Professional Documents

Culture Documents

Welding Symbol 1

Welding Symbol 1

Uploaded by

Edo DestradaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Symbol 1

Welding Symbol 1

Uploaded by

Edo DestradaCopyright:

Available Formats

3

Welding symbols 1

Butt/groove welds

The butt/groove welding symbols are shown in Fig. 3.1(ah).

Figure 3.1(a) illustrates a single-V butt/groove weld, which is the

commonest form of edge preparation for this type of weld.

Figure 3.1(b) shows a square butt/groove weld. This weld will be

limited to a maximum section thickness depending on the welding

process used. If a backing strip is used, the section thickness can be

increased considerably.

Guidance on edge preparations is included in BS EN 29692 and

ISO 9692: 1992, in which the range of thickness recommended for

this type of weld is 38 mm.

Without a backing strip, a maximum section thickness of 4 mm is

recommended with a gap equal to the thickness. With a backing

strip, a gap of 68 mm is recommended. Dimensions of edge preparations are not included with weld symbols in ISO 2553 but these

can be included with AWS symbols. This can make a drawing

complex and, in some cases, may lead to confusion. It is preferable

to include details of edge preparations in a Welding Procedure Specification (WPS).

Figure 3.1(c) shows a single bevel butt/groove weld. This edge

preparation is generally used when it is only possible to prepare one

edge of adjoining sections.

Figure 3.1(d) illustrates a single-U butt/groove weld, which is

used to restrict the quantity of weld metal required in sections

greater than 12 mm thick.

Figure 3.1(e) shows a single-J butt/groove weld. This weld is used

to restrict the quantity of weld metal required in sections greater

than 16 mm thick when it is only possible to prepare one edge of

adjoining sections.

Figure 3.1(f) illustrates a butt weld between plates with raised

edges (ISO) or edge weld on a flanged groove joint (AWS). The AWS

term is a more accurate description of this weld, which is an edge

weld, described in Section 4. In this weld the edges are melted down

to form a low strength sealing weld. In the AWS system, if full penetration is required, the welding symbol includes the melt-through

symbol (shown in Fig. 8.10 on page 21) placed on the opposite side

of the reference line.

Figures 3.1(g) and (h) indicate single-V and single bevel butt

welds with broad root faces. These symbols are included in ISO

2553 but not in AWS A2.498. They are illustrated in Fig. 3.1 but

best avoided, as described below.

Dimensions of a broad root face are specified in ISO 9692: 1992.

A root face of 23 mm is specified for section thicknesses of

540 mm, whereas for a single-V butt weld (Fig. 3.1(a)) a maximum

root face of 2 mm is used for thicknesses of 310 mm. This is unnecessarily confusing and it is recommended that the broad root face

Welding symbols on drawings

Designation

Illustration

Symbol

Single-V butt/groove

weld

(a)

Square butt/groove

weld

(b)

Single bevel

butt/groove weld

(c)

Single-U butt/groove

weld

(d)

Single-J butt/groove

weld

(e)

(f )

Butt weld between

plates with raised

edges (ISO)

Edge weld on a

flanged groove joint (AWS)

ISO

AWS

Single-V butt weld

with broad root face

(g)

Single bevel butt weld

with broad root face

(h)

3.1 (ah) Examples of elementary welding symbols 1.

Welding symbols 1

terms and symbols should be avoided. A root dimension can be

specified whatever its thickness and there is no point in having a

special definition broad root face when the root face is greater than

2 mm.

As stated previously, when ISO 2553 is used, the dimensions of

the edge preparations are not included as part of the welding symbol

and should be given as part of the WPS. With the AWS system, the

depth of the groove can be specified by a number on the left hand

side of the weld symbol. This dimension, subtracted from the

section thickness, will indicate the size of the root face (Fig. 3.2).

Weld cross-section

AWS

1

2

7

8

3

8

1

2

3.2 Size of root face (dimensions are in inches).

Welding symbols on drawings

You might also like

- Sandvik Metal Cutting Technology Training HandbookDocument364 pagesSandvik Metal Cutting Technology Training HandbookITL200_U95% (21)

- Design of WeldmentsDocument9 pagesDesign of Weldmentsssaramail100% (2)

- Starting Woodturning A Beginners GuideDocument15 pagesStarting Woodturning A Beginners Guideandrelessa01No ratings yet

- What's A Full Penetration WeldDocument17 pagesWhat's A Full Penetration WeldRichard B. Margarita100% (2)

- 8 Welding SymbolsDocument43 pages8 Welding Symbolsjamilhse77590% (1)

- Design of Welded Connections - AWSDocument43 pagesDesign of Welded Connections - AWSnunosobral100% (1)

- Q2-03, Smaw Teacher's Made LMTDocument6 pagesQ2-03, Smaw Teacher's Made LMTFelix MilanNo ratings yet

- HSS Radius 742c7a4e 5e10 4b0b 8ba8 A8516cdafd9fDocument14 pagesHSS Radius 742c7a4e 5e10 4b0b 8ba8 A8516cdafd9fTerraManNo ratings yet

- Chapter 6-Connections PDFDocument12 pagesChapter 6-Connections PDFTemesgenAbiy100% (2)

- Control Distortion During Design StageDocument5 pagesControl Distortion During Design StagebalamuruganNo ratings yet

- Cswip - Section 09-Welding SymbolsDocument14 pagesCswip - Section 09-Welding SymbolsNsidibe Michael Etim100% (1)

- Connections For Skewed BeamsDocument7 pagesConnections For Skewed BeamstrabajosicNo ratings yet

- Welding SymbolDocument52 pagesWelding SymbolShriram Avasarkar100% (5)

- 08 Welding Symbols 30-03-07 - NoRestrictionDocument14 pages08 Welding Symbols 30-03-07 - NoRestrictionMohammed ShaffiNo ratings yet

- Distorsion Prevented by DesignDocument3 pagesDistorsion Prevented by DesignMathew RodriguezNo ratings yet

- Welding Symbol B231013Document29 pagesWelding Symbol B231013Dwi DarsonoNo ratings yet

- 9 Welding SymbolsDocument15 pages9 Welding SymbolsSampath KumarNo ratings yet

- Welding SymbolsDocument8 pagesWelding SymbolsSantosh Kumar100% (1)

- AWS ReferenceDocument2 pagesAWS ReferenceKent TanakNo ratings yet

- Use Double Sided Groove WeldsDocument3 pagesUse Double Sided Groove Weldskumaravel_indNo ratings yet

- Sand and Permanent Mold Casting Errata WatermarkDocument7 pagesSand and Permanent Mold Casting Errata Watermarkprakashp111No ratings yet

- Simboluri SudareDocument8 pagesSimboluri SudarecornelutsNo ratings yet

- Economics of Structural Steel Work WeldingDocument9 pagesEconomics of Structural Steel Work Weldingthomas kilianNo ratings yet

- Scallops Are Cut Outs in Weld Corners Which Are Used in Many Structures As in BridgesDocument3 pagesScallops Are Cut Outs in Weld Corners Which Are Used in Many Structures As in BridgesJanuel BorelaNo ratings yet

- Weld and Welding Symbols: Er Latest Technology in The Widest Product Range, ComprDocument27 pagesWeld and Welding Symbols: Er Latest Technology in The Widest Product Range, ComprFYNo ratings yet

- Bolted Beam Column ConnectionsDocument16 pagesBolted Beam Column Connectionslael00No ratings yet

- Chapter 5 Shear, Bond and TorsionDocument82 pagesChapter 5 Shear, Bond and TorsiondavidNo ratings yet

- Introduction-Design-Guide 2Document16 pagesIntroduction-Design-Guide 2Sutha100% (1)

- Weld and Welding Symbols: 3-4. GENERALDocument24 pagesWeld and Welding Symbols: 3-4. GENERALAnonymous D2GXdENo ratings yet

- Bolted Joints-ExamplesDocument14 pagesBolted Joints-Examplesmandregomes100% (1)

- A L F I: Cceptance Imit OR MperfectionsDocument29 pagesA L F I: Cceptance Imit OR MperfectionsDavid MacatangayNo ratings yet

- Welding SymbolesDocument8 pagesWelding Symbolesvimal_mech123No ratings yet

- Simboluri SuduriDocument32 pagesSimboluri SuduriGabriel MateiNo ratings yet

- Practices: Fillet Weld PositionsDocument37 pagesPractices: Fillet Weld PositionshadushberheNo ratings yet

- Welding ProcDocument48 pagesWelding ProcJulioNo ratings yet

- FASTENERSDocument34 pagesFASTENERSEmreNo ratings yet

- Lesson 6 - Weld SymbolsDocument6 pagesLesson 6 - Weld SymbolsMidhun K Chandrabose100% (1)

- Steel Connections: Research in Building Tech 3Document10 pagesSteel Connections: Research in Building Tech 3Angelica Marie AzucenaNo ratings yet

- Solid Rivet InformationDocument6 pagesSolid Rivet InformationKukyong LeeNo ratings yet

- Welded Connections FinalDocument42 pagesWelded Connections FinalSainaveen ThotaNo ratings yet

- Hollow Sections ConnectionsDocument4 pagesHollow Sections Connectionsאחמד סלאח כאמלNo ratings yet

- Steel DetailerDocument3 pagesSteel DetailerKooroshNo ratings yet

- Welding Symbols: A Useful System or Undecipherable Hieroglyphics?Document7 pagesWelding Symbols: A Useful System or Undecipherable Hieroglyphics?Lahiru Prabhatha AmarasenaNo ratings yet

- New Microsoft Office Word DocumentDocument9 pagesNew Microsoft Office Word DocumentKhalid PerwezNo ratings yet

- Design - Part 1 - TWIDocument9 pagesDesign - Part 1 - TWIFreddie KooNo ratings yet

- Equipment Design Chapter 3Document30 pagesEquipment Design Chapter 3Miguel Magat JovesNo ratings yet

- 6 Connections ModifiedDocument59 pages6 Connections Modifiedkebede amezeneNo ratings yet

- Basic Requirements WeldingDocument7 pagesBasic Requirements Weldingbrpnaidu2157100% (1)

- pkpadmin,+42_1_031Document14 pagespkpadmin,+42_1_031Ayush LolusareNo ratings yet

- 171CE113-bolted ConnectionDocument9 pages171CE113-bolted ConnectionARJUN RNo ratings yet

- Joint DesignDocument4 pagesJoint Designhafiz zullaileNo ratings yet

- CH 7 Simple Beam End Connections-9-13Document60 pagesCH 7 Simple Beam End Connections-9-13JakesNo ratings yet

- Weld Profile B16.25 - B 16.9Document2 pagesWeld Profile B16.25 - B 16.9f_riseNo ratings yet

- Welding Ends Butt Welded Acc To ASME B16.25 and ASME B16.9Document2 pagesWelding Ends Butt Welded Acc To ASME B16.25 and ASME B16.9Anonymous 6WgvYyNo ratings yet

- Structural Tolerances Bs4 - 2004Document4 pagesStructural Tolerances Bs4 - 2004Anonymous 8bH7sXpcEHNo ratings yet

- Weld SymbolsDocument26 pagesWeld SymbolsAju aju100% (1)

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Joining of Polymer-Metal Hybrid Structures: Principles and ApplicationsFrom EverandJoining of Polymer-Metal Hybrid Structures: Principles and ApplicationsSergio T. Amancio FilhoNo ratings yet

- 4 Welding Symbols 2: Fillet and Edge Welds, Backing Run or Weld, Flare Groove and Bevel Welds, and Plug or Slot WeldDocument2 pages4 Welding Symbols 2: Fillet and Edge Welds, Backing Run or Weld, Flare Groove and Bevel Welds, and Plug or Slot WeldEdo DestradaNo ratings yet

- Introduction To Welding API 577 Capter 7Document12 pagesIntroduction To Welding API 577 Capter 7Edo Destrada100% (1)

- Finite Element Analysis of The Orthogonal Metal Cutting Process 2000 Journal of Materials Processing TechnologyDocument15 pagesFinite Element Analysis of The Orthogonal Metal Cutting Process 2000 Journal of Materials Processing TechnologyEdo DestradaNo ratings yet

- Analysis of The Cutting Mechanics Under The Influence of Worn Tool Geometry 2013 Procedia CIRPDocument6 pagesAnalysis of The Cutting Mechanics Under The Influence of Worn Tool Geometry 2013 Procedia CIRPEdo DestradaNo ratings yet

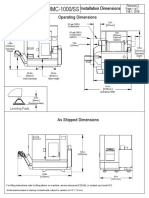

- UMC-1000 SS PP Layout Drawing 2019-11BDocument7 pagesUMC-1000 SS PP Layout Drawing 2019-11BHau Le TrungNo ratings yet

- Technical Data Sheet - PE Granules-BasellDocument3 pagesTechnical Data Sheet - PE Granules-Basellbtv.mylepham.208No ratings yet

- AL 6XN General PropertiesDocument1 pageAL 6XN General Propertiesah1525No ratings yet

- Unbrako New Price List Jan 2021-3 PDFDocument1 pageUnbrako New Price List Jan 2021-3 PDFManoj Doshi67% (3)

- Anti FoamDocument20 pagesAnti FoamNduong NguyenNo ratings yet

- HhyjyuDocument76 pagesHhyjyuBardalianNo ratings yet

- Y Strainer - ShieldDocument1 pageY Strainer - Shieldmilton rebelloNo ratings yet

- Atv DVWK A 281 e LibreDocument25 pagesAtv DVWK A 281 e LibrerafapoNo ratings yet

- AE 250DS ManualDocument13 pagesAE 250DS ManualLuis SalazarNo ratings yet

- Blasch FCCU Wear PresentationDocument33 pagesBlasch FCCU Wear PresentationKhaled BOUALINo ratings yet

- Chapter 6: Admixtures For ConcreteDocument6 pagesChapter 6: Admixtures For ConcreteMae Louisse AllasNo ratings yet

- Calculation Manufacturing ProcessDocument18 pagesCalculation Manufacturing ProcessEncik MaaNo ratings yet

- TDS - CRAYVALLAC® EF 30P - en - WWDocument1 pageTDS - CRAYVALLAC® EF 30P - en - WWBorja AzkargortaNo ratings yet

- Injection Moulding PPT Presentation F16me11Document24 pagesInjection Moulding PPT Presentation F16me11AbdulRehman Ahmed SoomroNo ratings yet

- Production 09Document3 pagesProduction 09gdgokhale_76No ratings yet

- Selectrode: 317L Flux Coated TigDocument3 pagesSelectrode: 317L Flux Coated TigUta GilangNo ratings yet

- Alu Technologies Book - Lecture-Notes - 1606 PagesDocument1,606 pagesAlu Technologies Book - Lecture-Notes - 1606 PagesPaul RosiahNo ratings yet

- Astm E-1417-PtDocument11 pagesAstm E-1417-PtRamadhan AdityaNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetBenjaminNo ratings yet

- QAQC Procedure For Fabrication - Flare KOD Rev ADocument9 pagesQAQC Procedure For Fabrication - Flare KOD Rev ARajesh K Pillai100% (1)

- Confix Epoxy CementDocument2 pagesConfix Epoxy CementJohn vincent SalazarNo ratings yet

- NAME: Swapnil Sanjay Gaikwad Roll No: Sch-15Document4 pagesNAME: Swapnil Sanjay Gaikwad Roll No: Sch-15yaseen sheikhNo ratings yet

- Milling Cold CuttingDocument20 pagesMilling Cold CuttingMossstazzzaNo ratings yet

- Pump, Tandem (Front) 404281a1Document3 pagesPump, Tandem (Front) 404281a1JESUSNo ratings yet

- Att 6. Tentative Commissioning Sequence & System PriorityDocument3 pagesAtt 6. Tentative Commissioning Sequence & System PriorityMahadevan MahalingamNo ratings yet

- Synchro-Feed Welding System: Maximum Current Increased ToDocument2 pagesSynchro-Feed Welding System: Maximum Current Increased ToEdwin GeovannyNo ratings yet

- Electrode: Flux Lime Silica Calcium FluorideDocument2 pagesElectrode: Flux Lime Silica Calcium FluoridemihirthakkarNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 4957Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 4957farshid KarpasandNo ratings yet