Professional Documents

Culture Documents

Duties of QC

Duties of QC

Uploaded by

Anonymous 4e7GNjzGWCopyright:

Available Formats

You might also like

- Inspection ChecklistDocument2 pagesInspection ChecklistSendi Dwi Oktaviandi57% (7)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 4 out of 5 stars4/5 (9)

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- Excel Construction Project Management Templates Construction Budget TemplateDocument19 pagesExcel Construction Project Management Templates Construction Budget TemplateAnonymous 4e7GNjzGW100% (3)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Successful Instrumentation and Control Systems Design, Second EditionFrom EverandSuccessful Instrumentation and Control Systems Design, Second EditionRating: 4.5 out of 5 stars4.5/5 (10)

- CNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingFrom EverandCNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingNo ratings yet

- Asme Ix QW PDFDocument183 pagesAsme Ix QW PDFAnonymous 4e7GNjzGW100% (4)

- Hair - School - Business - Plan SAMPLE Wo FINANCIALSDocument17 pagesHair - School - Business - Plan SAMPLE Wo FINANCIALSsegun Timileyin100% (2)

- The Unhappy SupervisorDocument5 pagesThe Unhappy SupervisorGio Dale100% (3)

- Duties & Responsibilities of Welding InspectorDocument3 pagesDuties & Responsibilities of Welding InspectorAshwani Dogra57% (7)

- CV of Welding InspectorDocument4 pagesCV of Welding Inspectorramesh77c100% (2)

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 pageFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWNo ratings yet

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 pageFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWNo ratings yet

- Hydrostatic Test (Log) : Quality Control FormDocument22 pagesHydrostatic Test (Log) : Quality Control FormAnonymous 4e7GNjzGWNo ratings yet

- Welding Defect - MACRO PDFDocument5 pagesWelding Defect - MACRO PDFAnonymous 4e7GNjzGWNo ratings yet

- Bob Jessop - Fordism and Post-FordismDocument22 pagesBob Jessop - Fordism and Post-Fordismqrs-ltd100% (1)

- #2 Duties of Welding InspectorsDocument13 pages#2 Duties of Welding InspectorsherawanadifNo ratings yet

- Duties Before WeldingDocument1 pageDuties Before WeldingMuhammed ThanzeelNo ratings yet

- Before, During and After Welding.Document2 pagesBefore, During and After Welding.ashwinNo ratings yet

- Preparation: Inspection Before WeldingDocument3 pagesPreparation: Inspection Before WeldingDaison PaulNo ratings yet

- ARAMCO Interview 2015 PDFDocument15 pagesARAMCO Interview 2015 PDFm.srinivasanNo ratings yet

- Module 4 - Welding Procedure Specification As Per AWS D1.1Document24 pagesModule 4 - Welding Procedure Specification As Per AWS D1.1strucmeNo ratings yet

- CSWIP 3.1-2010 The Welding Inspection of SteelDocument317 pagesCSWIP 3.1-2010 The Welding Inspection of Steelapply19842371100% (1)

- 9 Cswip 3.1 Book 2010 Coloured BookDocument338 pages9 Cswip 3.1 Book 2010 Coloured BookBùi Công LộcNo ratings yet

- 1 Duties and Responsibilities Section 1Document22 pages1 Duties and Responsibilities Section 1azizieh5701No ratings yet

- Welding Inspection CourseDocument23 pagesWelding Inspection CoursepouyaNo ratings yet

- Duties of Welding InspectorDocument3 pagesDuties of Welding InspectorSalman SyedNo ratings yet

- Cswip 3.1 New BookDocument342 pagesCswip 3.1 New BookMohsin Rasul90% (52)

- ElectricalDocument59 pagesElectricalHitendra Panchal100% (1)

- Shortcut To A WPSDocument18 pagesShortcut To A WPSCepi Sindang Kamulan100% (1)

- 1 Duties and Responsibilities Section 1Document22 pages1 Duties and Responsibilities Section 1Saeed AnwarNo ratings yet

- 1 Typical Duties of Welding InspectorsDocument7 pages1 Typical Duties of Welding InspectorspandimrNo ratings yet

- Section 2 DutiesDocument3 pagesSection 2 DutiesUmaibalanNo ratings yet

- Method Statement For Welding PDFDocument8 pagesMethod Statement For Welding PDFpadmasree200283% (6)

- QAQC References 2Document138 pagesQAQC References 2Mohd SharainiNo ratings yet

- Duties of A Weld InspectorDocument2 pagesDuties of A Weld Inspectorshanebowen31No ratings yet

- Weld Inspection Norsok ChecklistDocument1 pageWeld Inspection Norsok Checklisthalim abas100% (1)

- Responsible Welding CoordinatorDocument637 pagesResponsible Welding Coordinatorscott2355100% (6)

- WPS PQR WQT WPQDocument43 pagesWPS PQR WQT WPQAmmar Čabaravdić100% (1)

- Inspeksi LasDocument83 pagesInspeksi Lassyahrial cahyantoNo ratings yet

- Welding Works RequirementsDocument48 pagesWelding Works RequirementsrogersampaiocostaNo ratings yet

- QUALITY INSPECTOR (Welding Inspector) : Basic FunctionDocument1 pageQUALITY INSPECTOR (Welding Inspector) : Basic FunctionEdy AlamNo ratings yet

- Welding Procedure SpecificationsDocument14 pagesWelding Procedure SpecificationsBasavaraj KaraningNo ratings yet

- Steps To CE Marking According To BS EN 1090-1Document1 pageSteps To CE Marking According To BS EN 1090-1CE_WizardNo ratings yet

- Welding Procedure SpecificationDocument21 pagesWelding Procedure Specificationboypardede100% (9)

- Inspection Test Procedure ModelDocument8 pagesInspection Test Procedure ModelMahesh SuthaNo ratings yet

- Section - I: Cover Page Section - II:: IndexDocument21 pagesSection - I: Cover Page Section - II:: Indexamit rajputNo ratings yet

- General Procedure of Manufacturing The Custom Built Sound Proof Enclosures With PanelsDocument14 pagesGeneral Procedure of Manufacturing The Custom Built Sound Proof Enclosures With PanelspawanNo ratings yet

- Ajin BabuDocument4 pagesAjin BabuJithuJohnNo ratings yet

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Total Quality Process Control for Injection MoldingFrom EverandTotal Quality Process Control for Injection MoldingRating: 5 out of 5 stars5/5 (1)

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AFrom EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANo ratings yet

- Construction Methodologies & Procedures for Civil Engineers - Part -1From EverandConstruction Methodologies & Procedures for Civil Engineers - Part -1No ratings yet

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- SCAFFOLDING - THE HANDBOOK FOR ESTIMATING and PRODUCT KNOWLEDGEFrom EverandSCAFFOLDING - THE HANDBOOK FOR ESTIMATING and PRODUCT KNOWLEDGENo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Good Documentation Practices (GDP) in Pharmaceutical IndustryFrom EverandGood Documentation Practices (GDP) in Pharmaceutical IndustryNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Aircraft Dispatcher Oral Exam Guide: Prepare for the FAA oral and practical exam to earn your Aircraft Dispatcher certificateFrom EverandAircraft Dispatcher Oral Exam Guide: Prepare for the FAA oral and practical exam to earn your Aircraft Dispatcher certificateNo ratings yet

- BGAS-CSWIP Welding and Coating Inspection: Certification, Process, Exam Preparation and Q&AFrom EverandBGAS-CSWIP Welding and Coating Inspection: Certification, Process, Exam Preparation and Q&ANo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Safety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesFrom EverandSafety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesNo ratings yet

- Construction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsFrom EverandConstruction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- Name Name Name Name: To: CCDocument1 pageName Name Name Name: To: CCAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldAnonymous 4e7GNjzGW100% (1)

- Weld Joint Preparation Weld Joint PreparationDocument1 pageWeld Joint Preparation Weld Joint PreparationAnonymous 4e7GNjzGWNo ratings yet

- Kafou Health Safety Loss Prevention ProgramDocument117 pagesKafou Health Safety Loss Prevention ProgramAnonymous 4e7GNjzGWNo ratings yet

- Warrior Tech Spare Parts List 2Document1 pageWarrior Tech Spare Parts List 2Anonymous 4e7GNjzGWNo ratings yet

- Shielded Metal Arc Welding (Smaw / "Stick") Shielded Metal Arc Welding (Smaw / Â Œstickâ )Document2 pagesShielded Metal Arc Welding (Smaw / "Stick") Shielded Metal Arc Welding (Smaw / Â Œstickâ )Anonymous 4e7GNjzGWNo ratings yet

- QW484Document1 pageQW484Anonymous 4e7GNjzGWNo ratings yet

- SKTCO ISO 9001 2008 Gap Analysis ChecklistDocument17 pagesSKTCO ISO 9001 2008 Gap Analysis ChecklistAnonymous 4e7GNjzGWNo ratings yet

- Bio Data-01.07.13Document2 pagesBio Data-01.07.13Anonymous 4e7GNjzGWNo ratings yet

- Request For Inspection: Client: Contractor: Contract No. Rfi No. Project: Location: Date: Description of InspectionDocument2 pagesRequest For Inspection: Client: Contractor: Contract No. Rfi No. Project: Location: Date: Description of InspectionAnonymous 4e7GNjzGWNo ratings yet

- Numbering Format: Project DocumentationDocument1 pageNumbering Format: Project DocumentationAnonymous 4e7GNjzGWNo ratings yet

- HSMC Employee Induction Procedure (Offices)Document3 pagesHSMC Employee Induction Procedure (Offices)Anonymous 4e7GNjzGWNo ratings yet

- Notes-Api Exams-Prathap DhasDocument7 pagesNotes-Api Exams-Prathap DhasAnonymous 4e7GNjzGWNo ratings yet

- G. Std. ITP For Pipeline Job PDFDocument4 pagesG. Std. ITP For Pipeline Job PDFAnonymous 4e7GNjzGW100% (1)

- 5 Page Ses Resume SampleDocument7 pages5 Page Ses Resume Samplevofysyv1z1v3100% (1)

- Labor Eco Ques BankDocument8 pagesLabor Eco Ques BankNitesh N AjwaniNo ratings yet

- Junior Analyst - Bayt PDFDocument1 pageJunior Analyst - Bayt PDFshane kairuNo ratings yet

- Employers QuestionnaireDocument2 pagesEmployers QuestionnaireJoywins7No ratings yet

- Adverb PhrasesDocument10 pagesAdverb PhraseslilytiangNo ratings yet

- Trade Union Act, 1926Document48 pagesTrade Union Act, 1926Naberius Orca100% (1)

- II.C.9 Coca-Cola Bottlers v. Agito, February 13, 2009Document5 pagesII.C.9 Coca-Cola Bottlers v. Agito, February 13, 2009Jin AghamNo ratings yet

- Nda Vs Cir & Ntwu - G.R. No. L-15422 - Nov 30, 1962Document3 pagesNda Vs Cir & Ntwu - G.R. No. L-15422 - Nov 30, 1962ELMER T. SARABIANo ratings yet

- Google People Operations - The Secrets of The World's Most Scientific Human Resources DepartmentDocument3 pagesGoogle People Operations - The Secrets of The World's Most Scientific Human Resources DepartmentAtul KohliNo ratings yet

- Organizational Behavior Multiple Choice QuizDocument3 pagesOrganizational Behavior Multiple Choice QuizMuhammad YahyaNo ratings yet

- Online Indian Astrology, Indian Vedic Astrology, Future Predictions, Horoscopes, Astrological Remedies, Astrological SolutionsDocument3 pagesOnline Indian Astrology, Indian Vedic Astrology, Future Predictions, Horoscopes, Astrological Remedies, Astrological SolutionsDeepak MishraNo ratings yet

- Vietnamese Coffee Shop Opening ProjectDocument12 pagesVietnamese Coffee Shop Opening ProjectNgoc Tuan Anh BuiNo ratings yet

- In Tray GuideDocument10 pagesIn Tray Guidejitendrasutar1975No ratings yet

- CMQ Exam 4 - ResponsesDocument40 pagesCMQ Exam 4 - ResponsesVusal AgakisiyevNo ratings yet

- Review Jurnal - 3Document20 pagesReview Jurnal - 3eko hadiNo ratings yet

- HealthCo+Workforce Diversity and Wellness Kel 2 FIXDocument24 pagesHealthCo+Workforce Diversity and Wellness Kel 2 FIXDandy100% (1)

- Rephrase PT OlimpiadaDocument8 pagesRephrase PT OlimpiadaRoxana Elena Vasile100% (1)

- Virtusa PDFDocument2 pagesVirtusa PDFAllu Vijay100% (1)

- Entrepreneurial CompetenciesDocument7 pagesEntrepreneurial Competenciesamit_sepl100% (1)

- Fulltxt PDFDocument98 pagesFulltxt PDFAnkita RaniNo ratings yet

- Incentive SGS & SGL March 2020 Paid On Payroll Juli Region Cluster Employee ID Employee Name Amount PositionDocument10 pagesIncentive SGS & SGL March 2020 Paid On Payroll Juli Region Cluster Employee ID Employee Name Amount PositionZiki PermanaNo ratings yet

- Report of The National Commission On LabourDocument169 pagesReport of The National Commission On LabourshailendrachimadeNo ratings yet

- Leadership Theories and Educational Management: An Insight: June 2015Document10 pagesLeadership Theories and Educational Management: An Insight: June 2015Godofredo HermosuraNo ratings yet

- Public Personnel AdministrationDocument8 pagesPublic Personnel AdministrationChristian ChavezNo ratings yet

- Eis Assignment - V1aDocument2 pagesEis Assignment - V1aSameera VadakelNo ratings yet

- MihretDocument3 pagesMihretaschalewteshome155No ratings yet

- Gender EqualityDocument11 pagesGender EqualityTeresa FariaNo ratings yet

Duties of QC

Duties of QC

Uploaded by

Anonymous 4e7GNjzGWOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Duties of QC

Duties of QC

Uploaded by

Anonymous 4e7GNjzGWCopyright:

Available Formats

7

Safety consciousness is a duty of all employees and a Welding Inspector

should:

Be aware of all safety regulations for the workplace

Ensure that safety equipment that will be needed is available and in

suitable condition

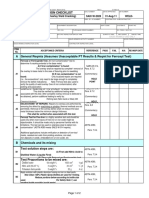

Duties before welding

Check

Material

Action

In accordance with drawing/WPS

Identified and can be traced to a test certificate

In suitable condition (free from damage and

contamination

WPSs

Have been approved and are available to welders

(and inspectors)

Welding equipment

In suitable condition and calibrated as appropriate

Weld preparations

In accordance with WPS (and/or drawings)

Welder qualifications Identification of welders qualified for each WPS to be

used. All welder qualification certificates are valid (in

date)

Welding

Those to be used are as specified by the WPSs are

consumables

being stored/controlled as specified by the QC

Procedure

Joint fit-ups

In accordance with WPS/drawings tack welds are to

good workmanship standard and to code/WPS

Weld faces

Are free from defects, contamination and damage

Preheat (if required) Minimum temperature is in accordance with WPS

Duties during welding

Check

Site/field welding

Welding process

Preheat (if required)

Interpass

temperature

Welding

consumables

Welding parameters

Root run

Gouging/grinding

Interrun cleaning

Welder

Rev 1 January 2009

Typical Duties of Welding Inspectors

Copyright TWI Ltd 2009

Action

Ensure weather conditions are suitable/comply with

Code (conditions will not affect welding)

In accordance with WPS

Minimum temperature is being maintained in

accordance with WPS

Maximum temperature is in accordance with WPS

Inn accordance with WPS and being controlled as

Procedure

Current, volts, travel speed are in accordance with

WPS

Visually acceptable to Code (before filling the joint)

(for single sided welds)

By an approved method and to good workmanship

standard

To good workmanship standard

On the approval register/qualified for the WPS being

used

Duties after welding

Check

Weld identification

Weld appearance

Dimensional survey

Drawings

NDT

Repairs

PWHT (if required)

Pressure/load test (if

required)

Documentation

records

Rev 1 January 2009

Typical Duties of Welding Inspectors

Copyright TWI Ltd 2009

Action

Each weld is marked with the welder's identification

and is identified in accordance with drawing/weld

map

Ensure welds are suitable for all NDT (profile,

cleanness etc)

Visually inspect welds and sentence in accordance

with Code

Check dimensions are in accordance with

drawing/Code

Ensure any modifications are included on as-built

drawings

Ensure all NDT is complete and reports are available

for records

Monitor in accordance with the Procedure

Monitor for compliance with Procedure (check chart

record)

Ensure test equipment is calibrated

Monitor test to ensure compliance with

Procedure/Code. Ensure reports/records are

available

Ensure all reports/records are completed and collated

as required

You might also like

- Inspection ChecklistDocument2 pagesInspection ChecklistSendi Dwi Oktaviandi57% (7)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 4 out of 5 stars4/5 (9)

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- Excel Construction Project Management Templates Construction Budget TemplateDocument19 pagesExcel Construction Project Management Templates Construction Budget TemplateAnonymous 4e7GNjzGW100% (3)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Successful Instrumentation and Control Systems Design, Second EditionFrom EverandSuccessful Instrumentation and Control Systems Design, Second EditionRating: 4.5 out of 5 stars4.5/5 (10)

- CNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingFrom EverandCNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingNo ratings yet

- Asme Ix QW PDFDocument183 pagesAsme Ix QW PDFAnonymous 4e7GNjzGW100% (4)

- Hair - School - Business - Plan SAMPLE Wo FINANCIALSDocument17 pagesHair - School - Business - Plan SAMPLE Wo FINANCIALSsegun Timileyin100% (2)

- The Unhappy SupervisorDocument5 pagesThe Unhappy SupervisorGio Dale100% (3)

- Duties & Responsibilities of Welding InspectorDocument3 pagesDuties & Responsibilities of Welding InspectorAshwani Dogra57% (7)

- CV of Welding InspectorDocument4 pagesCV of Welding Inspectorramesh77c100% (2)

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 pageFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWNo ratings yet

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 pageFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWNo ratings yet

- Hydrostatic Test (Log) : Quality Control FormDocument22 pagesHydrostatic Test (Log) : Quality Control FormAnonymous 4e7GNjzGWNo ratings yet

- Welding Defect - MACRO PDFDocument5 pagesWelding Defect - MACRO PDFAnonymous 4e7GNjzGWNo ratings yet

- Bob Jessop - Fordism and Post-FordismDocument22 pagesBob Jessop - Fordism and Post-Fordismqrs-ltd100% (1)

- #2 Duties of Welding InspectorsDocument13 pages#2 Duties of Welding InspectorsherawanadifNo ratings yet

- Duties Before WeldingDocument1 pageDuties Before WeldingMuhammed ThanzeelNo ratings yet

- Before, During and After Welding.Document2 pagesBefore, During and After Welding.ashwinNo ratings yet

- Preparation: Inspection Before WeldingDocument3 pagesPreparation: Inspection Before WeldingDaison PaulNo ratings yet

- ARAMCO Interview 2015 PDFDocument15 pagesARAMCO Interview 2015 PDFm.srinivasanNo ratings yet

- Module 4 - Welding Procedure Specification As Per AWS D1.1Document24 pagesModule 4 - Welding Procedure Specification As Per AWS D1.1strucmeNo ratings yet

- CSWIP 3.1-2010 The Welding Inspection of SteelDocument317 pagesCSWIP 3.1-2010 The Welding Inspection of Steelapply19842371100% (1)

- 9 Cswip 3.1 Book 2010 Coloured BookDocument338 pages9 Cswip 3.1 Book 2010 Coloured BookBùi Công LộcNo ratings yet

- 1 Duties and Responsibilities Section 1Document22 pages1 Duties and Responsibilities Section 1azizieh5701No ratings yet

- Welding Inspection CourseDocument23 pagesWelding Inspection CoursepouyaNo ratings yet

- Duties of Welding InspectorDocument3 pagesDuties of Welding InspectorSalman SyedNo ratings yet

- Cswip 3.1 New BookDocument342 pagesCswip 3.1 New BookMohsin Rasul90% (52)

- ElectricalDocument59 pagesElectricalHitendra Panchal100% (1)

- Shortcut To A WPSDocument18 pagesShortcut To A WPSCepi Sindang Kamulan100% (1)

- 1 Duties and Responsibilities Section 1Document22 pages1 Duties and Responsibilities Section 1Saeed AnwarNo ratings yet

- 1 Typical Duties of Welding InspectorsDocument7 pages1 Typical Duties of Welding InspectorspandimrNo ratings yet

- Section 2 DutiesDocument3 pagesSection 2 DutiesUmaibalanNo ratings yet

- Method Statement For Welding PDFDocument8 pagesMethod Statement For Welding PDFpadmasree200283% (6)

- QAQC References 2Document138 pagesQAQC References 2Mohd SharainiNo ratings yet

- Duties of A Weld InspectorDocument2 pagesDuties of A Weld Inspectorshanebowen31No ratings yet

- Weld Inspection Norsok ChecklistDocument1 pageWeld Inspection Norsok Checklisthalim abas100% (1)

- Responsible Welding CoordinatorDocument637 pagesResponsible Welding Coordinatorscott2355100% (6)

- WPS PQR WQT WPQDocument43 pagesWPS PQR WQT WPQAmmar Čabaravdić100% (1)

- Inspeksi LasDocument83 pagesInspeksi Lassyahrial cahyantoNo ratings yet

- Welding Works RequirementsDocument48 pagesWelding Works RequirementsrogersampaiocostaNo ratings yet

- QUALITY INSPECTOR (Welding Inspector) : Basic FunctionDocument1 pageQUALITY INSPECTOR (Welding Inspector) : Basic FunctionEdy AlamNo ratings yet

- Welding Procedure SpecificationsDocument14 pagesWelding Procedure SpecificationsBasavaraj KaraningNo ratings yet

- Steps To CE Marking According To BS EN 1090-1Document1 pageSteps To CE Marking According To BS EN 1090-1CE_WizardNo ratings yet

- Welding Procedure SpecificationDocument21 pagesWelding Procedure Specificationboypardede100% (9)

- Inspection Test Procedure ModelDocument8 pagesInspection Test Procedure ModelMahesh SuthaNo ratings yet

- Section - I: Cover Page Section - II:: IndexDocument21 pagesSection - I: Cover Page Section - II:: Indexamit rajputNo ratings yet

- General Procedure of Manufacturing The Custom Built Sound Proof Enclosures With PanelsDocument14 pagesGeneral Procedure of Manufacturing The Custom Built Sound Proof Enclosures With PanelspawanNo ratings yet

- Ajin BabuDocument4 pagesAjin BabuJithuJohnNo ratings yet

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Total Quality Process Control for Injection MoldingFrom EverandTotal Quality Process Control for Injection MoldingRating: 5 out of 5 stars5/5 (1)

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AFrom EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANo ratings yet

- Construction Methodologies & Procedures for Civil Engineers - Part -1From EverandConstruction Methodologies & Procedures for Civil Engineers - Part -1No ratings yet

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- SCAFFOLDING - THE HANDBOOK FOR ESTIMATING and PRODUCT KNOWLEDGEFrom EverandSCAFFOLDING - THE HANDBOOK FOR ESTIMATING and PRODUCT KNOWLEDGENo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Good Documentation Practices (GDP) in Pharmaceutical IndustryFrom EverandGood Documentation Practices (GDP) in Pharmaceutical IndustryNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Aircraft Dispatcher Oral Exam Guide: Prepare for the FAA oral and practical exam to earn your Aircraft Dispatcher certificateFrom EverandAircraft Dispatcher Oral Exam Guide: Prepare for the FAA oral and practical exam to earn your Aircraft Dispatcher certificateNo ratings yet

- BGAS-CSWIP Welding and Coating Inspection: Certification, Process, Exam Preparation and Q&AFrom EverandBGAS-CSWIP Welding and Coating Inspection: Certification, Process, Exam Preparation and Q&ANo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Safety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesFrom EverandSafety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesNo ratings yet

- Construction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsFrom EverandConstruction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- Name Name Name Name: To: CCDocument1 pageName Name Name Name: To: CCAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldAnonymous 4e7GNjzGW100% (1)

- Weld Joint Preparation Weld Joint PreparationDocument1 pageWeld Joint Preparation Weld Joint PreparationAnonymous 4e7GNjzGWNo ratings yet

- Kafou Health Safety Loss Prevention ProgramDocument117 pagesKafou Health Safety Loss Prevention ProgramAnonymous 4e7GNjzGWNo ratings yet

- Warrior Tech Spare Parts List 2Document1 pageWarrior Tech Spare Parts List 2Anonymous 4e7GNjzGWNo ratings yet

- Shielded Metal Arc Welding (Smaw / "Stick") Shielded Metal Arc Welding (Smaw / Â Œstickâ )Document2 pagesShielded Metal Arc Welding (Smaw / "Stick") Shielded Metal Arc Welding (Smaw / Â Œstickâ )Anonymous 4e7GNjzGWNo ratings yet

- QW484Document1 pageQW484Anonymous 4e7GNjzGWNo ratings yet

- SKTCO ISO 9001 2008 Gap Analysis ChecklistDocument17 pagesSKTCO ISO 9001 2008 Gap Analysis ChecklistAnonymous 4e7GNjzGWNo ratings yet

- Bio Data-01.07.13Document2 pagesBio Data-01.07.13Anonymous 4e7GNjzGWNo ratings yet

- Request For Inspection: Client: Contractor: Contract No. Rfi No. Project: Location: Date: Description of InspectionDocument2 pagesRequest For Inspection: Client: Contractor: Contract No. Rfi No. Project: Location: Date: Description of InspectionAnonymous 4e7GNjzGWNo ratings yet

- Numbering Format: Project DocumentationDocument1 pageNumbering Format: Project DocumentationAnonymous 4e7GNjzGWNo ratings yet

- HSMC Employee Induction Procedure (Offices)Document3 pagesHSMC Employee Induction Procedure (Offices)Anonymous 4e7GNjzGWNo ratings yet

- Notes-Api Exams-Prathap DhasDocument7 pagesNotes-Api Exams-Prathap DhasAnonymous 4e7GNjzGWNo ratings yet

- G. Std. ITP For Pipeline Job PDFDocument4 pagesG. Std. ITP For Pipeline Job PDFAnonymous 4e7GNjzGW100% (1)

- 5 Page Ses Resume SampleDocument7 pages5 Page Ses Resume Samplevofysyv1z1v3100% (1)

- Labor Eco Ques BankDocument8 pagesLabor Eco Ques BankNitesh N AjwaniNo ratings yet

- Junior Analyst - Bayt PDFDocument1 pageJunior Analyst - Bayt PDFshane kairuNo ratings yet

- Employers QuestionnaireDocument2 pagesEmployers QuestionnaireJoywins7No ratings yet

- Adverb PhrasesDocument10 pagesAdverb PhraseslilytiangNo ratings yet

- Trade Union Act, 1926Document48 pagesTrade Union Act, 1926Naberius Orca100% (1)

- II.C.9 Coca-Cola Bottlers v. Agito, February 13, 2009Document5 pagesII.C.9 Coca-Cola Bottlers v. Agito, February 13, 2009Jin AghamNo ratings yet

- Nda Vs Cir & Ntwu - G.R. No. L-15422 - Nov 30, 1962Document3 pagesNda Vs Cir & Ntwu - G.R. No. L-15422 - Nov 30, 1962ELMER T. SARABIANo ratings yet

- Google People Operations - The Secrets of The World's Most Scientific Human Resources DepartmentDocument3 pagesGoogle People Operations - The Secrets of The World's Most Scientific Human Resources DepartmentAtul KohliNo ratings yet

- Organizational Behavior Multiple Choice QuizDocument3 pagesOrganizational Behavior Multiple Choice QuizMuhammad YahyaNo ratings yet

- Online Indian Astrology, Indian Vedic Astrology, Future Predictions, Horoscopes, Astrological Remedies, Astrological SolutionsDocument3 pagesOnline Indian Astrology, Indian Vedic Astrology, Future Predictions, Horoscopes, Astrological Remedies, Astrological SolutionsDeepak MishraNo ratings yet

- Vietnamese Coffee Shop Opening ProjectDocument12 pagesVietnamese Coffee Shop Opening ProjectNgoc Tuan Anh BuiNo ratings yet

- In Tray GuideDocument10 pagesIn Tray Guidejitendrasutar1975No ratings yet

- CMQ Exam 4 - ResponsesDocument40 pagesCMQ Exam 4 - ResponsesVusal AgakisiyevNo ratings yet

- Review Jurnal - 3Document20 pagesReview Jurnal - 3eko hadiNo ratings yet

- HealthCo+Workforce Diversity and Wellness Kel 2 FIXDocument24 pagesHealthCo+Workforce Diversity and Wellness Kel 2 FIXDandy100% (1)

- Rephrase PT OlimpiadaDocument8 pagesRephrase PT OlimpiadaRoxana Elena Vasile100% (1)

- Virtusa PDFDocument2 pagesVirtusa PDFAllu Vijay100% (1)

- Entrepreneurial CompetenciesDocument7 pagesEntrepreneurial Competenciesamit_sepl100% (1)

- Fulltxt PDFDocument98 pagesFulltxt PDFAnkita RaniNo ratings yet

- Incentive SGS & SGL March 2020 Paid On Payroll Juli Region Cluster Employee ID Employee Name Amount PositionDocument10 pagesIncentive SGS & SGL March 2020 Paid On Payroll Juli Region Cluster Employee ID Employee Name Amount PositionZiki PermanaNo ratings yet

- Report of The National Commission On LabourDocument169 pagesReport of The National Commission On LabourshailendrachimadeNo ratings yet

- Leadership Theories and Educational Management: An Insight: June 2015Document10 pagesLeadership Theories and Educational Management: An Insight: June 2015Godofredo HermosuraNo ratings yet

- Public Personnel AdministrationDocument8 pagesPublic Personnel AdministrationChristian ChavezNo ratings yet

- Eis Assignment - V1aDocument2 pagesEis Assignment - V1aSameera VadakelNo ratings yet

- MihretDocument3 pagesMihretaschalewteshome155No ratings yet

- Gender EqualityDocument11 pagesGender EqualityTeresa FariaNo ratings yet