Professional Documents

Culture Documents

NT/N14 LPF Cylinder Liner Installation Instructions NT/N14 LPF Cylinder Liner Installation Instructions

NT/N14 LPF Cylinder Liner Installation Instructions NT/N14 LPF Cylinder Liner Installation Instructions

Uploaded by

jengandxbOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NT/N14 LPF Cylinder Liner Installation Instructions NT/N14 LPF Cylinder Liner Installation Instructions

NT/N14 LPF Cylinder Liner Installation Instructions NT/N14 LPF Cylinder Liner Installation Instructions

Uploaded by

jengandxbCopyright:

Available Formats

NT/N14 LPF Cylinder Liner Installation Instructions

NT/N14 LPF Cylinder Liner Installation Instructions

1. Proper liner protrusion for this application is .004- .007 (0.10mm-0.18mm).

To achieve this protrusion specification the correct thickness liner flange seal ring

must be used.

1. Proper liner protrusion for this application is .004- .007 (0.10mm-0.18mm).

To achieve this protrusion specification the correct thickness liner flange seal ring

must be used.

2. Make sure the cylinder block deck, counter bore, lower receiving bore, liner seal

ring and the cylinder liner are clean and dry.

2. Make sure the cylinder block deck, counter bore, lower receiving bore, liner seal

ring and the cylinder liner are clean and dry.

3. Install the counter bore seal ring (shim) into the cylinder block counter bore.

Warning: Do not use any type of sealant.

3. Install the counter bore seal ring (shim) into the cylinder block counter bore.

Warning: Do not use any type of sealant.

4. Install the wide crevice seal in the top liner groove.

4. Install the wide crevice seal in the top liner groove.

5. Install the two black O-rings in the center and bottom liner grooves. Verify neither

O-ring is twisted.

5. Install the two black O-rings in the center and bottom liner grooves. Verify neither

O-ring is twisted.

6. Lubricate the crevice seal and the O-rings with vegetable oil. Warning: Do not

use engine oil.

6. Lubricate the crevice seal and the O-rings with vegetable oil. Warning: Do not

use engine oil.

7. Lubricate the lower packing bore area of the cylinder block with vegetable oil.

7. Lubricate the lower packing bore area of the cylinder block with vegetable oil.

8. Place the liner into the cylinder bore taking care not to allow any oil to touch the

counter bore or seal ring.

8. Place the liner into the cylinder bore taking care not to allow any oil to touch the

counter bore or seal ring.

9. Use hand pressure push the liner into the cylinder block.

9. Use hand pressure push the liner into the cylinder block.

10. Use a proper liner installation tool to press the liner to its final installed position.

Before removing the installation tool check the liner protrusion with a dial

indicator at four locations 90 apart. The protrusion must be .004- .007

(0.10mm-0.18mm) at all four points.

10. Use a proper liner installation tool to press the liner to its final installed position.

Before removing the installation tool check the liner protrusion with a dial

indicator at four locations 90 apart. The protrusion must be .004- .007

(0.10mm-0.18mm) at all four points.

11. If the specified protrusion is not attained the liner must be removed and the

procedure repeated. If the protrusion is correct remove the installation tool and

proceed to step 12.

11. If the specified protrusion is not attained the liner must be removed and the

procedure repeated. If the protrusion is correct remove the installation tool and

proceed to step 12.

12. Check the liner bore with a dial bore gauge. The bore must not be out of round

more than .003 (.08mm) at the top 1 inch of the liner bore and not more than

.002 (.05mm) out of round in the balance of the liner bore.

12. Check the liner bore with a dial bore gauge. The bore must not be out of round

more than .003 (.08mm) at the top 1 inch of the liner bore and not more than

.002 (.05mm) out of round in the balance of the liner bore.

You might also like

- 99 AX Booster Assembly ManualDocument34 pages99 AX Booster Assembly ManualFernando NunezNo ratings yet

- QuickServe Online - (4021539) QST30 Service ManualDocument7 pagesQuickServe Online - (4021539) QST30 Service Manualjengandxb33% (3)

- QuickServe Online - (3666121) Holset® Air Compressors Master Repair ManualDocument2 pagesQuickServe Online - (3666121) Holset® Air Compressors Master Repair ManualjengandxbNo ratings yet

- QSK78 Owners Manual PDFDocument17 pagesQSK78 Owners Manual PDFjengandxb100% (2)

- QuickServe Online - (5411406) Fluids For Cummins® Products Service ManualDocument7 pagesQuickServe Online - (5411406) Fluids For Cummins® Products Service Manualjengandxb100% (1)

- K38, K50, Owners ManualDocument3 pagesK38, K50, Owners ManualjengandxbNo ratings yet

- CentinalDocument2 pagesCentinaljengandxb0% (1)

- QSK78 Troubleshooting and Repair Manual PDFDocument4 pagesQSK78 Troubleshooting and Repair Manual PDFjengandxbNo ratings yet

- Smash FW110 PDFDocument66 pagesSmash FW110 PDFbrian balmater50% (2)

- Mayweather-McGregor Unofficial Blank ScorecardDocument1 pageMayweather-McGregor Unofficial Blank ScorecardOskar GarciaNo ratings yet

- Piston RingsDocument1 pagePiston RingsOlimpiu Vuia100% (1)

- QuickServe Online - (3666422) ICON™ Idle Control SystemDocument18 pagesQuickServe Online - (3666422) ICON™ Idle Control Systemjengandxb100% (1)

- QuickServe Online - (4021528) GTA38, K38, K50, QSK38, and QSK50 Service ManualDocument9 pagesQuickServe Online - (4021528) GTA38, K38, K50, QSK38, and QSK50 Service Manualjengandxb100% (2)

- Main Bearing Torque K50Document1 pageMain Bearing Torque K50jengandxb100% (1)

- Main Bearing Torque K50Document1 pageMain Bearing Torque K50jengandxb100% (1)

- Katalog New Holland Kombayn tc56 Combine PDFDocument783 pagesKatalog New Holland Kombayn tc56 Combine PDFAndreyIvanovNo ratings yet

- 2 1 E28093 Structure and Function of The Ventilation SystemDocument10 pages2 1 E28093 Structure and Function of The Ventilation Systemapi-343368893No ratings yet

- Installation Instructions Oil Filter Relocation Kit PART # 15749Document2 pagesInstallation Instructions Oil Filter Relocation Kit PART # 15749Alex BernalNo ratings yet

- 4000 Winch NarDocument14 pages4000 Winch NarJITENDRA KUMAR SHARMANo ratings yet

- Installation Guide: Isnorkel020Document6 pagesInstallation Guide: Isnorkel020Miguel CerdaNo ratings yet

- Instalación SnorkelDocument5 pagesInstalación SnorkelManoloNo ratings yet

- Piston Kit InstructionsDocument2 pagesPiston Kit InstructionsMoto ExpertNo ratings yet

- Installation Work Instructions For Mechanical SealDocument2 pagesInstallation Work Instructions For Mechanical SealAnees Ud DinNo ratings yet

- 1CV Overhaul PDFDocument15 pages1CV Overhaul PDFsteve@air-innovations.co.zaNo ratings yet

- Daewo Matiz2Document54 pagesDaewo Matiz2hipo84575% (4)

- C5 - C6 - Z06 Corvette Install ManualDocument46 pagesC5 - C6 - Z06 Corvette Install ManualAdam GrahamNo ratings yet

- Transfer CaseDocument6 pagesTransfer CaseTim SmithNo ratings yet

- May Cap Da Voi Nhiet DienDocument14 pagesMay Cap Da Voi Nhiet Dienlinhcdt3No ratings yet

- Group 4-Cylinder BlockDocument48 pagesGroup 4-Cylinder BlockNikkikumar MaisuriyaNo ratings yet

- Jet 700 4l60 e Billet Powr ServoDocument4 pagesJet 700 4l60 e Billet Powr ServoJavier VelasquezNo ratings yet

- Hyundai Coupe 2.0Document11 pagesHyundai Coupe 2.0BrandonHiDudNo ratings yet

- Maintenance Procedure MK 17Document5 pagesMaintenance Procedure MK 17HankNo ratings yet

- Ringendgap Piston Ring 4jb1Document3 pagesRingendgap Piston Ring 4jb1Shimmer CrossbonesNo ratings yet

- CanrigBJWPC ICO Manual PDFDocument42 pagesCanrigBJWPC ICO Manual PDFCarlos Patiño SuarezNo ratings yet

- Manual EVK SealDocument18 pagesManual EVK Sealpanamajack26No ratings yet

- g312 ManualDocument14 pagesg312 Manualflasher_for_nokiaNo ratings yet

- Installing T400 Load Sensors: Doc #: 11080 Rev:A T400 InstallationDocument7 pagesInstalling T400 Load Sensors: Doc #: 11080 Rev:A T400 InstallationHusnulKhotimahNo ratings yet

- SKF Mount - 22232 CCK-W33 - Hydraulic Nut - Adapter SleeveDocument11 pagesSKF Mount - 22232 CCK-W33 - Hydraulic Nut - Adapter SleeveMohamed Abo elkhairNo ratings yet

- Installation Instructions: BW Seals Q, QB SeriesDocument8 pagesInstallation Instructions: BW Seals Q, QB Seriesaliihsan3461No ratings yet

- Ring and Pinion Installation InstructionsDocument8 pagesRing and Pinion Installation InstructionsJonathanNo ratings yet

- Hyco - 091 7010 0Document12 pagesHyco - 091 7010 0david mendozaNo ratings yet

- Installation Instructions: BW Seals Q, QB SeriesDocument8 pagesInstallation Instructions: BW Seals Q, QB SeriesJoseGarciaRNo ratings yet

- Side Stand DraftDocument3 pagesSide Stand Draftapi-327987286100% (1)

- Rammer 1655 Service 2015Document52 pagesRammer 1655 Service 2015SerkanAlNo ratings yet

- TPMSposter90 1033Document1 pageTPMSposter90 1033robertfrick100% (1)

- Propeller Fitting InstructionsDocument7 pagesPropeller Fitting Instructionsrubens0001No ratings yet

- Starrett 3814 ManualDocument15 pagesStarrett 3814 ManualcdokepNo ratings yet

- SOP TemplateDocument2 pagesSOP TemplateAnkur Dhir100% (1)

- VE5C VE Commodore Hard Lid ManualDocument13 pagesVE5C VE Commodore Hard Lid ManualmathewNo ratings yet

- RP2Document24 pagesRP2Vennia PapadipoulouNo ratings yet

- TEM FluidEnds MPDocument15 pagesTEM FluidEnds MPGeorge BuitragoNo ratings yet

- TTR125 150BigBore Update2Document4 pagesTTR125 150BigBore Update2eddielindermannNo ratings yet

- Kbu KBZ3Document9 pagesKbu KBZ3Andrew VNo ratings yet

- 186 6802 0revb - 1Document8 pages186 6802 0revb - 1marranNo ratings yet

- Piston Ring Installation GenericDocument1 pagePiston Ring Installation GenericMinibikeTech100% (1)

- DYNAenergetics 1.90 Short Mechanical Firing Head Re-Dress ProcedureDocument8 pagesDYNAenergetics 1.90 Short Mechanical Firing Head Re-Dress ProceduremahsaNo ratings yet

- JC 2648 Seal IOM Manual PDFDocument4 pagesJC 2648 Seal IOM Manual PDFRené Mora-CasalNo ratings yet

- Engine Air Intake: Service When IndicatedDocument14 pagesEngine Air Intake: Service When IndicatedLeandro Sienra100% (1)

- Cummins Injector Install ProcedureDocument15 pagesCummins Injector Install ProcedureLawrence Shafer100% (7)

- Engine Assembly-Repair ProcedurDocument24 pagesEngine Assembly-Repair Procedurfebri yuliantoNo ratings yet

- Equipment Assembly A3Document3 pagesEquipment Assembly A3adamnassir91No ratings yet

- Tool List: Please Read Completely Before BeginningDocument5 pagesTool List: Please Read Completely Before BeginningDavíð Örn SvavarssonNo ratings yet

- Rear SealDocument9 pagesRear SealHammad Uddin JamilyNo ratings yet

- Assembly and Disaassembly of PumpsDocument5 pagesAssembly and Disaassembly of Pumpsshin deiru100% (1)

- Injectors STCDocument7 pagesInjectors STCLionnel ParantNo ratings yet

- IS233Document2 pagesIS233Carlos Lara CastroNo ratings yet

- SAP PARTS: Installation Guidelines For Installation Guidelines For Duo-Cone SealsDocument5 pagesSAP PARTS: Installation Guidelines For Installation Guidelines For Duo-Cone SealsRavi MirzaNo ratings yet

- Chapter (4) Pump InstallationDocument21 pagesChapter (4) Pump Installationkarioke mohaNo ratings yet

- ClutchtDocument6 pagesClutchtchanakawidNo ratings yet

- Install The ATF (Automatic Transaxle Fluid) Oil Cooler Hoses (C) - Page 116 of 138Document15 pagesInstall The ATF (Automatic Transaxle Fluid) Oil Cooler Hoses (C) - Page 116 of 138flash_24014910No ratings yet

- Cylinder Block - Repair ProcedurDocument34 pagesCylinder Block - Repair Procedurfebri yulianto100% (1)

- QFC Valve ManualDocument27 pagesQFC Valve ManualLeandro100% (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- K38 - Cylinder Head InstallationDocument3 pagesK38 - Cylinder Head InstallationjengandxbNo ratings yet

- QuickServe Online - (4915540) QSX15 Owners ManualDocument4 pagesQuickServe Online - (4915540) QSX15 Owners ManualjengandxbNo ratings yet

- Fault Code 113: Electronic Step Timing Control (STC) CircuitDocument2 pagesFault Code 113: Electronic Step Timing Control (STC) CircuitjengandxbNo ratings yet

- Preparatory Steps: (/qs3/pubsys2/xml/en/manual/4021528/4021528-Titlepage - HTML)Document7 pagesPreparatory Steps: (/qs3/pubsys2/xml/en/manual/4021528/4021528-Titlepage - HTML)jengandxbNo ratings yet

- Remove: (/qs3/pubsys2/xml/en/manual/4021539/4021539-Titlepage - HTML)Document2 pagesRemove: (/qs3/pubsys2/xml/en/manual/4021539/4021539-Titlepage - HTML)jengandxbNo ratings yet

- ECM TroubleshootingDocument27 pagesECM Troubleshootingjengandxb100% (4)

- Preparatory Steps: (/qs3/pubsys2/xml/en/manual/4021528/4021528-Titlepage - HTML)Document7 pagesPreparatory Steps: (/qs3/pubsys2/xml/en/manual/4021528/4021528-Titlepage - HTML)jengandxbNo ratings yet

- QSK78 Troubleshooting and Repair ManualDocument4 pagesQSK78 Troubleshooting and Repair Manualjengandxb0% (1)

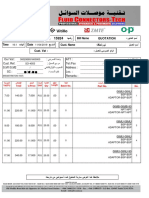

- Pay Type No. Bill Name Cust. Name Time Date Cust. VatDocument3 pagesPay Type No. Bill Name Cust. Name Time Date Cust. VatjengandxbNo ratings yet

- Cummins K-50 Performance PartsDocument10 pagesCummins K-50 Performance Partsjengandxb100% (1)

- General Information: Industrial EnginesDocument17 pagesGeneral Information: Industrial EnginesjengandxbNo ratings yet

- Pay Type No. Bill Name Cust. Name Time Date Cust. VatDocument3 pagesPay Type No. Bill Name Cust. Name Time Date Cust. VatjengandxbNo ratings yet

- Pay Type No. Bill Name Cust. Name Time Date Cust. Vat::: QuotationDocument3 pagesPay Type No. Bill Name Cust. Name Time Date Cust. Vat::: QuotationjengandxbNo ratings yet

- Pay Type No. Bill Name Cust. Name Time Date Cust. VatDocument6 pagesPay Type No. Bill Name Cust. Name Time Date Cust. VatjengandxbNo ratings yet

- Electronic Parts Catalog - Option DetailDocument2 pagesElectronic Parts Catalog - Option DetailjengandxbNo ratings yet

- LinersDocument4 pagesLinersjengandxbNo ratings yet

- Single Phase AlternatorsDocument3 pagesSingle Phase AlternatorsjengandxbNo ratings yet

- K50 Cylinder Head TorqueDocument1 pageK50 Cylinder Head Torquejengandxb100% (1)

- Make Your Own Miniature Electric Hub Motor - 6Document12 pagesMake Your Own Miniature Electric Hub Motor - 6jengandxbNo ratings yet

- Pil - Sport - Football - 20190927Document42 pagesPil - Sport - Football - 20190927VEMATELNo ratings yet

- Lesson 7 Computer Workstation ErgonomicsDocument17 pagesLesson 7 Computer Workstation ErgonomicsRonaldo PalomaNo ratings yet

- Big, Bigger, BiggestDocument2 pagesBig, Bigger, BiggestAdelaide TeixeiraNo ratings yet

- Cronin 2006Document10 pagesCronin 2006asepsumpenaNo ratings yet

- Mantenimiento de Caja Chery QQ PDFDocument14 pagesMantenimiento de Caja Chery QQ PDFJose FerrerNo ratings yet

- Rodrigo Costa Felix Fado PortugueseDocument7 pagesRodrigo Costa Felix Fado Portuguesetpwalker0% (1)

- Fall 2023 Brochure Darien YMCADocument22 pagesFall 2023 Brochure Darien YMCAPatty KaneNo ratings yet

- Customized For Your Members, Trainers & BusinessDocument29 pagesCustomized For Your Members, Trainers & BusinessPancrasio PancrasioNo ratings yet

- Pe Obe Syllabus in P.E 4 Ball SportsDocument8 pagesPe Obe Syllabus in P.E 4 Ball SportsPeter Jhon TaroyNo ratings yet

- RK Chain Guide ChartDocument5 pagesRK Chain Guide ChartSalam AbdulNo ratings yet

- History of Indian Sport by Dr. Rajkumar G MalkappagolDocument3 pagesHistory of Indian Sport by Dr. Rajkumar G MalkappagolRolwynloboNo ratings yet

- Reinforcing Accessories Starter Bars Footing Cages Ribwire SpiralsDocument1 pageReinforcing Accessories Starter Bars Footing Cages Ribwire SpiralsAnonymous imkwF8N7TeNo ratings yet

- Talleres Finalización Primer PeriodoDocument8 pagesTalleres Finalización Primer PeriodoFerley Caso PNo ratings yet

- Surya NamaskarDocument12 pagesSurya NamaskarBaskaran Sowrirajulu100% (1)

- The Quick and Simple RPG SystemDocument9 pagesThe Quick and Simple RPG SystemAxel RagnarsonNo ratings yet

- D&D 5E - Homebrew - Pistoleiro (Spellslinger)Document12 pagesD&D 5E - Homebrew - Pistoleiro (Spellslinger)Pedro Lucas0% (1)

- Komatsu W60 Wheel Loader: Looking To Purchase This Item? Need To Sell Equipment?Document2 pagesKomatsu W60 Wheel Loader: Looking To Purchase This Item? Need To Sell Equipment?eka sukanda0% (1)

- Mta Alumni RosterDocument12 pagesMta Alumni Rosterapi-293637068No ratings yet

- THREE X THREE Video Drill GuideDocument3 pagesTHREE X THREE Video Drill GuideAmlan PatiNo ratings yet

- Crash 2023 06 14 - 17.15.26 FMLDocument5 pagesCrash 2023 06 14 - 17.15.26 FMLEspeciales ???No ratings yet

- Grimoire of Heart Character SheetDocument16 pagesGrimoire of Heart Character Sheetnão interessaNo ratings yet

- 1500 Metres Official.Document2 pages1500 Metres Official.RICHARDNo ratings yet

- RE 2 - M222CIL MPT PM LSP 3001 - Rev B1 PDFDocument6 pagesRE 2 - M222CIL MPT PM LSP 3001 - Rev B1 PDFsumit kumarNo ratings yet

- Directory Producers & EngineersDocument14 pagesDirectory Producers & Engineersstudio1bcNo ratings yet

- Hope 2 Q3 M3Document14 pagesHope 2 Q3 M3Earl Mienard MonaresNo ratings yet

- Hartman Training CourseDocument18 pagesHartman Training CourseJuan Pablo Cortes CallejasNo ratings yet