Professional Documents

Culture Documents

Drill Deep Root Cause Analysis Worksheet

Drill Deep Root Cause Analysis Worksheet

Uploaded by

LipecaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drill Deep Root Cause Analysis Worksheet

Drill Deep Root Cause Analysis Worksheet

Uploaded by

LipecaCopyright:

Available Formats

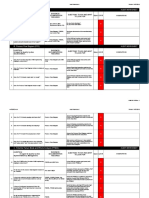

Drill Deep Worksheet

Date:

10/01/04

Issue title: (Part Number) Wind Shield Missing Red Dot Sticker

Customer concern: Customer received a windshield where the left side Red Dot was missing to set the wiper blade.

Defect on part: Missing red wiper dot sticker

5 Whys

Why did the planning process not

predict the defect?

Predict

Planning process informational content

in FMEAs and CPs

Corrective Action

Owner

Due Date

Simpson

10/18/04

P1

Recommended action not completed Add recommended actions to Quality

as timely as expected

Boss chart to track progress

P2

No scheduled review of FMEA for

updating recommended actions

P3

Waiting on approval for spending

Approval has been granted for

capital to install dot detection system speding capital for detection system

Sislack

09/27/04

P4

Scope of project not completely

defined

Krusty

10/31/04

P5

Difficulty in accomodating adjustable Define scope of detection system,

design for multiple parts

send for quote

Flanders

10/31/04

Detection system to be standardized Pending removal of dots; install

on all production lines applying red

standard detection system on all

dot

production lines

Skinner

11/30/04

P-RC

Implement FMEA review for NMI

projects after launch based on

lessons learned from production runs

Define scope of detection system,

send for quote

Burns

M1

Visual inspection did not detect

missing dot

M2

Failure to follow instructions

Prevent

M3

Lack of detail (pictures) in assembly

instruction for inspection of red dots

Update WI to include pictures of

inspection areas

E. Cartman

10/07/04

Manufacturing process standardized work and

error proofing

M4

No poke-yoke in priming/assembly

equipment to detect missing dot

Pending removal of dots; install

standard detection system on all

production lines

K. Brovlowski

11/30/04

M5

Waiting on approval for spending

Approval has been granted for

capital to install dot detection system speding capital for detection system

S. Marsh

09/27/04

Q1

Visual inspection of part in rack not

adequate

Add offline inspection of product on

dock prior to shipment

Garrison

09/25/04

Q2

Left wiper dot not easily visible in

rack

Verify left dot by elevating rack for

inspection

Chef

09/25/04

Q3

Dot is at center of rack and partially

primed over

Suggest elimination of left dot or all

dots; including existing

programs/launches using dots

Kenny

Why did the manufacturing process

not prevent the defect?

M-RC

Why did the quality process not

protect the customer from the

defect?

Protect

Quality process detection &

responsiveness

Q4

Q5

Q-RC

What are the key findings based on

this quality issue and the above 5

Why analysis?

K1

K2

K3

K4

K5

337202361.xls

Revision 5.0 03/08/04

You might also like

- ISO 9001 Process Audit Turtle DiagramDocument1 pageISO 9001 Process Audit Turtle DiagramJoel Alcantara100% (3)

- Integrated Management Systems: QMS, EMS, OHSMS, FSMS including Aerospace, Service, Semiconductor/Electronics, Automotive, and FoodFrom EverandIntegrated Management Systems: QMS, EMS, OHSMS, FSMS including Aerospace, Service, Semiconductor/Electronics, Automotive, and FoodNo ratings yet

- CSR Matrix (Example Only)Document24 pagesCSR Matrix (Example Only)hmp90100% (1)

- TurtlesDocument15 pagesTurtlesshobhit2310100% (4)

- Core Tools Forms V5dDocument119 pagesCore Tools Forms V5dIng. Alberto AguilarNo ratings yet

- VDA FMEA TemplateDocument53 pagesVDA FMEA Templatewatna0% (2)

- Global 8D WorkbookDocument52 pagesGlobal 8D WorkbookBalaji100% (10)

- HD1500 7Document12 pagesHD1500 7De Lacruz KevinNo ratings yet

- 8D Problem SolvingDocument7 pages8D Problem SolvingLokesh Narasimhaiah100% (1)

- MAstering IATFDocument20 pagesMAstering IATFGyanesh_DBNo ratings yet

- Manufacturing Process AuditDocument1 pageManufacturing Process AuditSachin Kumbhar100% (1)

- 8D ReportDocument33 pages8D ReportvundavilliravindraNo ratings yet

- MSA Bias & GRRDocument2 pagesMSA Bias & GRRRamchandrarao DeshpandeNo ratings yet

- PFMEA AuditingDocument18 pagesPFMEA AuditingelevendotNo ratings yet

- CQI 9 3rd Edition Errata SheetDocument2 pagesCQI 9 3rd Edition Errata SheetANONIMONo ratings yet

- Processaudit VDA 6.3 2010 enDocument37 pagesProcessaudit VDA 6.3 2010 enAdilson DoboszNo ratings yet

- Presentation Guidelines: Case Study - Zero Defect Drive by Laxmikant MishraDocument28 pagesPresentation Guidelines: Case Study - Zero Defect Drive by Laxmikant MishrapiyushNo ratings yet

- SPC Course MaterialDocument118 pagesSPC Course MaterialKrunal Pandya100% (1)

- BIQS Manual Auditoria 2017 PDFDocument168 pagesBIQS Manual Auditoria 2017 PDFJuan Carlos PadillaNo ratings yet

- Standardized Work Combination FormDocument3 pagesStandardized Work Combination FormisolongNo ratings yet

- Product Audit ReportDocument2 pagesProduct Audit ReportManoharar R100% (2)

- Machine Capability For Process AuditsDocument4 pagesMachine Capability For Process AuditsBrian Pringle0% (2)

- Six Sigma ToolsDocument92 pagesSix Sigma ToolsjoseggNo ratings yet

- Kaizen Case StudyDocument44 pagesKaizen Case StudyTanmoy ChakrabortyNo ratings yet

- Shainin Tools PDFDocument17 pagesShainin Tools PDFDEVIKA PHULENo ratings yet

- Layer Process AuditDocument8 pagesLayer Process AuditR JNo ratings yet

- Layered Audit ChecklistDocument4 pagesLayered Audit ChecklistNavnath TamhaneNo ratings yet

- Shriram Pistons & Rings LTD, Pathredi: Layered Audit Check Sheet Monthly (Plant Hod)Document5 pagesShriram Pistons & Rings LTD, Pathredi: Layered Audit Check Sheet Monthly (Plant Hod)deepak sharma100% (1)

- Kaizen Desk Reference Standard PDFDocument466 pagesKaizen Desk Reference Standard PDFAwadhut MaliNo ratings yet

- 5 Why TrainingDocument17 pages5 Why TrainingGURMUKH SINGHNo ratings yet

- VDA TS MappingDocument20 pagesVDA TS MappingdavidNo ratings yet

- QualityoneASQ PresentationDocument42 pagesQualityoneASQ Presentationfmkhan786No ratings yet

- 8D Training For SuppliersDocument25 pages8D Training For SuppliersiqbalmuarNo ratings yet

- 8DDocument9 pages8DPedro Pi100% (3)

- Poka Yoke or Error ProofingDocument9 pagesPoka Yoke or Error Proofingiforcett100% (2)

- Launch Readiness Audit (LRA) ChecksheetDocument19 pagesLaunch Readiness Audit (LRA) ChecksheetBaljeet100% (2)

- GP-9 Process Control Plan Audit Summary SheetDocument5 pagesGP-9 Process Control Plan Audit Summary SheetAsifNo ratings yet

- GM 1927 36 Group D Elements BIQSDocument41 pagesGM 1927 36 Group D Elements BIQSVanessa GurrolaNo ratings yet

- 8D TrainingDocument33 pages8D TrainingRohan Shrivastava100% (1)

- TAFE Process Audit Check List - Revision 2Document16 pagesTAFE Process Audit Check List - Revision 2Vijay OfficialNo ratings yet

- 5S TrainingDocument29 pages5S TrainingponNo ratings yet

- Pecb Iatf 16949 Lead Auditor Exam Preparation GuideDocument14 pagesPecb Iatf 16949 Lead Auditor Exam Preparation GuideR.BALASUBRAMANI100% (1)

- Office (Eng)Document31 pagesOffice (Eng)kingathur26681100% (1)

- 703 Fmea m3 LatestDocument24 pages703 Fmea m3 Latestom cncNo ratings yet

- System Audit RequirementDocument37 pagesSystem Audit Requirementavinashbatra171% (7)

- Paradise IATF IA Presentation PDFDocument211 pagesParadise IATF IA Presentation PDFSameer SaxenaNo ratings yet

- Daimler-Chrysler Layered Process AuditsDocument27 pagesDaimler-Chrysler Layered Process AuditsMarcela Gonçalves100% (3)

- ISO 9001 Key Process Turtle TemplateDocument1 pageISO 9001 Key Process Turtle TemplateShirleyNo ratings yet

- Apqp FormsDocument32 pagesApqp FormsAnonymous A2jnZ5MNPxNo ratings yet

- Q411 - 8D ReportDocument13 pagesQ411 - 8D ReportAnandha VasanNo ratings yet

- Iatf 16949 Clause To Eqms ModuleDocument8 pagesIatf 16949 Clause To Eqms Modulepodrao100% (3)

- Process Audit - FormatDocument16 pagesProcess Audit - FormatPradeep Yadav0% (2)

- Spec Characteristics GdlnesDocument2 pagesSpec Characteristics Gdlnessathyabalaraman0% (1)

- Transition ISO/TS 16949:2009 To IATF-16949:2016: CQA - Paul de Geyter - September 2016Document39 pagesTransition ISO/TS 16949:2009 To IATF-16949:2016: CQA - Paul de Geyter - September 2016Joseph StephenNo ratings yet

- Bqs Asq Lpa Overview 2 3 2017 Rev 11 PDFDocument48 pagesBqs Asq Lpa Overview 2 3 2017 Rev 11 PDFelyesNo ratings yet

- 5 S & Lean 6 SigmaDocument16 pages5 S & Lean 6 SigmaAkshay KumarNo ratings yet

- Design for Six SIGMA Complete Self-Assessment GuideFrom EverandDesign for Six SIGMA Complete Self-Assessment GuideRating: 1 out of 5 stars1/5 (1)

- Behavioral Activation Worksheet Activity Log 1 1Document3 pagesBehavioral Activation Worksheet Activity Log 1 1Anca DobarleanuNo ratings yet

- HSFG Bolt PDFDocument6 pagesHSFG Bolt PDFSatish PawarNo ratings yet

- Staging and Scaffolding of Bridge Deck SlabDocument3 pagesStaging and Scaffolding of Bridge Deck SlabPhanindra Nath50% (2)

- Covalent Bonding MSDocument7 pagesCovalent Bonding MStasfia2829No ratings yet

- Full Test Bank For Vanders Human Physiology 15Th Edition by Eric Widmaier PDF Docx Full Chapter ChapterDocument36 pagesFull Test Bank For Vanders Human Physiology 15Th Edition by Eric Widmaier PDF Docx Full Chapter Chaptergenevafigueroag9ec100% (15)

- WEG cfw700 Programming Manual 10001006882 2.0x Manual EnglishDocument283 pagesWEG cfw700 Programming Manual 10001006882 2.0x Manual EnglishalienepriscilaNo ratings yet

- GESE G7-9 - Classroom Activity 4 - Preparing The ConversationDocument8 pagesGESE G7-9 - Classroom Activity 4 - Preparing The Conversationatm4uNo ratings yet

- Introduction To EconomicsDocument26 pagesIntroduction To EconomicsReyasat AliNo ratings yet

- Course: Bfc43502 Occupational Safety and Health (Osh) Semester/Year: Sem 1 2021/ 2022 Task: Project-Group (20%)Document3 pagesCourse: Bfc43502 Occupational Safety and Health (Osh) Semester/Year: Sem 1 2021/ 2022 Task: Project-Group (20%)Ooi Chin KaiNo ratings yet

- Carregadeira Volvo L90EDocument16 pagesCarregadeira Volvo L90ELucasNo ratings yet

- Thoreson, Scott Resume-Cc FinalizedDocument2 pagesThoreson, Scott Resume-Cc Finalizedapi-281404829No ratings yet

- On Intermediate RegimesDocument8 pagesOn Intermediate RegimesNikhil SNo ratings yet

- Ce 4Document8 pagesCe 4Goutam MandalNo ratings yet

- Module 1 and 2 Output Belison GroupDocument4 pagesModule 1 and 2 Output Belison GroupMarie Nelsie Marmito100% (1)

- (Main) : Computer Based Test (CBT)Document12 pages(Main) : Computer Based Test (CBT)Resonance Eduventures100% (1)

- Connectors 14.03.11Document4 pagesConnectors 14.03.11Susana MoraisNo ratings yet

- Cover Letter For Risk Analyst PositionDocument5 pagesCover Letter For Risk Analyst Positione71381x2100% (1)

- rd-m592 2Document1 pagerd-m592 2faizgpNo ratings yet

- Question Week 3Document11 pagesQuestion Week 3Angelica May BangayanNo ratings yet

- SAP Script: Printing Layout Set Output Program ConfigurationDocument65 pagesSAP Script: Printing Layout Set Output Program Configurationplayboy117No ratings yet

- Radar EquationDocument15 pagesRadar EquationLintang AnggitiadewiNo ratings yet

- UGRD Schedule 2021 Main Campus Ver 1.4Document48 pagesUGRD Schedule 2021 Main Campus Ver 1.4Ahmed NisarNo ratings yet

- Merits and Demerits of AveragesDocument3 pagesMerits and Demerits of AveragesUsama Ismail75% (4)

- Stanford BinetDocument11 pagesStanford Binetsam0% (1)

- Ansys Aqwa BrochureDocument4 pagesAnsys Aqwa BrochureHoang Tien DungNo ratings yet

- CarletonSOP AbhiDocument2 pagesCarletonSOP AbhiKeyurNo ratings yet

- Crain Etal2017Document30 pagesCrain Etal2017Antonio CodinaNo ratings yet

- Concept of C ProgrammingDocument74 pagesConcept of C ProgrammingAbhishek KumarNo ratings yet