Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

69 viewsGreenStar 25 CDi PDF

GreenStar 25 CDi PDF

Uploaded by

1cvbnmCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Iphone 6S Schematic - Vietmobile - VNDocument60 pagesIphone 6S Schematic - Vietmobile - VN1cvbnm60% (15)

- Iphone 6S Schematic - Vietmobile - VNDocument60 pagesIphone 6S Schematic - Vietmobile - VN1cvbnm60% (15)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Beko Zz7.194r-5 Power Supply SCHDocument3 pagesBeko Zz7.194r-5 Power Supply SCH1cvbnmNo ratings yet

- Yamaha Rx-V559 Dsp-Ax559 Htr-5950 SMDocument116 pagesYamaha Rx-V559 Dsp-Ax559 Htr-5950 SM1cvbnmNo ratings yet

- Single Phase Tefc Cage MotorsDocument12 pagesSingle Phase Tefc Cage Motors1cvbnmNo ratings yet

- XTW100 Mini Programmer Schematic and Driver One TransistorDocument1 pageXTW100 Mini Programmer Schematic and Driver One Transistor1cvbnmNo ratings yet

- B140XTN02.0 40 Pin PDFDocument27 pagesB140XTN02.0 40 Pin PDF1cvbnmNo ratings yet

- Ibm r40 Laptop SchematicsDocument60 pagesIbm r40 Laptop Schematics1cvbnmNo ratings yet

- XTW100 Mini Programmer Schematic and Driver One TransistorDocument1 pageXTW100 Mini Programmer Schematic and Driver One Transistor1cvbnmNo ratings yet

- Ibm Lenovo Whistler Rev s1.3 SCHDocument52 pagesIbm Lenovo Whistler Rev s1.3 SCH1cvbnmNo ratings yet

- Acer Aspire 5542 5542G (Wistron JV50-TR8) Wistron JV50-TR 8VRAM JV50-TR8 Rev-1Document63 pagesAcer Aspire 5542 5542G (Wistron JV50-TR8) Wistron JV50-TR 8VRAM JV50-TR8 Rev-11cvbnmNo ratings yet

- Fujitsu Siemens Amilo l7310 Mitac 8650 Rev R0a SCHDocument34 pagesFujitsu Siemens Amilo l7310 Mitac 8650 Rev R0a SCH1cvbnmNo ratings yet

- Acer Aspire 5551G 5552G (Compal LA-5911P) Laptop SchematicsDocument55 pagesAcer Aspire 5551G 5552G (Compal LA-5911P) Laptop Schematics1cvbnmNo ratings yet

- R 25 & 30 HE Combi: Installation and Servicing InstructionsDocument48 pagesR 25 & 30 HE Combi: Installation and Servicing Instructions1cvbnmNo ratings yet

- R 25 & 30 HE Combi: Installation and Servicing InstructionsDocument48 pagesR 25 & 30 HE Combi: Installation and Servicing Instructions1cvbnmNo ratings yet

- R 30/35/40 HE Plus Combi: Installation and Servicing InstructionsDocument52 pagesR 30/35/40 HE Plus Combi: Installation and Servicing Instructions1cvbnmNo ratings yet

- iPhone-3G Battery SVCM enDocument6 pagesiPhone-3G Battery SVCM en1cvbnmNo ratings yet

- Quadro ctv-55d10 ctv-55f12 ctv-55v20 ctv-55n11 ctv-55z10 ctv-55x10 ctv-37d10 ctv-37x10 TXT Mkii Chassis 5p60 PDFDocument40 pagesQuadro ctv-55d10 ctv-55f12 ctv-55v20 ctv-55n11 ctv-55z10 ctv-55x10 ctv-37d10 ctv-37x10 TXT Mkii Chassis 5p60 PDF1cvbnmNo ratings yet

- AN Self-Programming+Examples+for+78K0 Kx2+MicrocontrollersDocument78 pagesAN Self-Programming+Examples+for+78K0 Kx2+Microcontrollers1cvbnmNo ratings yet

GreenStar 25 CDi PDF

GreenStar 25 CDi PDF

Uploaded by

1cvbnm0 ratings0% found this document useful (0 votes)

69 views60 pagesOriginal Title

GreenStar 25 CDi.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

69 views60 pagesGreenStar 25 CDi PDF

GreenStar 25 CDi PDF

Uploaded by

1cvbnmCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 60

NSTAR CDi

[RSF GAS-FIRED CONDENSING COMBINATION BOILER

EATING SYSTEMS AND MAINS FED DOMESTIC HOT WATER

THE APPUANCE IS FOR USE WITH

NATURAL GAS ORLPG. (Cat I2H3P TYPE C13 4.633)

NATURAL GAS:

WORCESTER GREENSTAR 2500! GC NUMBER 4711-02

WORCESTER GREENSTAR 206Di GC NUMBER 47-31-99

WORCESTER GREENSTAR S5CD! GC NUMBER 47-11-04

WORCESTER GREENSTAR 400DiGC NUMBER 4711-05

LIQUID PETROLEUM GAS:

WORCESTER GREENSTAR 25CD: GC NUMBER 47-91-96

WORCESTER GREENSTAR S0CDi GC NUMBER 47-011-97,

WORCESTER GREENSTAR 35CD: GO NUMBER 4711-08

WORCESTER GREENSTAR 40CDi GC NUMBER 47-4001

INSTRUCTION MANUAL

INSTALLATION, COMMISSIONING

& SERVICING

Genchmark

CONTACT INFORMATION

INSTALLATION & SERVICING INSTRUCTIONS

WORCESTER BOSCH:

TECHNICAL: 06705 260241

‘SERVICE 00487 256206,

‘SPARES: 01905 762571

UTERATURE: 01905 752656

TRAINING: ‘01908 752528

SALES: ‘01905 752640

WEBSITE: wwwworcesterboschcouk

WATER TREATMENT;

FERNOX 01799 s60611

wonademen.com

SENTINEL 0181 420 9595

wun betadearbor.comfeetina

FLUE TERMINAL GUARO:

TOWER FLUE COMPONENTS.

VALERISE

TONBRIDGE

wo 1Te

STORE THE APPLIANCE IN A DRY AREA

PRIOR TO INSTALLATION

LUFTING AND CARRYING PRECAUTIONS:

+ Litonlya manageable weight, or ak for

hp

‘+ Whan ting the bode, band tha knees,

‘and keep the back staight and fet spat

+ Donot it and tie a the same tie.

+ Lita cary the bolar cose tothe body

+ Weer protective cehing and loves to

protect rom any sharp edge

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE STARTING INSTALLATION.

THESE INSTRUCTIONS ARE APPLICABLE TO THE WORCESTER BOSCH APPLIANCE

MODEL(S) STATED ON THE FRONT COVER OF THIS MANUAL ONLY AND MUST NOT BE

USED WITH ANY OTHER MAKE OR MODEL OF APPLIANCE,

THE INSTRUCTIONS APPLY IN THE UK ONLY AND MUST BE FOLLOWED EXCEPT FOR ANY

STATUTORY OBLIGATION,

THIS APPLIANCE MUST BE INSTALLED BY A COMPETENT PERSON. FAILURE TO INSTALL

CORRECTLY COULD LEAD TO PROSECUTION.

IF YOU ARE IN ANY DOUBT CONTACT WORCESTER BOSCH TECHNICAL HELPLINE,

DISTANCE LEARNING AND TRAINING COURSES ARE AVAILABLE FROM WORCESTER

BOSCH.

PLEASE LEAVE THESE INSTRUCTIONS, THE USER GUIDE AND THE COMPLETED.

BENCHMARK LOG BOOK OR A CERTIFICATE CONFIRMING COMPLIANCE WITH IS 613,

(IRE ONLY) WITH THE USER OR AT THE GAS METER AFTER INSTALLATION OR SERVIC-

nc.

[ABBREVIATIONS USED IN THIS MANUAL:

2 Diameter

NG Natural Gas

LPG Liquid Petroleum Gas

CH Cental Heating

DHW Domestic Hot Water

IP ages Protection

‘SEDBUK Seasonal Eficieny of Domestic Bola inthe United Kingdom

‘SYMBOLS USED IN THIS MANUAL:

cette Tew ena

oo, Cental heating

&

Yo vv ant

6

Gas sve

Programmertiner

INSTALLATION &

‘SERVICING INSTRUCTIONS.

‘ouuno ancnosoonnacansazancananun QANORCESTER

emsameies — peeneep

CONTENTS

‘SAFETY & REGULATIONS

SAFETY PRECAUTIONS

INSTALLATION REGULATIONS:

APPLIANCE INFORMATION.

‘GENERAL INFORMATION

TECHNICAL DATA,

LAYOUT & COMPONENTS

PRE:NSTALLATION

CLEAVING PRNARY TENS

ARS SUPPLIES

WATER SYSTEMS EPIPEWORR

CONDENSATE PPEWORK

BOILER LOCATON & CLEARANCES —

PLUNNG WANIFOLD

FLUE TERMINAL POSITIONS:

FLUE OPTIONS

INSTALLATION

UNPACKING WALL FRAME AND ANCILLARY ITEMS.

WALL MOUNTING PLATE /FLUE OPENING:

(CHARGING LINK (FILLING LOOP)

‘UNPACKING THE APPUANCE

"FITTING THE APPLANCE /BOILER CONNECTIONS

FLUE INSTALLATION.

(CONDENSATE CONNECTION. _

ELECTRICAL

“POSITION OF WIRED COMPONENTS

‘COMMISSIONING

PRE-COMMISSIONING CHECKS:

FILLING THE SYSTEM

STARTING THE APPLANGE,

WATER TREATMENT

COMMISSIONING.

FINISHING COMMISSIONING

SERVICING & SPARES

INSPECTION AND SERVIGE

REPLACEMENT OF FARTS

‘SETTING THE GAS/AIR RATIO

‘SHORT PARTS LST

CONVERSION KITS.

LPG. CONVERSION

FAULT FINDING & DIAGNOSIS.

FAULT FINDING:

‘CENTRAL HEATING FUNCTION

PREHEAT AND DHW FUNCTION

PROTECTION FUNCTION

22

23

24

25

2628

29

a

6

slele

none) emer emou

1’ ERD aeEaGaee

SAFETY PRECAUTIONS

INSTALLATION REGULATIONS

IF YOU SMELL Gi

2X DONT SMOKE OR STRIKE MATCHES

2% DONT TURN ELECTRICAL SWITCHES ON OR OFF

DO PUT OUT NAKED FLAMES

DO OPEN DOORS AND WINDOWS

DO KEEP PEOPLE AWAY FROM THE AREA AFFECTED

¥ DO TURN OFF THE CONTROL VAIVE AT THE METER

TELEPHONE YOUR GAS COMPANY

Gencimerhy

|ABenchimark Log Book’ provided by the manufacture fr the instar to complete

inching thie CORGI egstaton number to cent tha the bodes hasbeen tale,

commissioned and sorvcod according to the manufacturers ncructons

IMPORTANT: Tho completed Benchmark Check! willbe requited

warranty werk and maybe required by the local Bulking Control nspector,

event of any

HEALTH & SAFETY

‘The appliance contains no asbestos and no substances have been used in the

constuction process that contravene the COSHH Regulations (Contrel ot Substances

Hazardous to Health Regulations 1988)

COMBUSTIBLE AND CORROSIVE MATERIALS

Do not store or use ary combustible mata (paper, thinner, paints ote.) inside or

wii the vicinity ofthe appiance

Chemically aggressive substances, such as halogenated hydrocarbons containing

hone o urine compounds can cade the appliance and invite any waranty

FITTING & MODIFICATIONS.

Fiting the appliance and any contols tothe appliance may only be cared out by a

compstent engineer in accordance with the Gas Safety [installation and Use)

equations 1908.

Fuo systems must not be modified in any way oer than a docesbed in the iting

ineteutions. Any miause or unauthoried modifications tothe appliance, fue or

associated componenis and aystoms could invalidate the waranty. The manulacturer

copia no abit arising rom any Such action, exclung stators

SERVICING

‘Advise the user to have the ayetem serviced annualy by a competent, qualified

‘engineer Guch as Bich Gat or CORGI registered personnel) using proved spares,

te lp msintsin tho economy, safety and reliably ofthe apolince

IMPORTANT - The service engineer must complete the Service Record in the

nchmark section after each service.

Gas Safty {instalation & Use) Regulations:

All gas appliances must be installed by a

competent parson in accordance with th above

regulations. Fale to intl appliances conecty

cou ead o prosecution

The appliance must be insted ia socordance

with, and comply to, the curent: Gas Salty

Rogulations, IEE Regulations, Building

Regulations, Building Standarde (Scotland)

(Consolation), Builing Reguiaions (Norther

Irland), local water bylaws, Heath & Salty

Document 635 (The Electricity at Work

Rogulations 1989) and ary other local

requrements

th Sted:

‘Tho rloant Bish Standard should be flowed,

ined:

[BS70781: Code of practice for domestic and hot

ate upp

{856801 : Installation of low preseure gas

pw up to 20re (R

[855540 stalaton of gas hot water spies for

domestic paposes

EN:12828: Cantal heating er domes romisos

[B95440:1: Fee and venation for gus apt

ancos oad heating rt exceeding TOR (nt

Fuse

{855440:2 : Flues and venation for ga app

scot of ated heating not exceeding TORN (et)

Ai Sipoy

[257600 1 Testmant of water in domestic hot

wate coral heating Systm

1S 6708 : alton of gas fred bol of ated

ino upto 7OKW (ret)

Where no speci inerucon is given, reference

hold be ade to the eevant Btn Standard

codes of Practice

LPG. tlio:

‘An apace using LPG, must ot bo irtaled n

a room orinonal pace belowground eel unless

cone side ofthe biting is open othe ground

“Tirber ame bulge

Where th bolero be ted to a tine rec

balding the guinea down fn BSS440: Pat

1 and IGE "Gas instalation in Timber Frame

Buicngs hod bo adhered.

Potable water:

Al seas, joints and compounds (mcuding fax

land solder) and components used as part of

the secondary domestic water eystem must be

approved by WRAS,

SAFETY PRECAUTIONS:

INSTALLATION REGULATIONS

voxacince YAVORCESTER

GENERAL INFORMATION

STANDARD PACKAGE!

[A+ Wal hung gas fred condensing combi bol

for contal heating and domestic ot water

1B Wal mounting pla

(C- Hanging bracket

D.- Pre-plumbing manifold

E- Hardware pack

FF» Charging Link Assonbly

G- Lterature pack

1H Bottom pane

1+ Tiap/ Syphon Outlet Connection

(22mm Paste Pee)

‘SPECIFICATIONS:

rewired and pre-plumbed

Cavarised steel nner tame

Digital conta syst

‘Automatic ignition

Dict bumer ignition

BBultin ost theemostat (oor protection)

Buitin fault nding agnostics

Modulating automatic eas valve

Combustion aan with speed regulator

CH temperature sensor & conto

Pum ant-seizue protection

Fe gas temperature Inter

Condensate rap & syphon

HW tow censor & temperature conta

Pate type DHW heat exchanger

Moduinting exeuating pump

(GENERAL INFORMATION

TECHNICAL DATA

NATURAL AS es

oesominon uns | z5co1_soca_s8¢01 cai | asco, anco1 ston

id

Tat BL Bese est me | as

ed aw Bese sae | eae

Ta a eee

so TT wD

Ta a ao Be eae a ae

Saas oR a THEO HOTT

San ie at ae ATS Te Loss ae es

Ta Danas a ae OST a

ores

a dere a Biss eae as

Tis ope ETS ww [wee sa ans [eae

Max. rated heat output net SO/30°C ai kw [26 318 318 8 | ee 1888

~ Max. rated heat output net 80/60°C Kw | 250 300 800 300 | 250 900 900

Min. ratod heat output net 40/30°C ew 86 Co 98 cc

Tees ps m7 iW [as 6666 Tos [or er er

Yee at 0060S wb mes [or ara

(Min, rated heat input net i ka 80 80 cy a8 on oF ot

‘Max. flow temperature =C__[nom.90 nom.80 nem. 80 nom, 00 nem. 90 nom, 80 nom. 20

‘Max. permissibie operating pressure ber | 30 30 30 30 | ao 30 20

‘Available pump head at 21°C systern temperature rise = m 2 He 2 2 2 Ey 2

Ga ena rine ro og

‘Natural Gaa G20 wn [20 92 37 46 | ae

Pope GaP) ‘oh ail aaoiuvealides

fee

Five Gas Temp. 60/60°O, rated win loud “c | 7058 76/58 76/58 86/56 | 70/58 76/58 76/58

Fos Ga Top (090°, td ud “S| ras oases some [ ave essa

Good aa @ [ce 3606 — 07 | 108 oa 108

vel at min. rated heat output ct % 9.0 20, 90 94 105 105 10.5

NOx- cass 306 HE LEE Hee sore reeceee Ler Ost

Conde

Ti: ec eee ea eae

hci

Sot er Tex | woo a so sO

ine) e [ooo [ow

Ts aa a

“General Dato

Fp pion fe

ee La

Ferber unpooe “| ban 0x0 ps0 oan | a0 e00 080

Nominal capecity of eppliance 1 [am a7 375 975 | 875 976 3.75

Tse aa al aie aw 7 [ea

“Total bolle weight (it weight) wo | #85 405 485 405 | 485 485 488

SEDOUK [os ons wos wo [ays 008

a aan ecmarereecemencmmnnes SAVORCESTER

reeamota Baerga

LAYOUT & COMPONENTS:

‘he cagray opposite shows the cont nthe

senicng poston and excades the oer ase

1 FLAME VIEWING window

2 IGNITION ELECTRODE AND FLAME

SENSE ELECTRODE

9. HEAT EXCHANGER

OVERHEAT THERMOSTAT

5 ACCESS POINT FOR CLEANING HEAT

EXCHANGER

6 PLATETO PLATE DHW

HEAT EXCHANGER

7 PUMP

© SYSTEM PRESSURE GAUGE

9 ORANPOINT

30 MAINS COLD WATER

11 CHRETURN

12 CHARGING LNK ASSEMBLY

13. GAS INLET CONNECTION 22 mm

COMPRESSION

16 COVER FOR EXTERNAL WIRING

CONNECTIONS.

15. CONTROL PANEL IN SERVICE

PosiTion

16 ACCESS COVER FOR TRANSFORMER,

aPcB

7 DEW OUT

18 CHFLOW

19 TRAP/ SYPHON OUTLET CONNEC:

TION (22 mm PLASTIC PIPE)

20 INLET PRESSURE TEST POINT

21 TRAP/ SYPHON

22 GAS VALVE

23 DHW TEMPERATURE SENSOR

26 AIRY GAS ADJUSTMENT SCREW

26 TESTING POINT FOR FAN PRESSURE

26 FAN

27 PRIMARY SENSOR

28 EXPANSION VESSEL

20 REMOVABLE TOP CASE PANEL FOR

SERVICING

acs ee oseears

ne ormen zmaang

nooner cosocorcarc isu cues

LAYOUT & COMPONENTS

6 PLATE TO PLATE DHW HEAT

EXCHANGER.

9. DRAIN POINT

92 SYSTEM PUMP.

36 FLOW TURBINE

‘37 UNUSED PORT

98 AUTO AIRVENT

‘39 FLOW CONNECTION FROM BOILER

HEAT EXCHANGER

40 DAW SENSOR

‘41, CH FLOW CONNECTION TO SERVICE

VALE

42, DHW OUT CONNECTION

49 COLD WATERIN CONNECTION

44 CHRETURN CONNECTION TO SER-

VICE VANE

45 DIVERTER VANE

46 PRESSURE RELIEF VALVE

487, COMPACT HYDRAULIC MOUNTING

‘SCREW (2}70 BOLER

48. CH TEMPERATURE CONTROL

49, MAINS ON/OFF INDICATOR/OUGNOS-

TeUGHT (BLUE

50 DHW TEMPERATURE CONTROL

51 CENTRAL HEATING BOOST BUTTON

52 SERVICE BUTTON.

59 BURNER ON INDICATOR LIGHT

(GREEN)

MASTER SWITCH ON/OFF

HOLIDAY BUTTON

ECO BUTTON

FAULT RESET BUTTON

SYSTEM PRESSURE GAUGE

POSITION FOR OPTIONAL,

PROGRAMMER

DISPLAY

Besege

8

nr ete enuresis osWoRCTER FOS emo EOE R

exon) — aoaere

CLEANING PRIMARY SYSTEMS,

KEY

©«

ae

TUPORTANT: Debris from the system ean]

[damage the baller and reduce efticiency

Failure to comply withthe guidelines tor

the use of water treatment with the apo

ance wil alate the appliance warrenty

BEFORE CLEANING THE SYSTEM

ENSURE THE SYSTEM AND PIPEWORK IS

GOOD WORKING ORDER

KEEP THE EXISTING BOILER!

CIRCULATING PUMP WHERE POSSIBLE

ORUSE A POWER FLUSHING MACHINE

TO AID THE CLEANSING PROCEDURE

BEFORE INSTALLING A NEW BOILER.

CLEANING THE PRIMARY SYSTEM

1 Ftthosjstom wih cold wator and check

for bea.

2 Open al ean cocks an sain the sytem.

9. Clone dain cook and add a sitable

ushing agent a the corect strength for

the astam condition in aceedance with

the mandate ucts.

Ciretate he thing agent before the

odor ie rod up

4 Rum the boiaveystom at nomal oprating

temperature a5 cected by the manufacturer

‘ofthe tushing agent

5 Drain sed thorougiy fish the sytem 10

remove the feshing agent and debris.

AFuoncssre

COLEANING PRIMARY SYSTEMS

MAINS WATER EXPANSION VESSEL:

[A+ Mii expereion vest part No, 7716 102 105,

1 Maine ater iet pipe

© Non tin valve

0 Boise

MAINS SUPPLIES

ELECTRIC SUPPLY:

+ Supply 280 50He

(S00 Tecnica! Data for Pratings)

+ Cable: PVCineulsted 0:76mm?

(24 0.2mm) tempersturs rated to 90°C.

+ External 3A fo fo 81962,

+ Tho appliance must be sartas.

+ Allppos tothe bolermus! be rose

bonded.

+ Wing must comply wth IEE wing regu

‘ons and ary local egulatons which may

299 to fed wing toa stationary ape

Gas SUPPLY

+ Bolers using NG must be connected ta

‘governed moter.

+ LPG boters must be connected toa

relator

Instalaion and connestion ofthe gas sup

yt the beler must bein aocordance with

‘sean

“+ Under no citeuetanoe eho th oi of

2 suppl pipe be eee than that of ho

spplanos inet conection.

+The meter or regulator and ppowork to tho

meter most be hacked, preferaby bythe

(922 suppl, to ensure ite in good working

‘order and ea et the gas ow and pres

sue requirements in adcon tothe demand

from any oir appliance boing Served. This

‘doesnot include the pipework from he

metro the bole:

WaTER SUPPL

Wes Maine Pressure:

+ Miimum mains water pressure 18 upto

25 bar (Goo tenia! data on page 6) for

‘mazimum perfomance.

+ Mayumam maine fod wate rostire 10. bat

I necessary fa pressure raducing va

IMPORTANT: Nonelurn, back flow pre-

vention devices (including those assocat-

ced with water meters) fited to the mains

water supaly can cause a pressure build

Lup which could demage the boiler and!

other household appliances.

+ Whore tho maine water supply has & non:

rower, back fow prevention va ited, a

tin erpansion veel (A) should be com

ected f the mains water et pipe 8)

between the norretum vale (C} andthe

bode (0) 2 shown opposite

Use in hrd water areas:

Normally theres no need fr water tretment

to provent scale formation as the maximum

‘tomporaturo of the DAW heat exchanger

Ite by the electronic contol eeu

In areas where the temporary water naraness

exceeds 200 ppm, consideration may need to

be given to the fiting of a scale prevention

device In such creumstances, the ace of

the local water authoy should be sought

Daesees ee ge

cmmevamouss peace

WATER SYSTEMS & PIPEWORK

PLASTIC PIPEWORK:

1 Any plate pipowork must have a pyc

‘bara with 09 mn (rrr) length of

‘oan ose spe connected othe bl

Plasto ppework used for underoe heating

must bo corrocty consoled witha theeno-

‘abe Bang va ting the lemparture

ofthe cre to approx. 50°C,

Tha pipework rm the bolero the blending

valve must ben copper or steel prtected

‘rom coroson.

CONNECTONSINALES:

‘Allester connections tape and ng

‘elves muot bo capable of esting a pres

‘ayo up 10 S bax

+ Radiator ves should conform to

97767:10

+ Allother aos should conform 10 831010

+ Thomostaic ator valves (RV) must be

sed ona racators within the slaeping

_cconmiodeton bu nat the radiator whore

the oom thermostat ie sied. This must be

ted with wheelhead and ockhild valvos

and ft open,

+ dain cocks requred atthe lowest port

‘onthe ojo.

+ An airvont is requted atthe highest pont

‘onthe tom

'SHOWERS/SIDETS

+ It shower head cane immersed in water

‘comes closer than 25 ren from the Yop

‘2dge ofa bath or shower try gpl over level

‘hen an aisipon deve must be fited 0

the shower ose

+ Biot wth direct hot & cod main water

‘an be used (th he spocoral ofthe local

water authority) and must be the over

fishing type with shrouded outlets to re

vont the fing of hard held sprays.

Reet ecieaer

genes cousomnce ira

ae mee es

gee beara enaad

Seem Sten eee

Some Gccerwuces

Seen mi ee ceeaereeee

oe } 4 foceee coe

! | tothe applancein the conta heapg

eee cote ie

See

vininoteopsce

«Bonotan gene! ios oon,

TRI |

E

<

PRE O Se a S

CONDENSATE PIPEWORK

CONDENSATE PIPEWORK:

‘The condensate pipe mist be amininam of

2mm plastic pipe

‘The condensate pipework mustallat east

‘50 mm per mete towards the outlet and

‘should take the shortest practicable route

‘The pipework must flow one of the options

shown epposite nto an internal sorvicesbl-

‘rap (i. 75 mm) such asa sinwashing

machine) snd dscharge direct into a vot

‘tack () min. 450 mm above pie invertor

ito aguley (0) below ground but above

‘he wate vel

Use waterproot pe insulation in exposed

positions and for excessive rune of exter

al pipowork (over 3 metres).

IMPORTANT: Ensure there are no block-

es in the pipe run.

ig

2

3

4

A

B.

c.

D

e

iF

s

H

a

K

PR

Internal sink/washing machine rain

Internal waste drainage eystem

Sol/vent stack

External drainage system

External condensate absorption point

Condensate rm bate

Sink

22 mm O plastic condensate pipe

Gulley

Intnl so and vent tack

Serviceable waste rap (75mm mi)

200 nn 100 mm @ aened plastic tubo

(Ground level

Drainage hloo 60 mm fom base of tubo

(12 mm @ at 25 ren carte) facing ancy

from bulding

Limaetonachippinge

{ESSURE RELIEF PIPEWORK.

IMPORTANT. The pressure relief valve is @

safety devico forthe boiler and activated

‘may discharge boiling wate or steam

through the relief vale drain pie.

‘Care shouldbe taken when siting the out-

et pipe so that t does not cause an

obstruction or discharge above a window,

entrance or other puble access where

could cause a hazard,

te

‘The presou rai ein pipe (MO) om

the boiler shoud be at laa 15 rm rotor

_capp2ppe and run dowrwvarde away from

any elective oF oor hazard, roars

anvtcnal sain o eoakaway

Pipe should be frishod wih par

and, nar the cute aoe the exer

al (a¢ehown) to hap prevent teeing

Use waterproo! pipe inaulation exposes

postions and for etemal pipework,

Outside wat

M,O- Dean poe

Eternal dain

‘CONDENSATE PIPEWORK

erate

SERVICING CLEARANCES bed Pee BOILER LOCATION &

VENTILATED Sere

‘COMPARTMENT teat : CLEARANCES

‘Tis baler only table or instaling intomaly

within a pronerty at & suitable lestion ono &

fod gi nar combustbe srace at leat the

‘same sit asthe bollor and capable of suppor

ing the baler weight

‘COMPARTMENTS:

{Using 100 mem fo kt Follow the requicernonte of BS6708 and

$H12mm $5440 Pat 2 end note

sig 128 mm fe et ‘+ Minimum eeorancea must bo maintained

=1182.mm

+ An anvess door i required oneal, service

and mina the bole and ary ancilary

equipment.

+i iting te bor into an sng eupboare

use a non-combat prfrated mata

(rasan hole sizes of 13m) to seperate

the bole from the ang space,

BOILER CLEARANCES:

- The diagram opposite shows tho misimuny

space requced tonal and eonoe the bolo.

VENTILATION FREE Hg boiler i installed in a compartrnont with

COMPARTMENTS ‘clearances lesa than shown in the diagram

INSTALLATION CLEARANCES below, ventilation is required. Roer to tables

below for ste,

‘Greenstar ODI

Vert [Toroamor | Drectto

positon | intemal space | eutside

High evel | Menu hea | Meum ge

rea 122 en*_| area 6h om

Tawiava | Minimum fee | Minimum Rem

ron 23 cm] area ot om

BOILER CLEARANCES - UNVENTILATED

COMPARTMENT:

‘Te diagrame (A and B) oppoeite show two

options for the minimum space roquted to

install and seven tho bode inside an unvent

Isle compariont.

"This spseo cen be reduced to mm for ene

1 ony ae long as Both the side clearances

fd upto the total of both tho sie measure

ents shawn oF mre

100nm*

200m"

orempiable door

00m"

Frnt clearance

forsorsce

Ain ee

BOILER LOCATION &

CLEARANCES

BATHROOMS:

he baler can be installed in 29068 2043.12

rachanical or RFmocharica mers ed the

oder canon be instal in ane &

See IEE wiring regulations

(See Technical Data for P ratings)

IMPORTANT: any switch or appliance]

contro using 230 V mains eletcty must

not be able to be touched by @ person,

sing he bath or shower.

Electrical switches, fused spur and socket

outlets must not be situstod In the bath

00mm radias

Eg cee eee Tg meee

clones cross

dls sy =

tal tA Ff mae vera tonsive ton sv apne) 18am

; £ itt

Maine Gas Supply 22 nm

A

PLUMBING MANIFOLD.

‘CONNECTIONS:

Heating Sstom: 22 mm oompressionftrgs

HW: 15 mm compression tings

Ga 22 mm comprossin tinge

Uso the fitings supplied in the Hardware

pack,

PREPLUMBING

With the plumbing manifold installed,

pipework can be nataled othe vals on tho

rmantov.

‘The systom esn be filed (without the bole

being connected) using tho charging lnk

ascanbly (oe page 23)

Te valves can be cloged eaalg the DW

‘and CH systems tobe tested, The boder can

be stale tater dete,

RUNNING PIPES BEHIND THE BOILER

H the baler pipes ate to be rin behind the

‘applenco enero thatthe pipoe pass close to

the wall ge shown inthe diagram cpp,

‘ad withthe pips ui,

PLUMBING MANIFOLD

Minimum dimensions off terminal positions for balanced room sealed flues with

fanned draught

awa, [TERMINAL POSITION oIstaNcE

ners

1° | Dresty bow an opening, bk opaing windows ee | 300mm

8° _| Avior anoreing a ik oping wind 300 rm

© | Rote i bk, oprng wide 300 nm

| alow guts, slips or ern poe on

Bow avs aa 200m

F__| exw baconie orcar pr ot lone pi a

fom vera din pipe oro p= 500m

—___| sen

1 | Aor grunt oo ebony 00m

1 | froma arfac ng torial oon

1__| Fro tina acing te terial 2000

| Fran cso nhc ot or vido te dana) 1200ren

| Wertiay toma twin on he same wa 16000

| oz rom ated othe sae wal cone

© | froma ren combust othe oo *

P| Above unscion win ea ~

FLUE TERMINAL POSITIONS.

+ Tho ve mast titel an terminated

accordance with the recommendation of

1888440 Par 1

+The fue mast nt cause an obtain.

+ Discharge and any nse oe he fe ou

Flas gases havea tendency to pume and in

Ccecain weather conditions a white plane of

‘condensation wil be charged from the

{ue outlet. Whee this could be a ruiaarce,

for ample, noe eecurty lighting an ater

rate positon should be found,

+ Tho sirieltioutot dct and th terminal of

the boder must not be elzer han 25m to

any combustible mato.

Detaled recommendatons on protection of

‘combustible materiale er given n

Bs seco

A protective temirs guard must be tat

‘he tials 2m ores above a surface to

hich people hava access.

‘The guard mast be spaced squat (rit

‘nur 60 mi) sound he fs and Bred to

‘the wall with lated secs. See Contact

Infomation nde fron cover

1 In editor the termina should not be noaar than 150mm (lannod draught) oan eporing

In the busting fabri formed er he pupoee of accommodating bull elemant such as a

indo ame,

2 Net recommended.

2 Ses instructions suppliod wih vertical kts.

[oa

Hy O

4

boundary

: eff]

t U

W om

ALL ay]

aa a a aaa Poca

rmmemows — Qemanw

FLUE OPTIONS 25CDi

'STANDARO FLUE HORIZONTAL MAXIMUM FLUE VERTICAL

START +2 BENDS,

ants used athe maximum fo lng fr

‘each configuration of 100 mm and

128 mm © hues.

‘Shaded fue components inticat the stan

‘dud 100 nm @ horizontal fue,

(Onl saight Wu sections canbe reduoed

in ength and ou

+The fie terminal end canbe fied from the

Inside or outside ofthe bul,

Fring hts are supped withthe Mae exter

Qo—ur a Fore

:—

co

2100 £000 mm

+ Teagan (opposite) sow the compo:

100

MAX 689mm Ax1

MIN 250 mm Ax 1°

2125

MAX 1070 mm Axt

MIN 250mm Ax 1"

Regis eating

We + Fat

0128-21000

AxL+0x2+ B22 ~~

Fx

sien tts

Hezonta 128 mm @ and Vertical 100 mm

and 125 me fe sae aso wth

MAXIMUM FLUE HORIZONTAL MAXIMUM FLUE VERTICAL _—~7|__goparteinetuctions, Contact your upper

| START+38END8 Py Wexoener Booch,

soz

Ooo «+ =)

A co

—>

a Beton

12100-10000 mm

Axi4 8x10

+ Bx + Fat — a

(2125 23000 mm

ce gi women. att tb mon

2 ee cin

Calculating te te loath:

Mosse the tla ue length recuked, noting

‘hat the maximum straight fue length ineluding

the ternal i

Hoyiaontl 0/100 mm @: 10000 rm

eriont! 80/128 mn @: 28000 rm

orc! 80/100 mm @: 11800 mm

orca! 80/125 mm 2: 23000 ram

sere oar

pieces es {cla ern

see LO

(ictus taint)

+ Pat Baal + Dx2 +601

‘Then reduce the total straight fue longth for

each eva fue bend (acluding the tet by:

2000 mim for 9

MAXIMUM FLUE HORIZONTAL +1 BEND VERTICAL FLUE WITH 1900 mm for 45°

200" BENDS:

Fu ecension total eng:

Ocorr s Horicntl Verio! 6000 mm: 960 en

= a 8 Horsntl Vera 80/25 mm 2: 1000 mn

Qe |

(2100-6000 mm

Agt4 Bx94C21

12125-21000 mm

Axt4 Ox +041

—— Fue terminal ft onthe:

LY Weoriconts 60100 ren O: 800 mm

c QD orion! 60/128 mi Q: 1200 ram

(0100 700 mm = Vorioal 60100 mm @: 1140 mm

(clung trial) orca 80/125 mm 2: 1365 mm

Bx9+ Cx2 HEX?

(0125-19000 rm

(ictcing torial)

Bx20+ x2 +EX1 arma iana

imaceata ae era aa ocaemiseeunaet aes

‘STANDARD FLUE HORIZONTAL

acm, [oe

‘e100

MAX 686mm Ax

MIN 250mm Axt*

ons

MAX 1070"mm Aas

MIN 250 mm Ax *

* Requtes euting

MAXIMUM FLUE HORIZONTAL

aocors

———ae

2100. 7000 mn

Ant 8x8

12128-18500 mm

Axt+ Bx18

[MAXIMUM FLUE VERTICAL START + 1 BEND.

Fo coors

ate

Oe |

12100-7900 mn =r

Art+ Oxi Bx9 :

+ Fat

2128-18500 mm

Arte cxte Baris KS

+P

[MAXIMUM FLUE HORIZONTAL + 1 BEND

ores ft

a re

ae =)

2100-6900 mm

Axt+ Bx740x1

(8128-16500 men

Axl + BxI7+Ox1

FLUE OPTIONS 30CDi

MAXIMUM FLUE VERTICAL,

START +2 BENDS.

‘Te cagrane (opposite) show the compo-

eats used an the maximum Bue lngth for

‘ach coniigaton of 100 mn snd

128 mm Ofves.

‘Shaded fue components indicat the stan

ard 100 men @ hain

(Ony stright fo sections canbe reduced

in ength and ew

‘The fe terminal end can be tte fom the

inside or outside of the bung

Fring kts are supa withthe fue exon

sion ts.

Horzontl 125 mn @ and Vertical 100 mm

and 125 mm 0 fe ks ae avalabe with

‘separate instuctions, Contact your upper

FaCorA

———)

co

2100-5900 mm

Ani +Cx2+ Bxo

Fe

2125-16500 mm

Axi+C194 8x18

+ Pet

(MAXIMUM FLUE VERTICAL 1

START + 8 BENDS

2100 co

MAX 686 mm Ax 1

£100 4500 mm

oan ara AxteCx2t Bx6

ons +x

MAX 1070 0mm Ax 1

MIN 260mm Ax”

* Roches cuting

(2128-14900 mm

Arts 0x24 8x15

Fer

(MAXIMUM FLUE VERTICAL

| START+8.BENDS

MAXIMUM FLUE HORIZONTAL

goes

= 8 ff

(2100-2800 mm

(100-6500 mm

aes +65 + Fat

pec retaa 126-1200 a

fe . Axt+x8

asin RUEVERTCAL START +1 BEND MASMUMFLUEVERTCAL

ww 2 6" B=NDS

=e — 7

Qe a

eo 28

o100-6500mm

12100-8000 mm

Bets ess eee (cling terminal)

2x64 Dx2 + Ext

‘2128-16000 mm

Ault Cx14 Bre

+Fxt

(2125-14000 mm

finch trminl)

Byte Dx2 Ext

(MAXIMUM FLUE HORIZONTAL + 1 BEND. VERTICAL FLUE WITH

2X00" BENDS.

eos eee

ae

100-4800 mn co

Ants Bx54+Gx1 eatin ie

198-4000 mn fecudng ein

Axt4 8xw4cnt 8x54 Cea +Ex1

(2125-12000 mm

‘cing teins)

Brit C2 +E con

FLUE OPTIONS 35CDi

+ The diagrams (opposite show the compo-

rents used and the msi fe length for

‘ach configuration of 100 me and

125 ra @ fs.

+ Shaded fue component indicate the stare

‘dard 109 mm © horizontal ue

+ Onl aight te seotions can be reduced

intength and cat

+The fu terinlend oan be ited rom the

inside oes f the bik.

+ Fing kts ar supped with he fe ete

Sonkis

+ Heviontl 125 mmm @ and Vota! 100 mm

nd 125 eB tht ro aalble with

operate ieiuctons, Contact yur eupalior

oF Woreoeta Bosch,

a ec oD

gcor 9 8

— a

‘Stand hozona uo (100 mm @ shown)

‘Straight fe extension

Fue bend, 90°

Fun bende, 45°

orca terminal (vetia adaptor suppl’

vst termina

+ Vorieal adaptor (used wit horzontal

‘senna

CCaloatng the fe ena

Measure the total fue length cequred, noting

thatthe mavimum straight fue length including

the terminalis

Hevizontl 60/100 rm @: 6500 mm

Horizont! 80/125 ren: 16000 mm

Vertical 60100 mm @: 8000 ren

Veron! B0/25 mm 18000 mn

Thon roducs the total eraight fue longth for

‘each ona tse bend (exctudng the tut by:

2000 men for 90"

1000 mm for 45°

Fue extension tte lengths

Horizontal & Verteal 60/100 sn 9: 960 ms

Horizontal & Vertcl 80125 mm ®: 1000 mm

Fue tein total onthe:

Horizont! 80/100 ren : 800 ren

Horizontal 80/126 mm @: 1200 rn

Vertical 60700 mm Q: 1740 mm

Vertis! 80/28 mm 2: 1985 mm

a a ae SS

exch ee emmanamoune

FLUE OPTIONS 38¢Di

FLUE OPTIONS 40CDi

STANDARD FLUE HORIZONTAL (MAXIMUM FLUE VERTICAL

Sars 2 BENDS

LES + Medians pont owe con

gocours eco nerd ar rier gr

—— Swenson oon a

ts an hen

ra co ‘+ Shaded flue components indicate the stan-

eee eae 100- N/A, dard 100 mm @ horivontat flue,

MIN 250mm Ax1*

ons

+ Onl straight tuo sections canbe reduced

inength are eu.

MAX 1070 men Ax 1 + The fe terminal end can be file om the

2128-10800 men

MIN 250mm Axt™ rites aioe inside or outside of the bung,

*Reuies cuting woe + Fsng its aro supp wih the fv een

sion ts.

+ Honsontal 125 mm @ and Vertical 100 mm

and 125 mm @ fi ts ae avaiable with

MAXIMUM FLUE HORIZONTAL, MAXMUM FLUE VERTICAL _——* operate intetine. Contact your supplor

} START+9BENDS: (r Wovcoster Booch,

: &

° A co

to oct 7 6

©100- Wa =

|

2100-2600 mm

Axis Bx2 ——=5 a

108-12600 nm ors-aso0mm

Axt+ 8x12 Axton -A~ Standard ict fe (10 mn © shown)

ani + Fe B- Stig te exenson

©. Fun bend 0"

D- Fue bends 45°

Vora emia cal adaptor upped

wi eri)

WAXIMUM FLUE VERTICAL START +1 BEND MAXIMUM FLUE VERTICAL Fara adaptor (ed wi harzrtd

‘Wms 2x 45° BENDS tein

so 4

as .o—

ac ”o CCleulting the fhe length

Measure the toa fue lng require, ntng

Caer er0-2000mm ae that einai a a hg

a (ousegtemnan —[ the emia

Brat Os? +Ext | Horta 80/00 mm: 2600 wn

rete LS caw Lo Sitaram

eat ae eis eta ‘ert 60726 men 9: 16000

Bate Ded E81 re en: 18000 mm

“Thon ree the ttl etaght fue lng for

cach ona bd ecg th tet by:

2000 rmfor 90°

MAXIMUM FLUE HORIZONTAL + 1 BEND vermoaL FLUE we 1000 me fe a8*

2x80 BENDS

Pavesi tl ogi

Pata rl 69700 rn: 989

E antl &Verial 2725 rn: 1000 mv

e

:.o Fue ternal total enh

avisootl 69/100 mm: 200 rem

co eviootl 80/125 mn @: 1200 mm

Ante Bet 4Gxt

100-1vA Vera! 60/100 rem Q: 180 wen

(0125-10500 mm a erica! 807128 man O: 1988 ro

Ant + Bx 4Ox1

iat 19128-12000 mn

(intuding tema)

BxIS+Cx24E81 creamer

ae oetceueca: nourovssinencretironrenwmemcnscccumsconcaaceancn ANORCESTER

Po

UNPACKING WALL FRAME

AND ANCILLARY ITEMS

LIFTING AND CARRYING PRECAUTIONS:

+ Uitony a manageable weght, or ak for

op.

+ When fing the Baler, band the knees,

nd koop the back stig and fost apart,

“+ Dio nat and ita the same ten.

+ Lit and cary the bate close to the body

1+ Wear protective cothing and gloves io

roc rm ay sharp edge.

Canon

= Wal mounting plate

Hanging bracket

Prepumbing manleld

Hardware pack

+ Charging Unk Accembly

Literature pack

Bottom pane

“rap / Siphon ute Connection

(22mm Paste Pips)

+ Uppor support (plytyeene)

yrotmoomr

porta HANDUNG INSTRUCTIONS

‘tis advice that to people are vee to

‘ay tho carton em the van tothe pont of

salvo

+ Once he carton has been dover the

{op ofthe carton i pane. sharp ipl

rents uted make sue the carton snot

perced and that the knplement is used in

such away 2 hat it may nt cause person

lj, Al sharp objects mast be covered

or he blade reacted ater use and put

sway nase place

> 1. The upper supports now removed with

the componente (bottom panel, pre-plum

‘ng mantole, ngs, documentation ast,

charging ink, hanging bracket,

2. The bil wal mounting plato can now

be pled out.

Akon reqremeets for 00! epace instal

1+ The bole shoud bo frst unpacked before

ascending lasers ct spac.

1+ Two ets of tap shoud be use.

+ Two pecple should share he sting of the

ber upto the loft hich, where the bofor

isentered iat thot space tted and ef

‘on ts Bock tothe lt.

‘Gace the appance i removed tem its pack

‘ing check the content aguinat tho packing

ist,

Before instaling appliance ensure system

has boon cleaned as explained on page 8

areca es eh

an ivan souaum

UNPACKING WALL FRAME AND

ANCILLARY ITEMS,

WALL MOUNTING PLATE

FLUE OPENING

Penne

ort

Leena

SAFETY:

Al tlovnt sakely precautions must be urdec-

taken, Poteove dotting, footweas, gloves and

‘salty goggles must be wer as appropriate

FIXING THE POSITION OF THE WALL

MOUNTING PLATE:

‘+ Tho dagram opposte shows the este

poston of the Mao and the fing of tho wall

‘mounting plat, the mounting plate and pe

lunbing man

> Place the wall muting pate age

walln the desired pean

> Mri ing points through the holes (A, B,

() inthe wa mounting plate

» Dil he @ hoes for wall mounting pate, wal

hanging bracket and pre-lunting manld.

> Secare wal mounting plate with hanging

bracket wih 9 sorews(eupplln with he

bole. Do not uly estan the lower 2

the

> Use te orzo losin the wall mounting

lato level the hanging bracket, mark te

‘the and cay

> Ficandsecute the hanging backs with

both scr

Fwe ouner

Follow tho diagram opposite to mark the

ee conta of the fo for rear cut I & 2

forsice outlet (2&3),

* Note: increase ths eh by 52mm for

every 1000 me of rn length that he

uo outlet aay re he bel.

> For the 6000 mm © fe make a 128 rn

ameter hole Urough the wal using « 2x0

ee ors

Fortes using an optional weather calle

‘ted om inside the bviding msko a

160 mm 8 hole.

Clear away any tra.

FRING THE PRE-PLUMBING MANIFOLD:

Mount he pre-plumbig manld on tho 2

lowor soem and eocure the screws.

aia ae uncmcrnmaparasacamacmeoranananwes AYORCESTER

RE OSENING tavoneun © WORE

CHARGING LINK

(FILLING LOOP)

> Fully cose th song aves on both the

DDHW inlet ans CH retum connections

> Check thatthe gas and water connections

aotght

11 Unscrew the blanking plugs em both

the DHW int and CH retun connections.

> Place the fiterinste the int side ofthe

‘Charging Link onsuing thatthe filter mesh

is inside the inlet,

> tthe Charging Link assombly ono the

DEW inet and CH tum connections

> Do rot inset th Charging Koy ath siege,

412 Enoure hat he Charging Links pushed

in ful tothe stop tabs on both ides of the

‘Charging Link

> Fittwo I sevens complet wth washers

to each of he two connects. NB: Its not

poset to cess the thie sorew hole so

thi can bolt

» Dorotattangt totum ho brass hexagon

43 Ensure that he white plastic Control

‘Serow onthe Charging Lnkie tuned fly

ito its closed positon, se dhagram (1)

> Open ta icalating valves on bath the DEW.

blot and CH roten connactins

> Insert te Chrgng Koy ntaly aging tho

‘row on tho oy wih tho “unlock eb!

‘on the Charging Link body. Eneurs thatthe

ky ie ingrtes uly an tun to tho “Tock?

potion, Chock thatthe ey i ecu, soe

agra (13)

Toll the esta rm the OHW inet im

‘he white plastic Control Screw onthe

‘Charging Link oth yo poston

>» Onca the system has sen fled turn the

white Conte! Sow ois closed poston

12nd then remove the Charging Key by ta

ing back tos “unlock” poston and with

‘drawing. Store the Charging Key in the op

CH Rewn provided on the inside ofthe bottom pnd

Connection

Blanking Pug

: Charging Link

DHW Inet

Connection porae:

M4 Screw ‘Charging Key

and Washer

Fier

PAUORCESTER “n> enerenimernaramnsinnion

Pm EDESIEEDE CHARGING LINK (FILLING LOOP)

UNPACKING THE APPLIANCE

UNPACKING THE APPLIANCE

A= Outer carton

B- Packaging base

C- Prosatne waging

D- Appliance out case

E-Serowe

F-Clp

G - Protective packaging

> 1. With tho wal ame and anil tome

romovod (ee p20 the carton (A) on it

back

2. Open tne ert bottom fap and fold

under oder, Da not emove th peckaging

base

3 Stand carta (A wat baller peg on

the packaging base (8).

> 4, Remove outer cation (A) and place saely

‘wy fro tha working era.

> 5. Remove the protective weapsing (C)

> 6 Le the bole ona back,

> 7 Remove the packaging bae (8) and

‘place safely away rom the worn aro.

REMOVING OUTER CASE

> B.Loosen but donot remove the 2 serous

(©) curing llr casing athe bottom of

the appliance.

> 8.Pullupmard orlease the cp (Fon top

cof he oder and pul tho caso upwards

10. Remove the outer case

Te Remove the protective packaging (6)

tromtheeactode acm

Donot wee a

the ame

sherds

UROO HEATING anmmnmannnenenmnimnan, QREESTER

FITTING THE APPLIANCE

De motte

et BOILER CONNECTIONS

Prunus

eeu as

re rte ray

eens

(GAS AND WATER CONNECTIONS:

> System pipes may be run verzally upwards

behind the bole or below it. See Pumbing

Mani Section on page 15.

‘ACH flow (22 mn),

BCH run (22 en),

© Gas not (22 ne,

- DHW out (16 mn)

Maine water not (15 re,

> 1. Fitoolng washer o sare vaves

beter hanging ber

IMPORTANT: Before hanging the baller onto

the wall mounting pte ensure that the pray

‘sre rele valve connection i athe DOWN

poston, This is located onthe righthand sido

‘ofthe wal rama he re

> 2,Pullhe extended tebover orward and

own unt thre eno futher travel

> .tang the bail on tothe hanging back

ft The luge pace through the rectangular

hol in he boi back pana

Tato care roto at the washers on the

NOTE: tis recommended that thie iting

‘eperation ie care out by 2 peopl,

‘observing al precautions forthe sae iting

of hoary object

Do not bythe tp case panel. Thre ao

‘wo haring ales incarpexated inc the

inner casing tan ight the lower ec

tin athe appliance.

> 4. Lower the contol pana nt he service

poston by removing the soe 0X) om the

Feiining bracket.

> 5.Make connections tothe hosting syters

> Connect th gos suppl tothe baller gas

cee 22 me compression

> Connect maine waterin and DH out

a

IMPORTANT: The pressure rebel connector

‘must be repostined ator the boiler has been

‘correctly meurted othe wall mcurting pate.

> 6 Push te lever onthe pressure re! com

rector UP unt the stp onthe sie ofthe

hans eve the shoulder ofthe metal

bracket to secure i place

1 2tmen 18mem 2mm tm Sm

FANORCESTER 12 L20ers yimcnsnnnraete cme neva HITTING THE APPLANCE

ee eee BONER CONNECTIONS,

FLUE INSTALLATION

HORIZONTAL FLUE

(607100 mm ciarnoter)

For vet fues and 80125 mn hoot oes

please refer separate Five Ki insrions.

NOTE: ease to assambl ove conzonent,

‘spp scone ubicant sing suices.

The instutone for the 80700 nn dameter fue

«re shaun babu.

MEASURING THE FLUE (Standard

> Mosaure from the outdo wal tothe cane

fina of re fue ture (engt

R >» Subirac 82 rm forthe length Lio ge

ge amen : the comeot mension othe ue elbow con

Seater > The terminal ection shouldbe cut othe

linension, however ust not be shorter

‘han 250 rm,

> ter cuting the ond mst be square and

fre rom burs to prevent damage to the

fe sea

a Sa ecg

Toeeneee, © WORCES

Camp

\ 23800

be

Testi an tn tte

semm 960mm 734 em a4 mm

Tunet——Extonsion Cut Longin ‘Standard Flue

Recited Lenath 1

i |

FLUE INSTALLATION

MEASURING THE FLUE (Extension Fe Kis):

‘ONLY CUT EXTENDED FLUE LENGTHS

> As tte Stand Fue measure frm the

‘outside wat the centre ne ofthe fe tur

ret length.

Subtract he usable length of to elandard

fue (694 mm) om fngth L

> Subtract the veblelongth ofthe twret

(2mm) from length.

» Sublrect 960 mm or esc length ster

‘on rom tha igure

‘Catone oth oorsions to tho rman.

> Carte tos squae taking caro rot to don

the tbes.

> Ramove sry ture

xan

Length = 2980 men

‘Subtract Standard Fue — 694 men

SubtactTuret — — 52mm

‘Subwact FullEenson = 960mm

Cat Length = 734mm

NOTE: Where extensions are reduce cut

length which DOES NOT contain the sea

ADDITION OF FL.UE BENDS:

‘waa fu bonds ae being used en allowance

of 84mm or bond must be allowed fom the

Centre fine of the bend In he exo ahown

sing a fue extension (960 mm) with 2 bends

sieve afta length af 1148 em

Fragen ons gnomermeroninan saa

FLUE INSTALLATION

Standard Fe

Internal Wall Set

External Wall Seal

Clamp

Extension Duet

This serew should

be fited int or

vw ‘easier instalation

Fat t beck

| Tis screw should

be ited lat or

FLUE INSTALLATION

ASSEMBLING THE FLUE

1 Sie inner cota (8) onto terminal (A)

2 Adena extanion or bonds

Posh ia exerslons/bend/terial

together and sacure connactions wih

‘camps (0). The slope ofthe erina uve

ust face downwards,

FITTING THE FLUE.

{Fite terminal (A) hsough the Rut opeing

inthe wal, exposing te plate outlet

section tothe ous ac the out

‘ie colle (Core the notches to sure.

4 Assemble tue to baler using the thee

screws (200 below)

Note: Sous are a Bodor orn Hue it

FITTING THE TURRET:

+ Fle turet shoud push crecty down and

not be twisted into corest poston

» Btturt onto appliance and tan with

thee sero

NOTE: Ths clamping plat fa should boat

tho reae ofthe applanoe,

ADDITIONAL NOTES AND REMINDERS:

1 Ensure tat al cut length ae aquare anc

{ro ron br.

+The fv, when assembled, is uly sealed

«and components are puted home,

+ Thee set at an angle ofS or 52mm

per addtional tm length of extension used,

ce ee

emmensonovs — peaenerow

CONDENSATE CONNECTION

Never terminate or discharge into any open

source, including: sink bath, shower, bidet,

toilet ee.

ote: any extemal condensate pipework of

fercestive rune should be protected with

‘weather resistant insulation to help prevent

freezing,

+ Ensure thatthe condensate drains 22 mm

diamoter plastic pipe. must al at last

50 mm per mete towards th out

+ An acapler (Ain 22 mm pipe is contained

inthe ting pack

Frroncesieg oo unconanuiaunsunannanananana” gongeneat Gomecnon 9

ELECTRICAL

Creer

Be ee ecu

meters

Danger of short circult: When connecting]

the eables ensure thal no cable pleces fall

into the Heatroric,

Mote: Maine eupply tothe boiler must bo

trough fused duble pole iglsor stated

adjacent to the appliance. The istator must

Ihave a contact separation ofS mm minima in

pote.

2 wos

(rer seoee Les, Acco toc concn:

ea

area erenpaeeaiiee

canbntyemmteg ie wce Doon Be

aries

1) Che eten sro (en th bask

Jf” PRS pate oe

ones

2. Ure cal cmp)

4 Cuter ea oy ale

Since ate

5. Tmoulerenring oo (0) anclcon

eae

thea ne cable dao (0 ou ew

ee ee

Tuna cg se 2 cc

Seruveabosnepes cary (m0

ae

6, Mains power 290 V connection (STI:

> Separate wis fam cable end and sip to

nm

{Connoct LIVE wit to ering (L)

‘Connect NEUTRAL wet the teminal{N)

[Connact EARTH vieo to tho earth cone:

tore)

NOTE! Earth cable tbe longer eo tatit

pul out ast f sie cables enaggc.

7. Optional extemal fost thermostat connec

son aro

Cont ost amos spe nett

ro

» Conet st emos eum we te

at

&. 230V:com amos andor ema mer

‘sre

+ Rove ak

+ Conant oom moda LE ply

tormral ts)

> Comoot on temesatLNE eu

2 watt

H + Connatoom omosat NEUTRAL

E weal)

7

©. Ret conte pane ore

> Refit panel and seca with orews

cng tho contl pana its upser postion

sand a it with ser (A

et a eee PAPORCESTER

feree toon

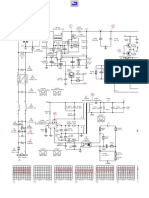

POSITION OF WIRED

COMPONENTS

HEAT CELL

pump ) "ne

om

Anne oo as

See SONS

PRE-COMMISSIONING

CHECKS:

Pea Cen

> 1.Oheck thatthe senice and water pipes

are connected to the ooreot postion onthe

randold.

A- CH ow (220m),

1B CH retom (22mm),

Gosint (22mm),

1D DHW out (1m)

E-Maie water int (Ime),

2.Chack he as ype spaced onthe den

‘iteation plate (F) maaches hat ofthe gas

‘supp. Tum onthe ain ga sup, chock

the ons pipework, connections and rectly

ary looks.

» 8 Check thatthe prssure reef connector

located on the ight hand sie atthe botor

the wal Fame, its up poston,

A. Chock thatthe condensete pipe has been

cannectod io tho adapter

IMPORTANT: I the boilers nt to be com-

missioned immediately then: after sucess-|

uty completing all ofthe checks and any

rectification work close the gas and water

valves, shutoff the gas supply and elect

cally isolate the boiler.

ECOMRONNE SHES —_—Smnannmncamnmomnminaens AQOREESTER

FILLING THE SYSTEM

1 Enaure al estem and baler dain points ae

ocos,

2. Remove the bot pane i fed)

{3 Ensure thatthe wht paste conto screw

(C)on the charging nko ued tu nto

its lose postion

4 Open hooting vv on both the DHW

intend CH coun connections

5 neat he charging hey (0) (uted in te

‘toraga poston (E) en tho botom cover of

the bode) nia aligning th arrow onthe

‘ay wits the“nloce” eymbol en the charg

ing ek be Ens that te key iinet

{uly and tum othe ok” postion. Chock

that tha ay is cure

6 Tol he system om the DHW inet um

tho white plastic contrl screw (C) on the

charging Ink to tho flyout poston,

7. Once the system has boon Sled 9 pres:

‘47001 baru the white contol stew

(tots closed positon.

8 en allalator,righton when competes

and chock th ejtom and correct any looks.

+The bole ntogral expansion voeoo ie

precharged 100.75 ber equal oa etatic

head of 75 metor (22 A] A Schacter

‘ype vabo fied the expansion veel o

low for pressure adjustment # required.

Wan extra expansion vessel is ited tothe

‘ental heating ran, adjust the same

pressure asthe appliance intemal expan

‘sion tank, efor o separate inucions wit

the era expansion vessel

{8 Brey open the pressure reel vahe to test

its operation,

10 Reiltheeystom upto 1 bar. Tun the whe

Teat gas suey or eoundness as desorbed

inpseser

FRIORCESTER Wines oncinonyasrn weaves uno ncaorransac eee

fae

STARTING THE APPLIANCE

IMPORTANT: Never run the appliance

when the appliance/system is empty

or partially filed.

‘SWITCHING THE APPLIANCE ON/OFF:

11 Tum en mire power pel.

> Turn on ary ovtrnal conto.

Set tho thomoetai talatos controls

‘matimum tomportre.

Set th clock/regrarmer to continuously

(ON and the room armostat to maximus

temperature

2 A-Oniot button

Ono and fut inestor (BLUE)

C- Conta heating temperate contol

1D- Bumer indicator (GREEN)

E+ Recet bation

F- Service button

G-DHW temperate cota

H- ECO button

1 ystem prossure gauge

J-Cover or options! programmer

Display

E L- Conta eating boost button

M- Holiday button

N- Automate ae vent

> Prsebuton (A) andthe power on inca

toe (6) unos BLUE Ate af seconde

ecg a how to flow ampere

8.» Tu he CH tenperatr conte (0) 0

asin Tener on ndeatr() Ba

tates GREEN when the burr has

ores:

* Theft time the alance i switched

7, orca venkng hncton sect

‘The heating pup hon ewiches onan

of atin, This sequence lass abou 8

‘ito. The pay shows shows on

oration wh tho CH How tamper

Te automata vet) mua be open

peat wet.

the ote un fr 1 mies a mun

mating eure il he cadena rap

{opi (0) alerates betas “I”

the centalhssrg fow tmpraura

THis occurs every tne the mais supply

tas boon nore.

4p the bode als oh the BLUE power

inecater (2) and eet baton (E) wl fh

alternately,

Te rset proce and hal ho ect button (2)

for 2 second. The boo wa be roca

sowracncoancs SANORCESTER

STARTING THE APPLIANCE rao sen NICS FER RCESTER EOE EET

vate

af

©] Flushing

fae!

©} vite —

WATER TREATMENT

TMPORTANT: Dobris from the system ean]

demege the boller and ceduce efficiency.

Feilure to comply with the guidelines for

the use of water treatment withthe appl-

2nco wil invalidata the appiance warranty

ENSURE THAT THE SYSTEM HAS BEEN

CLEANED AS ON PAGE 9 OF THESE

INSTRUCTIONS.

FLUSHING (Central Heating

1.» Switch of the br.

> Opon al an cocks (B) and cain the

‘system (0) whe the appiance isha.

2. » Close dain cake (D) and add a suitable

ftushing agont ©) at he core etength or

the system condton in cordance ith she

smandacture instructions.

8. » Run the hotedeytom at normal operating

temperature (Fr the tie ated by the

manacturerof the Rushing agont (3)

4. » Drain H) and shoroughy fash th eters

to remove he fusing agent and debris

INHIBITOR (Cental Heating:

5. » Chock dean cocks are elased and al

radiator vals are open (K) before adding &

‘lil inher (or combined inhibitor!

ant-heeze if the oytem a expozod ofreez+

ing conditions) to the heating eyter water

{Win aeordance wth tho manuicctrore

6. » Fava the bitin ling cop to between 1

ne 2 br using he ling ay

2. » Venta raitrsretighton vont won

completo tN),

1, » Repressurine necessary to 1 ar (O

» Seta contro asinum(@).

> Record the date when the inhibitor was

‘aséed to he stom onthe gusartoo car

NOTE: The concentration level of iniior in

the eystem should bo checked every 12

-monhs or sooner i system contents lost

The adslton of sealing agente to to eystam

ater is not recammendled as tie can eavee

probloms with doposits lott in the heat

exchanger

compatible with aluminium. The pH

value ofthe system water must be less

than 8 or the appliance guarantee will

be lnvalidated.

Anne oo

pole pela

WATER TREATMENT

COMMISSIONING

mode, the boiler

‘the central heating and the domestic| THE COMBUSTION FOR THE APPLIANCE

hot water circuits. IS FACTORY SET.

sufficient time for this part of the| No ADJUSTMENT IS REQUIRED IF THE

‘commissioning procedure. It will bo| Gas INLET PRESSURE IS CORRECT.

necessary to run water through the

domestic hot water circuit to ensure

that the boiler wil not cycle on low

heating demands,

CHECKING GAS INLET PRESSURE:

‘The inlet pressure tothe applance must be

‘hacked using the follwing pocedure:

SETTING THE BOILER TO MAXIMUM:

1» Press ceria! heating boost button (Lor

ton seconds and cot Conta Heating tr

peature fo masinur.

* Te canal hesting boost button wil him

ate continual.

MEASURING THE INLET PRESSURE:

2 Slachen tho eerow i the inl rossuro

teat point and comect a manometer

Measure the prossuro wit he boler

running st max.

+ Check he ga sucoy working pressure st

the ga vale lt poi

NG. min 16 mbar

LPG. 37 mbar

Tho gas rate should be moastred at he

‘gas meter for 10 minutos operation at

resin, See tachrical deta section a the

front of this manus

> Enoure inlet preseuresatistactory with

other ge epptancos working

+ Replace contle cover NOTE: Tho bllor

'eclcignd with a iorenti of 20°C

‘axons the hoxtng stom.

IMPORTANT: Do not continue.

commissioning until the correct

{gas inlet pressure is achieved.

pressure ie etitactry pra the canta

‘nesting boot button (L) again and the boi

ery ctura a nomal peraton.

“HfL in the service mode the contet will

return to oral operation ater 15 mites.

> Re-eal he screw in tho ga int preceure

test pont

DOMESTIC HOT WATER:

Contraling the hot water temperature

Toe hot water ermpealue can beet 0

locas between aoprozmate 40°C and 60°C

|B - On/aif and faut indicator (BLUE) eo

C-Ceninl eating terperirecentot ——_DOMESTICHOT WATER PREHEAT:

- Bumerindctr {GREEN} Pea on tien et

voter a the tp and is cot y 1

Reset bution a

F -Seroe Baten > Presse ECO bln to select ter:

Spe eee etree ‘When the ECO button is not illuminated the

ECO buten boiler wil bein prechest made (which wil

|. Syetem preoure gauge rec the time tae to prakice hot water at

tetas)

J+ Cover or optional progammer

Ke Dispay on

1L- Cental heating boost button When the ECO tuston I luminstd the boter

Held ban wit be in Economy mode with pre-heat no

longer active

COMMISSIONING.

sees

cmerene, AWorces

FINISHING COMMISSIONING

‘The bolior has been factory set, so there

_should be no need to adjust any controls

REPLACE OUTER CASING:

1 Replace outer casing making sure that he

securing poits are prope locatd

> Poss he cp (A) downwards to secure

casing ont.

> Retghin bottom two rows

INSTALLING BOTTOM PANEL:

2 The bottom panel ede orto two lee

{© oar Sof he boa tae.

> Hold the pene up against the undarsiso

the blr nd fd towards he rear unt

ay engage

HANDOVER

Complete the Benchark checks

> Setup the cenrols an show the oer how

to operate al the conta shown in the User

Guide.

+ fine appanceis unused and exposed to

freeing conditions; shut off lth maine

supplies and eran the estem and bole

PAMORCESTER e104 sevens nemcnnsronwostEG8 FOS CMEHEUR EEUEDIEEWEH ERIS HING COMMISSIONING

CTT aaa ken enn)

recur UCL euP neces

terrane ret

IMPORTANT: AFTER REPLACEMENT OF ANY COMPONENTS ALWAYS

CHECK FOR GAS SOUNDNESS WHERE RELEVANT AND CARRY OUT

FUNCTIONAL CHECKS AS DESCRIBED IN COMMISSIONING,

ANY O-RING OR GASKET THAT APPEARS DAMAGED MUST BE

REPLACED.

INSPECTION AND SERVICE.

IMPORTANT: Any service work must De

carried out by competent registered engi-

ears such as British Gas or Corgi reals-

tered engineer

+ To ensue the continued efcient operation

cf he appnce it must be checked a regu

larintersle

+ The requony of servicing wil depend upon

the particular ntalaton condone end

nage. However an anal eervco ree

commended

+ The extent ofthe sonice required by the

appliance ie detomined by te operating

conditen ofthe applance when tested by

‘uly qualified engineers.

INSPECTION

4. Chock that the temine and the fein

(9u40, fe, ar clear and uname.

2, Wthe appliance ina compartment 1 cu

bose check hat the specified serves

pace acund the appianos i ear,

{8 Chock allthe joins and comnsction inthe

‘ystom and reake ary that chow agno cf

loakago. Rell nd e-proceurce# applica

bio ae decerbed in Conmiseioning

>» Oporto the applance ad take not of

‘ny regulars. Call up the at faut toed

bythe Bosch Hera, Senice Function

0. Refer to Fast Fring for rctieaton

procedures.

INSPECTION AND SERVICE

R

emensmove pene

INSPECTION AND SERVICE,

(COMPONENT ACCESS

1. Removing outer case

44. Remove batt pane! by pula it forward

and ft.

“14. Undo but do ao romene the 2 cere

(securing boter casing at the boom of

‘he apliance

1.2 Pul upwards to relase th cp (B] on top

ofthe bode

1.8 Palcato “eres and ronovo

2. Adjusting boiler control to

service position

24 Reena sew (X securing contch

22 Gent pul forward url mos to

rastinceriee psiten.

Primary Heat Exchanger

Theresa special accessory kt avaabio

spectioaly designed for leaning tho heat

trchanger lf requed order? 719001 998,

1 » Check fan preesurs al he tst point net

tothe fan using an lector manometer

» The bole must be run at macizncut.

Pressure willead nogatve and be grater

than

2600) 2.7 moar

80CD)- 4 ar

950D)-51 mbar

4000) -5.2 mbar

» Pressures measured below thane figures

wines thatthe heat exctanger wil

reqpire clearing,

Vaan

WORCESTER So

INSPECTION AND SERVICE

Setting Boiler to Maximum,

NOTE: When running inthe heating boost

mode the bor wil operate both the Cental

Heating and DHW circuits. This is allow sul

ficient tne for seting procedure.

Ie wil be necessary trun weter though the

DHW circuit o ensure thatthe biter wil not

cycle om low heating demands

|A-Onvot burton

5 - Ovo and faut incicator (BLUE)

{© Conta heating temperature contol

1 - Bumer incioator (GREEN)

E- Reset baton

F- Service baton

G- DHW temperate contol

H-ECO button

1+ Syetom possi gauge

J+ Cover cr opinal programmer

M- Holiday baton

1 » Prete and HOLD cer! heating Boost

bation (U for 10 cond and eet Cantal

Heating temperature to masa.

+The conta hoatngbooet button wi ilu

sate continu.

+The bel wl tay in the mode for 15

minits unlec te cent hosing boost

bultlon is pressed agsin.

2» Pathe cover ctf and connect a mancmar

ter to tho an prossure test point

After measurement replace test point

Pressure wil read ogatve and be grate than

26C01-2.7 mbar

3000-41 mbar

350Di-81 mbar

4000\-8.2 ber

+ Procewrea measured blow tho gues

‘salina that he heat exchanger wil

require searing

1 There isa spacial accessory kt sulle

‘specitcly designed for leaning the beat

ttchanger If raquted order 7 719001 996.

INSPECTION AND SERVICE

aa | ORCESTEN

emmsneme.es Beat @eep

INSPECTION AND SERVICE

To Clean the Heat Exchanger

+ Remove outer case and bane panel and

inca the appliance from power.

1. » Remove clearing access cove (8), esa)

(©) and meta pat (0) securing i # pre

sont

21» Loceen any dopo inthe heat exchanger

‘tom top t9 botom using the Gearing isda

2.2» Clan he heat exchanger tom top to bot

tom ug the brush

» Raft the clean out coverplatesin reverse

ade using anew seal (C} and tighten

serous toa txque of aporoxinatcly 5 Nm.

PWORCESTER 212015 2mern nemcro ree wicca ae EDI ese INSPECTION AND SERVICE p

INSPECTION AND SERVICE

To Clean the Burner

1. Remove cover panel (A) by removing the

sorewa (8)

> Check that he boter ie completly ot

fd tom tho gas supe.

2, + Remove the clips (C) and unsorew te

wo bots (0).

+ Unsere and emeve the tao hexagon

sores (E) soci the tan,

» Sacken fy tho rear securing bot (F

+ Rema the bumer cover plate (G1)

|. + Remove te bumer (Hand clean compo:

nents, Do not use wire brush

To Check the Diaphragm

In Burner Cover

4. > Carol withdraw diaphragm (rom fan

intake tube and chock for ealing and ets.

> Carel rit dlaphragm (the conect

‘ray rund nt tho fn intako hbo

[Nota The flaps ofthe chan () must

open upwards.

> Re-asconbio buna in ovese order using

‘new seal)

> Act guar ratio. Refer o section

"Soting the gas ato

To Clean the Condensate Trap

‘ty Pull condensate pipe out of the adartes,

{52+ Remove tap fiom bail.

> Clean rap ed check thatthe connection

tothe heat exchangers cleo.

> Fil the condensate tap with appro

rately 174 lire f wator and rftinroverae

ondon

ee

omen eoee

Oe amald Ceca REPLACEMENT OF PARTS:

eau CRE CLanS

Eta

IMPORTANT: AFTER REPLACEMENT OF

[ANY COMPONENTS ALWAYS CHECK FOR

GAS SOUNDNESS WHERE RELEVANT

[AND CARRY OUT FUNCTIONAL CHECKS

AS DESCRIBED IN COMMISSIONING,

[ANY O-RING OR GASKET THAT APPEARS

DAMAGED MUST BE REPLACED.

1. Removing outer case

1.» Remove boom pane by paling forward

and oft.

1 Loosen but donot remove he 2 serene

(0) securing boar casing athe boton of

the appliance.

1.2» Put upwards to rlease tho clip (8) top

ofthe bar

{ae Pull case forward and remove.

2. Moving boiler control to service

position

2A» Remove soxow (Xoseutng conta

226 Gently pul forward

9. Primary sensor

> ross elining lp on plastic mauling

tnd pall uprards unt lear of pocket in

heat exchenge.

> Separate seasortom connector, coat

new seacor wih het conductive paste and

ropiac.

Overheat thermostat

> Remove two electiel connectors fom

thermostat

> Unscrew the seae

5. Flue limit thermostat

» Remove eecreal conection

> Unsorew thermostat fom fn.

6. Expansion Vessel

» Drain the appliance

181» emovo locking serow (0).

{82s Unde the union conection (E tthe bot

{om ofthe expansion vse.

» Remove expansion vassal tm boll.

» Set the pressre ofthe new voselto Hat

roqpies by he sytem.

Aaa

ea ermaneenioury

REPLACEMENT OF PARTS

11 Undo top gas connection (B) 1 ga va.

1» Undo bottom goa connocton (C} 1 ga8

vale,

72> Undo two securing srows (D} on tho

Uundorside of casing.

» Pulvalve up and forward outa boll.

Dieconnoet letra! connections

Replace va wth new seals and chock

{ex gas soundnose.

‘Note: Theva wil ruleset, flow pro-

cedure "Seting the gasar ratio in tho gas

8. Siphon

1 Pu condensate pipe ou! othe adante,

82+ Remove treo fom bolle.

» Clean rap and check that the conection

to tho heat exchangoria low.

> Filho condenest tap with appro:

smatly 14 le ct water and ftin reverse

ode

eR ceunt os Bite nana SNE RTI LOD Arroncesten

REPLACEMENT OF PARTS

‘Access to boller contro!

components

» Remove 3 screws (A) and move

cover rom contro

. PCB fuse

> Remove se (8) fom the POB and

replace,

> Theroio a spare tse inne into he

|. Transformer / PCB.

» Disconnect el tect! cnmactions

from he contol

» Romove 5 eorewe ()etaning the

rox pan of tho contol and remove

pare

PAIORCESTER 101014 sevcre ness roxworee borer crete eR seaes arcu 9

Somheru eran nan

REPLACEMENT OF PARTS

IMPORTANT: AFTER REASSEMBLY

THE COMBUSTION MUST BE

CHECKED USING THE PROCE-

DURE IN THE SECTION “SETTING

THE GAS AIR RATIO". MEASURE-

MENT AND SETTING (IF NECES-

SARY) OF THE GAS RATIO MUST

NOT BE ATTEMPTED UNLESS THE

PERSON IS EQUIPPED WITH A

COMBUSTION ANALYSER CON-

FORMING TO BS 7927 AND IS COM-

PETENT IN ITS USE.

12, Fan assembly

+ Remove electrical comectx from fan

> Remove condansate tap

(eee page 42).

121. Undo the union eonnocton (8.

> Remove we lip (B) rom at/gas

austen assombiy (6) hen pull gas

pe down.

122 > Unscrew two sora (O)

123. + Remove fan tom beter

124 + Remove tee serous ining the

sielgas adjustment assembly (6)

> Reasaerble with ew fan assuring that

sear comecty ited

B

13, Electrode assembly

» Disconnect spark electrodes and fame

+ Remove two screws (P.

> Ramove aprkilame secrede aso

by (G) rom hoat exchange

Reet AgeueNT OF mara seunemwcnnenenoetovecarnamannmnnosincontt Ariorci

REPLACEMENT OF PARTS

14, Alt/gas manifold

141+ Remove cover panel) by romaning

tha serows (@)

» Check that he bodes completly io:

lated rom he gas soppy.

142. » Remove te clips (©) and unscrew the

‘wo bolt (0).

> Unscrew and erove the to hexagon

screws () securing the fon.

» Secken fly tho ear securing bot (F.