Professional Documents

Culture Documents

624-1e Techn Data BE 1

624-1e Techn Data BE 1

Uploaded by

maxilencinaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

624-1e Techn Data BE 1

624-1e Techn Data BE 1

Uploaded by

maxilencinaCopyright:

Available Formats

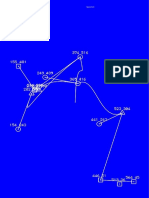

h5

h4

h6 h2

d2

v3

d4

l1

d1

h3

h1

RL

h8 Nominal level

RL

DIMENSIONS

CBT

d3

l3

l4

v2

l2

TBF Turbofoil

a1

h7

600

v1

vU

Agitator shaft

d5

d6

d5

d6

ID (immersion depth)

insulation collar, top

insulation ring, top

a2

insulation ring,

centre

insulation ring,

d5

d6

100

bottom

Insulation

FBT

PBT

d7

Baffle

DN1

h12

h12

DN1

h11

h11

DN

2

DN

2

RCI Impeller

Anchor

APA valve

AMA valve

Turbines

Supporting structures

a3

d8

d8

d9

max

Rim-shaped support

ring (2 sections)

d8

9

max

Support ring with

web plates

d9

max

Support ring with web plates

and loose ring (2 sections)

d9

max

Side brackets

Tubular legs

up to BE 6300

Profiled legs

from BE 8000,

diam. 2200

Supporting structures

2. Agitators

The reactors are available with the

Made for DIN reactors BE: Cryo-Lock

following support structures:

by Pfaudler, the flexible agitating system:

Rim-shaped support ring acc. to

DIN 28145-4

Support ring with web plates without

loose ring acc. to DIN 28145-4, design A

Support ring with web plates and

loose ring acc. to DIN 28145-4,

design D

Systematics

The Pfaudler DIN reactors BE comprise

the following subassemblies:

A large selection of agitators, including

multi-stage arrangements of turbines are

possible

An economic system:

Tubular legs acc. to DIN 28145-8

efficient exchange of turbines with

(up to BE 6300)

mounted shaft and mounted drive unit.

Profiled iron legs acc. to

Turbines are inserted through the

DIN 28145-8 (from BE 8000)

manhole. Most shafts can also be

exchanged using the manhole.

Jacket connections

Baffle

acc. to DIN 28151, optionally:

The technical data on the following

depending on process requirements.

energy-saving turbines. Quick and cost-

Agitator

Accessories

can be mounted quickly and easily

Side brackets

Reactor

Drive

A shaft on which different turbines

nozzle position A1/A2, without

agitating nozzles

A safe system: the manhole is the

largest opening reduced gasket length,

higher pressure resistance, fewer

leakages.

nozzle position B1/B2, with agitating

pages are sorted according to these

nozzles; the agitating nozzles are

Turbines

systematics and reactor sizes and

included in the part numbers

CBT: the universal agitator, high

marked with different colors.

Manhole unit

shearing effect, radial flow

The manhole unit is available in two

TBF: the economic Turbofoil agitator,

different designs:

high axial flow with relatively low flow

1. Reactor

Inner vessel, shape BE according to

Hinged manhole cover acc. to

disturbance, low torque/low power input

DIN 28136, BE 1600 similar to DIN.

DIN 28153-1, with spring balanced

FBT: high shearing force, mere

Reactors BE 10000, BE 12500 and

opening device, shape KE 1, sight glass

radial flow

BE 16000 diam. 2600 are

DN100 acc. to DIN 28121 and a

PBT: medium shearing effect, combined

manufactured with larger baffle nozzles

manhole protecting ring acc. to

radial/axial flow

DN300 (N4 and N9).

DIN 28153-1

RCI: the classical impeller in its latest

Jacket:

Manhole cover with swivel device

version: strong radial flow, a relatively

Agitator flange acc. to DIN 28137-2

acc. to DIN 28153-1, shape SE 1, sight

high flow disturbance required

Split flanges acc. to DIN 28150

glass DN100 acc. to DIN 28121 and

ANC: the anchor-type agitator for highly

Gaskets for glasslined nozzles acc. to

manhole protecting ring acc. to

viscous products, low shearing forces,

DIN 28148, optionally with gasket

DIN 28153-1

tangential flow, high torque

inserts made of AF 2000 or graphite.

Coating system

Rust protection primer Alucrom, double

coat, minimum layer thickness in dry

state 60 m, temperature resistance

-25/+200 C

CONSTRUCTION

AND

FUNCTION

Opt for a single-stage universal agitator

3. Baffles

or have your own agitator assembled

The Quatro-Pipe a multi-functional

separate cooling and sealing functions.

with units from the agitator shaft table

baffle with four different functions for a

The cooling effect is retained even in dry

and the turbine table according to your

single reactor nozzle:

operation

requirements. The honed surface protection from fluorine ethylene propylene

flow disturbance function acts like

a flange-type baffle with constant effects

integrated cooling jacket with

low maintenance, long life,

low friction

(FEP) temporarily covers the unused

immersion tube function

honed surfaces on multi-stage agitator

temperature monitoring

the possibility of subsequently adding

monitoring for glass damages

additional modules

shafts.

modular design: basic systems with

signals glass damages in the reactor

(optional). Paddle-type baffles in flange

The proven PC719 mechanical seal

Pumping capacity

design are available as an alternative

continues to be available.

2.5

4. VSO drives

The accessory set consisting of a

2.0

1.5

top drive units with belt drive

and a thermo-manometer is necessary

flexible adaption of the agitator

for all mechanical seals.

speed by exchanging the motor

Suitable sealing liquid assemblies or

V-belt pulley

thermosiphon units are listed under the

connection to reactors acc. to

1.0

heading Fluid control equipment.

DIN 28136 with 63 ... 40,000 l capacity

for agitator flanges acc. to

0.5

DIN 28137, parts 1 and 2

easily accessible from all sides

glasslined intermediate flange, gaskets

RCI

1100

CBT

835

PBT

890

TBF

990

6. Motors

The most common motors in protection

classes T3 and T4 as well as the design

thanks to an open profile-type of

for frequency inverter operation (T4) are

construction

described in the data section. Only West

quick exchange of the mechanical

European OEM equipment will be used.

seal using Pfaudler assembly tools

Mixing time

2.5

low-noise gear

The motor rating was based on the

long life due to reinforced bearings

following data:

minimal axial and radial play

0.8

Density 1100 kg/m3

Viscosity 100 mPas

Remember to order the belt drive!

0.6

Motors for deviating operating

conditions on request! The motor

0.4

0.2

5. Mechanical seal Pfaudler-fleXeal

speeds are indicated together with the

The new Pfaudler generation offers even

motors, the maximum agitator speeds

more safety:

together with the drives.

double-acting seal with two sets of

mechanical seals

0

RCI

1100

CBT

835

PBT

890

TBF

990

additional emergency seal

chamber gasket between

mechanical seal and intermediate flange

BE 1600

Supporting structures

[mm]

225206 Supporting ring, rim shaped

d8 = 1890, d9 max. = 1720

265182 Jacket connections arrangement A2,

without agitating nozzles

265186 Jacket connections arrangement B2,

with integrated agitating nozzles

203808 Supporting ring with web plates

d8 = 1890, d9 max. = 1720

265183 Jacket connections arrangement A2,

without agitating nozzles

265187 Jacket connections arrangement B2,

with integrated agitating nozzles

203824 Supporting ring with loose ring

d8 = 1890, d9 max. = 1720

265184 Jacket connections arrangement A2,

without agitating nozzles

265188 Jacket connections arrangement B2,

with integrated agitating nozzles

Reactor type BE 1600

Basic reactor consisting of:

496355 Inner vessel type BE 1600

similar to DIN 28136

045046 4 brackets a3 = 180, d9 max. = 1740

265185 Jacket connections arrangement A1,

without agitating nozzles

265189 Jacket connections arrangement B1,

with integrated agitating nozzles

265321 Agitator flange

201637 Jacket

265272 Jacket attachments

251886 Set of split flanges

251875 Set of Pfaudler gaskets type AF2000

with asbestos-free inserts

2518753 Set of Pfaudler gaskets type graphite

Reactor specifications

1600 l

Overall capacity:

2309 l

Overall jacket capacity:

353 l

Heat exchange surface:

7.33 m2

251015 Sight glass DN100 according to

DIN 28121 on N6, design EC, with

lighting 230 V, explosion protection

type EExdeIIC T4, incl. halogen lamp

12 V, 20 W

Insulation

part #

design

d5

d6

d7

251689

251688

251690

251691

Insulation ring, top

Insulation collar, top

Insulation ring, centre

Insulation ring, bottom

1500

1500

1500

1700

1700

1700

500

h5

525

h6

236

h7

73

h8

1180

d1

1400

d2

1500

N3

[mm]

r1

475

575

575

550

575

550

575

575

0

h9

125

25

25

50

25

50

25

25

80

N5

25

r1

r1

O

L

N6

N1

h9

0

60

95

135

180

225

265

300

N2

h9

h4

1210

h10

h3

1800

[mm]

h9

h2

100

Nozzles

052115 Rust protection type Alucrom, double

coating

[mm]

h1

1973

DN

500

100

100

200

100

200

100

100

100

100

150

Coating

approx. 3000 kg

Main dimensions

N1

N2

N3

N5

N6

N7

N9

N10

K

L

R

225312 Manhole cover DN500 according to

DIN 28153-1, shape SE1, suitable for

using a swiveling device, with sight

glass DN100 according to

DIN 28121, design EC and manhole

protecting ring DN500 according to

DIN 28153-1

2253123 Same as #225312, however with

type graphite gaskets

265288 Manhole swiveling device and 1 set of

clamps

Sight glass with lighting

Nominal volume:

Total weight:

225165 4 tube legs

265185 Jacket connections arrangement A1,

without agitating nozzles

265189 Jacket connections arrangement B1,

with integrated agitating nozzles

Manhole units

265284 Manhole cover DN500 according to

DIN 28153-1, shape KE1, suitable for

use with spring balanced opening

device, with sight glass DN100

according to DIN 28121, design EC

and manhole protecting ring DN500

according to DIN 28153-1

2652843 Same as #265284, however with

type graphite gaskets

265285 Manhole opening device and 1 set of

clamps

N7

N10

N9

624-2 e

BE 1600

Baffle/Quatro-Pipe

Agitator shafts

part #

no. of stages d4

[mm]

a1

[mm]

l1

[mm]

202814

202957

240004

1

2

3

198

198

198

2160 210

2160 210

2160 210

65

65

65

l2

l3

[mm] [mm]

650

500

l4

[mm]

Vu

[l]

V1

[l]

V2

[l]

V3

[l]

790

161

161

161

333

333

333

978

758

1183

for nozzle:

immersion depth (ID):

width of paddle (a2):

volume below

Quatro-Pipe/baffle:

DN200

1550 mm

180 mm

290 l

5950030 Quatro-Pipe

Turbines

[mm]

part #

type

d3

d4

210350

210442*

210447*

210352*

210354*

210353*

210369

2541970

CBT

735

65

GST

600

65

MXT

600

65

TBF

760

65

FBT

685

65

PBT

685

65

RCI

840

65

Protection for honed surface, FEP

Cryo-Lock agitator assemblies**

202828 Cryo-Lock agitator type CBT

202825 Cryo-Lock agitator type TBF

202908 Cryo-Lock agitator type ANC***

** single-stage

5950032 Quatro-Pipe with temperature

probe 2xTW

2076910 Paddle type baffle, flange design

2076912 Paddle type baffle, flange design

with temperature probe 2xTW

265312 Baffle/Quatro-Pipe fixing kit

***special shaft lengths for anchor type

*part # refers to one turbine part

Fluid control equipment

Mechanical seals

204384X Mechanical seal, type PC719,

double-acting for wet operation, with

cooling jacket, shaft diameter 80 mm,

material combination: AI2O3carbon

265302 Set of accessories for PC719

consisting of: glasslined intermediate

flange, thermo-manometer, set of

gaskets, bolting

260011 Mechanical seal, type fleXeal UF8,

double-acting for wet operation, with

cooling jacket, shaft diameter 80 mm,

material combination: SiCcarbon

265337 Set of accessories for UF8

consisting of: glasslined intermediate

flange, thermo-manometer, set of

gaskets, bolting

Motors

021761 Three-phase motor EExeII T3, design

V6, 5 kW, 1450 min-1, 400 V, 50 Hz

021768 Three-phase motor EExdeIIC T4,

design V6, 5.5 kW, 1440 min-1,

400 V, 50 Hz

K03496F Three-phase motor for frequency

inverter operation EExdeIIC T4, design

V6, 7.5/5.5 kW (mains/inverter),

range of adjustment 1:5, 1450 min-1,

400 V, 50 Hz

260019 Mechanical seal, type fleXeal BF 7,

double-acting for dry operation,

balanced, with cooling jacket, shaft

diameter 80 mm, material

combination: SiCcarbon

260035 Mechanical seal, type fleXeal GF 7

double-acting for dry operation, non

contacting gas film lubrication, with

cooling jacket, shaft diameter 80 mm,

material combination: SiCcarbon

265353 Set of accessories for BF7 and GF7

consisting of: glasslined intermediate

flange, thermo-manometer, set of

gaskets, bolting

204905 Sealing liquid assembly SAM1, volume

1.7 l, static operation, for pressure

2/50 bar

204931 Assembly kit SAM1 for PC719

A62-000 Assembly kit SAM1 for UF8

204451 Thermosiphon system consisting of:

vessel (1.4571) with cooling spiral

and sight glass, volume 8 l,

max. pressure 25 bar,

working temperature -10/+250 C,

manual refilling unit

2044511 Same as #204451, however with

pressure/temperature instrumentation

for local indication of system

operating conditions

A64-000 Assembly kit thermosiphon for UF8

Agitator drive

265291 Agitator drive VSO, type 8/80,

without motor, agitator speed

125 min-1, max. torque 600 Nm

260040 Humidifier for BF7

A66-000 Assembly kit humidifier for BF7

260041 Gas supply unit BGS

Belt drive

A13-003 Belt drive VSO 8/80

Outlet valves

Accessories for outlet valves

DN1/DN2 = 100/80, working temp. = 60/+200 C, working press. = 1/+10 bar, h12 = 110 mm

Proximity switches

V10MBOO Outlet valve AMA-BT 100/80, manually operated, h11 = 508 mm, without probe

Assembly kit for outlet valves

V10MBWO Same as # V10MBOO, however with resistance thermometer TMI

Lateral manual opening aid for APA-BT

V10PBOO Outlet valve APA-BT 100/80, pneumatically operated, h11 = 598 mm, without probe

V10PBWO Same as # V10PBOO, however with resistance thermometer TMI

624-2 e

BE 2500

Supporting structures

[mm]

225207 Supporting ring, rim shaped

d8 = 2090, d9 max. = 1920

265182 Jacket connections arrangement A2,

without agitating nozzles

265186 Jacket connections arrangement B2,

with integrated agitating nozzles

203809 Supporting ring with web plates

d8 = 2090, d9 max. = 1920

265183 Jacket connections arrangement A2,

without agitating nozzles

265187 Jacket connections arrangement B2,

with integrated agitating nozzles

203825 Supporting ring with loose ring

d8 = 2090, d9 max. = 1920

265184 Jacket connections arrangement A2,

without agitating nozzles

265188 Jacket connections arrangement B2,

with integrated agitating nozzles

Reactor type BE 2500

Basic reactor consisting of:

496323 Inner vessel type BE 2500

according to DIN 28136

045046 4 brackets a3 = 180, d9 max. = 1940

265185 Jacket connections arrangement A1,

without agitating nozzles

265189 Jacket connections arrangement B1,

with integrated agitating nozzles

204769 Agitator flange

201638 Jacket

265272 Jacket attachments

251886 Set of split flanges

251875 Set of Pfaudler gaskets type AF2000

with asbestos-free inserts

2518753 Set of Pfaudler gaskets type graphite

Reactor specifications

2500 l

Overall capacity:

3472 l

Overall jacket capacity:

453 l

Heat exchange surface:

9.6 m2

225312 Manhole cover DN500 according to

DIN 28153-1, shape SE1, suitable for

using a swiveling device, with sight

glass DN100 according to

DIN 28121, design EC and manhole

protecting ring DN500 according to

DIN 28153-1

2253123 Same as #225312, however with

type graphite gaskets

265288 Manhole swiveling device and 1 set of

clamps

Coating

052115 Rust protection type Alucrom, double

coating

251015 Sight glass DN100 according to

DIN 28121 on N6, design EC, with

lighting 230 V, explosion protection

type EExdeIIC T4, incl. halogen lamp

12 V, 20 W

approx. 3870 kg

[mm]

Insulation

h1

2232

h2

100

h3

2060

h4

1210

h5

525

part #

design

d5

d6

d7

h6

259

h7

72

h8

1405

d1

1600

d2

1700

251693

251692

251694

251691

Insulation ring, top

Insulation collar, top

Insulation ring, centre

Insulation ring, bottom

1700

1700

1700

1900

1900

1900

500

0

65

95

135

180

225

265

295

r1

550

675

675

625

675

625

675

675

0

h9

125

10

10

50

10

50

10

10

80

N5

25

r1

r1

O

L

N6

N1

h9

DN

500

100

100

200

100

200

100

100

100

100

150

N2

h9

N1

N2

N3

N5

N6

N7

N9

N10

K

L

R

N3

[mm]

h10

Nozzles

[mm]

h9

Main dimensions

265284 Manhole cover DN500 according to

DIN 28153-1, shape KE1, suitable for

use with spring balanced opening

device, with sight glass DN100

according to DIN 28121, design EC

and manhole protecting ring DN500

according to DIN 28153-1

2652843 Same as #265284, however with

type graphite gaskets

265285 Manhole opening device and 1 set of

clamps

Sight glass with lighting

Nominal volume:

Total weight:

225165 4 tube legs

265185 Jacket connections arrangement A1,

without agitating nozzles

265189 Jacket connections arrangement B1,

with integrated agitating nozzles

Manhole units

N7

N10

N9

624-2 e

BE 2500

Agitator shafts

Baffle/Quatro-Pipe

part #

no. of stages d4

[mm]

a1

[mm]

l1

[mm]

202815

202959

240006

1

2

3

202

202

202

2415 210

2415 210

2415 210

65

65

65

l2

l3

[mm] [mm]

760

580

l4

[mm]

Vu

[l]

V1

[l]

V2

[l]

V3

[l]

950

195

195

195

419

419

419

1476

1130 1841

for nozzle:

immersion depth (ID):

width of paddle (a2):

volume below

Quatro-Pipe/baffle:

DN200

1750 mm

180 mm

457 l

5950040 Quatro-Pipe

Turbines

[mm]

part #

type

d3

d4

210350

210442*

210447*

210352*

210354*

210353*

210371

2541970

CBT

735

65

GST

600

65

MXT

600

65

TBF

760

65

FBT

685

65

PBT

685

65

RCI

960

65

Protection for honed surface, FEP

Cryo-Lock agitator assemblies**

202829 Cryo-Lock agitator type CBT

5950042 Quatro-Pipe with temperature

probe 2xTW

202826 Cryo-Lock agitator type TBF

2076920 Paddle type baffle, flange design

202909 Cryo-Lock agitator type ANC***

2076922 Paddle type baffle, flange design with

temperature probe 2xTW

** single-stage

***special shaft lengths for anchor type

265312 Baffle/Quatro-Pipe fixing kit

*part # refers to one turbine part

Mechanical seals

204384X Mechanical seal, type PC719, doubleacting for wet operation, with cooling

jacket, shaft diameter 80 mm,

material combination: AI2O3carbon

265302 Set of accessories for PC719

consisting of: glasslined intermediate

flange, thermo-manometer, set of

gaskets, bolting

260011 Mechanical seal, type fleXeal UF8,

double-acting for wet operation, with

cooling jacket, shaft diameter 80 mm,

material combination: SiCcarbon

265337 Set of accessories for UF8 consisting

of: glasslined intermediate flange,

thermo-manometer, set of gaskets,

bolting

Motors

021762 Three-phase motor EExeII T3, design

V6, 6.8 kW, 1480 min-1, 400 V, 50 Hz

021768 Three-phase motor EExdeIIC T4,

design V6, 5.5 kW, 1440 min-1, 400V,

50 Hz

K03496F Three-phase motor for frequency

inverter operation EExdeIIC T4, design

V6, 7.5/5.5 kW (mains/inverter),

range of adjustment 1:5, 1450 min-1,

400 V, 50 Hz

Fluid control equipment

260019 Mechanical seal, type fleXeal BF7,

double-acting for dry operation,

balanced, with cooling jacket, shaft

diameter 80 mm, material

combination: SiCcarbon

260035 Mechanical seal, type fleXeal GF7,

double-acting for dry operation,

non contacting gas film lubrication,

with cooling jacket, shaft diameter

80 mm, material combination:

SiCcarbon

265353 Set of accessories for BF7 and GF7

consisting of: glasslined intermediate

flange, thermo-manometer, set of

gaskets, bolting

204905 Sealing liquid assembly SAM1, volume

1.7 l, static operation, for pressure

2/50 bar

204931 Assembly kit SAM1 for PC719

A62-000 Assembly kit SAM1 for UF8

204451 Thermosiphon system consisting of:

vessel (1.4571) with cooling spiral

and sight glass, volume 8 l,

max. pressure 25 bar,

working temperature -10/+250 C,

manual refilling unit

2044511 Same as #204451, however with

pressure/temperature instrumentation

for local indication of system

operating conditions

A64-000 Assembly kit thermosiphon for UF8

Agitator drive

265290 Agitator drive VSO 8/80,

without motor, agitator speed

125 min-1, max. torque 600 Nm

260040 Humidifier for BF7

A66-000 Assembly kit humidifier for BF7

260041 Gas supply unit BGS

Belt drive

A13-003 Belt drive VSO 8/80

Outlet valves

Accessories for outlet valves

DN1/DN2 = 100/80, working temp. = 60/+200 C, working press. = 1/+10 bar, h12 = 110 mm

Proximity switches

V10MBOO Outlet valve AMA-BT 100/80, manually operated, h11 = 508 mm, without probe

Assembly kit for outlet valves

V10MBWO Same as # V10MBOO, however with resistance thermometer TMI

Lateral manual opening aid for APA-BT

V10PBOO Outlet valve APA-BT 100/80, pneumatically operated, h11 = 598 mm, without probe

V10PBWO Same as # V10PBOO, however with resistance thermometer TMI

624-2 e

BE 4000

Supporting structures

[mm]

225208 Supporting ring, rim shaped

d8 = 2290, d9 max. = 2120

265190 Jacket connections arrangement A2,

without agitating nozzles

265194 Jacket connections arrangement B2,

with integrated agitating nozzles

203810 Supporting ring with web plates

d8 = 2290, d9 max. = 2120

265191 Jacket connections arrangement A2,

without agitating nozzles

265195 Jacket connections arrangement B2,

with integrated agitating nozzles

203826 Supporting ring with loose ring

d8 = 2290, d9 max. = 2120

265192 Jacket connections arrangement A2,

without agitating nozzles

265196 Jacket connections arrangement B2,

with integrated agitating nozzles

Reactor type BE 4000

Basic reactor consisting of:

496325 Inner vessel type BE 4000

according to DIN 28136

045046 4 brackets a3 = 180, d9 max. = 2140

265185 Jacket connections arrangement A1,

without agitating nozzles

265197 Jacket connections arrangement B1,

with integrated agitating nozzles

204770 Agitator flange

201639 Jacket

265272 Jacket attachments

251888 Set of split flanges

251877 Set of Pfaudler gaskets type AF2000

with asbestos-free inserts

2518773 Set of Pfaudler gaskets type graphite

265284 Manhole cover DN500 according to

DIN 28153-1, shape KE1, suitable for

use with spring balanced opening

device, with sight glass DN100

according to DIN 28121, design EC

and manhole protecting ring DN500

according to DIN 28153-1

2652843 Same as #265284, however with

type graphite gaskets

265285 Manhole opening device and 1 set of

clamps

225312 Manhole cover DN500 according to

DIN 28153-1, shape SE1, suitable for

using a swiveling device, with sight

glass DN100 according to

DIN 28121, design EC and manhole

protecting ring DN500 according to

DIN 28153-1

2253123 Same as #225312, however with type

graphite gaskets

265288 Manhole swiveling device and 1 set of

clamps

Coating

052115 Rust protection type Alucrom, double

coating

Sight glass with lighting

Reactor specifications

Nominal volume:

4000 l

Overall capacity:

5390 l

Overall jacket capacity:

605 l

Heat exchange surface:

13.23 m2

Total weight:

225166 4 tube legs

265185 Jacket connections arrangement A1,

without agitating nozzles

265197 Jacket connections arrangement B1,

with integrated agitating nozzles

Manhole units

253891 Sight glass DN150 according to

DIN 28121 on N6, design EC, with

lighting 230 V, explosion protection

type EExdeIIC T4, incl. halogen lamp

12 V, 20 W

approx. 5910 kg

[mm]

Insulation

h1

2700

h2

130

h3

2500

h4

1418

h5

590

part #

design

d5

d6

d7

h6

299

h7

70

h8

1760

d1

1800

d2

1900

251697

251696

251698

251691

Insulation ring, top

Insulation collar, top

Insulation ring, centre

Insulation ring, bottom

1900

1900

1900

2100

2100

2100

500

10

0

65

95

135

180

225

265

295

r1

630

725

725

675

725

675

725

725

0

h9

150

0

0

25

0

25

0

0

110

N5

25

r1

r1

O

L

N6

N1

h9

DN

500

150

150

250

150

250

150

150

100

100

200

N2

h9

N1

N2

N3

N5

N6

N7

N9

N10

K

L

R

N3

[mm]

h10

Nozzles

[mm]

h9

Main dimensions

N7

N10

N9

624-2 e

BE 4000

Agitator shafts

Baffle/Quatro-Pipe

part #

no. of stages d4

[mm]

202739

202963

240010

1

2

3

a1

[mm]

114.3 200

114.3 200

114.3 200

Turbines

l1

[mm]

2950 280

2950 280

2950 280

[mm]

d3

l2

l3

[mm] [mm]

part #

type

d4

210243

210443*

210448*

210308*

210321*

210314*

210380

2541972

CBT

835

114.3

GST

760

114.3

MXT

760

114.3

TBF

990

114.3

FBT

685

114.3

PBT

685

114.3

RCI

1100

114.3

Protection for honed surface, FEP

1010

770

l4

[mm]

Vu

[l]

218

218

1260 218

V1

[l]

V2

[l]

V3

[l]

604

604

604

2380

1796 2988

Cryo-Lock agitator assemblies**

202718 Cryo-Lock agitator type CBT

240054 Cryo-Lock agitator type TBF

202911 Cryo-Lock agitator type ANC***

** single-stage

***special shaft lengths for anchor type

for nozzle:

immersion depth (ID):

width of paddle (a2):

volume below

Quatro-Pipe/baffle:

DN250

2100 mm

180 mm

730 l

5950060 Quatro-Pipe

5950062 Quatro-Pipe with temperature

probe 2xTW

2076940 Paddle-type baffle, flange design

2076942 Paddle type baffle, flange design with

temperature probe 2xTW

265313 Baffle/Quatro-Pipe fixing kit

*part # refers to one turbine part

Mechanical seals

204450X Mechanical seal, type PC719, doubleacting for wet operation, with cooling

jacket, shaft diameter 100 mm,

material combination: Al2O3carbon

265303 Set of accessories for PC719

consisting of: glasslined intermediate

flange, thermo-manometer, set of

gaskets, bolting

260012 Mechanical seal, type fleXeal UF8,

double-acting for wet operation, with

cooling jacket, shaft diameter

100 mm, material combination:

SiCcarbon

265338 Set of accessories for UF8 consisting

of: glasslined intermediate flange,

thermo-manometer, set of gaskets,

bolting

Fluid control equipment

260020 Mechanical seal, type fleXeal BF7,

double-acting for dry operation,

balanced, with cooling jacket, shaft

diameter 100 mm, material

combination: SiCcarbon

260036 Mechanical seal, type fleXeal GF7,

double-acting for dry operation,

non contacting gas film lubrication,

with cooling jacket, shaft diameter

100 mm, material combination:

SiCcarbon

265354 Set of accessories for BF7 and GF7

consisting of: glasslined intermediate

flange, thermo-manometer, set of

gaskets, bolting

204905 Sealing liquid assembly SAM1, volume

1.7 l, static operation, for pressure

2/50 bar

204933 Assembly kit SAM1 for PC719

A62-001 Assembly kit SAM1 for UF8

204451 Thermosiphon system consisting of:

vessel (1.4571) with cooling spiral

and sight glass, volume 8 l,

max. pressure 25 bar,

working temperature -10/+250 C,

manual refilling unit

2044511 Same as #204451, however with

pressure/temperature instrumentation

for local indication of system

operating conditions

A64-001 Assembly kit thermosiphon for UF8

260040 Humidifier for BF7

Motors

021763 Three-phase motor EExeII T3, design

V6, 10 kW, 1465 min-1, 400 V, 50 Hz

021769 Three-phase motor EExdeIIC T4,

design V6, 11 kW, 1460 min-1, 400 V,

50 Hz

K03763F Three-phase motor for frequency

inverter operation EExdeIIC T4, design

V6, 15/11 kW (mains/inverter), range

of adjustment 1:5, 1450 min-1, 400 V,

50 Hz

Agitator drive

265293 Agitator drive VSO 16/100A,

without motor, agitator speed

125 min-1, max. torque 1250 Nm

A66-001 Assembly kit humidifier for BF7

260041 Gas supply unit BGS

Belt drive

A15-000 Belt drive VSO 16/100

Outlet valves

Accessories for outlet valves

DN1/DN2 = 100/80, working temp. = 60/+200 C, working press. = 1/+10 bar, h12 = 110 mm

Proximity switches

V10MBOO Outlet valve AMA-BT 100/80, manually operated, h11 = 508 mm, without probe

Assembly kit for outlet valves

V10MBWO Same as # V10MBOO, however with resistance thermometer TMI

Lateral manual opening aid for APA-BT

V10PBOO Outlet valve APA-BT 100/80, pneumatically operated, h11 = 598 mm, without probe

V10PBWO Same as # V10PBOO, however with resistance thermometer TMI

624-2 e

11

BE 6300

Supporting structures

[mm]

225209 Supporting ring, rim shaped

d8 = 2510, d9 max. = 2340

265198 Jacket connections arrangement A2,

without agitating nozzles

265202 Jacket connections arrangement B2,

with integrated agitating nozzles

203811 Supporting ring with web plates

d8 = 2510, d9 max. = 2340

265199 Jacket connections arrangement A2,

without agitating nozzles

265203 Jacket connections arrangement B2,

with integrated agitating nozzles

203827 Supporting ring with loose ring

d8 = 2510, d9 max. = 2340

265200 Jacket connections arrangement A2,

without agitating nozzles

265204 Jacket connections arrangement B2,

with integrated agitating nozzles

Reactor type BE 6300

Basic reactor consisting of:

496326 Inner vessel type BE 6300

according to DIN 28136

045047 4 brackets a3 = 200, d9 max. = 2365

265201 Jacket connections arrangement A1,

without agitating nozzles

265205 Jacket connections arrangement B1,

with integrated agitating nozzles

203759 Agitator flange

201640 Jacket

265272 Jacket attachments

265016 Set of split flanges

265066 Set of Pfaudler gaskets type AF2000

with asbestos-free inserts

2650663 Set of Pfaudler gaskets type graphite

225312 Manhole cover DN500 according to

DIN 28153-1, shape SE1, suitable for

using a swiveling device, with sight

glass DN100 according to

DIN 28121, design EC and manhole

protecting ring DN500 according to

DIN 28153-1

2253123 Same as #225312, however with

type graphite gaskets

265288 Manhole swiveling device and 1 set of

clamps

Coating

052115 Rust protection type Alucrom, double

coating

Sight glass with lighting

Reactor specifications

Nominal volume:

6300 l

Overall capacity:

8190 l

Overall jacket capacity:

795 l

Heat exchange surface:

18.02 m2

Total weight:

225167 4 tube legs

265201 Jacket connections arrangement A1,

without agitating nozzles

265205 Jacket connections arrangement B1,

with integrated agitating nozzles

Manhole units

265284 Manhole cover DN500 according to

DIN 28153-1, shape KE1, suitable for

use with spring balanced opening

device, with sight glass DN100

according to DIN 28121, design EC

and manhole protecting ring DN500

according to DIN 28153-1

2652843 Same as #265284, however with

type graphite gaskets

265285 Manhole opening device and 1 set of

clamps

253891 Sight glass DN150 according to

DIN 28121 on N6, design EC, with

lighting 230 V, explosion protection

type EExdeIIC T4, incl. halogen lamp

12 V, 20 W

approx. 8150 kg

[mm]

Insulation

h1

3268

h2

130

h3

3050

h4

1418

h5

590

part #

design

d5

d6

d7

h6

304

h7

88

h8

2235

d1

2000

d2

2100

251701

251700

251702

251703

Insulation ring, top

Insulation collar, top

Insulation ring, centre

Insulation ring, bottom

2100

2100

2100

2300

2300

2300

550

12

0

60

95

135

180

225

265

300

r1

700

800

800

750

800

750

800

800

0

h9

150

0

0

25

0

25

0

0

110

N5

25

r1

r1

O

L

N6

N1

h9

DN

500

150

150

250

150

250

150

150

150

100

200

N2

h9

N1

N2

N3

N5

N6

N7

N9

N10

K

L

R

N3

[mm]

h10

Nozzles

[mm]

h9

Main dimensions

N7

N10

N9

624-2 e

BE 6300

Agitator shafts

Baffle/Quatro-Pipe

part #

no. of stages d4

[mm]

202740

202965

240012

1

2

3

a1

[mm]

114.3 198

114.3 198

114.3 198

l1

[mm]

l2

l3

[mm] [mm]

3500 280

3500 280

3500 280

1250

930

l4

[mm]

Vu

[l]

238

238

1580 238

V1

[l]

V2

[l]

V3

[l]

698

698

698

3602

2644 4590

for nozzle:

immersion depth (ID):

width of paddle (a2):

volume below

Quatro-Pipe/baffle:

DN250

2660 mm

180 mm

788 l

5950080 Quatro-Pipe

Turbines

[mm]

part #

type

d3

d4

210243

210443*

210448*

210308*

210322*

210315*

210374

2541972

CBT

835

114.3

GST

760

114.3

MXT

760

114.3

TBF

990

114.3

FBT

890

114.3

PBT

890

114.3

RCI

1100

114.3

Protection for honed surface, FEP

Cryo-Lock agitator assemblies**

202719 Cryo-Lock agitator type CBT

202760 Cryo-Lock agitator type TBF

202912 Cryo-Lock agitator type ANC***

** single-stage

***special shaft lengths for anchor type

5950082 Quatro-Pipe with temperature

probe 2xTW

2076960 Paddle type baffle, flange design

2076962 Paddle type baffle, flange design with

temperature probe 2xTW

265313 Baffle/Quatro-Pipe fixing kit

*part # refers to one turbine part

Mechanical seals

204450X Mechanical seal, type PC719, doubleacting for wet operation, with cooling

jacket, shaft diameter 100 mm,

material combination: Al2O3carbon

265303 Set of accessories for PC719

consisting of: glasslined intermediate

flange, thermo-manometer, set of

gaskets, bolting

260012 Mechanical seal, type fleXeal UF8,

double-acting for wet operation, with

cooling jacket, shaft diameter

100 mm, material combination:

SiCcarbon

265338 Set of accessories for UF8 consisting

of: glasslined intermediate flange,

thermo-manometer, set of gaskets,

bolting

Fluid control equipment

260020 Mechanical seal, type fleXeal BF7,

double-acting for dry operation,

balanced, with cooling jacket, shaft

diameter 100 mm, material

combination: SiCcarbon

260036 Mechanical seal, type fleXeal GF7,

double-acting for dry operation,

non contacting gas film lubrication,

with cooling jacket, shaft diameter

100 mm, material combination:

SiCcarbon

265354 Set of accessories for BF7 and GF7

consisting of: glasslined intermediate

flange, thermo-manometer, set of

gaskets, bolting

204905 Sealing liquid assembly SAM1, volume

1.7 l, static operation, for pressure

2/50 bar

204933 Assembly kit SAM1 for PC719

A62-001 Assembly kit SAM1 for UF8

204451 Thermosiphon system consisting of:

vessel (1.4571) with cooling spiral

and sight glass, volume 8 l,

max. pressure 25 bar,

working temperature -10/+250 C,

manual refilling unit

2044511 Same as #204451, however with

pressure/temperature instrumentation

for local indication of system

operating conditions

A64-001 Assembly kit thermosiphon for UF8

260040 Humidifier for BF7

Motors

021764 Three-phase motor EExeII T3, design

V6, 13.5 kW, 1460 min-1, 400 V,

50 Hz

Agitator drive

265292 Agitator drive VSO 16/100,

without motor, agitator speed

125 min-1, max. torque 1250 Nm

A66-001 Assembly kit humidifier for BF7

260041 Gas supply unit BGS

021769 Three-phase motor EExdeIIC T4,

design V6, 11 kW, 1460 min-1, 400 V,

50 Hz

K03763F Three-phase motor for frequency

inverter operation EExdeIIC T4, design

V6, 15/11 kW (mains/inverter), range

of adjustment 1:5, 1450 min-1,

400 V, 50 Hz

Belt drive

A15-000 Belt drive VSO 16/100

Outlet valves

Accessories for outlet valves

DN1/DN2 = 150/100, working temp. = 60/+200 C, working press. = 1/+10 bar, h12 = 135 mm

Proximity switches

V15MBOO Outlet valve AMA-BT 150/100, manually operated, h11 = 508 mm, without probe

Assembly kit for outlet valves

V15MBWO Same as # V15MBOO, however with resistance thermometer TMI

Lateral manual opening aid for APA-BT

V15PBOO Outlet valve APA-BT 150/100, pneumatically operated, h11 = 598 mm, without probe

V15PBWO Same as # V15PBOO, however with resistance thermometer TMI

624-2 e

13

BE 8000 DIAM. 2200

Supporting structures

[mm]

225210 Supporting ring, rim shaped

d8 = 2710, d9 max. = 2540

265206 Jacket connections arrangement A2,

without agitating nozzles

265209 Jacket connections arrangement B2,

with integrated agitating nozzles

203812 Supporting ring with web plates

d8 = 2710, d9 max. = 2540

265207 Jacket connections arrangement A2,

without agitating nozzles

265210 Jacket connections arrangement B2,

with integrated agitating nozzles

203828 Supporting ring with loose ring

d8 = 2710, d9 max. = 2540

265208 Jacket connections arrangement A2,

without agitating nozzles

265211 Jacket connections arrangement B2,

with integrated agitating nozzles

Reactor type BE 8000

Basic reactor consisting of:

496368 Inner vessel type BE 8000

according to DIN 28136

045048 4 brackets a3 = 200, d9 max. = 2565

265201 Jacket connections arrangement A1,

without agitating nozzles

265205 Jacket connections arrangement B1,

with integrated agitating nozzles

203759 Agitator flange

201642 Jacket

265273 Jacket attachments

265018 Set of split flanges

265068 Set of Pfaudler gaskets type AF2000

with asbestos-free inserts

2650683 Set of Pfaudler gaskets type graphite

Nominal volume:

8000 l

Overall capacity:

9367 l

Overall jacket capacity:

800 l

Heat exchange surface:

18.01 m2

225155 4 profil iron legs

265201 Jacket connections arrangement A1,

without agitating nozzles

265205 Jacket connections arrangement B1,

with integrated agitating nozzles

253891 Sight glass DN150 according to

DIN 28121 on N6, design EC, with

lighting 230 V, explosion protection

type EExdeIIC T4, incl. halogen lamp

12 V, 20 W

Insulation

part #

design

d5

d6

d7

251709

251708

251710

251703

Insulation ring, top

Insulation collar, top

Insulation ring, centre

Insulation ring, bottom

2300

2300

2300

2500

2500

2500

550

h4

1418

h5

590

h6

464

h7

88

h8

2385

d1

2200

d2

2300

[mm]

r1

800

840

840

840

800

840

800

840

840

840

0

h9

150

---10

-10

---

110

h10

-40

40

40

-40

-40

40

40

N3

N4

N2

N5

30

N1

r1

r1

O L

N6

h9

0

50

77.5

110

145

180

215

250

282.5

310

h10

Nozzles

h9

h3

3000

[mm]

h9

h2

130

14

Coating

052115 Rust protection type Alucrom, double

coating

[mm]

h1

3218

N1

N2

N3

N4

N5

N6

N7

N8

N9

N10

K

L

R

265289 Manhole swiveling device and 1 set of

clamps

approx. 8600 kg

Main dimensions

DN

600

150

150

150

300

150

300

150

150

150

150

100

200

265287 Manhole opening device and 1 set of

clamps

Sight glass with lighting

Reactor specifications

Total weight:

Manhole units

265286 Manhole cover DN600 according to

DIN 28153-1, shape KE1/ SE1,

suitable for use with spring balanced

opening device or for using a

swiveling device, with sight glass

DN100 according to DIN 28121,

design EC and manhole protecting

ring DN600 according to DIN 28153-1

2652863 Same as #265286, however with

type graphite gaskets

N7

N10

N9

N8

624-2 e

BE 8000 DIAM. 2200

Baffle/Quatro-Pipe

Agitator shafts

part #

no. of stages d4

[mm]

202742

202969

240016

1

2

3

a1

[mm]

114.3 253

114.3 253

114.3 253

l1

[mm]

l2

l3

[mm] [mm]

3395 280

3395 280

3395 280

1280

950

l4

[mm]

Vu

[l]

337

337

1620 337

V1

[l]

V2

[l]

V3

[l]

851

851

851

4482

3282 5719

for nozzle:

immersion depth (ID):

width of paddle (a2):

volume below

Quatro-Pipe/baffle:

DN300

2600 mm

260 mm

783 l

5950090 Quatro-Pipe

Turbines

[mm]

part #

type

d3

d4

210244

210444*

210449*

210308*

210322*

210315*

210374

2541972

CBT

1040

114.3

GST

960

114.3

MXT

960

114.3

TBF

990

114.3

FBT

890

114.3

PBT

890

114.3

RCI

1100

114.3

Protection for honed surface, FEP

Cryo-Lock agitator assemblies**

202721 Cryo-Lock agitator type CBT

202762 Cryo-Lock agitator type TBF

202914 Cryo-Lock agitator type ANC***

** single-stage

***special shaft lengths for anchor type

5950092 Quatro-Pipe with temperature

probe 2xTW

2076970 Paddle type baffle, flange design

2076972 Paddle type baffle, flange design with

temperature probe 2xTW

265314 Baffle/Quatro-Pipe fixing kit

*part # refers to one turbine part

Fluid control equipment

Mechanical seals

204450X Mechanical seal, type PC719, doubleacting for wet operation, with cooling

jacket, shaft diameter 100 mm,

material combination: Al2O3carbon

265303 Set of accessories for PC719

consisting of: glasslined intermediate

flange, thermo-manometer, set of

gaskets, bolting

260012 Mechanical seal, type fleXeal UF8,

double-acting for wet operation, with

cooling jacket, shaft diameter

100 mm, material combination:

SiCcarbon

265338 Set of accessories for UF8 consisting

of: glasslined intermediate flange,

thermo-manometer, set of gaskets,

bolting

260020 Mechanical seal, type fleXeal BF7,

double-acting for dry operation,

balanced, with cooling jacket, shaft

diameter 100 mm, material

combination: SiCcarbon

260036 Mechanical seal, type fleXeal GF7,

double-acting for dry operation,

non contacting gas film lubrication,

with cooling jacket, shaft diameter

100 mm, material combination:

SiCcarbon

265354 Set of accessories for BF7 and GF7

consisting of: glasslined intermediate

flange, thermo-manometer, set of

gaskets, bolting

204905 Sealing liquid assembly SAM1, volume

1.7 l, static operation, for pressure

2/50 bar

204933 Assembly kit SAM1 for PC719

A62-001 Assembly kit SAM1 for UF8

204451 Thermosiphon system consisting of:

vessel (1.4571) with cooling spiral

and sight glass, volume 8 l,

max. pressure 25 bar,

working temperature -10/+250 C,

manual refilling unit

2044511 Same as #204451, however with

pressure/temperature instrumentation

for local indication of system

operating conditions

A64-001 Assembly kit thermosiphon for UF8

260040 Humidifier for BF7

Motors

021764 Three-phase motor EExeII T3, design

V6, 13.5 kW, 1460 min-1, 400 V,

50 Hz

Agitator drive

265292 Agitator drive VSO 16/100,

without motor, agitator speed

125 min-1, max. torque 1250 Nm

A66-001 Assembly kit humidifier for BF7

260041 Gas supply unit BGS

021770 Three-phase motor EExdeIIC T4,

design V6, 15 kW, 1450 min-1, 400 V,

50 Hz

K03339F Three-phase motor for frequency

inverter operation EExdeIIC T4, design

V6, 18.5/14 kW (mains/inverter),

range of adjustment 1:5, 1470 min-1,

400 V, 50 Hz

Belt drive

A15-000 Belt drive VSO 16/100

Outlet valves

Accessories for outlet valves

DN1/DN2 = 150/100, working temp. = 60/+200 C, working press. = 1/+10 bar, h12 = 135 mm

Proximity switches

V15MBOO Outlet valve AMA-BT 150/100, manually operated, h11 = 508 mm, without probe

Assembly kit for outlet valves

V15MBWO Same as # V15MBOO, however with resistance thermometer TMI

Lateral manual opening aid for APA-BT

V15PBOO Outlet valve APA-BT 150/100, pneumatically operated, h11 = 598 mm, without probe

V15PBWO Same as # V15PBOO, however with resistance thermometer TMI

624-2 e

15

BE 10000

Supporting structures

[mm]

225211 Supporting ring, rim shaped

d8 = 2910, d9 max. = 2740

265212 Jacket connections arrangement A2,

without agitating nozzles

265215 Jacket connections arrangement B2,

with integrated agitating nozzles

203813 Supporting ring with web plates

d8 = 2910, d9 max. = 2740

265213 Jacket connections arrangement A2,

without agitating nozzles

265216 Jacket connections arrangement B2,

with integrated agitating nozzles

203829 Supporting ring with loose ring

d8 = 2910, d9 max. = 2740

265214 Jacket connections arrangement A2,

without agitating nozzles

265217 Jacket connections arrangement B2,

with integrated agitating nozzles

Reactor type BE 10000

Basic reactor consisting of:

496386 Inner vessel type BE 10000

modified DIN

045049 4 brackets a3 = 200, d9 max. = 2765

265201 Jacket connections arrangement A1,

without agitating nozzles

265205 Jacket connections arrangement B1,

with integrated agitating nozzles

203760 Agitator flange

201606 Jacket

265273 Jacket attachments

265019 Set of split flanges

265069 Set of Pfaudler gaskets type AF2000

with asbestos-free inserts

2650693 Set of Pfaudler gaskets type graphite

10000 l

Overall capacity:

11768 l

Overall jacket capacity:

911 l

Heat exchange surface:

20.75 m2

225156 4 profil iron legs

265201 Jacket connections arrangement A1,

without agitating nozzles

265205 Jacket connections arrangement B1,

with integrated agitating nozzles

253894 Sight glass DN200 according to

DIN 28121 on N6, design EC, with

lighting 230 V, explosion protection

type EExdeIIC T4, incl. halogen lamp

12 V, 20 W

Insulation

part #

design

d5

d6

d7

251713

251712

251714

251703

Insulation ring, top

Insulation collar, top

Insulation ring, centre

Insulation ring, bottom

2500

2500

2500

2700

2700

2700

550

h4

1723

h5

680

h6

521

h7

86

h8

2510

d1

2400

d2

2500

[mm]

r1

850

925

925

900

900

925

900

925

900

925

0

h9

150

---------

111

h10

-40

40

15

15

40

15

40

15

40

N3

N4

N2

N5

30

N1

r1

r1

O L

N6

h9

0

55

82.5

110

145

180

215

250

277.5

305

h10

Nozzles

h9

h3

3180

[mm]

h9

h2

135

16

Coating

052115 Rust protection type Alucrom, double

coating

[mm]

h1

3401

N1

N2

N3

N4

N5

N6

N7

N8

N9

N10

K

L

R

265289 Manhole swiveling device and 1 set of

clamps

approx. 11170 kg

Main dimensions

DN

600

200

200

300

300

200

300

200

300

200

150

100

250

265287 Manhole opening device and 1 set of

clamps

Sight glass with lighting

Reactor specifications

Nominal volume:

Total weight:

Manhole units

265286 Manhole cover DN600 according to

DIN 28153-1, shape KE1/ SE1,

suitable for use with spring balanced

opening device or for using a

swiveling device, with sight glass

DN100 according to DIN 28121,

design EC and manhole protecting

ring DN600 according to DIN 28153-1

2652863 Same as #265286, however with

type graphite gaskets

N7

N10

N9

N8

624-2 e

BE 10000

Baffle/Quatro-Pipe

Agitator shafts

part #

no. of stages d4

[mm]

202744

202971

240018

1

2

3

a1

[mm]

114.3 251

114.3 251

114.3 251

l1

[mm]

l2

l3

[mm] [mm]

3670 280

3670 280

3670 280

1350

990

l4

[mm]

Vu

[l]

363

363

1700 363

V1

[l]

V2

[l]

V3

[l]

944

944

944

5557

3998 7073

for nozzle:

immersion depth (ID):

width of paddle (a2):

volume below

Quatro-Pipe/baffle:

DN300

2600 mm

260 mm

1460 l

5950090 Quatro-Pipe

Turbines

[mm]

part #

type

d3

d4

210244

210444*

210449*

210309*

210323*

210316*

210375

2541972

CBT

1040

114.3

GST

960

114.3

MXT

960

114.3

TBF

1220

114.3

FBT

1090

114.3

PBT

1090

114.3

RCI

1300

114.3

Protection for honed surface, FEP

Cryo-Lock agitator assemblies**

202722 Cryo-Lock agitator type CBT

202764 Cryo-Lock agitator type TBF

202916 Cryo-Lock agitator type ANC***

** single-stage

***special shaft lengths for anchor type

5950092 Quatro-Pipe with temperature

probe 2xTW

2076970 Paddle type baffle, flange design

2076972 Paddle type baffle, flange design with

temperature probe 2xTW

265314 Baffle/Quatro-Pipe fixing kit

*part # refers to one turbine part

Fluid control equipment

Mechanical seals

204386X Mechanical seal, type PC719, doubleacting for wet operation, with cooling

jacket, shaft diameter 125 mm,

material combination: Al2O3carbon

265304 Set of accessories for PC719

consisting of: glasslined intermediate

flange, thermo-manometer, set of

gaskets, bolting

260013 Mechanical seal, type fleXeal UF8,

double-acting for wet operation, with

cooling jacket, shaft diameter

125 mm, material combination:

SiCcarbon

265339 Set of accessories for UF8 consisting

of: glasslined intermediate flange,

thermo-manometer, set of gaskets,

bolting

260021 Mechanical seal, type fleXeal BF7,

double-acting for dry operation,

balanced, with cooling jacket, shaft

diameter 125 mm, material

combination: SiCcarbon

260037 Mechanical seal, type fleXeal GF7,

double-acting for dry operation,

non contacting gas film lubrication,

with cooling jacket, shaft diameter

125 mm, material combination:

SiCcarbon

265355 Set of accessories for BF7 and GF7

consisting of: glasslined intermediate

flange, thermo-manometer, set of

gaskets, bolting

204906 Sealing liquid assembly SAM2, volume

1.7 l, static operation, for pressure

2/50 bar

204918 Assembly kit SAM2 for PC719

A62-002 Assembly kit SAM2 for UF8

204451 Thermosiphon system consisting of:

vessel (1.4571) with cooling spiral

and sight glass, volume 8 l,

max. pressure 25 bar,

working temperature -10/+250 C,

manual refilling unit

2044511 Same as #204451, however with

pressure/temperature instrumentation

for local indication of system

operating conditions

A64-002 Assembly kit thermosiphon for UF8

260040 Humidifier for BF7

Motors

021766 Three-phase motor EExeIl T3, design

V6, 24 kW, 1475 min-1, 400 V, 50 Hz

021772 Three-phase motor EExdeIIC T4,

design V6, 22 kW, 1465 min-1, 400 V,

50 Hz

K03386F Three-phase motor for frequency

inverter operation EExdeIIC T4,

design V6, 30/23 kW (mains/inverter),

range of adjustment 1:5, 1470 min-1,

400 V, 50 Hz

Agitator drive

265296 Agitator drive VSO 32/125,

without motor, agitator speed

125 min-1, max. torque 2400 Nm

A66-002 Assembly kit humidifier for BF7

260041 Gas supply unit BGS

Belt drive

A17-006 Belt drive VSO 32/125

Outlet valves

Accessories for outlet valves

DN1/DN2 = 150/100, working temp. = 60/+200 C, working press. = 1/+10 bar, h12 = 135 mm

Proximity switches

V15MBOO Outlet valve AMA-BT 150/100, manually operated, h11 = 508 mm, without probe

Assembly kit for outlet valves

V15MBWO Same as # V15MBOO, however with resistance thermometer TMI

Lateral manual opening aid for APA-BT

V15PBOO Outlet valve APA-BT 150/100, pneumatically operated, h11 = 598 mm, without probe

V15PBWO Same as # V15PBOO, however with resistance thermometer TMI

624-2 e

17

BE 12500

Supporting structures

[mm]

225211 Supporting ring, rim shaped

d8 = 2910, d9 max. = 2740

265218 Jacket connections arrangement A2,

without agitating nozzles

265221 Jacket connections arrangement B2,

with integrated agitating nozzles

203813 Supporting ring with web plates

d8 = 2910, d9 max. = 2740

265219 Jacket connections arrangement A2,

without agitating nozzles

265222 Jacket connections arrangement B2,

with integrated agitating nozzles

203830 Supporting ring with loose ring

d8 = 2910, d9 max. = 2740

265220 Jacket connections arrangement A2,

without agitating nozzles

265223 Jacket connections arrangement B2,

with integrated agitating nozzles

Reactor type BE 12500

Basic reactor consisting of:

045049 4 brackets a3 = 200, d9 max. = 2765

265201 Jacket connections arrangement A1,

without agitating nozzles

265205 Jacket connections arrangement B1,

with integrated agitating nozzles

496387 Inner vessel type BE 12500

modified DIN

203760 Agitator flange

201643 Jacket

265273 Jacket attachments

265019 Set of split flanges

265069 Set of Pfaudler gaskets type AF2000

with asbestos-free inserts

Manhole units

265286 Manhole cover DN600 according to

DIN 28153-1, shape KE1/ SE1,

suitable for use with spring balanced

opening device or for using a

swiveling device, with sight glass

DN100 according to DIN 28121,

design EC and manhole protecting

ring DN600 according to DIN 28153-1

2652863 Same as #265286, however with type

graphite gaskets

265287 Manhole opening device and 1 set of

clamps

265289 Manhole swiveling device and 1 set of

clamps

Coating

052115 Rust protection type Alucrom, double

coating

225157 4 profil iron legs

265201 Jacket connections arrangement A1,

without agitating nozzles

265205 Jacket connections arrangement B1,

with integrated agitating nozzles

2650693 Set of Pfaudler gaskets type graphite

Sight glass with lighting

Reactor specifications

Nominal volume:

12500 l

Overall capacity:

14360 l

Overall jacket capacity:

1199 l

Heat exchange surface:

25.27 m2

approx. 12690 kg

[mm]

Insulation

part #

design

d5

d6

d7

251713

251712

251714

251703

Insulation ring, top

Insulation collar, top

Insulation ring, centre

Insulation ring, bottom

2500

2500

2500

2700

2700

2700

550

h1

4001

h2

135

h3

3780

h4

1723

h5

680

h6

521

h7

86

h8

3090

d1

2400

d2

2500

18

0

55

82.5

110

145

180

215

250

277.5

305

r1

850

925

925

900

900

925

900

925

900

925

0

h9

150

---------

111

h10

-40

40

15

15

40

15

40

15

40

N3

N4

N2

N5

30

N1

r1

r1

O L

N6

h9

N1

N2

N3

N4

N5

N6

N7

N8

N9

N10

K

L

R

DN

600

200

200

300

300

200

300

200

300

200

150

100

250

[mm]

h10

Nozzles

[mm]

h9

Main dimensions

h9

Total weight:

253894 Sight glass DN200 according to

DIN 28121 on N6, design EC, with

lighting 230 V, explosion protection

type EExdeIIC T4, incl. halogen lamp

12 V, 20 W

N7

N10

N9

N8

624-2 e

BE 12500

Baffle/Quatro-Pipe

Agitator shafts

part #

no. of stages d4

[mm]

202746

202973

240020

1

2

3

a1

[mm]

114.3 251

114.3 251

114.3 251

l1

[mm]

l2

l3

[mm] [mm]

4270 280

4270 280

4270 280

1640

1180

l4

[mm]

Vu

[l]

363

363

2080 363

V1

[l]

V2

[l]

V3

[l]

944

944

944

6813

4821 8718

for nozzle:

immersion depth (ID):

width of paddle (a2):

volume below

Quatro-Pipe/baffle:

DN300

3300 mm

260 mm

1043 l

5950100 Quatro-Pipe

Turbines

[mm]

part #

type

d3

d4

210244

210444*

210449*

210309*

210323*

210316*

210375

2541972

CBT

1040

114.3

GST

960

114.3

MXT

960

114.3

TBF

1220

114.3

FBT

1090

114.3

PBT

1090

114.3

RCI

1300

114.3

Protection for honed surface, FEP

Cryo-Lock agitator assemblies**

202723 Cryo-Lock agitator type CBT

202766 Cryo-Lock agitator type TBF

202918 Cryo-Lock agitator type ANC***

** single-stage

***special shaft lengths for anchor type

5950102 Quatro-Pipe with temperature

probe 2xTW

2076980 Paddle type baffle, flange design

2076982 Paddle type baffle, flange design with

temperature probe 2xTW

265314 Baffle/Quatro-Pipe fixing kit

*part # refers to one turbine part

Fluid control equipment

Mechanical seals

204386X Mechanical seal, type PC719, doubleacting for wet operation, with cooling

jacket, shaft diameter 125 mm,

material combination: Al2O3carbon

265304 Set of accessories for PC719

consisting of: glasslined intermediate

flange, thermo-manometer, set of

gaskets, bolting

260013 Mechanical seal, type fleXeal UF8,

double-acting for wet operation, with

cooling jacket, shaft diameter

125 mm, material combination:

SiCcarbon

265339 Set of accessories for UF8 consisting

of: glasslined intermediate flange,

thermo-manometer, set of gaskets,

bolting

260021 Mechanical seal, type fleXeal BF7,

double-acting for dry operation,

balanced, with cooling jacket, shaft

diameter 125 mm, material

combination: SiCcarbon

260037 Mechanical seal, type fleXeal GF7,

double-acting for dry operation,

non contacting gas film lubrication,

with cooling jacket, shaft diameter

125 mm, material combination:

SiCcarbon

265355 Set of accessories for BF7 and GF7

consisting of: glasslined intermediate

flange, thermo-manometer, set of

gaskets, bolting

204906 Sealing liquid assembly SAM2, volume

1.7 l, static operation, for pressure

2/50 bar

204918 Assembly kit SAM2 for PC719

A62-002 Assembly kit SAM2 for UF8

204451 Thermosiphon system consisting of:

vessel (1.4571) with cooling spiral

and sight glass, volume 8 l,

max. pressure 25 bar,

working temperature -10/+250 C,

manual refilling unit

2044511 Same as #204451, however with

pressure/temperature instrumentation

for local indication of system

operating conditions

A64-002 Assembly kit thermosiphon for UF8

260040 Humidifier for BF7

Motors

021766 Three-phase motor EExeIl T3, design

V6, 24 kW, 1475 min-1, 400 V, 50 Hz

021772 Three-phase motor EExdeIIC T4,

design V6, 22 kW, 1465 min-1,

400 V, 50 Hz

K03386F Three-phase motor for frequency

inverter operation EExdeIIC T4,

design V6, 30/23 kW (mains/inverter),

range of adjustment 1:5, 1470 min-1,

400 V, 50 Hz

Agitator drive

265296 Agitator drive VSO 32/125,

without motor, agitator speed

125 min-1, max. torque 2400 Nm

A66-002 Assembly kit humidifier for BF7

260041 Gas supply unit BGS

Belt Agitator drive

A17-006 Belt drive VSO 32/125

Outlet valves

Accessories for outlet valves

DN1/DN2 = 150/100, working temp. = 60/+200 C, working press. = 1/+10 bar, h12 = 135 mm

Proximity switches

V15MBOO Outlet valve AMA-BT 150/100, manually operated, h11 = 508 mm, without probe

Assembly kit for outlet valves

V15MBWO Same as # V15MBOO, however with resistance thermometer TMI

Lateral manual opening aid for APA-BT

V15PBOO Outlet valve APA-BT 150/100, pneumatically operated, h11 = 598 mm, without probe

V15PBWO Same as # V15PBOO, however with resistance thermometer TMI

624-2 e

19

BE 16000 DIAM. 2600

Supporting structures

[mm]

225212 Supporting ring, rim shaped

d8 = 3120, d9 max. = 2950

265218 Jacket connections arrangement A2,

without agitating nozzles

265224 Jacket connections arrangement B2,

with integrated agitating nozzles

203814 Supporting ring with web plates

d8 = 3120, d9 max. = 2950

265219 Jacket connections arrangement A2,

without agitating nozzles

265225 Jacket connections arrangement B2,

with integrated agitating nozzles

203831 Supporting ring with loose ring

d8 = 3120, d9 max. = 2950

265220 Jacket connections arrangement A2,

without agitating nozzles

265226 Jacket connections arrangement B2,

with integrated agitating nozzles

Reactor type BE 16000

Basic reactor consisting of:

496388 Inner vessel type BE 16000

modified DIN

045050 4 brackets a3 = 200, d9 max. = 2965

265201 Jacket connections arrangement A1,

without agitating nozzles

265227 Jacket connections arrangement B1,

with integrated agitating nozzles

203760 Agitator flange

201644 Jacket

265273 Jacket attachments

265019 Set of split flanges

265069 Set of Pfaudler gaskets type AF2000

with asbestos-free inserts

2650693 Set of Pfaudler gaskets type graphite

Nominal volume:

16000 l

Overall capacity:

18200 l

Overall jacket capacity:

1451 l

Heat exchange surface:

29.56 m2

265289 Manhole swiveling device and 1 set of

clamps

Coating

052115 Rust protection type Alucrom, double

coating

225158 4 profil iron legs

265201 Jacket connections arrangement A1,

without agitating nozzles

265227 Jacket connections arrangement B1,

with integrated agitating nozzles

253894 Sight glass DN200 according to

DIN 28121 on N6, design EC, with

lighting 230 V, explosion protection

type EExdeIIC T4, incl. halogen lamp

12 V, 20 W

Insulation

part #

design

d5

d6

d7

251721

251720

251722

251703

Insulation ring, top

Insulation collar, top

Insulation ring, centre

Insulation ring, bottom

2700

2700

2700

2900

2900

2900

550

h4

1723

h5

680

h6

573

h7

85

h8

3370

d1

2600

d2

2700

[mm]

r1

900

1025

1025

950

950

1025

950

1025

950

1025

0

h9

150

---------

111

h10

-65

65

20

20

65

20

65

20

65

N3

N4

N2

N5

30

N1

r1

r1

O L

N6

h9

0

55

82.5

110

145

180

215

250

277.5

305

h10

Nozzles

h9

h3

4080

[mm]

h9

h2

135

20

265287 Manhole opening device and 1 set of

clamps

[mm]

h1

4300

N1

N2

N3

N4

N5

N6

N7

N8

N9

N10

K

L

R

2652863 Same as #265286, however with

type graphite gaskets

approx. 15010 kg

Main dimensions

DN

600

200

200

300

300

200

300

200

300

200

150

100

250

265286 Manhole cover DN600 according to

DIN 28153-1, shape KE1/ SE1,

suitable for use with spring balanced

opening device or for using a

swiveling device, with sight glass

DN100 according to DIN 28121,

design EC and manhole protecting

ring DN600 according to DIN 28153-1

Sight glass with lighting

Reactor specifications

Total weight:

Manhole units

N7

N10

N9

N8

624-2 e

BE 16000 DIAM. 2600

Baffle/Quatro-Pipe

Agitator shafts

part #

no. of stages d4

[mm]

202436

202977

240024

1

2

3

a1

[mm]

114.3 250

114.3 250

114.3 250

l1

[mm]

l2

l3

[mm] [mm]

4570 280

4570 280

4570 280

1770

1280

l4

[mm]

Vu

[l]

392

392

2280 392

V1

[l]

V2

[l]

V3

[l]

1036

1036 8591

1036 6093 11192

for nozzle:

immersion depth (ID):

width of paddle (a2):

volume below

Quatro-Pipe/baffle:

DN300

3600 mm

260 mm

1174 l

5950110 Quatro-Pipe

Turbines

[mm]

part #

type

d3

d4

210356

210444*

210449*

210309*

210323*

210316*

210376

2541972

CBT

1120

114.3

GST

960

114.3

MXT

960

114.3

TBF

1220

114.3

FBT

1090

114.3

PBT

1090

114.3

RCI

1350

114.3

Protection for honed surface, FEP

Cryo-Lock agitator assemblies**

202438 Cryo-Lock agitator type CBT

202444 Cryo-Lock agitator type TBF

202922 Cryo-Lock agitator type ANC***

** single-stage

***special shaft lengths for anchor type

5950112 Quatro-Pipe with temperature

probe 2xTW

2076990 Paddle type baffle, flange design

2076992 Paddle type baffle, flange design with

temperature probe 2xTW

265314 Baffle/Quatro-Pipe fixing kit

*part # refers to one turbine part

Mechanical seals

204386X Mechanical seal, type PC719, doubleacting for wet operation, with cooling

jacket, shaft diameter 125 mm,

material combination: Al2O3carbon

265304 Set of accessories for PC719

consisting of: glasslined intermediate

flange, thermo-manometer, set of

gaskets, bolting

260013 Mechanical seal, type fleXeal UF8,

double-acting for wet operation, with

cooling jacket, shaft diameter

125 mm, material combination:

SiCcarbon

265339 Set of accessories for UF8 consisting

of: glasslined intermediate flange,

thermo-manometer, set of gaskets,

bolting

Fluid control equipment

260021 Mechanical seal, type fleXeal BF7,

double-acting for dry operation,