Professional Documents

Culture Documents

Ysv 130711 Case Story Deutz TBD 616v16

Ysv 130711 Case Story Deutz TBD 616v16

Uploaded by

Tyler GoodwinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ysv 130711 Case Story Deutz TBD 616v16

Ysv 130711 Case Story Deutz TBD 616v16

Uploaded by

Tyler GoodwinCopyright:

Available Formats

PROJECT OVERVIEW:

DEUTZ TBD 616V16 Repaired and Overhauled

TYPE OF VESSEL

THRILL RIDE BOAT

74 FEET

OVERHAUL

2x DEUTZ TBD 616 V16 Engines

RECONDITIONING

INJECTION PUMPS

TURBOCHARGERS

WATER PUMPS

CYLINDER HEADS

HEAT EXCHANGERS

AIR COOLERS

ENGINE: DEUTZ TBD 616V16

PROJECT OVERVIEW

REPLACED

MAIN BEARINGS

BIG END BEARINGS

CYLINDER LINERS

PISTON RINGS

CRANKSHAFT SEALS

MSHS completed the repair and overhaul of two DEUTZ TBD 616

V16 engines on the 74 foot thrill ride boat Seadog.

In March 2012, MSHS first surveyed the commercial passenger

vessel Seadog. The customer reported that the engines were

overheating. After the initial inspection, MSHS found that the

engines had been affected by heavy corrosion from water leaks

above the engines.

MSHS engineers concluded that a complete overhaul of both

engines was necessary to extend the lifetime and safe operation of

the engines and in order to get the engines in good condition for the

upcoming season. At the customer's request, the engine overhauls

had to be completed prior to the start of the 2012 season.

PROJECT OVERVIEW:

Connecting rods lined up for measuring

The MSHS contract included:

Complete overhaul of two DEUTZ TBD 616 V16 main engines

Reconditioning of 2 x 2 injection pumps

Reconditioning of 2 x 2 turbochargers

Reconditioning 2 x 2 fresh and raw water pumps

Reconditioning of 2 x 16 cylinder heads

Repair and reconditioning of 2 x 1 heat exchangers

Repair and cleaning of 2 x 2 charge air coolers

Replacing all main bearings, big end bearings, cylinder liners,

and piston rings

Changing front and rear crankshaft seals including race rings

Ten years ago, MSHS sold the pair of DEUTZ TBD 616 V16

engines to the original owner of the vessel. Despite the heavy duty

use of the engines since 2003, including full 180-360 spins, high

speeds up to 30 knots and sharp twists and turns, the engines

remain in full operation.

The DEUTZ TBD 616 V16 engines met the requirements of the

customer. The boat management wanted an extremely compact

configuration with an optimal power-to-weight ratio (engine

weight: 2600 kg (5730 lb), engine output: 960 kW / 1287 HP,

engine speed: 2100 min).

Engine assembly in full progress

For the duration of the overhaul, the thrill ride boat was docked in

Baltimore, Maryland. MSHS managed the logistically challenging

transport of the two engines to the MSHS facility in Fort

Lauderdale, Florida and then returned them to Baltimore.

The completely overhauled engines were delivered to the

customer within one month as determined by the contract. MSHS

met the deadline and the Seadog was back in the water.

BENEFITS OF OVERHAUL:

Safe operation of the engine

Extends life of engine

Higher engine efficiency

Reduces emission & fuel consumption

Eliminates cost of new engine replacement

Lowers longterm operational costs

MSHS offers complete mechanical and electrical services, repairs

and overhauls. For information, contact joerg.scheele@mshs.com .

Final touches

Motor-Services Hugo Stamp, Inc. (MSHS) is the authorized distributor and service center for most of the worlds

major diesel engine and turbocharger manufacturers and is proud to operate under ISO 9001:2000 certification.

Through innovative products and services, MSHS specializes in the testing, maintenance, repair, and overhaul of

diesel engines, turbochargers, water jets, and filtration systems. Factory-trained service engineers and technicians

are on 24-hour call providing everything from complete overhauls to laser alignment, engine diagnostics, and video

inspections. MSHS maintains an extensive inventory of OEM parts.

3190 SW 4th Avenue | Ft. Lauderdale, FL 33315 | USA

Toll Free: 800 622-6747 | Office: +1 954 763-3660 | www.mshs.com

abcde

You might also like

- Volvo Truck d11 d13 d16 Engine Workshop Service Ma 59c522a21723dd2c1ca9e5b9Document6 pagesVolvo Truck d11 d13 d16 Engine Workshop Service Ma 59c522a21723dd2c1ca9e5b9DEEPAK GOYAL0% (1)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- GranTurismo enDocument0 pagesGranTurismo enaiigee100% (1)

- Qj340 ManualDocument68 pagesQj340 Manualluis50% (2)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Howden BrochureDocument14 pagesHowden BrochureBrent Collins100% (1)

- QSK-19 Troubleshooting 3666098 PDFDocument690 pagesQSK-19 Troubleshooting 3666098 PDFMiguel Angel Garrido Cardenas100% (19)

- OM 654 - Launch of A NewDocument8 pagesOM 654 - Launch of A Newkammy4love9888100% (3)

- Cylinder Liner Change On Wartsila Main Engine - Container VesselDocument1 pageCylinder Liner Change On Wartsila Main Engine - Container VesselBourbon EngineNo ratings yet

- Heat Recovery Steam Generators Optimized For Any ApplicationDocument7 pagesHeat Recovery Steam Generators Optimized For Any ApplicationKVVNo ratings yet

- Ps 70 1 eDocument8 pagesPs 70 1 eMochamad Mujib Faozi NasirNo ratings yet

- Wartsila 9R32E Engine Block Replacement: General Cargo Ship in NycDocument1 pageWartsila 9R32E Engine Block Replacement: General Cargo Ship in NycMohamed AzeamNo ratings yet

- Tilting Pad Thrust BearingDocument6 pagesTilting Pad Thrust BearingChristopher GarciaNo ratings yet

- General Overview of WartsilaDocument34 pagesGeneral Overview of WartsilaantonNo ratings yet

- Daihatsu - Marine Propulsion Diesel EngineDocument24 pagesDaihatsu - Marine Propulsion Diesel Enginedimitaring75% (4)

- Hidrostal Submersible Immersible PDFDocument8 pagesHidrostal Submersible Immersible PDFariyamanjulaNo ratings yet

- Turbine TurgoDocument20 pagesTurbine TurgoJesus UgarteNo ratings yet

- Wartsila 9R32E Engine Block Replacement: General Cargo Ship in NycDocument1 pageWartsila 9R32E Engine Block Replacement: General Cargo Ship in NycClodoaldo BiassioNo ratings yet

- Cryostar Process Machinery PDFDocument0 pagesCryostar Process Machinery PDFJavad AmnianNo ratings yet

- Motoare Diesel - PropulsieDocument24 pagesMotoare Diesel - PropulsieDan Aurelian Popa100% (1)

- Himsen Cat h2533Document12 pagesHimsen Cat h2533Mohsen50% (2)

- API 618 Reciprocating CompressorDocument12 pagesAPI 618 Reciprocating Compressorfoobar2016No ratings yet

- ERT Calder PDFDocument8 pagesERT Calder PDFHatem JafouraNo ratings yet

- Wartsila 32 Diesel Engine AnalysisDocument8 pagesWartsila 32 Diesel Engine Analysisivanadityan100% (1)

- Diesel Generator ThesisDocument7 pagesDiesel Generator Thesisbrendapotterreno100% (2)

- Glandless Motor PumpsDocument4 pagesGlandless Motor PumpsmalsttarNo ratings yet

- GE Aeroderivative Product and Services SolutionsDocument16 pagesGE Aeroderivative Product and Services SolutionsCory TurnerNo ratings yet

- Dual Fuel Modifications of Wartsila 18 V46 BlockDocument2 pagesDual Fuel Modifications of Wartsila 18 V46 BlockSachinth Nalinda SilvaNo ratings yet

- Hy-Andritz-Submersible-Motors-Sm-En-Data Motors SubmersibleDocument12 pagesHy-Andritz-Submersible-Motors-Sm-En-Data Motors SubmersibleGary MosesNo ratings yet

- Hes Reciprocating Compressor PDFDocument2 pagesHes Reciprocating Compressor PDFBHAVINNo ratings yet

- HRSG 2011 BrochureDocument12 pagesHRSG 2011 BrochureAndry SetiawanNo ratings yet

- Marine Propulsion Engine: Powered by Your NeedsDocument2 pagesMarine Propulsion Engine: Powered by Your NeedsTran HanNo ratings yet

- Ground Steel Crude Oil Storage Tank Location and FoundationDocument20 pagesGround Steel Crude Oil Storage Tank Location and Foundationliz aldanaNo ratings yet

- GeneratorsDocument20 pagesGeneratorsAbderrahmane OuergliNo ratings yet

- Sulzer Pumps Retrofit: Increasing The Efficiency of Pumps: Technical and Economic OptimizationDocument8 pagesSulzer Pumps Retrofit: Increasing The Efficiency of Pumps: Technical and Economic OptimizationAri HeryadiNo ratings yet

- Hed and Hed-Ds: Between Bearings, Two-Stage, Radially Split PumpsDocument8 pagesHed and Hed-Ds: Between Bearings, Two-Stage, Radially Split PumpsdwiaguspriyonoNo ratings yet

- Appendix 3 FinalDocument96 pagesAppendix 3 FinalMehedi IslamNo ratings yet

- Wind PDFDocument12 pagesWind PDFRichard AvilésNo ratings yet

- Pump BrochureDocument10 pagesPump Brochuresen_subhasis_58100% (1)

- JsmeaDocument16 pagesJsmeamunhNo ratings yet

- Axial-Turbochargers Whitepaper PjdeDocument1 pageAxial-Turbochargers Whitepaper PjdeCommunications ShipyardNo ratings yet

- Doosan GeneratorsDocument20 pagesDoosan GeneratorsUhrinImreNo ratings yet

- Boletin Non ClogDocument12 pagesBoletin Non ClogulisesgeNo ratings yet

- bb1 CatDocument7 pagesbb1 Catrohituchani100% (1)

- 4-5 Rotrex Vanddampkompressor Anders KolstrupDocument17 pages4-5 Rotrex Vanddampkompressor Anders KolstrupZauron Kent TouchitNo ratings yet

- Doosan Steam TurbinesDocument24 pagesDoosan Steam TurbinesUhrin Imre0% (1)

- Submersible Vs ImmerseDocument3 pagesSubmersible Vs ImmersesatstarNo ratings yet

- GE Reciprocating Compressor BrochureDocument13 pagesGE Reciprocating Compressor Brochurepratik banerjeeNo ratings yet

- D7R IiDocument24 pagesD7R IiVictor M. Mejia DiazNo ratings yet

- Heavy Duty, Radially Split, Two-Stage Pumps: API 610 / ISO 13709Document10 pagesHeavy Duty, Radially Split, Two-Stage Pumps: API 610 / ISO 13709bandmmillwardNo ratings yet

- Realignment of ShipDocument23 pagesRealignment of ShipAlfredo Ortiz BocanegraNo ratings yet

- Marine Diesel Engines CatalogDocument16 pagesMarine Diesel Engines CatalogDamian Cid Morales100% (1)

- Hydrostatic 2006Document4 pagesHydrostatic 2006juliyanto88No ratings yet

- Diesel-To-Natural Gas Engine Conversions A Cost Effective AlternativeDocument14 pagesDiesel-To-Natural Gas Engine Conversions A Cost Effective AlternativeFahmi KurniawanNo ratings yet

- Drilling EDrilling - Equip2013 - PUE - Web - 2quip2013 PUE Web 2Document40 pagesDrilling EDrilling - Equip2013 - PUE - Web - 2quip2013 PUE Web 2MEREUEULEUNo ratings yet

- Vertical Turbine Fire PumpsDocument6 pagesVertical Turbine Fire PumpsSérgio Gnipper100% (1)

- RH 120e HandbookDocument8 pagesRH 120e HandbookEgyiri Frederick100% (1)

- Wartsila 200Document24 pagesWartsila 200Carl Anthony Chamberlain100% (1)

- Steering StabilisationDocument24 pagesSteering StabilisationRooftop Gardener100% (1)

- Vietshipping 2008Document22 pagesVietshipping 2008minus89aspire100% (1)

- Engine Driven RefrigerationDocument2 pagesEngine Driven RefrigerationValentin LupascuNo ratings yet

- Naval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsFrom EverandNaval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 3.5 out of 5 stars3.5/5 (2)

- Machines, Tools and Methods of Automobile ManufactureFrom EverandMachines, Tools and Methods of Automobile ManufactureRating: 4 out of 5 stars4/5 (1)

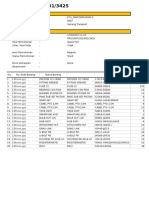

- Update Unit Ready 21062022Document1 pageUpdate Unit Ready 21062022Tyler GoodwinNo ratings yet

- Book 1Document4 pagesBook 1Tyler GoodwinNo ratings yet

- MRP Selesai Plus UploadDocument46 pagesMRP Selesai Plus UploadTyler GoodwinNo ratings yet

- Makenda Sales Yanmar Price ListDocument14 pagesMakenda Sales Yanmar Price ListTyler GoodwinNo ratings yet

- Modifiable Skills MatrixDocument84 pagesModifiable Skills MatrixTyler GoodwinNo ratings yet

- Plan Cycle Invest Tools Equip 2011Document12 pagesPlan Cycle Invest Tools Equip 2011Tyler GoodwinNo ratings yet

- D85ess P2uDocument1 pageD85ess P2uTyler GoodwinNo ratings yet

- Form Permintaan BarangDocument148 pagesForm Permintaan BarangTyler GoodwinNo ratings yet

- Bolt Double Wheel SJNWDocument6 pagesBolt Double Wheel SJNWTyler GoodwinNo ratings yet

- TCODESDocument3 pagesTCODESTyler GoodwinNo ratings yet

- SAP Inventory ManagementDocument26 pagesSAP Inventory ManagementTyler GoodwinNo ratings yet

- AplDocument49 pagesAplTyler GoodwinNo ratings yet

- AGCO InstallDocument10 pagesAGCO InstallTyler GoodwinNo ratings yet

- PT - United Tractors TBK: ConfidentialDocument1 pagePT - United Tractors TBK: ConfidentialTyler GoodwinNo ratings yet

- Excel Panel Chart - Examples: Regular Charts Panel ChartsDocument4 pagesExcel Panel Chart - Examples: Regular Charts Panel ChartsTyler GoodwinNo ratings yet

- Maintenance Planning and Control: Modeling and Analysis: Slides On Chapter 1Document47 pagesMaintenance Planning and Control: Modeling and Analysis: Slides On Chapter 1Tyler GoodwinNo ratings yet

- Top X Chart: Sales Data of TOP 10 CustomersDocument3 pagesTop X Chart: Sales Data of TOP 10 CustomersTyler GoodwinNo ratings yet

- Chapter 2 - Cooling System: Prepared by Muhammad Hilmi Bin ZaidDocument49 pagesChapter 2 - Cooling System: Prepared by Muhammad Hilmi Bin ZaidTyler GoodwinNo ratings yet

- Laporan 2 X Engine Ex OVH UT Reman Tha GroupDocument2 pagesLaporan 2 X Engine Ex OVH UT Reman Tha GroupTyler GoodwinNo ratings yet

- Learn Name ManagerDocument2 pagesLearn Name ManagerTyler GoodwinNo ratings yet

- PR Need FedbackDocument28 pagesPR Need FedbackTyler GoodwinNo ratings yet

- Letter To Honorable Chen Jining of The Chinese Ministry of Environmental ProtectionDocument2 pagesLetter To Honorable Chen Jining of The Chinese Ministry of Environmental ProtectionIsaiah X. SmithNo ratings yet

- HPT604 Level Sensor Datasheet-Fuel Application - RS485Document6 pagesHPT604 Level Sensor Datasheet-Fuel Application - RS485Md ShNo ratings yet

- Makati City Fire Station: Fire and Life Safety SeminarDocument60 pagesMakati City Fire Station: Fire and Life Safety SeminarAireen TanioNo ratings yet

- Documentatie Express 99 PDFDocument5 pagesDocumentatie Express 99 PDFIonuț CojocariuNo ratings yet

- Automotive Attachment ReportDocument22 pagesAutomotive Attachment ReportjeffkwentrickksivorNo ratings yet

- Shell Caprinus XS9 40 (En) TDSDocument2 pagesShell Caprinus XS9 40 (En) TDSAnonymous oAbjbl4HNo ratings yet

- EGES455Document520 pagesEGES455Wilson Bueno90% (10)

- 02 GG Pgt25 Dle Description VCNGDocument138 pages02 GG Pgt25 Dle Description VCNGolegprikhodko2809100% (4)

- Directive 009: Casing Cementing Minimum Requirements: July 1990Document17 pagesDirective 009: Casing Cementing Minimum Requirements: July 1990smithyry2014No ratings yet

- Ultrasonic Fuel Level Sensor: ManualDocument6 pagesUltrasonic Fuel Level Sensor: ManualArif ZaenNo ratings yet

- HVAC CatalogDocument47 pagesHVAC CatalogJoel BecherNo ratings yet

- Diagrama ElectricoDocument2 pagesDiagrama ElectricodptecnicocmspNo ratings yet

- Turbocharger Cut Out SystemDocument13 pagesTurbocharger Cut Out SystemCarpediem Maximus100% (2)

- Use of Hydrogen in Internal Combustion Engines: A Comprehensive StudyDocument13 pagesUse of Hydrogen in Internal Combustion Engines: A Comprehensive Studyfh100% (1)

- A Modified Quadratic Boost Converter Wit PDFDocument6 pagesA Modified Quadratic Boost Converter Wit PDFkadr sherpaNo ratings yet

- MB Bus Rescue GuidelinesDocument268 pagesMB Bus Rescue GuidelinesNatalia UrribarriNo ratings yet

- 9Y011-02704 KubotaDocument143 pages9Y011-02704 KubotaZaqi SatchNo ratings yet

- (LEHW0191-00) 3512C (HD) ATAAC With DGB PDFDocument4 pages(LEHW0191-00) 3512C (HD) ATAAC With DGB PDFHugo CiprianiNo ratings yet

- A Seminar On Electric CarDocument17 pagesA Seminar On Electric CarHimanshu YadavNo ratings yet

- 420E y 430E PDFDocument19 pages420E y 430E PDFRICHARDNo ratings yet

- 17OILGASMINE Ketsela Tadesse S2 PDFDocument37 pages17OILGASMINE Ketsela Tadesse S2 PDFgetasewNo ratings yet

- 45 - Miscible DisplacementDocument15 pages45 - Miscible Displacementrizal tri susilo67% (3)

- DP180LBDocument4 pagesDP180LBKazim AlrefaiNo ratings yet

- Ignition System - 1Document5 pagesIgnition System - 1Sudhakar Uppalapati100% (1)

- Minimun Pore Volume in Well TestDocument50 pagesMinimun Pore Volume in Well Testjorge_h_riveroNo ratings yet