Professional Documents

Culture Documents

NX650 Q Section 17 Ignition System

NX650 Q Section 17 Ignition System

Uploaded by

konsekventan0 ratings0% found this document useful (0 votes)

26 views5 pagesHonda Dominator 650

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHonda Dominator 650

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

26 views5 pagesNX650 Q Section 17 Ignition System

NX650 Q Section 17 Ignition System

Uploaded by

konsekventanHonda Dominator 650

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 5

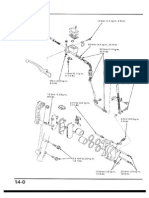

IGNITION SYSTEM

SYSTEM DIAGRAM

(icnirion (2) ENGINE STOP

SWITCH SWITCH

(3) STARTER

SWITCH

(4) IGNITION

(8) ALTERNATOR *() STARTER MOTOR.

STARTER SUB FUSE !aNITION

SWITCH TOA SWITCH

ELECTRIC —=vin: ST OnWiG-ON_O RB! o>

STARTER tT 7

SYSTEM vir Joa

-—~O= BI:

[Teper st uD FUSE

swiiTcn

Bin

Bur

MAIN FUSE

208

6 Bl

Pulse

GENERATOR

BATTERY

€.0.1, UNIT 12V BAH

IGNITION

coll

‘SPARK PLUG

Bee BLACK Br es BROWN

Y veuow 0 ORANGE

By ome BLUE Lb LIGHT BLUE

= Gov GREEN Ugo LIGHT GREEN

Revo RED P PINK

Woes WHITE Gr sR

17-0

17. IGNITION SYSTEM

SYSTEM DIAGRAM 17-0 IGNITION COIL 175

SERVICE INFORMATION 17-1 PULSEGENERATOR WT

TROUBLESHOOTING 17-2 IGNITION TIMING WT

SYSTEM INSPECTION 17-3

SERVICE INFORMATION

GENERAL

‘© When inspecting the ignition system, check the system components end lines step-by-step according to the troubleshoot

ing sequence on the next page.

© Ignition timing cannot be adjusted since the CDI (Capacitive Discharge Ignition) unit is non-adjustable.

For pulse generster 1emevsl and installation, see section 8.

For alternator removal and inst:

‘© For spark plug gap inspection and adjustinent procedure, see pege 9-C.

SPECIFICATIONS.

ITEM STANDARD

Spark plug - Standard DPRSEAS (NGK) X24EPR-UP (ND)

For extended high speed riding DPR9EAS (NGK) X27EPR-UP (ND)

| Spark plug aap | 0.80.9 mm (0.031—0.035 inl

lonition timing Initial B° BTDC at idle -

ull advance 28° BTDC at 4,000 «pm

Ignition col rosiatanes Primary coil 1.0.68

(20°C68"F} Secondary coil (without spark plug can) | 10.5—16.5K2

Secondary coll (with spark plug eap) 14-23 Ka

Puloo generator ragistance (20°C/63°F) 420—520 0

TOOLS

Circuit tester {SANWA) or 973080020000

Circuit tester |KOWAD or TH 5H

Digital multimeter IKOWA) 074110020000 or KS-AHM-32-003 1U.S.A. only)

IGNITION SYSTEM

TROUBLESHOOTING

Weak or no spark at plug

1. Ty spark test with known good epark plug. |-

WEAK OR NO SPARK

2. Check spark plug wire far lease or poor con

tect at the spark plug cap, then ty spark tact

again.

WEAK OR NO SPARK

a

3. Check CDI unit connectors far loose or poor

contact, then try spark tost again

NORMAL,

¥

Check the

Also chec!

resistance, continuity and voltage at the CDI unit connectors of the wire harness side (page 17 31,

k the ignition secandary coil rasiatance (page 17-3, 41

GOOD SPARK

spark plug

GOOD SPARK

+ Loose oF p0or contact of spark plug cap

ABNORMAL «Loose or peor contact of CDI unit connectors

J

ABNORMAL

ye

5. Chack the related componente in that part of

tho abnormal line. After checking, compare

the measurements of (6) with those of 14). |

17-2

ALL NORMAL,

+ Faulty CDI unit

NORMAL ABNORMAL

(DIFFERENT (SAME

MEASUREMENTS) MEASUREMENTS)

Fauity related components

Pulse generator ipage 17-4)

electric starter system line VIR)

ignition ecit (page 17-2, 4)

— ignition switch ipage 19-6

— engine stop switch (page 19-8)

ground wire {G)

battery Ipags 16.3)

fuse/108,

Loose or poor contact of the releted carnpanent

connectors

Open oF short circuit in the wire hamess be

‘iveen the related component and CDI unit

IGNITION SYSTEM

SYSTEM INSPECTION

NoTE

+ Check the system components and lines step-by-step ac-

cording to the troubleshooting on page 17-2.

+ This method doas not include an inspection of the ienition

timing advance system at the CDI unit.

Remove the right fairing (page 16-2).

Disconnect the CDI unit connectors and check them for loose

contact or corroded terminals.

Meacure the resistance, continuity and voltage between con-

nector terminale of the wiro harness sido as follows:

ITEM TERMINAL, ‘STANDARD

Ignition coil primary coll BUY and G 0.40.6 0 (at 20°Ci68°F)

Pulse generator coll Bul¥ and 6 420-520 0 (at 20°Ci6B°FY

lgnttion switch anc engine stop switch (Turn the ig: ) BIW >) and G Battery voltege.

nition switch ON and the engine stop switch RUN) -

Electiic starer system line (Tura the ignition switch | YPR (4) and G (—! Batiory voltage

‘GN and push the starter switch)

NOTE:

D Transmission must ben neu.

IGNITION COIL

INSPECTION

Remove the fuel tank (page 4.3)

Measure the primary coil resistance betwsen terminal,

STANDARD: 0.4—0.6 @ {at 20°C/68°F)

Maasure the secondary coil resistance with the sperk plug cap

in place by enacking for continuity between the plug cap ané

green terminal

D) stenoano 12-23 4 a 20rcveern

IGNITION SYSTEM

Remove the spark plug cap from the wires and measure the

secondary coll resistance,

STANDARD: 10.5—16.5 k@ lat 20°C, 68°F;

PULSE GENERATOR

NOTE

+ Itis not necessary to remove the fuel tank and fairing to

make this test

INSPECTION

Disconnect the pul

generator wire connector (2P mini).

‘Measure the resistance betwen the connector terminals.

STANDARD: 420-520 0 {at 20°C/68°F)

IGNITION TIMING

NOTE

+ The Capacitive Discharge Ignition (CDI) eyetem is factory

pre-set and does net require adjustment. To inspact the

funcvon of the CDI components, ignition timing inspection

procedures are givan here

‘Warm the engine up to the operating tampsrature.

Remove the timing hole cap.

Connect tachometer and timing light:

Start the engine and allow it to dle.

IDLE SPEED: 1,300 + 100 rom

{Inspect the ignition timing,

Timing is correct if the "F” mark on the altemater rotor is

aligned with the indax mark on the left crankcase cover at idle.

To check the advance, raise the engine speed to 4,000 + 100

rpm. The index maik should be between the advance marks.

If the ignition timing ie incorrect, perform the sytem i

tion (page 17-3)

43). 7F” MARK,

(2) ADVANCE MARK

17-4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Diagrama Elétrico PSI GM4.3Document1 pageDiagrama Elétrico PSI GM4.3LeandroLeiteNo ratings yet

- 115135150175-OptiMax-Direct Fuel Injection Starting Model Year 2000-Starting Serial Number OG960500Document653 pages115135150175-OptiMax-Direct Fuel Injection Starting Model Year 2000-Starting Serial Number OG960500LeandroLeiteNo ratings yet

- NX650 P Section 16 Battery Charging PDFDocument8 pagesNX650 P Section 16 Battery Charging PDFLeandroLeiteNo ratings yet

- NX650 V Section 21 Troubleshooting Pages PDFDocument5 pagesNX650 V Section 21 Troubleshooting Pages PDFLeandroLeiteNo ratings yet

- NX650 N Section 14 Hydraulic Brake PDFDocument12 pagesNX650 N Section 14 Hydraulic Brake PDFLeandroLeiteNo ratings yet

- NX650 M Section 13 Rear Wheel Brake Suspension PDFDocument23 pagesNX650 M Section 13 Rear Wheel Brake Suspension PDFLeandroLeiteNo ratings yet

- NX650 H Section 8 ClutchDocument11 pagesNX650 H Section 8 Clutchjurgute2000No ratings yet