Professional Documents

Culture Documents

J P Mukherji & Associates Pvt. Ltd. Basic Project Parameters

J P Mukherji & Associates Pvt. Ltd. Basic Project Parameters

Uploaded by

Anonymous 7ZYHilDOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

J P Mukherji & Associates Pvt. Ltd. Basic Project Parameters

J P Mukherji & Associates Pvt. Ltd. Basic Project Parameters

Uploaded by

Anonymous 7ZYHilDCopyright:

Available Formats

J P MUKHERJI & ASSOCIATES PVT. LTD.

TSFP

BASIC PROJECT PARAMETERS

Section-VI-A

Page - 1/6

BID DOCUMENT FOR

DIESEL POWER GENERATION PLANT

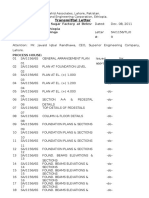

TABLE OF CLAUSES

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

11.0

12.0

GENERAL INFORMATION ........................................................................................ 2

GENERAL SITE DATA ............................................................................................... 2

PROVISION OF WATER SUPPLY............................................................................. 3

PREVAILING WIND.................................................................................................... 3

CANE QUALITY AND THROUGHPUT ...................................................................... 3

EXPECTED PERFORMANCE ................................................................................... 4

PRODUCT QUANTITY & QUALITY ........................................................................... 4

STORAGE REQUIREMENTS .................................................................................... 4

COGENERATION....................................................................................................... 4

STEAM GENERATION............................................................................................... 5

ELECTRCIAL SYSTEM PARAMETERS .................................................................... 5

EXPECTED FACTORY TIME ACCOUNT .................................................................. 6

J P MUKHERJI & ASSOCIATES PVT. LTD.

TSFP

BASIC PROJECT PARAMETERS

Section-VI-A

Page - 2/6

BID DOCUMENT FOR

DIESEL POWER GENERATION PLANT

SECTION - VI-A

BASIC PROJECT PARAMETERS

BASIC PARAMETERS TO BE CONSIDERED FOR THE PROJECT (WHEREVER

APPLICABLE)

1.0

GENERAL INFORMATION

The objective of the Tendaho Sugar project is to establish a new sugar plant with a

total design cane crushing capacity of 26,000 tons per day to produce about

600,000- tons/annum of raw sugar and 50 % of raw sugar is to be refined to produce

refined sugar of EEC Grade II specifications. The project site comprises of Tendaho

dam and the proposed sugar factory which is located in the lower portion [delta

region] of the Awash basin and in Afar Regional State of Ethiopia. The dam site is

located 575 km away from Addis Ababa, capital city of Ethiopia, and is connected

through a very well developed highway from Addis Ababa to City of Djubouti.

Semera is the new capital city of the Afar Regional State, which is still under

construction, is located on the Addis Ababa Djubouti highway at a distance of 580

km from Addis Ababa. Logia, Dubti and Asaita are other towns in the nearby area.

The detailed picture of Ethiopia showing Tendaho is shown in Figure 1a and the

project area/Site is shown in Figure 1b.

2.0

GENERAL SITE DATA

Road approach

Project site is located in the lower Awash valley of the

Afar Administration region and about 600 km North

East to Addis Ababa. Road transport on all weathered

surfaced road almost up to the site is available.

Sea Port

Port of entry for imported goods by marine transport is

Port Djibouti. The transportation from Port Djibouti to

Tendaho site is by Addis Djibouti tarmac highway.

Air Port

Port of entry for air transport is Addis Ababa (about 600

km from project site).

Factory coordinates

Height above msl

Rainy season

Average rainfall

UTME 764700 E and UTME 1278600 N

350 m

July to October

235 mm

Climatic condition

Hot & dry; climatic condition records indicate that the

hot season will normally restrict the crushing period to

about 39 Weeks, extending from October through to

June.

J P MUKHERJI & ASSOCIATES PVT. LTD.

TSFP

BASIC PROJECT PARAMETERS

Section-VI-A

Page - 3/6

BID DOCUMENT FOR

DIESEL POWER GENERATION PLANT

Relative humidity

Wet bulb temperature

Dry bulb temperature

Ambient temperature

Seismic data

3.0

4.0

96 % Max & 37% Min

24 C

39 C

Maximum 45 0C and Minimum17 0C

Located in seismic zone

PROVISION OF WATER SUPPLY

Water supply to factory

Awash water through Irrigation

Canals upto factory water sump.

For cooling and service water

Re-circulation and cooling by

cooling towers

For drinking water in Factory

Treated canal water

For sugar plant condensers

Once through (receive from

canal, use and discharge to

canal)

For DEC condenser

Re-circulation and cooling by

cooling towers

PREVAILING WIND

During the milling season the prevailing winds are approximately South Westerly

from May to October, North-easterly from November to April. The factory building

should be designed for wind speed of 79 km/h.

5.0

CANE QUALITY AND THROUGHPUT

Cane harvesting

Burnt cane manually and/or

mechanically

harvested

and

mechanically

loaded

before

transport to factory

Pol % Cane

12.98

Fibre % cane (average)

(For sugar factory capacity)

(For cogeneration plant capacity)

13.79

14.50

13.79

Bx % Primary Juice

Purity of Primary Juice

Cane through put

20.30

85.20

1,085 TCH

26,040 TCD on 24 hours basis

J P MUKHERJI & ASSOCIATES PVT. LTD.

TSFP

BASIC PROJECT PARAMETERS

Section-VI-A

Page - 4/6

BID DOCUMENT FOR

DIESEL POWER GENERATION PLANT

Margin for expansion

6.0

No margin need to be considered

in selection of equipment for

future expansion

Reduced mill extraction (RME)

- milling plant

- diffusion plant

96 %

97.5 %

Reduced boiling house recovery (RBHR)

90%

Imbibition % fibre

250 (max) for milling

350 (max) for Diffusion

Raw sugar

Direct consumption White sugar

Refined sugar

Specification of refined sugar

Refined Sugar expansion

100% of production

Nil

50 % of raw sugar produced to

be refined

EEC Gr2

Space is to be provided for future

expansion to 100 % refined

sugar.

EXPECTED PERFORMANCE

Performance (targeted) at 1085 TCH

7.0

8.0

9.0

PRODUCT QUANTITY & QUALITY

STORAGE REQUIREMENTS

Raw sugar storage

Bulk storage; maximum 100,000

t inside the factory premises.

Refined sugar storage

50 kg woven polythene sacks; 2

warehouses each suitable for

400,000 sacks with maximum 45

layers i.e. capacity of each

warehouse 20,000 t sugar.

Final Molasses

30 % of production in steel tanks

i.e. 5 tanks each of 10,000 cum

270 days

95 %

98 %

COGENERATION

Duration of Operation

No of operating days During Season

Time efficiency

Grid availability

J P MUKHERJI & ASSOCIATES PVT. LTD.

TSFP

BASIC PROJECT PARAMETERS

Section-VI-A

Page - 5/6

BID DOCUMENT FOR

DIESEL POWER GENERATION PLANT

Fuel

Auxiliary fuel

10.0

11.0

Bagasse

Fuel Oil (Bunker C grade)

STEAM GENERATION

No of boilers

Main fuel

Auxiliary fuel

Capacity of each boiler

Nos.

t/h

5

Bagasse

Furnace oil

150

Pressure at main

steam stop valve

bar (a)

66

Temperature at

Superheater outlet

510 5

ELECTRCIAL SYSTEM PARAMETERS

Generation

Factory distribution

-

Voltage

Frequency Hz

Phase

11000 V

50

3

Voltage

Frequency Hz

Phase

11000 & 400 V

50

3

110 & 230 V

50

3

110 V

230000 V

50

3

Lighting system, Control & instrumentation

Voltage

Frequency Hz

Phase

DC Power

Power Export

-

Voltage

Frequency Hz

Phase

Other Voltages

Low Voltage

Welding supplies

Socket outlets

Anti-condensation heater

Portable tool

Hand lamp transformers

Control circuit

Emergency lighting

Tripping supplies

400 V

400 V

400 V/230V

230 V

230 V

230 V

110 V

230 V

110 V

3 ph

3 ph

3ph /1 ph

1 ph

1 ph

1 ph

DC

1ph

DC

50 Hz

50 Hz

50 Hz

50 Hz

50 Hz

50 Hz

50Hz

J P MUKHERJI & ASSOCIATES PVT. LTD.

TSFP

BASIC PROJECT PARAMETERS

Section-VI-A

Page - 6/6

BID DOCUMENT FOR

DIESEL POWER GENERATION PLANT

12.0

EXPECTED FACTORY TIME ACCOUNT

-

Gross campaign hours in a year

Out of cane hours

Preventive maintenance hours

Net milling hours

Un planned stoppages hours

Actual grinding hours

6480 hrs

324 hrs

432 hrs

5724 hrs

216 hrs

5508 hrs

(100.00 %)

(5.00 %)

(6.67 %)

(88.33 %)

(3.33 %)

(85.00 %)

You might also like

- Industrial Training Report (ADTPS)Document16 pagesIndustrial Training Report (ADTPS)Shahid Tavar100% (2)

- DH3-31MA-T-SCT-0001 Commissioning Procedure of Complete-Set Startup of Steam Turbine REV.0Document24 pagesDH3-31MA-T-SCT-0001 Commissioning Procedure of Complete-Set Startup of Steam Turbine REV.0Lan Rung100% (1)

- Pe D A09134227266 Ge Sow 003 01 E - Sow Epcm Sgi MunteniDocument13 pagesPe D A09134227266 Ge Sow 003 01 E - Sow Epcm Sgi MunteniIoana PopescuNo ratings yet

- Sugar Plant Energy ConservationDocument24 pagesSugar Plant Energy Conservationtsrinivasan5083100% (5)

- J P Mukherji & Associates Pvt. Ltd. Basic Project ParametersDocument6 pagesJ P Mukherji & Associates Pvt. Ltd. Basic Project ParametersAnonymous 7ZYHilDNo ratings yet

- J P Mukherji & Associates Pvt. Ltd. Basic Project ParametersDocument5 pagesJ P Mukherji & Associates Pvt. Ltd. Basic Project ParametersAnonymous 7ZYHilDNo ratings yet

- IPTC-20219-MS A Systematic Approach To Increase Banyu Urip Crude OilDocument15 pagesIPTC-20219-MS A Systematic Approach To Increase Banyu Urip Crude OilGilbert OmittaNo ratings yet

- 30 Tons /day Ice PlantDocument4 pages30 Tons /day Ice PlantsureshNo ratings yet

- Process Design Basis Process Design BasisDocument17 pagesProcess Design Basis Process Design Basisdeion29100% (3)

- Sobreprecio 18MM: TM2500 de EPS A DerwickDocument33 pagesSobreprecio 18MM: TM2500 de EPS A DerwickTomás LanderNo ratings yet

- 00 Ta - S 41 002 001Document136 pages00 Ta - S 41 002 001BALACHITRA100% (2)

- Meshak Control Room OperatorDocument7 pagesMeshak Control Room Operatormsk649No ratings yet

- Com .& Start-Up Strategy 120926Document24 pagesCom .& Start-Up Strategy 120926rodinsendiong100% (1)

- Internship PDFDocument39 pagesInternship PDFFaizan MirNo ratings yet

- Nandpur: Gas Field, OgdclDocument5 pagesNandpur: Gas Field, OgdclAsad Ul HaqNo ratings yet

- ResumeDocument7 pagesResumeponthirumaranNo ratings yet

- Bread: 1.0 Product and Its ApplicationsDocument7 pagesBread: 1.0 Product and Its ApplicationsS_VenkatNo ratings yet

- Site VisitDocument10 pagesSite VisitAhmadNo ratings yet

- GLO-T800-PRO-EVA-TEC-000-00001-00 H01 (GLO Fuel Gas System Study Report For Gendalo FPU)Document100 pagesGLO-T800-PRO-EVA-TEC-000-00001-00 H01 (GLO Fuel Gas System Study Report For Gendalo FPU)Tifano Khristiyanto100% (3)

- File - 20220609 - 210203 - Ce Handing Over NotesDocument5 pagesFile - 20220609 - 210203 - Ce Handing Over NotesPhuc ChuNo ratings yet

- DPR Power PlantDocument22 pagesDPR Power PlantSandip Ray100% (1)

- Aker Kvaerner Design On Fixed TopsideDocument9 pagesAker Kvaerner Design On Fixed TopsideVăn HoàngNo ratings yet

- M20CDocument79 pagesM20CMuhammad AsifNo ratings yet

- PocketDiary SantaldihDocument198 pagesPocketDiary SantaldihJoydev GangulyNo ratings yet

- My CV Senior OeratorDocument8 pagesMy CV Senior OeratorSandesh RamdharneNo ratings yet

- Gharissa Ice Pilot Plant Qatar PDFDocument6 pagesGharissa Ice Pilot Plant Qatar PDFSanu PhilipNo ratings yet

- Harmonic AnalysisDocument17 pagesHarmonic Analysiscuongpham30160% (5)

- 2 - 1!01!02 - Basic Operation Concept For Turbine and Auxiliary Plant - r00Document59 pages2 - 1!01!02 - Basic Operation Concept For Turbine and Auxiliary Plant - r00Tiara Noir100% (3)

- Process Control and Shutdown PhilosophyDocument14 pagesProcess Control and Shutdown PhilosophyJoanrenis SaranyaNo ratings yet

- Vol II Rev 0Document637 pagesVol II Rev 0Anonymous nwByj9LNo ratings yet

- Lakwagaon - NIT - OILPROJECT - CNP - 62 - LKN - 01Document7 pagesLakwagaon - NIT - OILPROJECT - CNP - 62 - LKN - 01Sunil WadekarNo ratings yet

- Training Report MC 1-1Document60 pagesTraining Report MC 1-1Raj KumarNo ratings yet

- 2 of 25 - NIT For PGR at NFL Vijaipur - Tech NITDocument72 pages2 of 25 - NIT For PGR at NFL Vijaipur - Tech NITsudhirkumar99No ratings yet

- SGT-600 GT PowerGen ENDocument4 pagesSGT-600 GT PowerGen ENBehnamayoubzadehNo ratings yet

- Project Report On Rihand STPP Stage-II 2x500mwDocument175 pagesProject Report On Rihand STPP Stage-II 2x500mwSathesh ThangathuraiNo ratings yet

- C6.6 Generator Set C6T00001-UP (SEBP4820 - 23) - DocumentationDocument3 pagesC6.6 Generator Set C6T00001-UP (SEBP4820 - 23) - DocumentationFrancisco Eric CelestinoNo ratings yet

- Bhel (Transformer) Major TrainingDocument33 pagesBhel (Transformer) Major TrainingArpitSinghNo ratings yet

- My Siwes ReportDocument71 pagesMy Siwes ReportOrji Christian100% (2)

- Diesel Refinery BrochureDocument14 pagesDiesel Refinery BrochureHansphillipsNo ratings yet

- Complete Details On Bottle Grade SSP Plant SetupDocument26 pagesComplete Details On Bottle Grade SSP Plant SetupMK YogiNo ratings yet

- Prefeasibility Report Rajasthan Ganganagar As Per MoEF GuidelinesDocument25 pagesPrefeasibility Report Rajasthan Ganganagar As Per MoEF GuidelinesAmol DeshmukhNo ratings yet

- Task 2 Final Report PDFDocument94 pagesTask 2 Final Report PDFcarzanteNo ratings yet

- Sadaqat 1Document40 pagesSadaqat 1Umar DrazNo ratings yet

- Internship Report 2022Document25 pagesInternship Report 2022trick masterNo ratings yet

- Caterpillar CG260 - 60 y 50 HZDocument5 pagesCaterpillar CG260 - 60 y 50 HZEdutam67% (3)

- Cooker & Cooler & Mixer-Ccm-5: Uzermak Gida Endustri Mak. San. Ve Tic. A.SDocument8 pagesCooker & Cooler & Mixer-Ccm-5: Uzermak Gida Endustri Mak. San. Ve Tic. A.SSoli PapNo ratings yet

- Aggreko PPTDocument27 pagesAggreko PPTVaibhav KumarNo ratings yet

- Pon Vijay Gas Processing OpDocument4 pagesPon Vijay Gas Processing Opjohn MNo ratings yet

- Energy Conservation in Sugar IndustriesDocument7 pagesEnergy Conservation in Sugar IndustriesKetty Puspa JayantiNo ratings yet

- DNIT PM & RM LIS Keoli Approved From Circle OfficeDocument23 pagesDNIT PM & RM LIS Keoli Approved From Circle OfficeSuperintending Engineer IPH Circle SundernagarNo ratings yet

- Infinity Turbine BrochureDocument4 pagesInfinity Turbine BrochureDeepali Fulwani Sawanpally0% (1)

- 60 BPM CSD For 250 ML Arvind AquaDocument17 pages60 BPM CSD For 250 ML Arvind AquaOMKAR JADHAVNo ratings yet

- Biscuit Project Profile - Smallb SIDBI PDFDocument7 pagesBiscuit Project Profile - Smallb SIDBI PDFAnonymous EAineTizNo ratings yet

- Serck Services CatalogueDocument44 pagesSerck Services CatalogueMorgan PalmaNo ratings yet

- Ras Az Zawr FileDocument20 pagesRas Az Zawr FileMohammad Sazid AlamNo ratings yet

- Waste to Energy in the Age of the Circular Economy: Compendium of Case Studies and Emerging TechnologiesFrom EverandWaste to Energy in the Age of the Circular Economy: Compendium of Case Studies and Emerging TechnologiesRating: 5 out of 5 stars5/5 (1)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- 5.Covers-division Page of the Annex 26(完整)Document16 pages5.Covers-division Page of the Annex 26(完整)Anonymous 7ZYHilDNo ratings yet

- 3.part I General ConditionsDocument36 pages3.part I General ConditionsAnonymous 7ZYHilDNo ratings yet

- Awash Garage Maintenance ToollsDocument11 pagesAwash Garage Maintenance ToollsAnonymous 7ZYHilDNo ratings yet

- General Manpower Nos.: Total 498 Experts of OEM Personnel Man X MonthsDocument6 pagesGeneral Manpower Nos.: Total 498 Experts of OEM Personnel Man X MonthsAnonymous 7ZYHilDNo ratings yet

- Metals and Engineering Corporation: Siddaca Faage 137.5Mw Biomass Fired Thermal Power Plant Project Working ProgressDocument29 pagesMetals and Engineering Corporation: Siddaca Faage 137.5Mw Biomass Fired Thermal Power Plant Project Working ProgressAnonymous 7ZYHilDNo ratings yet

- 4E@RT-P170011B Design Shedule-2018.01.29 OkDocument2 pages4E@RT-P170011B Design Shedule-2018.01.29 OkAnonymous 7ZYHilDNo ratings yet

- Transmittal Letter: New Sugar Factory at Beles-1, Ethiopia DrawingsDocument2 pagesTransmittal Letter: New Sugar Factory at Beles-1, Ethiopia DrawingsAnonymous 7ZYHilDNo ratings yet

- Sixe MONTH REPORTE - New1Document16 pagesSixe MONTH REPORTE - New1Anonymous 7ZYHilDNo ratings yet

- Bill No - Civile Work WeigtageDocument3 pagesBill No - Civile Work WeigtageAnonymous 7ZYHilDNo ratings yet

- Cover PagesDocument4 pagesCover PagesAnonymous 7ZYHilDNo ratings yet

- Beles 1 Total Foundation Drawing ListDocument8 pagesBeles 1 Total Foundation Drawing ListAnonymous 7ZYHilDNo ratings yet

- Girmay - 9 July 2014 Cover PageDocument3 pagesGirmay - 9 July 2014 Cover PageAnonymous 7ZYHilDNo ratings yet

- Hotel Op Level LDocument14 pagesHotel Op Level LAnonymous 7ZYHilDNo ratings yet

- Mogule For Orking With Colleagues and CustomersDocument99 pagesMogule For Orking With Colleagues and CustomersAnonymous 7ZYHilDNo ratings yet