Professional Documents

Culture Documents

Aeroenfriador Ac-100 API Sheet Si

Aeroenfriador Ac-100 API Sheet Si

Uploaded by

Hernan CobaCopyright:

Available Formats

You might also like

- Data Sheet: LPG Filling Pump P-001/002/003/004/005/006Document5 pagesData Sheet: LPG Filling Pump P-001/002/003/004/005/006Denstar Ricardo Silalahi100% (1)

- Fluid Flow Hydraulics Sizing and Selection Rev WebDocument58 pagesFluid Flow Hydraulics Sizing and Selection Rev WebHitendra Panchal100% (1)

- Data Sheet: Description Unit Design DataDocument1 pageData Sheet: Description Unit Design DataEDUARDONo ratings yet

- Plate ExchangerDocument2 pagesPlate ExchangerEDUARDONo ratings yet

- DAT Exchanger PlateDocument2 pagesDAT Exchanger PlateEDUARDONo ratings yet

- Sp-210-E-103 Rev 0Document7 pagesSp-210-E-103 Rev 0Natarajan RavisankarNo ratings yet

- Air-Cooled Heat Exchanger Specification SheetDocument4 pagesAir-Cooled Heat Exchanger Specification SheetPanca KurniawanNo ratings yet

- Techstuff 3.09Document130 pagesTechstuff 3.09Víctor Rojas100% (1)

- Fire Water Make Up PumpDocument7 pagesFire Water Make Up PumpAlvin SmithNo ratings yet

- Chiller - TDSDocument5 pagesChiller - TDSKaviyarasu ENo ratings yet

- At SelectDocument1 pageAt Selectvishal.nithamNo ratings yet

- Reciprocating CompressorDocument6 pagesReciprocating CompressorEDUARDONo ratings yet

- 3Ph Horiz Sep 2010 Weir VerA SIDocument5 pages3Ph Horiz Sep 2010 Weir VerA SIBrenda DavisNo ratings yet

- Control Valves Specification Sheet PDFDocument2 pagesControl Valves Specification Sheet PDFjhonjimenez87No ratings yet

- 2phase Separator Size 2010 VerAADocument22 pages2phase Separator Size 2010 VerAAAnonymous a4Jwz14WNo ratings yet

- Shell-And-Tube Heat Exchanger: Performance of One UnitDocument4 pagesShell-And-Tube Heat Exchanger: Performance of One UnitGio Ibarra MolinaNo ratings yet

- Sewagw Treatment FilterDocument1 pageSewagw Treatment FilterEDUARDONo ratings yet

- English Unit Spec SheetDocument3 pagesEnglish Unit Spec SheetDanang PrakosaNo ratings yet

- Thumb Rules Xls For Chemical EngineerDocument44 pagesThumb Rules Xls For Chemical EngineershashibagewadiNo ratings yet

- Thumb Rules For Chemical EngineerDocument44 pagesThumb Rules For Chemical EngineerNallathambiNo ratings yet

- Giw1 GiwDocument4 pagesGiw1 GiwMihai AlexandruNo ratings yet

- Data Sheet: Hydraulic Power UnitDocument3 pagesData Sheet: Hydraulic Power UnitEDUARDONo ratings yet

- Air System Sizing Summary For LFS - EQUIPMENTDocument1 pageAir System Sizing Summary For LFS - EQUIPMENTHo Ngoc Thanh QuangNo ratings yet

- Output Summary: See Runtime Message Report For Warning MessagesDocument3 pagesOutput Summary: See Runtime Message Report For Warning MessagesSimranjeet SinghNo ratings yet

- Design of Shell & Tube HXDocument40 pagesDesign of Shell & Tube HXprateek_bhoirNo ratings yet

- 3PHASE Gas Separator - V2105 - 4.7x16 - For - OriginalDocument44 pages3PHASE Gas Separator - V2105 - 4.7x16 - For - Originalvgogulakrishnan100% (1)

- Phe PDSDocument4 pagesPhe PDSprabhuarunkumarNo ratings yet

- Air System Sizing Summary For GDC-CONTROL-ELECTRICDocument1 pageAir System Sizing Summary For GDC-CONTROL-ELECTRICHo Ngoc Thanh QuangNo ratings yet

- Air-Cooled Heat Exchanger Specification SheetDocument1 pageAir-Cooled Heat Exchanger Specification SheetaanNo ratings yet

- Heat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SideDocument1 pageHeat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SideMichael HaiseNo ratings yet

- Heat ExchangersDocument107 pagesHeat ExchangersMAMADO2015No ratings yet

- 2019-250 MW Barge Technical DiaryDocument33 pages2019-250 MW Barge Technical Diarydasnulmadi61No ratings yet

- Thermal Design Calculation Procedure (Rev 00)Document24 pagesThermal Design Calculation Procedure (Rev 00)mkfe2005No ratings yet

- Air System Sizing Summary For LFS-OFFICEDocument1 pageAir System Sizing Summary For LFS-OFFICEHo Ngoc Thanh QuangNo ratings yet

- Aspen 1 PDFDocument6 pagesAspen 1 PDFQamar AbbasNo ratings yet

- Self-Actuator Pressure Control Valve Data Sheet: End Conn. & RatingDocument2 pagesSelf-Actuator Pressure Control Valve Data Sheet: End Conn. & RatingHo KimNo ratings yet

- Filter Separator Revised Feb 19 2004Document1 pageFilter Separator Revised Feb 19 2004motalebyNo ratings yet

- Reciprocating Plunger Pump Data SheetDocument1 pageReciprocating Plunger Pump Data SheetSubodh KumarNo ratings yet

- 02 - Heat ExchangersDocument107 pages02 - Heat ExchangersMaheshNo ratings yet

- Heat Exchanger Spec SheetDocument1 pageHeat Exchanger Spec SheetAnnabellee ChuaNo ratings yet

- Air System Sizing Summary For GDC-CONTROL-PCOSB 101Document1 pageAir System Sizing Summary For GDC-CONTROL-PCOSB 101Ho Ngoc Thanh QuangNo ratings yet

- Hex-301 0209Document29 pagesHex-301 0209qilaqrsNo ratings yet

- Flowlink Industries Pvt. LTDDocument1 pageFlowlink Industries Pvt. LTDSurinder LuthraNo ratings yet

- 07-3116 333 EC-33301 Iss - 0Document5 pages07-3116 333 EC-33301 Iss - 0rajuNo ratings yet

- Htri Trial PDFDocument39 pagesHtri Trial PDFcroprobosNo ratings yet

- Obtencion de AcetonaDocument7 pagesObtencion de AcetonaLiz Laureano RodriguezNo ratings yet

- Sab87 Sab81 2stage Nh3Document2 pagesSab87 Sab81 2stage Nh3Yutt WattNo ratings yet

- Pump SpecificationDocument1 pagePump SpecificationFrancis FeiNo ratings yet

- PSVDocument8 pagesPSVtetiospamNo ratings yet

- Cyclone Type Separator Revised Feb 19 2004Document1 pageCyclone Type Separator Revised Feb 19 2004Dayo IdowuNo ratings yet

- Equipos para Procesos Intercambiadores de Calor 1: Heat Exchanger Specification SheetDocument1 pageEquipos para Procesos Intercambiadores de Calor 1: Heat Exchanger Specification SheetAlejandro EchevarriaNo ratings yet

- Seminar JournalDocument36 pagesSeminar Journaladharshaj2255No ratings yet

- Karbala Refinary Project: Preparing Fatima Ali MahdiDocument28 pagesKarbala Refinary Project: Preparing Fatima Ali Mahdiضياء محمدNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Geothermal Pipe Line DesignDocument15 pagesGeothermal Pipe Line DesignjohnjuantamadNo ratings yet

- FGS - Engineering & PipingDocument36 pagesFGS - Engineering & PipingHernan CobaNo ratings yet

- Ferrous Materials and MetallurgyDocument1,372 pagesFerrous Materials and MetallurgyHernan Coba0% (2)

- Optimal Operation of An Ammonia Refrigeration CycleDocument16 pagesOptimal Operation of An Ammonia Refrigeration CycleHernan CobaNo ratings yet

- Boiler Inspection TechniquesDocument288 pagesBoiler Inspection TechniquesHernan Coba100% (1)

- HVAC Essentials GuideDocument120 pagesHVAC Essentials GuideHernan CobaNo ratings yet

- Introduction To Practical Fluid FlowDocument375 pagesIntroduction To Practical Fluid FlowHernan Coba100% (2)

Aeroenfriador Ac-100 API Sheet Si

Aeroenfriador Ac-100 API Sheet Si

Uploaded by

Hernan CobaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aeroenfriador Ac-100 API Sheet Si

Aeroenfriador Ac-100 API Sheet Si

Uploaded by

Hernan CobaCopyright:

Available Formats

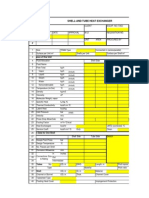

Aspen Exchanger Design and Rating

Air Cooled V8.8

Page 1

File: C:\Users\barragar\Desktop\EHX901 Application workshop\AC-100.edr

Printed: 10/28/2015 at 10:14:38 AM

API Sheet

Air-Cooled Heat Exchanger Specification Sheet

1

2

3

4

Company:

Location:

Service of Unit:

Item No.:

Our Reference:

Your Reference:

Date:

Size & Type

Surf/Unit-Finned Tube

Heat exchanged

Transfer Rate-Finned

Rev No.:

9.1

Job No.:

440.9993

538339.8

99208.3

20.7

Forced

152.8

Type

Number of Bays

Bare area/bundle

Clean

Fluid Circulated

12

Total Fluid Entering

kg/h

In

14

Temperature

15

Liquid

795090

13

16

Vapor

17

Noncondensable

18

Steam

kg/h

19

Water

20

Molecular wt, Vap

86.38

0

795090

0

/

/

/

/

44.097

21

Molecular wt, NC

22

Viscosity, Liq

cp

23

Viscosity, Vap

cp

kg/m

kg/m

Density, Liq

In

C

kg/h

kg/h

kg/h

Out

Density, Vap

26.02

795090

0

0

Specific Heat, Liq

Specific Heat, Vap

Therm. Cond, Liq

Therm. Cond, Vap

Freeze Point

Bubble / Dew point

44.097

0.0991

0.0105

Pres Drop, Allow/Calc

Fouling resistance

22.25

2.11

0.0256

37.59

2.811

0.0943

37.77

1303.11

13.109

5.666

m-K/W

PERFORMANCE DATA - AIR SIDE

25

Air Quantity, Total

26

Air Quantity/Fan

27

Static Pressure

28

Face Velocity

40000000

675520.6

0.11

2.69 m/s Mass velocity

kg/h

m/h

Altitude

kPa

3.19 kg/s/m

Temperature Out

0

25

m

C

33.9

0

C

C

Temperature In

Design Ambient

DESIGN-MATERIALS-CONSTRUCTION

29

Design pressure

1700

kPa

32

Size

33

Number/bay

34

Tube Rows

35

Arrangement

36

Bundles

37

Bays

38

Bundle frame

Type

Material

Passes

par

Gasket Mat.

par

Corr. Allow.

MISCELLANEOUS

39

Box

Carbon Steel

5

Specifications

OD

Pitch

Outlet nozzle ( 1

Carbon Steel

Material

No./Bun

Inlet nozzle ( 1

Tube

Plug Mat.

3

50

200

Design temperature

Header

9.1

m

3

5

kPa

Test Pressure

TUBE BUNDLE

31

mm

mm

mm

97.18

42.85

60

Min Thk.

Lng

/

51.96

1.65

8.5

mm

m

30

Degrees

G-finned

Aluminum 1060

Type

Material

Struct. Mount.

Special Nozzles

OD

41

Surf.Prep

Rating

No. 433

42

Louvers

TI

43

Vibration Switches

Chem Cleaning

PI

25.4

230

FIN

40

57.15

#/m

0.28

Tks

Design Temp

mm

C

Code

Stamp

Specs

MECHANICAL EQUIPMENT

44

45

Fan,Mfr., Model

46

No./Bay

47

Dia.

48

Pitch

Angle

RPM

Rating

49

Blade(s)

Hub

Enclosure

Ratio

RPM

1

Blade(s)

6.4008 m

36.328

kW

MinAmb

Driver, Type

Speed Reducer, Type

Mfr.

Mfr.&Model

No./Bay

No./Bay

50

hp/Fan

51

Control Action on Air Failure-

52

Degree Control of Outlet Process Temperature

53

Recirculation

54

Plot Area

55

Notes:

58

Out

492.89

C

C

kJ/kg

kPa

kPa

Latent heat

/

/

kJ/(kg-K)

kJ/(kg-K)

W/(m-K)

W/(m-K)

Inlet pressure (abs)

24

57

50

23.49

C

W/(m-K)

PERFORMANCE DATA - TUBE SIDE

11

56

Area ratio

8.9

486.6

MTD, Eff

486.6

Bare, Service

10

30

m

m

kW

V/Phase/Hz

hp

Support

Louvers

Steam Coil

Drawing No.

Wt.Bundle

6302.1

Wt. Unit

No

945314.2

kg

You might also like

- Data Sheet: LPG Filling Pump P-001/002/003/004/005/006Document5 pagesData Sheet: LPG Filling Pump P-001/002/003/004/005/006Denstar Ricardo Silalahi100% (1)

- Fluid Flow Hydraulics Sizing and Selection Rev WebDocument58 pagesFluid Flow Hydraulics Sizing and Selection Rev WebHitendra Panchal100% (1)

- Data Sheet: Description Unit Design DataDocument1 pageData Sheet: Description Unit Design DataEDUARDONo ratings yet

- Plate ExchangerDocument2 pagesPlate ExchangerEDUARDONo ratings yet

- DAT Exchanger PlateDocument2 pagesDAT Exchanger PlateEDUARDONo ratings yet

- Sp-210-E-103 Rev 0Document7 pagesSp-210-E-103 Rev 0Natarajan RavisankarNo ratings yet

- Air-Cooled Heat Exchanger Specification SheetDocument4 pagesAir-Cooled Heat Exchanger Specification SheetPanca KurniawanNo ratings yet

- Techstuff 3.09Document130 pagesTechstuff 3.09Víctor Rojas100% (1)

- Fire Water Make Up PumpDocument7 pagesFire Water Make Up PumpAlvin SmithNo ratings yet

- Chiller - TDSDocument5 pagesChiller - TDSKaviyarasu ENo ratings yet

- At SelectDocument1 pageAt Selectvishal.nithamNo ratings yet

- Reciprocating CompressorDocument6 pagesReciprocating CompressorEDUARDONo ratings yet

- 3Ph Horiz Sep 2010 Weir VerA SIDocument5 pages3Ph Horiz Sep 2010 Weir VerA SIBrenda DavisNo ratings yet

- Control Valves Specification Sheet PDFDocument2 pagesControl Valves Specification Sheet PDFjhonjimenez87No ratings yet

- 2phase Separator Size 2010 VerAADocument22 pages2phase Separator Size 2010 VerAAAnonymous a4Jwz14WNo ratings yet

- Shell-And-Tube Heat Exchanger: Performance of One UnitDocument4 pagesShell-And-Tube Heat Exchanger: Performance of One UnitGio Ibarra MolinaNo ratings yet

- Sewagw Treatment FilterDocument1 pageSewagw Treatment FilterEDUARDONo ratings yet

- English Unit Spec SheetDocument3 pagesEnglish Unit Spec SheetDanang PrakosaNo ratings yet

- Thumb Rules Xls For Chemical EngineerDocument44 pagesThumb Rules Xls For Chemical EngineershashibagewadiNo ratings yet

- Thumb Rules For Chemical EngineerDocument44 pagesThumb Rules For Chemical EngineerNallathambiNo ratings yet

- Giw1 GiwDocument4 pagesGiw1 GiwMihai AlexandruNo ratings yet

- Data Sheet: Hydraulic Power UnitDocument3 pagesData Sheet: Hydraulic Power UnitEDUARDONo ratings yet

- Air System Sizing Summary For LFS - EQUIPMENTDocument1 pageAir System Sizing Summary For LFS - EQUIPMENTHo Ngoc Thanh QuangNo ratings yet

- Output Summary: See Runtime Message Report For Warning MessagesDocument3 pagesOutput Summary: See Runtime Message Report For Warning MessagesSimranjeet SinghNo ratings yet

- Design of Shell & Tube HXDocument40 pagesDesign of Shell & Tube HXprateek_bhoirNo ratings yet

- 3PHASE Gas Separator - V2105 - 4.7x16 - For - OriginalDocument44 pages3PHASE Gas Separator - V2105 - 4.7x16 - For - Originalvgogulakrishnan100% (1)

- Phe PDSDocument4 pagesPhe PDSprabhuarunkumarNo ratings yet

- Air System Sizing Summary For GDC-CONTROL-ELECTRICDocument1 pageAir System Sizing Summary For GDC-CONTROL-ELECTRICHo Ngoc Thanh QuangNo ratings yet

- Air-Cooled Heat Exchanger Specification SheetDocument1 pageAir-Cooled Heat Exchanger Specification SheetaanNo ratings yet

- Heat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SideDocument1 pageHeat Exchanger Specification Sheet: Performance of One Unit Shell Side Tube SideMichael HaiseNo ratings yet

- Heat ExchangersDocument107 pagesHeat ExchangersMAMADO2015No ratings yet

- 2019-250 MW Barge Technical DiaryDocument33 pages2019-250 MW Barge Technical Diarydasnulmadi61No ratings yet

- Thermal Design Calculation Procedure (Rev 00)Document24 pagesThermal Design Calculation Procedure (Rev 00)mkfe2005No ratings yet

- Air System Sizing Summary For LFS-OFFICEDocument1 pageAir System Sizing Summary For LFS-OFFICEHo Ngoc Thanh QuangNo ratings yet

- Aspen 1 PDFDocument6 pagesAspen 1 PDFQamar AbbasNo ratings yet

- Self-Actuator Pressure Control Valve Data Sheet: End Conn. & RatingDocument2 pagesSelf-Actuator Pressure Control Valve Data Sheet: End Conn. & RatingHo KimNo ratings yet

- Filter Separator Revised Feb 19 2004Document1 pageFilter Separator Revised Feb 19 2004motalebyNo ratings yet

- Reciprocating Plunger Pump Data SheetDocument1 pageReciprocating Plunger Pump Data SheetSubodh KumarNo ratings yet

- 02 - Heat ExchangersDocument107 pages02 - Heat ExchangersMaheshNo ratings yet

- Heat Exchanger Spec SheetDocument1 pageHeat Exchanger Spec SheetAnnabellee ChuaNo ratings yet

- Air System Sizing Summary For GDC-CONTROL-PCOSB 101Document1 pageAir System Sizing Summary For GDC-CONTROL-PCOSB 101Ho Ngoc Thanh QuangNo ratings yet

- Hex-301 0209Document29 pagesHex-301 0209qilaqrsNo ratings yet

- Flowlink Industries Pvt. LTDDocument1 pageFlowlink Industries Pvt. LTDSurinder LuthraNo ratings yet

- 07-3116 333 EC-33301 Iss - 0Document5 pages07-3116 333 EC-33301 Iss - 0rajuNo ratings yet

- Htri Trial PDFDocument39 pagesHtri Trial PDFcroprobosNo ratings yet

- Obtencion de AcetonaDocument7 pagesObtencion de AcetonaLiz Laureano RodriguezNo ratings yet

- Sab87 Sab81 2stage Nh3Document2 pagesSab87 Sab81 2stage Nh3Yutt WattNo ratings yet

- Pump SpecificationDocument1 pagePump SpecificationFrancis FeiNo ratings yet

- PSVDocument8 pagesPSVtetiospamNo ratings yet

- Cyclone Type Separator Revised Feb 19 2004Document1 pageCyclone Type Separator Revised Feb 19 2004Dayo IdowuNo ratings yet

- Equipos para Procesos Intercambiadores de Calor 1: Heat Exchanger Specification SheetDocument1 pageEquipos para Procesos Intercambiadores de Calor 1: Heat Exchanger Specification SheetAlejandro EchevarriaNo ratings yet

- Seminar JournalDocument36 pagesSeminar Journaladharshaj2255No ratings yet

- Karbala Refinary Project: Preparing Fatima Ali MahdiDocument28 pagesKarbala Refinary Project: Preparing Fatima Ali Mahdiضياء محمدNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Geothermal Pipe Line DesignDocument15 pagesGeothermal Pipe Line DesignjohnjuantamadNo ratings yet

- FGS - Engineering & PipingDocument36 pagesFGS - Engineering & PipingHernan CobaNo ratings yet

- Ferrous Materials and MetallurgyDocument1,372 pagesFerrous Materials and MetallurgyHernan Coba0% (2)

- Optimal Operation of An Ammonia Refrigeration CycleDocument16 pagesOptimal Operation of An Ammonia Refrigeration CycleHernan CobaNo ratings yet

- Boiler Inspection TechniquesDocument288 pagesBoiler Inspection TechniquesHernan Coba100% (1)

- HVAC Essentials GuideDocument120 pagesHVAC Essentials GuideHernan CobaNo ratings yet

- Introduction To Practical Fluid FlowDocument375 pagesIntroduction To Practical Fluid FlowHernan Coba100% (2)