinholes: Description of Defects: Pinholes Description of Defects: Pinholes

Uploaded by

metkarthikOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pinholes: Description of Defects: Pinholes Description of Defects: Pinholes

Pinholes: Description of Defects: Pinholes Description of Defects: Pinholes

Uploaded by

metkarthikCopyright:

Available Formats

70

Description of defects: Pinholes

71

Description of defects: Pinholes

Pinholes

Assistance for decisions P. 154

Sand control P. 181

Pinhole porosity surface blowholes

Explanations

Differentiation is made between hydrogen pinholes, hydrogennitrogen pinholes and pinholes due to CO-slag reactions.

Hydrogen and hydrogen-nitrogen pinholes

The formation of pinholes progresses in several stages:

1. The surface reaction of water vapour with other elements in

the iron gives rise to metal oxides and atomic hydrogen

which diffuses into the molten metal. Similarly, nitrogenhydrogen compounds dissociate on the hot metal surface

and diffuse into the molten metal. Dissociation of molecular

nitrogen and hydrogen does not take place at the prevailing

casting temperatures.

2. Due to enrichments in the slag, the metal oxides react with

the carbon in the melt to form CO molecules which are precipitated from the melt and form micro-blowholes.

3. Hydrogen, and sometimes nitrogen, diffuse from the liquid

metal into the CO micro-blowholes and increase their size.

Characteristic features

Pores or small blowholes with a smooth surface. Sub-surface

blowholes often contain a thin graphite lm. There is no differentiation between hydrogen and hydrogen-nitrogen pinholes.

Pinholes due to CO-slag reaction also have smooth surfaces.

The size of sub-surface blowholes can vary considerably. Blowholes occur in conjunction with oxygen-rich slag.

Incidence of the defect

Pinholes can appear individually or over an area. All areas of the

casting can be affected. However, pinholes are more common in

areas of the casting located away from the gate. Hydrogen and

hydrogen-nitrogen pinholes occur in both grey and SG iron

castings. Pinholes due to CO-slag reaction only occur in grey iron

castings.

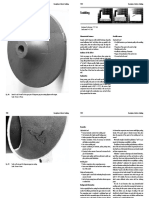

Fig. 32:

Large areas of surface blowholes/pinholes on a grey iron casting.

Scale: 10 mm = 4 mm

Pinholes due to CO-slag reaction

These occur due to the reaction of heavily oxidizing, molten slags

(mostly MnO / MnS-rich slags) with the carbon in the melt to

form CO. Later in the process, hydrogen can also diffuse into

these blowholes.

72

Description of defects: Pinholes

73

Possible causes

Remedies

Metallurgical

Ferrous metals

Nitrogen content in the melt too high due to the charge composition.

Proportion of oxides, hydroxides (rust) and other impurities

in the charge materials too high

Aluminium content in the melt too high

Manganese and sulphur contents in the melt too high

Metallurgical

Use charge components with low nitrogen content, e.g.

reduce the quantity of steel scrap.

Use scrap and return material free of rust, water and oil

impurities. Use circulating materials free of impurities

adhering to sand and feeder auxiliaries.

Use charge materials and especially inoculants and circulating materials with low aluminium and titanium contents.

Deoxidize melts as well as possible. Avoid excessive supply

of titanium or aluminium.

Reduce the formation of slag, and particularly the formation

of slags containing manganese sulphide, by adjusting the

manganese and sulphur content.

Clay-bonded sand

Nitrogen content in the sand too high

Moisture content of the sand too high

Lustrous carbon production in the moulding sand too low

Fig. 33:

Section through the surface of a grey iron casting in the area of pinhole formation. Pinhole formation is promoted by

surface oxidation, recognizable in the formation of ferrite. Scale: 10 mm = 0.08 mm

Description of defects: Pinholes

Resin-bonded sand

Nitrogen content in the core sand too high

Proportion of nitrogen/hydrogen compounds in the core

binder too high

Gating and pouring practice

Pouring passages too long

Too much turbulence and slag formation during pouring

Clay-bonded sand

Reduce nitrogen content in the sand. Reduce the quantity of

inowing nitrogen-containing core sand. If necessary, add

new sand to the circulating sand.

Reduce the moisture content of the sand.

Lower the bentonite content. Improve development of the

moulding sand. If necessary, reduce inert dust content. Keep

amount of lustrous carbon carrier at the minimum level.

With an oxidizing atmosphere in the mould cavity, if necessary increase the quantity of lustrous carbon producer in the

moulding sand. Avoid adding too much.

Resin-bonded sand

Reduce the amount of binder. Use binder with lower nitrogen content.

Improve core venting, dress core if necessary.

Add iron oxides to the core sand mixture.

Gating and pouring practice

Increase pouring temperature

Reduce ow rate into the mould

Avoid turbulence when pouring.

74

Description of defects: Pinholes

75

Description of defects: Pinholes

Background information

A distinction is made between pinholes caused by hydrogen,

nitrogen-hydrogen and sub-surface blowholes due to slag / CO

reactions.

Mechanism of pinhole formation

In the formation of CO bubbles, the surface tension of the melt is

proportional to the work to be expended. According to Frenkel

and Thompson, the intensity I of pinhole formation is described

by the following equation:

Blowholes/pinholes arise in a melt under the following conditions:

I=Ae

P = P0 + 2

r

Section through a surface pinhole in a grey iron casting, hydrogen-nitrogen defect recognizable by the graphite lm and

the partial decarburization of the surface zones. Scale: 10 mm = 0.05 mm

Necessary gas pressure to form a blowhole

P0

Atmospheric + metallostatic pressure

The inuence of surface tension on the formation of pinholes has

been investigated. Higher surface tension suppresses pinhole

formation.1

Surface tension of the melt

Surface tension at 1400C

Radius of the blowhole

Calculations of the gas pressure at which blowholes/pinholes can

occur shows that the melt must be considerably over-saturated

with gases such as nitrogen and / or hydrogen.

Sub-surface blowholes can form on solid reaction products in

the melt at considerably lower gas pressures (phase boundaries).

Similarly, where CO bubbles are formed through the reaction of

oxides with the carbon in the melt, the dissolved gases (nitrogen,

hydrogen) diffuse into the molecular gas pockets and form pinholes.

Sufcient oxygen enrichment near the surface of the melt is

necessary for the formation of CO bubbles. According to Gibbs,

the formation of molecular CO blowholes is determined through

the work to be expended:

Ak = 4 r

3

10,000

Surface tension [N / cm]

Fig. 34:

Ak

kT

No pinholes

8,000

6,000

4,000

No pinholes

Pinholes

Pinholes

2,000

0

0

0.1

0.2

0.3

0.4

Aluminium content [%]

Fig. 35: Inuence of aluminium content on surface tension and

pinhole occurence in grey cast iron.

76

Description of defects: Pinholes

77

Description of defects: Pinholes

Surface tension at 1400C

Surface tension [N / cm]

10,000

No pinholes

Tellurium

8,000

In addition to pure CO pinholes, molecular CO bubbles can be regarded as the nucleus for hydrogen and hydrogen-nitrogen pinholes.

Hydrogen pinholes

6,000

4,000

Titanium

Sulphur

2,000

Pinholes

0

0

0.1

0.2

0.3

Hydrogen is primarily introduced into a melt through the reaction of strong oxygen binding agents in the melt, e.g. aluminium,

magnesium and titanium, with water vapour.

0.4

Total of additives present [%]

S No pinholes

S Pinholes

Fig. 37: Inuence of sulphur, titanium and tellurium content on

surface tension and pinhole formation in grey cast

iron.

Pinholes due to CO-slag reactions

0.2

In the formation of this defect, low-viscosity silicate slags rich in

manganese oxide and enriched with manganese sulphide react

with the carbon in the melt and form CO. With high manganese

and low silicon contents, the manganese reduces silica from slags

and the refractory lining, forming highly liquid manganese oxide

slags. High sulphur contents enable the formation of MnS, which

is enriched in the slag and makes the slags even more reactive.2

0.15

1280C

No defects

1200C

0

0.4

0.8

1.2

Me + H2O MeO + 2H

The atomic hydrogen is immediately absorbed by the melt.

Water vapour is produced by moist refractories, rust-containing

input materials and the binding clays used in the moulds, and is

also present in the mould cavity air during pouring.

Table 1 shows how long a melt absorbs hydrogen from the

lining of a cupola.

Tapping time

7.00

7.20

7.40

9.00

11.00

12.00

14.15

Hydrogen content [ppm]

5.6

4.2

3.0

2.2

1.8

1.4

1.6

Cold blast test cupola, tap weight in each case 400 kg.

Cupola diameter 140 cm

Acid furnace lining

The furnace was lined 24 hrs. previously.

1350C

0.1

Sulphur [%]

Pinholes

0.05

Micrograph of a slag / gas defect in a grey iron casting.

Scale: 10 mm = 0.1 mm

Ti No pinholes

Ti Pinholes

Fig. 36:

Te No pinholes

Te Pinholes

1.6

Manganese [%]

Fig. 38: Inuence of manganese and sulphur content and pouring temperature on the formation of pinholes.

78

Description of defects: Pinholes

79

Description of defects: Pinholes

The precipitation of hydrogen is unlikely in a homogeneous melt.

Where oxide nuclei or CO bubbles form, precipitation is more

likely, due to the low pressure required. At high temperatures and

pressures, the molecular hydrogen formed reacts with the carbon in the melt and forms methane, which breaks down to form

graphite and hydrogen:

Cdissolved + 2H2

CH4

CH4

Cgraphite + 2H2

Fig. 39:

Blowholes/pinholes over the complete surface of a grey iron casting.

Scale: 10 mm = 8 mm

Whilst the dissolved carbon reacts with hydrogen, the precipitated graphite is not dissolved by the superheated hydrogen in the

formation of methane.

As a result of these processes, hydrogen pinholes nearly always contain a thin graphite lm. The bubbles are surrounded by

a pearlite-free ferrite layer.

Hydrogen pinholes are normally round. Contrary to this, nitrogen pinholes have a dendritic shape. The explanation lies in the

different rates of diffusion of the gases. Pure nitrogen blowholes/

pinholes contain no graphite lm.

Avoidance of hydrogen pinholes

Hydrogen is absorbed by an iron melt where the amounts of

reactive elements are too high. Cast iron melts should be free

of magnesium and, above all, aluminium. Aluminium contents

as low as 0.01 0.1 % can lead to dangerous hydrogen absorption.

Excessive titanium contents, as particularly found in circulating

materials, promote the formation of pinholes.

Since absorption of hydrogen usually occurs through the formation of water vapour, the content in the molten metal of hydroxides, rust, mould moisture, water combined in the clay etc.

should be kept as low as possible.

The formation of pinholes can also be avoided if there is sufcient

lustrous carbon producer in the mould. The reducing atmosphere

prevents the formation of CO bubbles. Various authors have highlighted that admixtures of pit coal dust and other lustrous carbon

producers can help to prevent pinholes.3 5

Nitrogen-hydrogen pinholes

In addition to hydrogen pinholes, nitrogen-hydrogen pinholes

occur where nitrogen-containing binding agents are used. Such

defects are primarily generated through the use of binders containing urea.

The nitrogen-hydrogen radicals are broken down near the surface of the melt, which immediately absorbs them in the atomic

state.

These surface blowholes often have a graphite lm and a ferrite seam like the hydrogen pinholes. They form in a similar way

to that described under hydrogen pinholes. Many reports have

been published on these pinhole phenomena.

Avoidance of nitrogen-hydrogen pinholes

These pinholes can occur where there is a high nitrogen content in

the melt resulting from the use of charge materials such as steel

scrap or nitrogen-containing carburizing compounds. Here, too, a

crucial contribution is made by the combined action of gases from

the mould cavity and the mould. High nitrogen contents in the

melt (over 100 ppm), in the carburizing agent, in the core binder

and in the bentonite-bonded sands should be avoided.

The use of increased proportions of lustrous carbon producers

in the moulding sand to achieve a reducing atmosphere has also

proved to be effective.

In the case of cores, the addition of iron oxides and barium sulphate will help to prevent this defect.

80

Description of defects: Pinholes

81

Pinholes due to CO-slag reactions

References

Additional references

Under certain conditions, oxygen-rich slags can react with the

carbon in the melt to form CO. Liquid iron oxide-rich slags also

react this way:

Orths K.; Weis W.; Lampic, M.

Verdeckte Fehler bei Gustcken aus Gueisen

Giess.-Forsch. 27, 1975, P. 103 111

FeO + C Fe + CO

The pinholes may be observed on the surface of the casting but

are sometimes not visible until it is machined. All slags formed

during melting and pouring can become highly uid through enrichment with FeO or MnO, and then react with carbon to form

blowholes/pinholes.

Pinholes of this type mostly have slag inclusions in the pockets,

such inclusions often containing MnS precipitations. The large inuence of MnS on the formation of the pinhole can be traced back

to the liquefaction of the slag and thus its increased reactivity.

Hydrogen also negatively inuences this defect.

Henke, F.

Mangan im Gueisen

Giess.-Prax. 1970, P. 281 294

Dawson, J. V.; Kilshaw, J. A.; Morgan, A. D.

Art und Entstehung von Gasblasen in Gueisenteilen

Mod. Cast. 47, 1965, P. 144 160

Bauer, W.

Einu der chemischen Zusammensetzung und der Formstoffe auf Gasblasenfehler im Gueisen

Gieerei-Rundschau 31, 1984, P. 7 13

Giess.-Prax. 1984, P. 198 205

Avoidance of slag-CO surface pinholes

In order to avoid this surface defect, it is necessary to increase

the pouring temperature, reduce the sulphur content and restrict

the manganese content.

BCIRA recommends foundries to keep to a 0.7 % manganese

content.

Other authors recommend that the manganese content be kept

no higher than 0.4 % of the Si content.

It is also recommended that the melt be given little opportunity

to oxidize. Turbulence during lling should be avoided and liquidmetal ow paths kept short. As water vapour has a strongly

negative effect, the bentonite content in the moulding sand

should be as low as possible.

Hernandesz, B.; Wallace, J. F.

Mechanismus der Randblasenbildung in Gueisen mit Lamellengraphit

AFS 1979 Research Reports, Des Plaines / Il 1979,

P. 39 52 (English)

Fujio, S.; Yamada, J.; Mizuno, K.; Yamauchi, Y.; Tanimura, H.

Vermeidung von Pinhole-Bildung bei Gueisen mit Kugelgraphit

Imono 56, 1984, P. 212 218 (Jap. w. Engl. summary)

Orths K.; Weis, W.; Lampic, M.

Gesetzmigkeiten und Zusammenwirken von Regelgren

bei der Entstehung verdeckter Fehler bei Gueisen

Giess.-Forsch. 28, 1976 , P. 15 26

Greenhill, J. M.

Fehlerdiagnose in Gueisenstcken

Foundry 99, 1971, P. 56 60 (English)

Author not named

Guoberchen verdeckte Blschen im Zusammenwirken

mit MnS-Ausscheidungen

Mod. Castings 1978, P. 53

Gittus, J.

Randblasen im Gueisen mit Kugelgraphit

BCIRA Journal 5, 1933, P. 394 & P. 603

Dawson, J. V.; Smith, L. W. L.

Pinholes-Bildung in Gusseisen und ihre Abhngigkeit von der

Wasserstoffabgabe aus dem Formsand

BCIRA Journal 6, 1956, P. 226

Description of defects: Pinholes

Pidgeon, C. L.

Einu der Zusammensetzung von Grnsandformen auf die

Bildung von Pinholes

BCIRA Journal 11, 1963, P. 319 335

Dawson, J. V.

Pinholes

BCIRA Journal 10, 1962, P. 433 437

Vogel, D.

Beabsichtigte Erzeugung von Pinholes im Gueisen mit

Kugelgraphit und seine Entstehung

Staatl. Ing. Schule Duisburg 1964, Diplomarbeit

Berndt, H.

Die Pinhole-Bildung von Gueisen mit Lamellengraphit bei

Verwendung von Hot-Box-Kernen

Gieerei 52, 1965, P. 548 555

Berndt, H.; Unger, D.

Prfung von Formsandmischungen f. das Hot-Box-Verfahren

Gieerei 53, 1966, P. 96 105

Nipper, H. A.; Knig, R.; Gries, H.

Zur Begasung u. Entgasung von schmelzssigem Gueisen

Buderus techn. Bl., Febr. 62, P. 60

Dawson, J. V.

Untersuchungen ber die Randblasenbildung in Gueisen

BCIRA Journal 8, 1960, P. 805 811

Patterson, W; v. Gienanth

Dipl.-Arbeit ber Nadelstichporositten im Gueisen

TH Aachen, May 1962

Murray, W. G.

Randblasen in Gueisen mit Kugelgraphit

Brit. Foundryman 55, 1962, P. 85 93

Author not named

Pinholes im Graugu

Foundry, 1965, P. 162

82

Description of defects: Pinholes

Chen, F.; Keverian, J.

Einu v. Stickstoff auf die Randblasenbildung bei Stahlgu

Mod. Cast. 50, 1966, P. 95 103

Berndt, H.; Unger, D.; Rde, D.

Die Bedeutung der Eisenoxidzugabe zum Formstoff

Gieerei 59, 1972, P. 61 71

Frommhagen, A.

Pinholes in Graugustcken

Giess.-Prax. 1964, P. 123 126

Author unknown

Ein Fall von Randblasen (Pinholes) in der Oberche von GG

Fonderie, Fondeur aujourdhui 1986, P. 27

Schitikow W. S.; Schulte G.; Gederewitsch, N. A.; Tschebotar

L. K.

Die Pinholesbildung in GGL

Lit. Proisv. 1973, P. 18

Gieereitechnik 22, 1974, P. 320

Poyet, P.; Elsen, F.; Bollinger, E.

Einu von Zustzen an Eisenoxid zum Formsand in der

Stahlgieerei

Hommes et Fonderie 161, 1986, P. 11 22 (French)

Kokonov, A. T.

Einu der Desoxidation auf die Pinholesbildung bei Stahlgustcken beim Gieen in kunstharzgebundene Formen

Lit. proisv. 1979, P. 9

Carter, S. F.; Evans, W. J.; Harkness, J. C.; Wallace, J. F.

Einugren bei der Pinhole-Bildung in Gueisen mit

Lamellengraphit und Gueisen mit Kugelgraphit

Amer. Foundrym. Soc. 87, 1979, P. 245 268 (English)

Giess. Prax. 1980, P. 219 246

VDG Fachbibliographie Nr. 352

Wasserstoffgehalte im Gueisen (67 literature references)

VDG Fachbibliographie Nr. 74

Gase im Gueisen (78 literature references)

Hner, K. E.

Zum Einu des Stickstoffs auf die Gasblasenbildung im

Stahlgu

Gieerei 62, 1975, P. 6 12

Middleton, J. M.

Einige Pros und Contras zu tongebundenen Formsanden

Proc. Annu. Conf. Steel Cast. Res. & Trade Assoc. Harrogate

1970, Vol. 1, 1970 Pap. 6, P. 8

Habibullah, P.

Allgemeine Betrachtungen ber Blasenbildung bei Stahlgustcken infolge der Metall-Formstoff-Reaktion

43me Congrs International de Fonderie, Bucuresti 1976

Paper No. 13., 7 P. (English)

Yamauchi, Y.; Yamada, J.; Mizuno, K.; Fujio, S.; Tanimura, H.

Pinholes bei Gustcken aus Gueisen mit Kugelgraphit

(Nagusand) und Manahmen zu deren Vermeidung

4th International Conference for Licensees of the GF Converter Process, Schaffhausen 1981, Paper No. 7, P. 14

83

Levi, L. I.; Grigorjan, S. A.; Dybenko, I. V.

Einu von Mn auf den Stickstoffgehalt im Gueisen und

dessen Bestimmungsverfahren

Izvestija vyssich. ucebnych. zavedenij, cernaja metallurgija

1977, P. 155 157 (Russian)

Strong, G. R.

Stickstoff in Tempergu Ein Literaturberblick

Trans. Amer. Foundrym. Soc. 85, 1977, P. 29 36 (Engl.)

Winterhager, H.; Koch, M.

Untersuchungen zur Vakuumentgasung von AluminiumSchmelzen.

Gieerei 65, 1978, P. 505 510

Stransky, K.

Thermodynamische Bedingungen fr die Pinhole-Bildung in

Stahlgu

Slevarenstvi 28, 1980, P. 373 377 (Czech)

Mechanisms of Pinhole Formation in Gray Iron

AFS Gray Iron Research Committee 5-C

AFS Research Reports 1979, P. 37

Description of defects: Pinholes

You might also like

- AFS Effects of Hot SandDocument10 pagesAFS Effects of Hot Sandvivek1312No ratings yet

- AFS Effects of Hot SandDocument10 pagesAFS Effects of Hot Sandvivek1312No ratings yet

- Determination Active Clay Percentage of Moulding Sand by Using Methylene BlueDocument9 pagesDetermination Active Clay Percentage of Moulding Sand by Using Methylene Bluevivek1312100% (2)

- SAT Chem 02 BondingDocument2 pagesSAT Chem 02 Bondingebola123No ratings yet

- GAS PROBLEM in Steel Sand CastingsDocument7 pagesGAS PROBLEM in Steel Sand CastingsVasu RajaNo ratings yet

- 23-IKO Poster Casting DefectsDocument1 page23-IKO Poster Casting DefectsGopal Jetani50% (2)

- Elkem Poster For Ductile Iron PDFDocument1 pageElkem Poster For Ductile Iron PDFvivek1312100% (4)

- White Wax 50 G White Petrolatum 950 G To Make 1000 GDocument3 pagesWhite Wax 50 G White Petrolatum 950 G To Make 1000 GRoseanne Legaspi CasayuranNo ratings yet

- Common Metallurgical Defects in Grey Cast IronDocument9 pagesCommon Metallurgical Defects in Grey Cast IronRolando Nuñez Monrroy100% (1)

- Casting Defect - Fissure DefectsDocument3 pagesCasting Defect - Fissure Defectsvivek1312No ratings yet

- FP 238Document32 pagesFP 238Mahmoud Atia100% (2)

- Filtration of Iron and Steel Castings PDFDocument24 pagesFiltration of Iron and Steel Castings PDFbvphimanshu100% (1)

- Causes and Remedies of Blow Holes in SanDocument33 pagesCauses and Remedies of Blow Holes in SanNikhil KumarNo ratings yet

- Carbon Dioxide Moulding ProcessDocument17 pagesCarbon Dioxide Moulding ProcessqwertyuioNo ratings yet

- Spheriodiser Cored Wire NewDocument6 pagesSpheriodiser Cored Wire NewamitkkambleNo ratings yet

- Positioning Ceramic Foam Filters in Gating System For Casting Alloy FiltrationDocument8 pagesPositioning Ceramic Foam Filters in Gating System For Casting Alloy FiltrationSiddharth GuptaNo ratings yet

- AFS Thermal Analysis of CupsDocument12 pagesAFS Thermal Analysis of Cupsyash_ganatraNo ratings yet

- Shrinkage in Iron CastingsDocument10 pagesShrinkage in Iron CastingskarthikkandaNo ratings yet

- Recovery of Magnesium in A Ductile Iron Process.: AbstractDocument8 pagesRecovery of Magnesium in A Ductile Iron Process.: AbstractJorge Prado DiazNo ratings yet

- Cast IronDocument12 pagesCast IronSurendra SonayeNo ratings yet

- Cast Iron BrochureDocument12 pagesCast Iron BrochureFlamarion BadaroNo ratings yet

- Foundry DefectsDocument12 pagesFoundry DefectsVirendra Gupta100% (1)

- Controlling The Chemistry and The and The Section Size Is Very ImportantDocument2 pagesControlling The Chemistry and The and The Section Size Is Very ImportantHeuzerGomesNo ratings yet

- Surface Graphite Degeneration in Ductile Iron CastDocument8 pagesSurface Graphite Degeneration in Ductile Iron CastKhairul MuzafarNo ratings yet

- Effect of Bismuth in Ductile IronDocument4 pagesEffect of Bismuth in Ductile Ironmarcotulio123100% (2)

- Why Primary Graphite Is Bad!Document4 pagesWhy Primary Graphite Is Bad!qwsx123No ratings yet

- Simulatiing Porosity in Ductile Iron - Etip17Document2 pagesSimulatiing Porosity in Ductile Iron - Etip17yeokbinNo ratings yet

- Common Metal Casting DefectsDocument12 pagesCommon Metal Casting DefectsMACKAY9999No ratings yet

- Partition of Slag Phases in The Treatment and Pouring of Ductile IronDocument2 pagesPartition of Slag Phases in The Treatment and Pouring of Ductile Ironarnaldorcr8646No ratings yet

- Carbidic Austempered Ductile Iron - ADIDocument8 pagesCarbidic Austempered Ductile Iron - ADITayfun TezanlarNo ratings yet

- Alternative Tundish Ladle DesignDocument2 pagesAlternative Tundish Ladle Designarnaldorcr8646No ratings yet

- FP240Document28 pagesFP240igorisakovNo ratings yet

- Casting Defects in SteelsDocument4 pagesCasting Defects in SteelsShamsur Rahman Russell100% (1)

- Nitrogen Fissures Defects in Iron Castings: Back ToDocument2 pagesNitrogen Fissures Defects in Iron Castings: Back ToJustin DixonNo ratings yet

- MAG Design GuideDocument32 pagesMAG Design Guidekarthik_thanguduNo ratings yet

- Niobium in Cast IronDocument13 pagesNiobium in Cast IronTayyab HussainNo ratings yet

- Application Manual Chapter 6 - Feeding & GatingDocument148 pagesApplication Manual Chapter 6 - Feeding & GatingVishal MaliNo ratings yet

- Disamatic GatingDocument7 pagesDisamatic Gatingtanto_deep_15No ratings yet

- Metallurgical Defects of Cast Steel: SeminarDocument26 pagesMetallurgical Defects of Cast Steel: SeminarAndré RibeiroNo ratings yet

- Common Metallurgical Defects in Grey Cast Irons 2Document1 pageCommon Metallurgical Defects in Grey Cast Irons 2Rasool MohammadiNo ratings yet

- Elkem InoculacaoDocument26 pagesElkem InoculacaoeduardolavratiNo ratings yet

- Composition of Grey Cast IronDocument2 pagesComposition of Grey Cast IronPranil GhatageNo ratings yet

- Introduction in Alloys and Influence of Elements: Alloys and Melting 01 - Alloys - and - Melting - EN - Docx 1/13Document13 pagesIntroduction in Alloys and Influence of Elements: Alloys and Melting 01 - Alloys - and - Melting - EN - Docx 1/13luisA1923No ratings yet

- Furane Sand PDFDocument118 pagesFurane Sand PDFOscar SotomayorNo ratings yet

- Gating-Risering Sec2Document35 pagesGating-Risering Sec2jagan_4u100% (1)

- Analysis of Casting DefectsDocument20 pagesAnalysis of Casting DefectsVarun Jain100% (1)

- 256412Document68 pages256412tabibkarim100% (1)

- AntiSegregation HopperDocument5 pagesAntiSegregation Hoppermecaunidos7771No ratings yet

- Casting DefectsDocument39 pagesCasting DefectsAnup Tigga100% (3)

- Effect of Minor and Trace Elements in Cast IronDocument2 pagesEffect of Minor and Trace Elements in Cast IronsachinguptachdNo ratings yet

- Carbide Dissolution in Thin Wall Ductile Iron PDFDocument8 pagesCarbide Dissolution in Thin Wall Ductile Iron PDFsachinguptachdNo ratings yet

- ATAS Metstar Kovis FoundryDocument18 pagesATAS Metstar Kovis FoundryslagmercuryNo ratings yet

- AFS Casting DefectDocument4 pagesAFS Casting Defectdarwin_huaNo ratings yet

- Principles of SolidificationDocument74 pagesPrinciples of SolidificationAnand ShivannaNo ratings yet

- RECHUPEDocument7 pagesRECHUPEmarcotulio123No ratings yet

- Pin HolesDocument4 pagesPin HolesEr WidodoNo ratings yet

- Sintering ProcessDocument4 pagesSintering ProcessNicollas Matheus100% (1)

- 07 Fissure Defects2Document3 pages07 Fissure Defects2Gh AbadiNo ratings yet

- Cacat PinholeDocument12 pagesCacat PinholeMaya Ida SilviaNo ratings yet

- Lectures On CementsDocument32 pagesLectures On CementsKaushik RNo ratings yet

- ZincDocument73 pagesZincAqsa BanoNo ratings yet

- Chemical AttackDocument35 pagesChemical AttackArjun V CivilNo ratings yet

- 5-Hot Tear PDFDocument9 pages5-Hot Tear PDFPeeka Prabhakara RaoNo ratings yet

- 01 Burnt-On SandDocument2 pages01 Burnt-On SandWert DasNo ratings yet

- 16 ScabbingDocument4 pages16 Scabbingvivek13120% (1)

- Sand Testing ProcedureDocument34 pagesSand Testing Procedurevivek1312100% (5)

- ALSTOM Different-Types-of-Mills PDFDocument39 pagesALSTOM Different-Types-of-Mills PDFvivek1312100% (1)

- Influence MN S Properties Cast IronDocument14 pagesInfluence MN S Properties Cast Ironvivek1312No ratings yet

- Common Metallurgical Defects in Ductile IronDocument1 pageCommon Metallurgical Defects in Ductile IronMehdi Koneshlou100% (1)

- The Oolitization Rate Determination of Bentonite Moulding MixturesDocument4 pagesThe Oolitization Rate Determination of Bentonite Moulding Mixturesvivek1312No ratings yet

- Foundry DefectsDocument74 pagesFoundry DefectsdanielsasikumarNo ratings yet

- Toyota PDFDocument8 pagesToyota PDFOHNo ratings yet

- Yogyata VikasDocument11 pagesYogyata Vikasvivek1312No ratings yet

- 4 OEE ExampleDocument8 pages4 OEE Examplevivek1312No ratings yet

- Gating System DesignDocument8 pagesGating System Designvivek1312No ratings yet

- GREEN SAND PREPARATION Manufacturing Lab Foundry PDFDocument21 pagesGREEN SAND PREPARATION Manufacturing Lab Foundry PDFvivek1312100% (1)

- WEAR The Wear Behaviour of Hi ChromiumDocument19 pagesWEAR The Wear Behaviour of Hi Chromiumvivek1312No ratings yet

- Expansion Silica SandDocument2 pagesExpansion Silica Sandvivek1312No ratings yet

- Mold Hardness Vs PermeabilityDocument4 pagesMold Hardness Vs Permeabilityvivek1312No ratings yet

- Mold Hardness Vs PermeabilityDocument4 pagesMold Hardness Vs Permeabilityvivek1312No ratings yet

- MM Daily - Monthly - Yearly Performance - DASH BOARD: Dispatch GCT Sales Value Rs. LacsDocument6 pagesMM Daily - Monthly - Yearly Performance - DASH BOARD: Dispatch GCT Sales Value Rs. Lacsvivek1312No ratings yet

- Green Sand For HPMLDocument2 pagesGreen Sand For HPMLvivek1312No ratings yet

- Kaizeninstitutemexico2013 130903094330Document13 pagesKaizeninstitutemexico2013 130903094330vivek1312No ratings yet

- Oxidation-Reduction by Mahima WaldiaDocument20 pagesOxidation-Reduction by Mahima WaldiaRahul Waldia100% (1)

- Qdoc - Tips - Chemistry Project On Factors Responsible For Tea XDocument21 pagesQdoc - Tips - Chemistry Project On Factors Responsible For Tea XKartikeya MishraNo ratings yet

- 1st Module - PointersDocument2 pages1st Module - PointersMariejoy Vargas Adlawan-SartigaNo ratings yet

- Product Veritas Health Science PVT LTD-1Document8 pagesProduct Veritas Health Science PVT LTD-1DRIVECURENo ratings yet

- Senza TitoloDocument28 pagesSenza TitoloGMSNo ratings yet

- Methyl Isocyanate - WikipediaDocument28 pagesMethyl Isocyanate - WikipediaABDulNafeNo ratings yet

- Anti-Fungal Activity of Carica Papaya Leaf ExtractDocument12 pagesAnti-Fungal Activity of Carica Papaya Leaf ExtractDaniel BartoloNo ratings yet

- 10 Science Notes 03 Metals and Non Metals 1Document10 pages10 Science Notes 03 Metals and Non Metals 1Rishu KaulNo ratings yet

- General BiochemistryDocument85 pagesGeneral BiochemistryHafrizDanielNo ratings yet

- Activated Carbons Produced by Pyrolysis of Waste Potato Peels Cobalt Ions Removal by AdsorptionDocument10 pagesActivated Carbons Produced by Pyrolysis of Waste Potato Peels Cobalt Ions Removal by AdsorptionLaura LambreaNo ratings yet

- Masterseal TC 242: Description Typical PropertiesDocument2 pagesMasterseal TC 242: Description Typical PropertiesGavriel NgNo ratings yet

- Periodic Table - Study NotesDocument19 pagesPeriodic Table - Study NotesTamoghna DeyNo ratings yet

- Chem 26.1 Practicals ReviewerDocument2 pagesChem 26.1 Practicals ReviewerKyla JavierNo ratings yet

- Worley Parsons - Balikpapan Project Overview - 2020Document4 pagesWorley Parsons - Balikpapan Project Overview - 2020Vraja DasiNo ratings yet

- Mark Scheme Jan 1996 Unit-1Document10 pagesMark Scheme Jan 1996 Unit-1Samira MahmoodNo ratings yet

- Enhanced Thermal Destruction of Toxic Microalgal Biomass by Using CO2Document9 pagesEnhanced Thermal Destruction of Toxic Microalgal Biomass by Using CO2Julian De BedoutNo ratings yet

- AVIS - Brucellosis - OIE Laboratory Techniques Antigen Production RBTDocument1 pageAVIS - Brucellosis - OIE Laboratory Techniques Antigen Production RBTRofiqul AlaNo ratings yet

- Application of Low Fouling RO Membrane Elements For Reclamation of Municipal WastewaterDocument17 pagesApplication of Low Fouling RO Membrane Elements For Reclamation of Municipal Wastewaterzerocool86No ratings yet

- Application Note Vapor Recovery Units PDFDocument4 pagesApplication Note Vapor Recovery Units PDFNicolae VisanNo ratings yet

- Electronegativity and The Bond TriangleDocument9 pagesElectronegativity and The Bond TriangleKSmklNo ratings yet

- Crystal Field Theory of Coordination ComplexesDocument2 pagesCrystal Field Theory of Coordination ComplexesMohammed ZiyadNo ratings yet

- PhEd-Some Basic Concepts of Chemistry-W.SDocument18 pagesPhEd-Some Basic Concepts of Chemistry-W.SSubharna ChauhanNo ratings yet

- I. Chaouki, L. Mouhir, M. Fekhaoui, A. El Abidi, A. Bellaouchou, M. El MorhitDocument10 pagesI. Chaouki, L. Mouhir, M. Fekhaoui, A. El Abidi, A. Bellaouchou, M. El MorhitBenjelloun MehdiNo ratings yet

- Name Reaction by Ashish SirDocument10 pagesName Reaction by Ashish SirSrishant KumarNo ratings yet

- Assecheur D'air COMEM-EnDocument7 pagesAssecheur D'air COMEM-EnTarek FawzyNo ratings yet

- Cloud PointDocument1 pageCloud PointRavi ShankarNo ratings yet

- Molecular Mechanism of Fluoride Induced Oxidative Stress and Its Possible Reversal by Chelation TherapyDocument27 pagesMolecular Mechanism of Fluoride Induced Oxidative Stress and Its Possible Reversal by Chelation TherapyAshitosh KumarNo ratings yet

- Alcohol Phenol Ethers Solved QuestionsDocument21 pagesAlcohol Phenol Ethers Solved QuestionssauravNo ratings yet