Professional Documents

Culture Documents

NX650 M Section 13 Rear Wheel Brake Suspension

NX650 M Section 13 Rear Wheel Brake Suspension

Uploaded by

konsekventan0 ratings0% found this document useful (0 votes)

17 views23 pagesHonda Dominator 650

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHonda Dominator 650

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

17 views23 pagesNX650 M Section 13 Rear Wheel Brake Suspension

NX650 M Section 13 Rear Wheel Brake Suspension

Uploaded by

konsekventanHonda Dominator 650

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 23

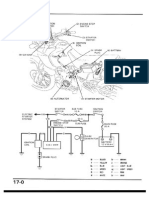

REAR WHEEL/BRAKE/SUSPENSION

75 Nem (7.5 kgan, 54 feb)

45 Nem (4.5 kam,

Feb)

95 Nem (8.5 kg-m,

69 tab)

45 Nem 14/6 kom,

32 fel)

45 Nem (4.5 kom, 32 flbp

13-0

13, REAR WHEEL/BRAKE/SUSPENSION

SERVICEINFORMATION 13-1 SHOCK ABSORBER 13-12

TROUBLESHOOTING 13-2 SHOCK LINKAGE 13-15

REAR WHEEL 13-3. SWING ARM 13-18

REAR BRAKE 13-9

SERVICE INFORMATION

GENERAL

© A box or work stand is required to support the motorcycle.

4 Use genuine suspension linkage and shock absorber pivotimount bolts. Note installation cirection of the bolts,

The shock absorber contains nitrogen under high pressure. Do not allow fire or heat near the shock absorber. Refore disposal of

the shock absorber, release the nitrogen (ee page 13-14).

+ Inhated asbestos fibers have been found to cause resplraiory disease and cancer. Never use an cir hose ar dry brush to clean brake

assemblies.

+ Inthe United States, use an OSHA-approved vacuum cleaner or alternate method approved by OSHA designed to minimize the

hazard caused by airborne asbestos fibers

SPECIFICATION

Te STANDARD SERVICE UMAT

Rear wheel runout Radial 2 mm (0.08 in) ___

Axl 2.0 mm (0.08 It)

Rear brake drum LD. 130.0 mm 6.12 | 181.0 mm (5.16 in)

Fear bre shoe wioknese 40mm0.18 i) 2.0 nm 0.08 I

Shock aboother spring foe nah 297.8 mm (8.96 in) 796.1 ym (8.28 in

[ear susoonsion damper conoresson 39 ka (72.8 28 ka (61.7 b)

TORQUE VALUES,

Driven eprockat nut 46 Nem [4.6 kg-m, 33 ft-lb) Apply ol ro the threads

Rear axle nut 95 Nemn (9.5 kur, 58 fib)

Brake erm nut 10 Nem 11.0 kgm, 7 fb)

Shock absorber spring lock nut 90 Nem {8.0 kg-m, BS Fb)

Shock absorber upper maunt nut 75 Nem 17.5 ka-m, 54 fib)

Shock absorbor lower mount bolt 48 Nem 5 kgm, 32 fb)

Shock arm-to-shock link nut 45 Nem 14.5 korm, 32 fb)

‘Shock link-o-swing arm nut 45 Nem 14.5 kg-m, 32 frib)

Shack arm-to-frame nut 45 Nam (4.5 kg-m, 32 fb}

Swing arm pivot nut 110 Nem {11.0 ka-m, 80 ft-b)

TOOLS

Special

Driver shatt (07946—MJ00100.

Neodlo bearing romever (07637 MA7co001 NOt avaliadle in U.S.A.

Bearing remover, 20 mm 078303710000

Remover handle 07936-3710100

Remover sliding weight 079363710200

13-1

REAR WHEEL/BRAKE/SUSPENSION

Common

Boaring remover head, 17 mm

Bearing remiover shaft

Driver

Attachment, 37 x 40 mm

Pilot, 17 mm

Attachment, 42 x 47 mm

Attachment, 24 x 26 mm

Pit, 20 mm

Pilot, 22 mm

TROUBLESHOOTING

Wobble or vibration in motorcycle

+ Bent rim

+ Loose wheel bearingts)

Loose or bent spokes.

Damaged tire

Axle net tightened properly

Swing arm pivot bearing worn

Chain adjusters not acjusted equally

Soft suspension

Weak spring

+ Improper shock absorber spring preoad

Hard suspension

+ Improper shock absorber spring preload

Bent damper rod

+ Swing arm pivot bearings damaged

+ Bent frame or siving arm

‘Suspension ncise

+ Faulty damper

+ Loose fasteners

+ Worn suspension linkage pivot bearingist

Poor brake performance

+ Improper brake adjustment

+ Worn brake shoes

+ Brake linings oily, greasy or dirty

+ Worn brake cam

+ Worn brake drum

+ Brake erm serrations improperly engaged

+ Brake shoes worn at car contact erea

13-2

077460050500

07746—0050100—

077490010000

07746 9010200

077460040400

07746—0010300

077460010700

07746—0040500

07746 9041000

- or equivalent commercially

availabe In U.S.A.

REAR WHEEL/BRAKE/SUSPENSION

REAR WHEEL

REMOVAL

Raise the rear wheel off the ground by placing a box or work

stand under the engine.

Ramove the adjustar from the brake rod.

Disconnect the brake rod from the brake arm.

Remove the axle nut and loosen the drive chain adjuster lock

rut and adjusting nut.

Move the rear wheel forward all the way and detach the drive

chain from the ¢riven sprocket

Remove the rear axle and rear wheel.

Remove the rear brake panal from the rear wheel

INSPECTION

S91 the axle on V blocks and measure the runout,

‘The actual runout is 1/2 of the total indiceter reading.

‘SERVICE LIMIT: 0.2 mm (0.01 int

Turn the inner race of each bearing with your finger.

‘The bearings should turn sincothly and quietly.

Also check that the bearing outer race fits tightly in the hub.

Remove and discard the bearines if the races do not tuin

‘smoothly. quietly, ar if they fit loosely in the hub.

NoTE

+ Replace wheel bearinge in p

For baaring roplacoment, see page 13-6.

(1) WHEEL BEARING

13-3

REAR WHEEL/BRAKE/SUSPENSION

Check the rim junout by placing the whee! on a truing stand.

Turn the wheel by hand and measure the runout using ¢ dali

dicator.

SERVICE LIBITS:

RADIAL: 2.0 mm (0.08 in}

AXIAL: 2.0 mm {0.08 in}

is -—

Check the condition of the final driven sprocket teath.. |

Roplace a worn or damaged sprocket. (1) Good (2) REPLACE

NOTE

+ The crive chain and drive eprokot must sleo be inspoctod if

‘the driven aprokot is worn er damagec.. Never install @ new

drive chain on worn sprockets or a worn chain on neve

sprockets. Both chain and sprocket must be in good condi

tion or the new replacement chain or sprockets will waar a

rapidly

WHEEL BALANCING

Fifer to page 12-6.

Do not dd the whee! weight more than 60 grams.

(1) WHEEL WEIGHT

DISASSEMBLY Pe COLLAR ES

Remove the axle collar and dust seal P ‘

Romove the final driven flange.

NOTE

+ When removing the driven sprocket, loosen the sprocket

bolt with the driven flange installed

13-4

REAR WHEEL/BRAKE/SUSPENSION

I the criven flange fits tightly in the hub, drive i out by tapping

several locations.

UP cOLLaR

‘When replacing the driven ‘lange bearing, remove the collar

from the bearing,

Drive out the driven flange bearing, if necessary.

Romove the driven epreckot from tho driven flango, if nocos-

sary.

Remove the damper rubbers.

Replace the damper rubbers if they are damaged or deteriorat-

ed.

Remave the O-ring,

REAR WHEEL/BRAKE/SUSPENSION

Drive out the wheel bearings and the distance coll

(1) REMOVER HEAD

NOTE

+ IW the bearings are removed, they shoukd be replaced with

TooLs:

Bearing remover head, 17 mm 077480060500

or equivalent commercially

available in U.S.A.

Booring remover shaft 07746—0050100

cr equivalent commercially

available in U.S.A.

ASSEMBLY

(2) DAMPER. (4) DRIVEN.

RUBBER FLANGE

i

() DUST (6) DRIVEN

SEAL SPROCKET

o “

shee COLLAR (7) SIDE

COLLAR

monn O-RING

13-6

REAR WHEEL/BRAKE/SUSPENSION

Place the rim and tire on the work bench.

Adjust the pesition so that the distance from the right end sur

face of the hub to the side of rim is @ mm {0.9 in} as shown,

Tighten the spokes in 2 or 3 progressive steps.

TORQUE: 4 Nem 10.4 kg-m, 3 fb)

TooL:

‘Spoke wrench C, 5.8.x 6.1mm 07701—0020300

oF equivalent commercially

able in U.S.A.

Install the rim band, rim lock, cube and the tre with its direc:

tional arrow mark pointing in the direction of normal rotation

for forward mation,

Tighten tha tim lock

TORQUE: 13 Nem (1.3 kgm, 9.4 ft-lb)

Check the wheel rim runout as shown on page 13-4, end

adjust as required

Pack the bearing cevities with grease,

Drive in the right bearing with te sealed side of the bearing

facing out away fram the center of the hub.

Be careful not to tilt the bearing while driving it into the hub

‘and make gure that it i fully coated

Install the distence collar in the hub, then dive io the left bear

Ing with its sealed side facing out,

em

+ Grease on the brake drum reduces stopping power. Keep grease

Off the brake dru,

TooL

Driv 077490010000

Attachment, 37 x 40 mm 077460010200

Pilot, 17 mm 077460040400

Pack a new driven flange bearing with graase, then drive i into

the driven flange with kes sealed end facing out.

Toots:

Driver 07748 -0010000

Attachment, 4247 mm (077460010300

Pilot, 20 mm 077460040500

Install the collar onto the driven flange bearing,

If the driven sprocket wee removed, install it with the teath

umber facing out.

Apply ol to the threads af the driven sprocket bolts and tight

fen the sprocket nuts to the specified torque.

TORQUE: 46 Nem (4.8 kg-m, 33 ftlb)

[8 mm 0-3ini

t

(2) ATTACHMENT

REAR WHEEL/BRAKE/SUSPENSION

Install the demper tubbers. (0) DAMPER (2) DRIVEN FLANGE

Apply grease to a new O-ring and install it onto the groove of RUBBER eye

the wheel hub, P

Inatall the driven flange.

‘Apply grease to the cust seal ip and install it.

Install the axle collar

INSTALLATION

Install the brake pnel on the wheel hub.

Prace the tear wheel between the swing arm and ral the ariva

chain over the drivan sprocket.

Lift the rear wheel and insert the tang on the swing arm into

‘the slot in the oraks panel, then insert the reer axle from right

side through swing arr,

Loosely install the axle nut.

Adjust the drive chain (pege 9-6).

Tighten the rear axle nut,

TORQUE: 90 Nem (9.0 kam, 65 ft1h)

13-8

REAR WHEEL/BRAKE/SUSPENSION

Connect the brake rod to the breke arm and install the adjust

ing nut

Adjust the rear brake pedal free play (page 2-11)

REAR BRAKE

INSPECTION

Remove the rear wheel (page 13-2).

Ramove the rear brake panel

Measure tho roar brake drum 1.0.

SERVICE LIMIT: 131 mm (5.16 in}

Maacure the rear brake lining shiokne

SERVICE LIMIT: 2.0 mm (0.08 in}

Replace the brake shoes if thinner than the service limit.

DISASSEMBLY

Remove the brake shoes and springs from the brake panel.

NOTE

+ Mark the shoas to indicata thai original positions before

moving thom,

REAR WHEEL/BRAKE/SUSPENSION

Remove the following parts from the brake panel:

= Bott nut, and brake arm

— Indicator plate

Brake cam.

= Thrust plate

— Dust seals

Clean all parts throughly.

(5) BRAKE,

ASSEMBLY

(2) DUST SEALS 3) THRUST (4) BRAKE CAM.

{1) INDICATOR

PLATE

(5) BRAKE

‘SHOES

(7) BRAKE PANEL

(8) BRAKE ARM.

Apply greaso to tho dust seals, and install therm inte the brake

pane.

Install the thrust plate by aligning the pin on the brake panel

with tha slot in the plate.

13-10

REAR WHEEL/BRAKE/SUSPENSION

Apply grease to the brake cam and installit

Apply areese to the anchor pin and thrust plate

=a

+ Grease on the brake linings will rechuce stepping power. Keep

grease off the brake linings, Wipe excess grease off the came and

chor pin.

Install the indicator plate onto the brake cam, aligning its tab

with cutout on the brake cam.

Install the brake arm by aligning the punch marks.

Install the belt and tighten the nut te the specified toraue.

TORQUE: 10.N-m (1.0 kgm, 7 ft-1b}

Position the brake shoes in their original positions snd install (4) graKe

the springs. SHOE:

Check the rear brake assembly for smooth operation by

moving the breke arm

EA

(2) SPRINGS.

torres

1

fT GRake Licht s

SWITCH SPRING

BRAKE PEDAL REMOVAL/INSTALLATION

Remove the following parts:

— Brake adjustor

— Brake red from the brake arm

Brake rod spring

— Brake pedal return spring

— Brake light switch spring

— Beta pin, nut and wash

Brake pedal

14) BETA PIN NUT (3) ROD

(5) RETURN SPRING AND WASHER SPRING

13-11

REAR WHEEL/BRAKE/SUSPENSION

eo" Si abvusren

(4) spAING

(1) BRAKE PEDAL

sen (6) Nur o

“Apply graase to the dust seal ips and brake pedal pivot, and in

stall the breke pecal

Install she fallowing parts:

— Washer, nut and beta pin

— Brake licht switch spring

— Brake pedal return spring

Brake rod spring

— Brake rod to the brake arm

— Brake adjuster

Acjust the braka padal free play (page 3-11)

SHOCK ABSORBER

REMOVAL

Rise the rear wheel off the ground by placing a box or work

stand under the engine,

Remove the shock arm bolt (shock link side] and shack absorb:

‘or lowar mount bolt.

Flemove the right side cover (page 15:2) and shock absorber

Upper mount bolt

5) BETA PIN

TH BRAKE LIGHT

ITCH SPRING

[ :

Z. adiwaster, NuT (31 ROD

(RETURN SPRING" RipceTa pin SPRING

in) LOWER MOUNT (2) UPPER MOUNT

13) SHOCK ARM 3OLT

(SHOCK LINK SIDE)

13-12

REAR WHEEL/BRAKE/SUSPENSION

DISASSEMBLY (1) LOCK NUT,

Hold the check upper mount

Towel

Remove the lock nut and adjusting nut.

Remove the shock spring.

18 viee with soft jawe ar a chos

Sis (2) ADJUSTING

NUT, 4

Check the spring fer damage, and meseure the spring ‘ree

length.

‘SERVICE Lim

‘+ The damper unitis filed with nitrogen gas under high pressure,

do not try to disascennble,

+: 235.1 mm (9.26 in)

camper rod for trusness. BUSHING (2) DAMPER

FUBGER

‘Check the camper unit for oll leaks oF other damage and the {" UPPER MOUNT

Check the spring seat stopper, spring seat, spring guide and

camper rubber far wear or damage. |S) STOPPER

‘Check the upper mount bushing for wear or demage.

4) DAMPER ROD

Mark the 10 mm position as shown of the damper rod.

Place the damper rod on a scale and measure the force re-

‘quired to compress the damper 10 mm (0.4 inl.

COMPRESSION FORCE: 33 kg (72.8 Ib}

If the force required is less than 28 kg |61.7 Ib), gas is leaking.

Examine the damper rod and reniace the damper unit if itis

bent or ecarad.

REAR WHEELIBRAKE/SUSPENSION

SHOCK ABSORBER DISPOSAL PROCEDURE

Contor punch the damper case to mark the dtiling point, ap- |

proximazely 16,0 mm (0.63 in} trom the top surface.

‘Wrap the damper unit inside @ plastic bag 1H) PLASTIC BAG

Support the demaer unit upright in a vise as shown,

(2) DRILL BIT

Woy

16.0 mv (0.83 in)

Through the open ond of the bag, insert a drill motor with a

sharp 2—3 mr (6/64—1/8 in) dil i

ow

+ Domot use a dull dri bit which could causea build-up of exees-

‘sive heat and pressure inside the damper, leading (0 explosion

and severe personal injury.

+ The shoek absorber contains nitrogen gas and oil under high

pressure. Da not drill any farther down the damper case than

the measurement given above, or you may dill into the off

‘chamber; oi escaping under High pressure may cause serious

personal injury.

+ Always wear eve protection to avoid getting metel shavings in

‘your eyes when the gas pressure is releared. The plastie bag is

‘only intended to shield you from the escaping gas.

Hold the bag around the drill moter and briefly run tho dri

‘moot Inside the beg; this will inflate the bag with air from the (3) DAMPER UNIT

‘motor end help keep the bag from getting caught in the bt

when you start.

ASSEMBLY

(2) Lock, (3) SPAING

NUT SEAT

(1 Agustin (4) DAMPER UNIT

NU

en sfine (5) SPRING GUIDE

13-14

REAR WHEEL/BRAKE/SUSPENSION

Install the spring, adjusting nut and lock nut [

Turn the spring acjusting nut until the spring length is as speci- (2) LOCK NUT

fied.

‘A: DECREASE THE SPRING LENGTH

B: INCREASE THE SPRING LENGTH

STANDARD SPRING LENGTH: 237.5 mm (9.35 in)

MAXIMUM LENGTI 239.9 mm (9.44 in)

MINIMUM LENGTH 235.1 mm (9.26 in)

NOTE

(One turn of the adjusting nut changes tho epring longth by

1.5 min,

Hold the shock absorber upper mount in @ vice with soft jaws.

for a shop towel

Using pin spanners, tighten the lock aut while holding tho ad

justing nut.

TORQUE: 90 Nem (9.0 ka-m, 65 fb)

Install the breather tube to the scat stepper.

Install the shack absorber te the frame with the bresther tube

toward the rear

Install and tighten the shock absorber upper mount bolt and

rut.

(a) Lowel mount

BOLT

iy UPPEn MOUNT

BOLT

TORQUE: 75 Nem (7.5 kom. 54 ftib)

Install and tighten the shock absorber lower mount belt

TORQUE: 45 Nem (4.5 kgm, 32 feb)

Inctall and tighten the thock arm-to-shock fine holt

TORQUE: 45 N-m (4.5 kgm, 32 fib)

(3) SHOCK ARIV-TO:

Install the right side cover (page 15-2)

‘ pear ~_SHOCK LINK BOLT

‘Cheok the operation of the shack abscrber ipage 3-14)

SHOCK LINKAGE

REMOVAL

TAP SHOCK ARMTTO:

FRAME BOLT

(2) LoweR MOUNT]

Raise the rear whee! of! the ground by placing a work stend or

box ungar the angina

Femove the following components:

— Shook arm-to-shack tink bolt

= Shook link-to-swing arm bolt

= Shock ink (5) SHOCK ARM-TO-

ck abeorber lowor mount bolt SHOCK LINK BOLT

— Shock arm-to-frame bolt 8 ee NY BO

= Shack arm RMB) stock Lyk Swing ARM BOLT,

REAR WHEEL/BRAKE/SUSPENSION

(1FCOLLAR (2) NEEDLE

BEARINGS

(3) DUST.

SEALS

__-SSHOCK ARM

NEEDLE BEARING REPLACEMENT

Drive the needle beatings out of the shock arm and ehack link.

TooLs:

Driver sheft 07946—NJ00100

or Not available in U.S.A

Driver 077490070000

Pilot, 22 mm 077450041000

SHOCK ABSORBER LOWER MOUNT BOLT PIVOT AND.

SHOCK ARM-TO-SHOCK LINK BOLT PIVOT

(1) DRIVER

Pack a new needle bearings with multi purpose creas

Prose tha neecle bearings into the shock atm until the bearing

outer ends are on a level with the shock aim inner edges.

NOTE

+ Press the needle bearing on the stamped ena,

Toots:

Driver 077490010000

Attachment, 24 x 26 mm 077460010700 (3) NEEDLE BEARINGS

13-16

REAR WHEEL/BRAKE/SUSPENSION

‘SHOCK ARM-TO-FRAME BOLT PIVOT

(1) NEEDLE BEARING

Pack a new needle bearing with multi pursose grace,

Measuring with a vernier caliper, press the needle bearing into

the shock arm 9 mm (0.35 in) below the outer edge of tne -

shock arm.

NOTE

D + Press the needle bearing on the stamped end.

_ — 2mm

ToOLs:

Driver 07749—0010000

Attachment, 24 x 26 mm 07746-0010700

Rie (2) BEARING (3) INNER

Pack a new needle bearings with multi purpose grease

Fill the space betwoon noodle bearings with grasee,

Press tne needle beerings into the shock link untl the besring

outer ends are on a level with the shock link inner edges.

NoTE

+ Press the needle bearing on the stamped end.

TooLs:

Driver 077490010000

Attachment, 24 x28 mm 077460010700

INSTALLATION

Note

+ Mako sure that the necdle rollers of the needle bearings are

in position before installing the pivot collars.

Apply multi purpose grease to the shock arm pivot collar sur

faces and dust seal lips.

Install the collars and dust seals into the shock arm,

Apply multi purpose grease 10 the shock tink pivot collar sur-

‘taces anc dust seal lps,

Install the coliars and dust seals into the shock link.

REAR WHEEL/BRAKE/SUSPENSION

Iretall tho shock arm and chock link, and loosely install each

bolt ana nut

NOTE

‘Tighten each bolt anc nut to the specified torque.

‘TORQUE:

Shock link-to-swing arm nut

45 Nem (4.5 kg-m, 32 ft-lb)

‘Shock absorber lower mount bolt

45 Nem (4.5 kg-m, 32 ftb}

Shock arm-to-shock link nut:

45 Nom (4.8 keg-m, 32 ft-lb)

Shook arm-to-frame nut:

45 N-m (4.5 kg-m, 32 frb)

SWING ARM

REMOVAL

Raise the rear whee! off the ground by placing box or work

stand under the engine.

Ramove the rear wheel (nage 13-3).

Remove the drive chain cover.

Remove the shock arm-to-shork link bolt and ehock absorber

lowar mount bolt,

(1) “UPMARK

i) SHOCK ARI-TO-

FRAME NUT

5) SHOCK ARN-TO,

SHOCK LINK NUT

(4) SHOCK LINK “SWING ARM NUT}

(1) DRIVE CHAIN COVER

|OCK ARM-TO-SHOCK LINK BOLT

13-18

REAR WHEEL /BRAKE/SUSPENSION

Remove the following parts:

— Swing arm nivot cap

— Swing arm pivot nut and belt

— Swing am

> DISASSEMBLY

Remove the folowing paris from the swing arm.

— Dust seals

= Swing atm pivot collar

— Diva chain alider

— Drive chain guids

INSPECTION

Inspect the dust seals, pivot collar and needle dearings for

wear or damage.

Raplaca tham if they have score marks, scratches, or exces

ive or abnormal soar.

PIVOT BEARING REPLACEMENT

Fomove the pivot side collars.

Set the needle bearing remover, screw out the pivet bearinas

‘ane digeard thor

oo

Needle bearing remover (07931 ~MA70000

Bearing remover, 20 mm 07936—3710600

Remover handle 07938—3710100

Remover sliding weight 07938 -3710200

(2) NEEDLE BEARING ©

13-19

———————————————

REAR WHEEL/BRAKE/SUSPENSION

Pack now nesdle bearings with multi purpose grease. (1) FIVER (2) ATTACHMENT #3)

Install the needle besring to the swing arm pivot with the %

stamped end facing our, and aress it into che pivot with the

pivot side collar

Toots: ‘

Driver 07748-00100 (4) NEEDLE aos

Attachment, 24 x 26 mm 077460010700 BEARING sss

Plot, 20 mm 077460040600 % pont

Pross in the othe: needle bearing end side collar.

ASSEMBLY

(5) CHAIN ADJUSTER.

(1) DUST SEAL

(2) SIDE

COLLAR

e

(3) NEEDLE @&

BEARING

a?

(8) CHAIN GUIDE

(4) COLLAR

i CHAIN

SLIDER

Apply grease to the pivot collar and dust seal lips

(2) COLLAR (oust sea.

13-20

REAR WHEEL/BRAKE/SUSPENSION

Install the collar and dust seals. (1) COLLAR,

(3) SWINGARM amy (HUST

PIVOT " SEAL

Drive chain slider

— Drive chain guide

Install tho ewing arm to tho frame.

From the ight side, insett the siving aim pivot bolt through the

‘swing arm.

Instell and tighten the swing arm pivot nut,

TORQUE: 110 Nem (11.0 kgm, 80 ft 1b)

Install the swing arm pivot cap.

Install and tighten the shock absorber lower mount bot.

TORQUE: 45 Nem (4.5 ka-m, 32 ftb)

Inotall the shock erm-to-sheck link bolt and nut, and tighten

‘the nut.

| TORQUE: 45 Nem (4.5 kam, 32 feb)

(2) GHEE ARHETO SHOCK LINK B07

13-21

eee

REAR WHEEL/BRAKE/SUSPENSION

Install the drive chain cover. (1) DRIVE CHAIN COVER

Inseall the rear wheel (page 13-8)

13-22

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Diagrama Elétrico PSI GM4.3Document1 pageDiagrama Elétrico PSI GM4.3LeandroLeiteNo ratings yet

- 115135150175-OptiMax-Direct Fuel Injection Starting Model Year 2000-Starting Serial Number OG960500Document653 pages115135150175-OptiMax-Direct Fuel Injection Starting Model Year 2000-Starting Serial Number OG960500LeandroLeiteNo ratings yet

- NX650 Q Section 17 Ignition System PDFDocument5 pagesNX650 Q Section 17 Ignition System PDFLeandroLeiteNo ratings yet

- NX650 V Section 21 Troubleshooting Pages PDFDocument5 pagesNX650 V Section 21 Troubleshooting Pages PDFLeandroLeiteNo ratings yet

- NX650 P Section 16 Battery Charging PDFDocument8 pagesNX650 P Section 16 Battery Charging PDFLeandroLeiteNo ratings yet

- NX650 N Section 14 Hydraulic Brake PDFDocument12 pagesNX650 N Section 14 Hydraulic Brake PDFLeandroLeiteNo ratings yet

- NX650 H Section 8 ClutchDocument11 pagesNX650 H Section 8 Clutchjurgute2000No ratings yet