Professional Documents

Culture Documents

ErP Directive en

ErP Directive en

Uploaded by

ManekGorisCopyright:

Available Formats

You might also like

- MS5001 PA Complete Maintenance MANUALDocument989 pagesMS5001 PA Complete Maintenance MANUALarabi222295% (59)

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionFrom EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNo ratings yet

- Iecex Certificate of ConformityDocument4 pagesIecex Certificate of ConformityFrancesco_CNo ratings yet

- Flans Chen Prospekt EngDocument2 pagesFlans Chen Prospekt Englorenzinho290No ratings yet

- VMSVTDocument363 pagesVMSVTabysslabsNo ratings yet

- Threaded Weld-In Socket Weld and Limited Space ThermowellsDocument2 pagesThreaded Weld-In Socket Weld and Limited Space ThermowellsRajadurai SinghNo ratings yet

- EN 455-2 - 2015 - Medical Gloves For Single Use - Part 2 Requirements and TestingDocument11 pagesEN 455-2 - 2015 - Medical Gloves For Single Use - Part 2 Requirements and Testingmargarida100% (2)

- PED 2014-68-EU Guidelines EN v4Document235 pagesPED 2014-68-EU Guidelines EN v4Nav TalukdarNo ratings yet

- Peugeot 208 - 2015 Owners Manual PDF - Welcome 1 - 341Document240 pagesPeugeot 208 - 2015 Owners Manual PDF - Welcome 1 - 341abual3ez0% (1)

- Basket Burst PressureDocument1 pageBasket Burst Pressurexaaabbb_550464353No ratings yet

- Manual Kaeser CSDX T Compress TranslateDocument170 pagesManual Kaeser CSDX T Compress Translateverel adamNo ratings yet

- Mss sp-67 PDFDocument18 pagesMss sp-67 PDFPratik DesaiNo ratings yet

- Es7 PDFDocument4 pagesEs7 PDFayoungaNo ratings yet

- PASCAL Check Valves CatalogueDocument19 pagesPASCAL Check Valves Cataloguecrys100% (1)

- A270Document6 pagesA270Anonymous O39pjWNo ratings yet

- Roark Mast CalculationsDocument1 pageRoark Mast Calculationsjamil voraNo ratings yet

- PD 5500Document572 pagesPD 5500Tarapong RakkedNo ratings yet

- The Definitive O Ring Design GuideDocument31 pagesThe Definitive O Ring Design GuideChezNo ratings yet

- GISF92Document14 pagesGISF92Jigs FelixNo ratings yet

- Flowjet Valves Product BrochureDocument18 pagesFlowjet Valves Product BrochureUday GokhaleNo ratings yet

- E91 202006 20orifice 20plate 20 - 20doschDocument6 pagesE91 202006 20orifice 20plate 20 - 20doschiaft100% (1)

- Iso 10294 2 1999 PDFDocument8 pagesIso 10294 2 1999 PDFhoang nguyenNo ratings yet

- Design of Weld Neck Flange As Per ASME Section VIII Division 1Document1 pageDesign of Weld Neck Flange As Per ASME Section VIII Division 1Dhakshina KNo ratings yet

- Dimensions, Sizes and Specification of JIS B2220 Standard Steel FlangesDocument8 pagesDimensions, Sizes and Specification of JIS B2220 Standard Steel FlangesdjvhNo ratings yet

- Ico3s Iom ManualDocument2 pagesIco3s Iom ManualAditya B. RyantoNo ratings yet

- ASTM A686 T72301 W1A 9.5 Steel Plate, ASTM T72301 W1A 9.5 Tool SteelDocument2 pagesASTM A686 T72301 W1A 9.5 Steel Plate, ASTM T72301 W1A 9.5 Tool SteelBernice JohnsonNo ratings yet

- Caesar II Enhancement ListDocument16 pagesCaesar II Enhancement Listr_surya05100% (1)

- A494Document7 pagesA494Prakash MakadiaNo ratings yet

- 13480-3 p5Document2 pages13480-3 p5Arjun NegiNo ratings yet

- WHRB-265!08!00 Front and Rear Mirrors, Shell CalculationDocument2 pagesWHRB-265!08!00 Front and Rear Mirrors, Shell CalculationmehmacarNo ratings yet

- Astm F 104-2002Document12 pagesAstm F 104-2002ZeshanNo ratings yet

- ErmetoDocument14 pagesErmetoJavier VespaNo ratings yet

- SKF Filament Wound BushingsDocument8 pagesSKF Filament Wound BushingsWes VendrigNo ratings yet

- Explomet PolandDocument6 pagesExplomet PolandLucian CiprianNo ratings yet

- Aisi O1: Cold Work Tool SteelDocument7 pagesAisi O1: Cold Work Tool Steeltewiinaba777No ratings yet

- Nozzle Interference Error SolvingDocument2 pagesNozzle Interference Error SolvingSakthi VelNo ratings yet

- En 12560-6Document18 pagesEn 12560-6DarshAwad100% (1)

- Iso 12952 16 2022Document28 pagesIso 12952 16 2022Jim FrenkenNo ratings yet

- Standard Metric Bolt Shank Dimensions PDFDocument2 pagesStandard Metric Bolt Shank Dimensions PDFbcvdocu100% (1)

- Companion GuideDocument65 pagesCompanion GuidemanishcguptaNo ratings yet

- Hydraulic PipingDocument1 pageHydraulic Pipingpandunugraha04100% (1)

- BS 5151Document18 pagesBS 5151Steva76No ratings yet

- Triple-Offset Butterflyvalves PDFDocument8 pagesTriple-Offset Butterflyvalves PDFDiwakar NigamNo ratings yet

- Valves Shell Design StrengthDocument10 pagesValves Shell Design Strengthمحمد عبدالدايمNo ratings yet

- Hinge DesignDocument2 pagesHinge Designpare222No ratings yet

- Stainless Steel Sightglass Din 28120 28121Document4 pagesStainless Steel Sightglass Din 28120 28121Thoa Tran VanNo ratings yet

- Vibration Mounts: Evolo® Series: Evolo® 633: Grade A-DDocument0 pagesVibration Mounts: Evolo® Series: Evolo® 633: Grade A-Daleksandar_djordjicNo ratings yet

- VALVITALIA-cat. PDA Actuators - Rev1.4Document8 pagesVALVITALIA-cat. PDA Actuators - Rev1.4lydia.wasprimaNo ratings yet

- Garlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 enDocument1 pageGarlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 ennmosilvaNo ratings yet

- PED - 2014-68-EU - Guidelines - EN - v6.0 Part 2Document124 pagesPED - 2014-68-EU - Guidelines - EN - v6.0 Part 2KailasNo ratings yet

- HT Aboveground Horizontal PDFDocument4 pagesHT Aboveground Horizontal PDFSenthil KumarNo ratings yet

- BS EN 1503-4 2002 Valves Materials For Bodies BonnetsDocument10 pagesBS EN 1503-4 2002 Valves Materials For Bodies BonnetsолегNo ratings yet

- Pulsating Heat Pipe ReportDocument65 pagesPulsating Heat Pipe ReportIdul Azharul HoqueNo ratings yet

- Asme PTCDocument3 pagesAsme PTCVijayakumar SengottuveluNo ratings yet

- Din 17177-79Document8 pagesDin 17177-79savanNo ratings yet

- Iso 10893 9 2011Document9 pagesIso 10893 9 2011basusonuNo ratings yet

- MSS SP-118-2007Document24 pagesMSS SP-118-2007masoudNo ratings yet

- EAs 4 BDocument7 pagesEAs 4 BRaza TabasamNo ratings yet

- Turbina GazDocument63 pagesTurbina GazAlexandru Stratulat100% (1)

- New Requirements For Air Handling Units in Compliance With Erp DirectiveDocument6 pagesNew Requirements For Air Handling Units in Compliance With Erp DirectivePrasath SivaNo ratings yet

- Compile ScheduleDocument68 pagesCompile ScheduleManekGorisNo ratings yet

- MD - MMD: Monobloc Centrifugal Electric Pump in Compliance With en 733Document21 pagesMD - MMD: Monobloc Centrifugal Electric Pump in Compliance With en 733ManekGorisNo ratings yet

- Plan Bricking 2010 New Rev.2Document14 pagesPlan Bricking 2010 New Rev.2ManekGoris100% (1)

- Max. Condensing Operating Condition in SummerDocument1 pageMax. Condensing Operating Condition in SummerManekGorisNo ratings yet

- Spesifikasi Pompa Pond & WWTPDocument4 pagesSpesifikasi Pompa Pond & WWTPManekGorisNo ratings yet

- Kebutuhan Flow MeterDocument2 pagesKebutuhan Flow MeterManekGorisNo ratings yet

- Bulan Downtime Durasi TanggalDocument1 pageBulan Downtime Durasi TanggalManekGorisNo ratings yet

- Harga Barang & Material Perencanaan Instalasi Hydrant Indoor & OutdoorDocument10 pagesHarga Barang & Material Perencanaan Instalasi Hydrant Indoor & OutdoorManekGorisNo ratings yet

- Tabell Spek PompaDocument11 pagesTabell Spek PompaManekGorisNo ratings yet

- Diameter Pipa OD: 4 " ID 100 MM 0.1 M Velocity (V) 2000 Mm/s Q 15.71 Mm3/SDocument1 pageDiameter Pipa OD: 4 " ID 100 MM 0.1 M Velocity (V) 2000 Mm/s Q 15.71 Mm3/SManekGorisNo ratings yet

- Harga Barang & Material Perencanaan Instalasi Hydrant Indoor & OutdoorDocument10 pagesHarga Barang & Material Perencanaan Instalasi Hydrant Indoor & OutdoorManekGorisNo ratings yet

- Tabell Spek PompaDocument11 pagesTabell Spek PompaManekGorisNo ratings yet

- Kebutuhan Panas Cement Mill (1) 1Document3 pagesKebutuhan Panas Cement Mill (1) 1ManekGorisNo ratings yet

- Hole Point Measurement DuctDocument1 pageHole Point Measurement DuctManekGorisNo ratings yet

- Cement Plant InvestmentDocument12 pagesCement Plant InvestmentManekGorisNo ratings yet

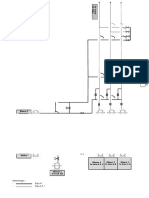

- Cement MIll Flow SheetDocument2 pagesCement MIll Flow SheetManekGorisNo ratings yet

- 15, Health, Safety & SecurityDocument25 pages15, Health, Safety & SecurityManekGorisNo ratings yet

- Physical Properties Classification: The Siam Refractory Industry Co., LTDDocument23 pagesPhysical Properties Classification: The Siam Refractory Industry Co., LTDManekGorisNo ratings yet

- Manufacturing Workforce Training Production: Operation Area(s) : Category: Module/Sub-Module: Presentation Name: DateDocument28 pagesManufacturing Workforce Training Production: Operation Area(s) : Category: Module/Sub-Module: Presentation Name: DateManekGorisNo ratings yet

- Trend Operasi & Foto Kondisi Grinding Ball Chamber 1 Cement MillDocument2 pagesTrend Operasi & Foto Kondisi Grinding Ball Chamber 1 Cement MillManekGorisNo ratings yet

- The Siam Refractory Industry Co., LTDDocument4 pagesThe Siam Refractory Industry Co., LTDManekGorisNo ratings yet

- Skema CF SiloDocument4 pagesSkema CF SiloManekGorisNo ratings yet

- (Qfxxnknhfynts 5M XNHFQ 5wtujwynjxDocument1 page(Qfxxnknhfynts 5M XNHFQ 5wtujwynjxManekGorisNo ratings yet

- 2 High Alumina BricksDocument25 pages2 High Alumina BricksManekGoris0% (1)

- EN EN: Commission of The European CommunitiesDocument32 pagesEN EN: Commission of The European CommunitiesrvsuhasNo ratings yet

- 9783866539457Document161 pages9783866539457Derrick Lynch100% (1)

- CA3 BOOK 2012 Ebook 201310Document374 pagesCA3 BOOK 2012 Ebook 201310hb_scribNo ratings yet

- Citing Guide Harvard Style 24062014Document40 pagesCiting Guide Harvard Style 24062014Ebuwa AmadasunNo ratings yet

- EN EN: European CommissionDocument3 pagesEN EN: European CommissioncosmpiroNo ratings yet

- EIA - Poultry Meat CertificationDocument200 pagesEIA - Poultry Meat CertificationbhaskarNo ratings yet

- Clariant Brochure Colorants For The Coloration of Consumer Goods 201312 enDocument84 pagesClariant Brochure Colorants For The Coloration of Consumer Goods 201312 enEudy CardozoNo ratings yet

- EU Directory of Regulations and Standards PDFDocument16 pagesEU Directory of Regulations and Standards PDFanon_684099349No ratings yet

- Judgment of The ECJ in Digital Rights Ireland Data Retention ChallengeDocument26 pagesJudgment of The ECJ in Digital Rights Ireland Data Retention ChallengeTJ McIntyre100% (2)

- ERA1209-037 Clarification About The Case To Apply For Changes (Not Extension) in AoUDocument8 pagesERA1209-037 Clarification About The Case To Apply For Changes (Not Extension) in AoUStan ValiNo ratings yet

- Education:: The European IPPC BureauDocument7 pagesEducation:: The European IPPC BureauGabriella ISAACNo ratings yet

- Machinery Directive Guide98 - 37Document269 pagesMachinery Directive Guide98 - 37i1976No ratings yet

- Andenas On European Company LawDocument74 pagesAndenas On European Company LawHarpott GhantaNo ratings yet

- GP Daily 1 MI0415175ENN 002.pdf - enDocument644 pagesGP Daily 1 MI0415175ENN 002.pdf - enKhan shahid kamal khanNo ratings yet

- Directive 87-404-EEC On Simple Pressure VesselsDocument18 pagesDirective 87-404-EEC On Simple Pressure VesselsValeriy GolovinNo ratings yet

- Employment LawDocument225 pagesEmployment LawAzlan Yusof Punding100% (2)

- Fall Arrest: EquipmentDocument5 pagesFall Arrest: EquipmentAamir AliNo ratings yet

- International Strategy For Sunderland 2008 2025Document30 pagesInternational Strategy For Sunderland 2008 2025AnyNo ratings yet

- WELMEC 06.0-Issue-3 PrepackagesDocument21 pagesWELMEC 06.0-Issue-3 PrepackagesCarlos GarciaNo ratings yet

- European Standard Norme Europeenne Europaische Norm: Metallic Products - Types of Inspection DocumentsDocument10 pagesEuropean Standard Norme Europeenne Europaische Norm: Metallic Products - Types of Inspection DocumentsGabriel RodriguezNo ratings yet

- Non Financial Reporting in Romania in The Pre Directive 2014 95 Eu PeriodDocument10 pagesNon Financial Reporting in Romania in The Pre Directive 2014 95 Eu PeriodMstefNo ratings yet

- Fuel Cells and Hydrogen 2 Joint Undertaking (FCH 2 Ju)Document56 pagesFuel Cells and Hydrogen 2 Joint Undertaking (FCH 2 Ju)ezeabrilNo ratings yet

- Tratado Constitutivo CeeacDocument56 pagesTratado Constitutivo CeeacBianca MendozaNo ratings yet

- Cen-Cenelec Guide 15: Tasks and Responsibilities of The New Approach ConsultantsDocument17 pagesCen-Cenelec Guide 15: Tasks and Responsibilities of The New Approach ConsultantszorbakiNo ratings yet

- ErP Directive enDocument13 pagesErP Directive enManekGorisNo ratings yet

- Panara, C. and de Becker, A. - The Role of The Regions in EU Governance PDFDocument350 pagesPanara, C. and de Becker, A. - The Role of The Regions in EU Governance PDFKypros SavvaNo ratings yet

- Direktiva 2004-54-EC o Minimalnim Sigurnosnim Uvjetima Za TuneleDocument21 pagesDirektiva 2004-54-EC o Minimalnim Sigurnosnim Uvjetima Za TuneleLudovikNo ratings yet

- Amarinth Technical Bulletin Specifying Reducing Measuring Pump Noise For Health Safety MP2615 100 RevADocument5 pagesAmarinth Technical Bulletin Specifying Reducing Measuring Pump Noise For Health Safety MP2615 100 RevAAsari Dear SNo ratings yet

- Celex 02003L0109-20110520 en TXTDocument22 pagesCelex 02003L0109-20110520 en TXTertanNo ratings yet

ErP Directive en

ErP Directive en

Uploaded by

ManekGorisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ErP Directive en

ErP Directive en

Uploaded by

ManekGorisCopyright:

Available Formats

-

PETUNJUK

d i r e c t i v e

Key Factors of Regulation (EU) 327/2011

DIRETTIVA

Erp-CBI-2013-IT

DIRECTIVE

DIRECTIVA

DIREKTIV

ErP

www.cbifans.com

Industrie CBI S.p.A. Via della Taccona, 77 20900 Monza (MB) Italy Tel. +39 039 73941

Industrie CBI S.p.A.

CBI Group Headquarters

www.cbifans.com | 2/13

E r P D ir ect iv e an d Re gul a ti o n (EU) 3 2 7/ 2 0 1 1

The Commission and the European Parliament, in accordance with the Kyoto Protocol which provides for a 20%

reduction of CO2 emissions into the atmosphere by 2020, have issued several directives and regulations with a

view to implementing the agreements on the reduction of energy consumption.

In this context Directive 2009/125/EC (ErP Energy-related Products) of 21 October 2009 was issued by the

European Parliament and by the Council for the establishment of a legislative framework for the setting of

ecodesign requirements for energy-related products.

The criteria for application of the Directive are inserted into appropriate regulations dedicated to the different

types of products.

As for fans, the European Commission issued Regulation No. 327/2011 of 30 March 2011 laying down detailed

rules for the application of Directive 2009/125/EC on the specific ecodesign requirements for fans with an

electric motor whose input power is between 125W and 500kW (note: 125W 500,000W) .

Application occurs in two phases, the first from 1 January 2013, the second from 1 January 2015.

For certain particular types of fans (e.g. roof exhaust), the regulations implementing the Directive have not yet

been finalized.

Scope of the Regulation

The Regulation applies to fans with power input of between 125W and 500kW.

However the following types of fans are excluded from the scope of the Regulation:

-

Fans designed for operation in potentially explosive atmospheres (ATEX) (designed and

manufactured in accordance with Directive 94/9/EC).

-

Fans designed exclusively for emergencies in relation to fire safety regulations 89/106/EC (e.g.

smoke and heat extractors).

-

Fans specifically designed to work when the operating temperature of the circulating gas exceeds

100 C.

-

Fans specifically designed to work with a motor whose ambient operating temperature, if located

outside the flow of gas, exceeds 65 C.

-

Fans specifically designed to work with an average annual temperature of the circulating gas and/

or the motor environment, if out of the flow of the gas, less than -40 C.

-

Fans specifically designed to work in toxic, highly corrosive, flammable environments or in

environments with abrasive substances.

Please note: Environments considered as creating abrasive substances and therefore excluded from the

scope of the Regulation may be considered the following:

Cement industry

Asphalt industry

Ceramic industry

Cereal milling industry

Glass Industry

Steel Industry

Brick Industry

Wood industry

Industrie CBI S.p.A. Via della Taccona, 77 20900 Monza (MB) Italy info@industriecbi.it www.cbifans.com

Industrie CBI S.p.A.

CBI Group Headquarters

www.cbifans.com | 3/13

E r P D ir ect iv e an d Re gul a ti o n (EU) 3 2 7/ 2 0 1 1

-

-

-

-

Fans for the transport of non-gaseous substances in industrial applications.

CBJET-type fans because the Regulation does not define how to calculate the efficiency of impulse fans.

Fans with a compression ratio R > 1.11

Fans destined for the extra-European market (even if sold to other manufacturers of machinery within the

Community)

Industrie CBI S.p.A. Via della Taccona, 77 20900 Monza (MB) Italy info@industriecbi.it www.cbifans.com

Industrie CBI S.p.A.

CBI Group Headquarters

www.cbifans.com | 4/13

E r P D ir ect iv e an d Re gul a ti o n (EU) 3 2 7/ 2 0 1 1

Re q u ire me nt s of the Regulation

The Regulation requires that fans of different types, falling within the scope of the Regulation, satisfy specific

minimum requirements for energy efficiency and provides calculation rules.

An "efficiency level" N that fans must reach is indicated, which corresponds to the target energy efficiency for

a unit with power of 10kW. The regulation also provides rules for calculating the value of the target energy

efficiency, called Target, as a function of the power and type of the fan, which in fact represents the minimum

value of the target energy efficiency that the fan, inclusive of the components responsible for the transformation

of energy (from electrical to aerolic), must reach.

Definition of the target energy efficiency

Target

There follow the efficiency levels N for the main types of fans and the consequent value of target energy efficiency

target Target.

(NB there are 2 different minimum values to be observed from 2013 and from 2015).

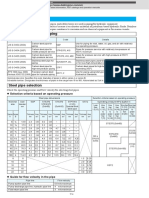

Fan type

N values

2013 2015

Measurement

Category

(B outlet duct,

C inlet duct)

Efficiency

category

(static or

total)

Axial fan

50

58

total

Centrifugal fan

with

forward-curved

or radial

blades

42

49

total

Centrifugal fan

with backwardcurved blades

(with casing)

61

64

total

Centrifugal fan

with backwardcurved blades

without casing

58

62

static

Calculation of the target energy efficiency

P = Electrical power of fan when operating at optimum energy

efficiency

0.125 P 10

10 P 500

0.125 P 10

10 P 500

0.125 P 10

10 < P 500

0.125 P 10

10 P 500

Target = 2.74 ln(P) - 6.33 + N

Target = 0.78 ln(P) - 1.88 + N

Target = 2.74 ln(P) - 6.33 + N

Target = 0.78 ln(P) - 1.88 + N

Target = 4.56 ln(P) - 10.5 + N

Target = 1.1 ln(P) - 2.6 + N

Target = 4.56 ln(P) - 10.5 + N

Target = 1.1 ln(P) - 2.6 + N

Industrie CBI S.p.A. Via della Taccona, 77 20900 Monza (MB) Italy info@industriecbi.it www.cbifans.com

Industrie CBI S.p.A.

CBI Group Headquarters

www.cbifans.com | 5/13

E r P D ir ect iv e an d Re gul a ti o n (EU) 3 2 7/ 2 0 1 1

Calculating the energy efficiency of the fan

Complete fan (without inverter)

The overall efficiency of the fan e is calculated using the following formula:

P U (S ) P e

Where:

- e is the overall efficiency

- P U ( S ) is the aerolic power of the fan

Obtained as the product of: Gas flow rate x Pressure difference x Compression factor, measured at the optimum

energy efficiency of the fan.

-

P e is the power measured at the ingress of the power supply to the fan motor when this last is operating at

optimum energy efficiency

Industrie CBI S.p.A. Via della Taccona, 77 20900 Monza (MB) Italy info@industriecbi.it www.cbifans.com

Industrie CBI S.p.A.

CBI Group Headquarters

www.cbifans.com | 6/13

E r P D ir ect iv e an d Re gul a ti o n (EU) 3 2 7/ 2 0 1 1

Complete fan (with inverter)

In case of use of variable speed drives, a compensation factor Cc is inserted in the formula for calculating the

efficiency. Overall efficiency is calculated according to the following:

Where;

-

(P U ( S )

P ed) C C

P ed is the power measured at the ingress of the power supply to the variable speed drive of the fan when this

last is operating at optimum energy efficiency

Where C C is a factor of partial compensation of the load, calculated as follows:

CC

= 1 without variable speed drive

CC

= 1.04 with variable speed drive and power Ped greater than or equal to 5 kW

C C = P e d < 5 kW, C C = - 0.03 ln(P ed ) + 1.088 with variable speed drive and power Ped

less than 5 kW

Incomplete fan

This is the case when the fan is supplied with "non-definitive assembly," i.e. when at least the impeller is mounted,

but the fan needs one or more components supplied externally to convert electrical energy into aerolic power

of the fan.

In this case the overall efficiency of the fan is calculated at optimum energy efficiency of the impeller using the

following equation:

e = r m T Cm CC

Where:

- r = Efficiency of the impeller

m = Efficiency of the motor

- T = Efficiency of the traction device

- C m = Compensation factor for Matching of the components = 0.9

- C C = Part load compensation factor

-

Industrie CBI S.p.A. Via della Taccona, 77 20900 Monza (MB) Italy info@industriecbi.it www.cbifans.com

Industrie CBI S.p.A.

CBI Group Headquarters

www.cbifans.com | 7/13

E r P D ir ect iv e an d Re gul a ti o n (EU) 3 2 7/ 2 0 1 1

LABELLING

The labelling required by the Regulation must contain:

-

-

-

-

-

Overall efficiency rounded to the first decimal

Measurement category used to determine the efficiency (A, B, C or D)

Efficiency category (Static or Total)

Efficiency level at optimum energy efficiency

Indication whether the fan requires the use of a variable speed drive and if, in that case, the variable speed

drive is integrated into the fan or must be installed together with the fan

Example of additional labelling:

Option a (without variable speed drive):

= 55.3%

(B, Total) N(2015)=62 N=65 VSD Not Provided

Option b (variable speed drive to be installed):

= 55.3%

(B, Total) N(2015)=62 N=65 VSD Must be installed

Option c (variable speed drive built-in):

= 55.3%

(B, Total) N(2015)=62 N=65 VSD Integrated

Where VSD stands for: Variable Speed Drive.

REPLACING FANS ALREADY INSTALLED

The Regulation does not require the adaptation of existing plant and buildings.

In case of replacement of fans installed in plant and buildings before 1 January 2013, the same, until 31 December

2014, may be replaced with identical fans (including those not conforming to the efficiency requirements of the

Regulation), as long as they are marked accordingly.

Industrie CBI S.p.A. Via della Taccona, 77 20900 Monza (MB) Italy info@industriecbi.it www.cbifans.com

Industrie CBI S.p.A.

CBI Group Headquarters

www.cbifans.com | 8/13

E r P D ir ect iv e an d Re gul a ti o n (EU) 3 2 7/ 2 0 1 1

From 1 January 2015, for a replacement, new fans will have to comply with the Regulation.

CBI FANS

Most CBI fans were conceived with design features that place them out of the scope of the Regulation, as they

are usually specifically designed for operation at temperatures greater than 100 C, or else for processing toxic

and corrosive gases or with abrasive substances typical of industrial environments.

Nevertheless CBI fans were designed with efficiency criteria high enough to satisfy in most cases the efficiency

parameters required by the Regulation.

CBI is able to provide where required an adequate selection of machines satisfying the criteria of efficiency

required by the Regulation.

Thanks to the selection software specially updated with the parameters required by the Regulation, CBI is able

to offer the best solution from the energy point of view.

Where fans are incomplete, typically without a motor, CBI is able to provide the value of optimum energy

efficiency of the incomplete fan, as indicated by the Regulation, and to provide all the additional elements for

the definition by the customer of the energy efficiency of the complete fan.

Industrie CBI S.p.A. Via della Taccona, 77 20900 Monza (MB) Italy info@industriecbi.it www.cbifans.com

Industrie CBI S.p.A.

CBI Group Headquarters

www.cbifans.com | 9/13

ErP D i re c ti v e a nd Re gul a ti o n (EU) 327 /2011

CBI GROUP PRODUCT RANGE

Centrifugal fan CH;

Fan for multiple industrial applications.

Backward-curved or airfoil blade;

Pressure up to 5,000 Pa and flow rates up to 300,000 m3/h.

Single inlet;

Designed for temperatures up to 300 C.

Direct coupling or V-belt drive;

Can be used to treat gas in industrial environments

including toxic and corrosive gases, or with abrasive

substances.

Centrifugal fan CHT;

Backward-curved or airfoil blade;

Double inlet;

Direct coupling or V-belt drive;

Backward-curved or radial or radial open

wheel blade;

Pressure up to 8,000 Pa and flow rates up to 300,000 m3/h.

Centrifugal fan Z;

ErP

Exempt

ErP 2015

Compliant

ErP

ErP 2015

Exempt if used to

Compliant

Pressure up to 5,000 Pa and flow rates up to 600,000 m3/h. treat gas in industrial

environments

Designed for temperatures up to 80 C.

including toxic and

corrosive gases,

Can be used to treat gas in industrial environments

or with abrasive

including toxic and corrosive gases, or with abrasive

substances

substances.

Fan for multiple industrial applications.

Direct coupling or V-belt drive;

Fulfilment of

Regulation

efficiency criteria

Fan for multiple industrial applications.

Centrifugal fan K;

Single inlet;

Applicability of

Regulation

ErP

Exempt

ErP 2015

Compliant

ErP

Exempt

ErP 2015

Compliant

Designed for temperatures up to 300 C.

Can be used to treat gas in industrial environments

including toxic and corrosive gases, or with abrasive

substances.

Fan for multiple industrial applications.

Backward-curved blade;

Pressure up to 5,000 Pa and flow rates up to 300,000 m3/h.

Single inlet;

Designed for temperatures up to 300 C.

Direct coupling or V-belt drive;

Can be used to treat gas in industrial environments

including toxic and corrosive gases, or with abrasive

substances.

Industrie CBI S.p.A. Via della Taccona, 77 20900 Monza (MB) Italy info@industriecbi.it www.cbifans.com

Industrie CBI S.p.A.

CBI Group Headquarters

www.cbifans.com | 10/13

ErP D i re c ti v e a nd Re gul a ti o n (EU) 327 /2011

Centrifugal fan S,M,X;

Fan for multiple industrial applications.

Backward-curved blade;

Pressure up to 22,000 Pa and flow rates up to 400,000

m3/h.

Single inlet;

Direct coupling or V-belt drive;

Centrifugal fan EVO;

Backward-curved blade without

casing;

Single inlet;

Direct coupling or V-belt drive;

ErP 2015

Compliant

ErP

Exempt

ErP 2015

Compliant

ErP

Exempt

ErP 2015

Compliant*

For several models R > 1.11.

Designed for temperatures up to 300 C.

Can be used to treat gas in industrial environments

including toxic and corrosive gases, or with abrasive

substances.

Fan for multiple industrial applications.

Designed for temperatures up to 300 C.

Can be used to treat gas in industrial environments

including toxic and corrosive gases, or with abrasive

substances.

Centrifugal fan HD, HX, HV;

Fan for multiple industrial applications.

Backward-curved or radial blade.

Pressure up to 15,000 Pa and flow rates up to 10,000 m3/h.

Single inlet;

For several models R > 1.11.

Direct coupling or V-belt drive;

Designed for temperatures up to 300 C.

Can be used to treat gas in industrial environments

including toxic and corrosive gases, or with abrasive

substances.

Axial fan AXL;

ErP

Exempt

Axial fan for ventilation of civil and industrial environments.

Airfoil blade;

Pressure up to 5,000 Pa and flow rates up to 830,000 m3/h.

Direct coupling or V-belt drive;

Can be used as emergency fan for forced evacuation of

smoke and heat.

*With the

exception of

certain sizes.

ErP

Exempt if used

exclusively as

emergency fan for

forced evacuation of

smoke and heat.

Industrie CBI S.p.A. Via della Taccona, 77 20900 Monza (MB) Italy info@industriecbi.it www.cbifans.com

ErP 2015

Compliant

Industrie CBI S.p.A.

CBI Group Headquarters

www.cbifans.com | 11/13

ErP D i re c ti v e a nd Re gul a ti o n (EU) 327 /2011

Fan GAV, GAX;

Axial fan for ventilation of civil and industrial

environments.

Airfoil blade;

Direct coupling;

Pressure up to 1,000 Pa and flow rates up to 300,000

m3/h.

Can be used as emergency fan for forced evacuation of

smoke and heat.

Fan GAT;

Axial fan for ventilation of civil and industrial

environments.

Airfoil blade;

Pressure up to 600 Pa and flow rates up to 50,000 m3/h.

V-belt drive;

Designed for temperatures up to 120 C.

Can be used as emergency fan for forced evacuation of

smoke and heat.

Fan EFA;

Axial fan for ventilation of civil and industrial

environments.

Airfoil blade;

Direct coupling;

Pressure up to 1,800 Pa and flow rates up to 480,000

m3/h.

Can be used as emergency fan for forced evacuation of

smoke and heat.

Fan AP;

Axial wall-mounted fan for ventilation of civil and

industrial environments.

Airfoil blade;

Direct coupling;

Pressure up to 100 Pa and flow rates up to 43,000 m3/h.

Can be used as emergency fan for forced evacuation of

smoke and heat.

Fan CBJET;

Axial jet fan for tunnels.

Airfoil blade;

Thrust from 500 to 3,000N.

Direct coupling;

Flow rates up to 260,000 m3/h.

ErP

Exempt if used

exclusively as

emergency fan for

forced evacuation of

smoke and heat.

ErP 2015

Compliant

ErP

Exempt

Exempt if used

exclusively as

emergency fan for

forced evacuation of

smoke and heat.

ErP 2015

Compliant

ErP

Subject.

Exempt if used

exclusively as

emergency fan for

forced evacuation of

smoke and heat.

ErP 2015

Compliant

ErP

Subject.

Exempt if used

exclusively as

emergency fan for

forced evacuation of

smoke and heat.

ErP 2015

Compliant

ErP

Exempt

Efficiency

calculation in

accordance

with Regulation

327/11

Not Applicable.

Can be used as emergency fan for forced evacuation of

smoke and heat.

Industrie CBI S.p.A. Via della Taccona, 77 20900 Monza (MB) Italy info@industriecbi.it www.cbifans.com

Industrie CBI S.p.A.

CBI Group Headquarters

www.cbifans.com | 12/13

ErP D i re c ti v e a nd Re gul a ti o n (EU) 327 /2011

Centrifugal fan APS, APF;

Fan for multiple industrial applications.

Forward-curved or radial blade;

Pressure up to 3,800 Pa and flow rates up to 2,300

m3/h.

Direct coupling;

Fan for multiple industrial applications.

Forward-curved blade;

Pressure up to 2,000 Pa and flow rates up to 20,000

m3/h.

Fan for multiple industrial applications.

Backward-curved, radial or radial

open wheel blade.

Pressure up to 8,000 Pa and flow rates up to 11,000

m3/h.

Direct coupling;

Designed for temperatures up to 150 C.

Fan VR;

Fan for multiple industrial applications.

Forward-curved blade;

Pressure up to 1,600 Pa and flow rates up to 1,500

m3/h.

Fan for multiple industrial applications.

Forward-curved blade;

Pressure up to 4,300 Pa and flow rates up to 4,500

m3/h.

Centrifugal fan DT;

Single or double stage with radial

blade.

Direct coupling;

ErP 2015

Compliant

ErP

Exempt.

ErP 2015

Compliant

ErP

Exempt.

ErP 2015

Compliant

ErP

Exempt.

ErP 2015

Compliant

ErP

Exempt.

ErP 2015

Compliant

Designed for temperatures up to 150 C.

Fan VRP;

Direct coupling;

ErP

Exempt.

Designed for temperatures up to 150 C.

Fan NC, NR, NF;

Direct coupling;

ErP 2015

Compliant

Designed for temperatures up to 150 C.

Centrifugal fan CBS;

Direct coupling;

ErP

Exempt.

Designed for temperatures up to 250 C.

Fan for multiple industrial applications.

Pressure up to 1,600 Pa and flow rates up to 400 m3/h.

Designed for temperatures up to 150 C.

Industrie CBI S.p.A. Via della Taccona, 77 20900 Monza (MB) Italy info@industriecbi.it www.cbifans.com

Industrie CBI S.p.A.

CBI Group Headquarters

www.cbifans.com | 13/13

ErP D i re c ti v e a nd Re gul a ti o n (EU) 327 /2011

Centrifugal fan BCN

Fan for multiple industrial applications.

Two or more stages with radial

blade.

Pressure up to 22,000 Pa and flow rates up to 600

m3/h.

Direct coupling;

For several models R > 1.11.

Centrifugal fan TBS

Designed for temperatures up to 110 C.

Fan for multiple industrial applications.

Three or more stages with radial

blade.

Pressure up to 28,000 Pa and flow rates up to 900

m3/h.

Direct coupling;

For several models R > 1.11.

Designed for temperatures up to 150 C.

Blower HG

Blower for multiple industrial applications.

Three or more stages with radial

blade.

Pressure up to 47,000 Pa and flow rates up to 1,900

m3/h.

Direct coupling;

R > 1.11.

Blower SSM/SSB

Single or double stage with radial

blade.

Direct coupling;

Designed for temperatures up to 150 C.

Blower for multiple industrial applications.

ErP

Exempt.

ErP 2015

Not Compliant

ErP

Exempt.

ErP 2015

Not Compliant

ErP

Exempt.

ErP 2015

Not Compliant

ErP

Exempt.

ErP 2015

Not Compliant

Pressure up to 66,000 Pa and flow rates up to 250

m3/h.

R > 1.11.

Industrie CBI S.p.A. Via della Taccona, 77 20900 Monza (MB) Italy info@industriecbi.it www.cbifans.com

You might also like

- MS5001 PA Complete Maintenance MANUALDocument989 pagesMS5001 PA Complete Maintenance MANUALarabi222295% (59)

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionFrom EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNo ratings yet

- Iecex Certificate of ConformityDocument4 pagesIecex Certificate of ConformityFrancesco_CNo ratings yet

- Flans Chen Prospekt EngDocument2 pagesFlans Chen Prospekt Englorenzinho290No ratings yet

- VMSVTDocument363 pagesVMSVTabysslabsNo ratings yet

- Threaded Weld-In Socket Weld and Limited Space ThermowellsDocument2 pagesThreaded Weld-In Socket Weld and Limited Space ThermowellsRajadurai SinghNo ratings yet

- EN 455-2 - 2015 - Medical Gloves For Single Use - Part 2 Requirements and TestingDocument11 pagesEN 455-2 - 2015 - Medical Gloves For Single Use - Part 2 Requirements and Testingmargarida100% (2)

- PED 2014-68-EU Guidelines EN v4Document235 pagesPED 2014-68-EU Guidelines EN v4Nav TalukdarNo ratings yet

- Peugeot 208 - 2015 Owners Manual PDF - Welcome 1 - 341Document240 pagesPeugeot 208 - 2015 Owners Manual PDF - Welcome 1 - 341abual3ez0% (1)

- Basket Burst PressureDocument1 pageBasket Burst Pressurexaaabbb_550464353No ratings yet

- Manual Kaeser CSDX T Compress TranslateDocument170 pagesManual Kaeser CSDX T Compress Translateverel adamNo ratings yet

- Mss sp-67 PDFDocument18 pagesMss sp-67 PDFPratik DesaiNo ratings yet

- Es7 PDFDocument4 pagesEs7 PDFayoungaNo ratings yet

- PASCAL Check Valves CatalogueDocument19 pagesPASCAL Check Valves Cataloguecrys100% (1)

- A270Document6 pagesA270Anonymous O39pjWNo ratings yet

- Roark Mast CalculationsDocument1 pageRoark Mast Calculationsjamil voraNo ratings yet

- PD 5500Document572 pagesPD 5500Tarapong RakkedNo ratings yet

- The Definitive O Ring Design GuideDocument31 pagesThe Definitive O Ring Design GuideChezNo ratings yet

- GISF92Document14 pagesGISF92Jigs FelixNo ratings yet

- Flowjet Valves Product BrochureDocument18 pagesFlowjet Valves Product BrochureUday GokhaleNo ratings yet

- E91 202006 20orifice 20plate 20 - 20doschDocument6 pagesE91 202006 20orifice 20plate 20 - 20doschiaft100% (1)

- Iso 10294 2 1999 PDFDocument8 pagesIso 10294 2 1999 PDFhoang nguyenNo ratings yet

- Design of Weld Neck Flange As Per ASME Section VIII Division 1Document1 pageDesign of Weld Neck Flange As Per ASME Section VIII Division 1Dhakshina KNo ratings yet

- Dimensions, Sizes and Specification of JIS B2220 Standard Steel FlangesDocument8 pagesDimensions, Sizes and Specification of JIS B2220 Standard Steel FlangesdjvhNo ratings yet

- Ico3s Iom ManualDocument2 pagesIco3s Iom ManualAditya B. RyantoNo ratings yet

- ASTM A686 T72301 W1A 9.5 Steel Plate, ASTM T72301 W1A 9.5 Tool SteelDocument2 pagesASTM A686 T72301 W1A 9.5 Steel Plate, ASTM T72301 W1A 9.5 Tool SteelBernice JohnsonNo ratings yet

- Caesar II Enhancement ListDocument16 pagesCaesar II Enhancement Listr_surya05100% (1)

- A494Document7 pagesA494Prakash MakadiaNo ratings yet

- 13480-3 p5Document2 pages13480-3 p5Arjun NegiNo ratings yet

- WHRB-265!08!00 Front and Rear Mirrors, Shell CalculationDocument2 pagesWHRB-265!08!00 Front and Rear Mirrors, Shell CalculationmehmacarNo ratings yet

- Astm F 104-2002Document12 pagesAstm F 104-2002ZeshanNo ratings yet

- ErmetoDocument14 pagesErmetoJavier VespaNo ratings yet

- SKF Filament Wound BushingsDocument8 pagesSKF Filament Wound BushingsWes VendrigNo ratings yet

- Explomet PolandDocument6 pagesExplomet PolandLucian CiprianNo ratings yet

- Aisi O1: Cold Work Tool SteelDocument7 pagesAisi O1: Cold Work Tool Steeltewiinaba777No ratings yet

- Nozzle Interference Error SolvingDocument2 pagesNozzle Interference Error SolvingSakthi VelNo ratings yet

- En 12560-6Document18 pagesEn 12560-6DarshAwad100% (1)

- Iso 12952 16 2022Document28 pagesIso 12952 16 2022Jim FrenkenNo ratings yet

- Standard Metric Bolt Shank Dimensions PDFDocument2 pagesStandard Metric Bolt Shank Dimensions PDFbcvdocu100% (1)

- Companion GuideDocument65 pagesCompanion GuidemanishcguptaNo ratings yet

- Hydraulic PipingDocument1 pageHydraulic Pipingpandunugraha04100% (1)

- BS 5151Document18 pagesBS 5151Steva76No ratings yet

- Triple-Offset Butterflyvalves PDFDocument8 pagesTriple-Offset Butterflyvalves PDFDiwakar NigamNo ratings yet

- Valves Shell Design StrengthDocument10 pagesValves Shell Design Strengthمحمد عبدالدايمNo ratings yet

- Hinge DesignDocument2 pagesHinge Designpare222No ratings yet

- Stainless Steel Sightglass Din 28120 28121Document4 pagesStainless Steel Sightglass Din 28120 28121Thoa Tran VanNo ratings yet

- Vibration Mounts: Evolo® Series: Evolo® 633: Grade A-DDocument0 pagesVibration Mounts: Evolo® Series: Evolo® 633: Grade A-Daleksandar_djordjicNo ratings yet

- VALVITALIA-cat. PDA Actuators - Rev1.4Document8 pagesVALVITALIA-cat. PDA Actuators - Rev1.4lydia.wasprimaNo ratings yet

- Garlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 enDocument1 pageGarlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 ennmosilvaNo ratings yet

- PED - 2014-68-EU - Guidelines - EN - v6.0 Part 2Document124 pagesPED - 2014-68-EU - Guidelines - EN - v6.0 Part 2KailasNo ratings yet

- HT Aboveground Horizontal PDFDocument4 pagesHT Aboveground Horizontal PDFSenthil KumarNo ratings yet

- BS EN 1503-4 2002 Valves Materials For Bodies BonnetsDocument10 pagesBS EN 1503-4 2002 Valves Materials For Bodies BonnetsолегNo ratings yet

- Pulsating Heat Pipe ReportDocument65 pagesPulsating Heat Pipe ReportIdul Azharul HoqueNo ratings yet

- Asme PTCDocument3 pagesAsme PTCVijayakumar SengottuveluNo ratings yet

- Din 17177-79Document8 pagesDin 17177-79savanNo ratings yet

- Iso 10893 9 2011Document9 pagesIso 10893 9 2011basusonuNo ratings yet

- MSS SP-118-2007Document24 pagesMSS SP-118-2007masoudNo ratings yet

- EAs 4 BDocument7 pagesEAs 4 BRaza TabasamNo ratings yet

- Turbina GazDocument63 pagesTurbina GazAlexandru Stratulat100% (1)

- New Requirements For Air Handling Units in Compliance With Erp DirectiveDocument6 pagesNew Requirements For Air Handling Units in Compliance With Erp DirectivePrasath SivaNo ratings yet

- Compile ScheduleDocument68 pagesCompile ScheduleManekGorisNo ratings yet

- MD - MMD: Monobloc Centrifugal Electric Pump in Compliance With en 733Document21 pagesMD - MMD: Monobloc Centrifugal Electric Pump in Compliance With en 733ManekGorisNo ratings yet

- Plan Bricking 2010 New Rev.2Document14 pagesPlan Bricking 2010 New Rev.2ManekGoris100% (1)

- Max. Condensing Operating Condition in SummerDocument1 pageMax. Condensing Operating Condition in SummerManekGorisNo ratings yet

- Spesifikasi Pompa Pond & WWTPDocument4 pagesSpesifikasi Pompa Pond & WWTPManekGorisNo ratings yet

- Kebutuhan Flow MeterDocument2 pagesKebutuhan Flow MeterManekGorisNo ratings yet

- Bulan Downtime Durasi TanggalDocument1 pageBulan Downtime Durasi TanggalManekGorisNo ratings yet

- Harga Barang & Material Perencanaan Instalasi Hydrant Indoor & OutdoorDocument10 pagesHarga Barang & Material Perencanaan Instalasi Hydrant Indoor & OutdoorManekGorisNo ratings yet

- Tabell Spek PompaDocument11 pagesTabell Spek PompaManekGorisNo ratings yet

- Diameter Pipa OD: 4 " ID 100 MM 0.1 M Velocity (V) 2000 Mm/s Q 15.71 Mm3/SDocument1 pageDiameter Pipa OD: 4 " ID 100 MM 0.1 M Velocity (V) 2000 Mm/s Q 15.71 Mm3/SManekGorisNo ratings yet

- Harga Barang & Material Perencanaan Instalasi Hydrant Indoor & OutdoorDocument10 pagesHarga Barang & Material Perencanaan Instalasi Hydrant Indoor & OutdoorManekGorisNo ratings yet

- Tabell Spek PompaDocument11 pagesTabell Spek PompaManekGorisNo ratings yet

- Kebutuhan Panas Cement Mill (1) 1Document3 pagesKebutuhan Panas Cement Mill (1) 1ManekGorisNo ratings yet

- Hole Point Measurement DuctDocument1 pageHole Point Measurement DuctManekGorisNo ratings yet

- Cement Plant InvestmentDocument12 pagesCement Plant InvestmentManekGorisNo ratings yet

- Cement MIll Flow SheetDocument2 pagesCement MIll Flow SheetManekGorisNo ratings yet

- 15, Health, Safety & SecurityDocument25 pages15, Health, Safety & SecurityManekGorisNo ratings yet

- Physical Properties Classification: The Siam Refractory Industry Co., LTDDocument23 pagesPhysical Properties Classification: The Siam Refractory Industry Co., LTDManekGorisNo ratings yet

- Manufacturing Workforce Training Production: Operation Area(s) : Category: Module/Sub-Module: Presentation Name: DateDocument28 pagesManufacturing Workforce Training Production: Operation Area(s) : Category: Module/Sub-Module: Presentation Name: DateManekGorisNo ratings yet

- Trend Operasi & Foto Kondisi Grinding Ball Chamber 1 Cement MillDocument2 pagesTrend Operasi & Foto Kondisi Grinding Ball Chamber 1 Cement MillManekGorisNo ratings yet

- The Siam Refractory Industry Co., LTDDocument4 pagesThe Siam Refractory Industry Co., LTDManekGorisNo ratings yet

- Skema CF SiloDocument4 pagesSkema CF SiloManekGorisNo ratings yet

- (Qfxxnknhfynts 5M XNHFQ 5wtujwynjxDocument1 page(Qfxxnknhfynts 5M XNHFQ 5wtujwynjxManekGorisNo ratings yet

- 2 High Alumina BricksDocument25 pages2 High Alumina BricksManekGoris0% (1)

- EN EN: Commission of The European CommunitiesDocument32 pagesEN EN: Commission of The European CommunitiesrvsuhasNo ratings yet

- 9783866539457Document161 pages9783866539457Derrick Lynch100% (1)

- CA3 BOOK 2012 Ebook 201310Document374 pagesCA3 BOOK 2012 Ebook 201310hb_scribNo ratings yet

- Citing Guide Harvard Style 24062014Document40 pagesCiting Guide Harvard Style 24062014Ebuwa AmadasunNo ratings yet

- EN EN: European CommissionDocument3 pagesEN EN: European CommissioncosmpiroNo ratings yet

- EIA - Poultry Meat CertificationDocument200 pagesEIA - Poultry Meat CertificationbhaskarNo ratings yet

- Clariant Brochure Colorants For The Coloration of Consumer Goods 201312 enDocument84 pagesClariant Brochure Colorants For The Coloration of Consumer Goods 201312 enEudy CardozoNo ratings yet

- EU Directory of Regulations and Standards PDFDocument16 pagesEU Directory of Regulations and Standards PDFanon_684099349No ratings yet

- Judgment of The ECJ in Digital Rights Ireland Data Retention ChallengeDocument26 pagesJudgment of The ECJ in Digital Rights Ireland Data Retention ChallengeTJ McIntyre100% (2)

- ERA1209-037 Clarification About The Case To Apply For Changes (Not Extension) in AoUDocument8 pagesERA1209-037 Clarification About The Case To Apply For Changes (Not Extension) in AoUStan ValiNo ratings yet

- Education:: The European IPPC BureauDocument7 pagesEducation:: The European IPPC BureauGabriella ISAACNo ratings yet

- Machinery Directive Guide98 - 37Document269 pagesMachinery Directive Guide98 - 37i1976No ratings yet

- Andenas On European Company LawDocument74 pagesAndenas On European Company LawHarpott GhantaNo ratings yet

- GP Daily 1 MI0415175ENN 002.pdf - enDocument644 pagesGP Daily 1 MI0415175ENN 002.pdf - enKhan shahid kamal khanNo ratings yet

- Directive 87-404-EEC On Simple Pressure VesselsDocument18 pagesDirective 87-404-EEC On Simple Pressure VesselsValeriy GolovinNo ratings yet

- Employment LawDocument225 pagesEmployment LawAzlan Yusof Punding100% (2)

- Fall Arrest: EquipmentDocument5 pagesFall Arrest: EquipmentAamir AliNo ratings yet

- International Strategy For Sunderland 2008 2025Document30 pagesInternational Strategy For Sunderland 2008 2025AnyNo ratings yet

- WELMEC 06.0-Issue-3 PrepackagesDocument21 pagesWELMEC 06.0-Issue-3 PrepackagesCarlos GarciaNo ratings yet

- European Standard Norme Europeenne Europaische Norm: Metallic Products - Types of Inspection DocumentsDocument10 pagesEuropean Standard Norme Europeenne Europaische Norm: Metallic Products - Types of Inspection DocumentsGabriel RodriguezNo ratings yet

- Non Financial Reporting in Romania in The Pre Directive 2014 95 Eu PeriodDocument10 pagesNon Financial Reporting in Romania in The Pre Directive 2014 95 Eu PeriodMstefNo ratings yet

- Fuel Cells and Hydrogen 2 Joint Undertaking (FCH 2 Ju)Document56 pagesFuel Cells and Hydrogen 2 Joint Undertaking (FCH 2 Ju)ezeabrilNo ratings yet

- Tratado Constitutivo CeeacDocument56 pagesTratado Constitutivo CeeacBianca MendozaNo ratings yet

- Cen-Cenelec Guide 15: Tasks and Responsibilities of The New Approach ConsultantsDocument17 pagesCen-Cenelec Guide 15: Tasks and Responsibilities of The New Approach ConsultantszorbakiNo ratings yet

- ErP Directive enDocument13 pagesErP Directive enManekGorisNo ratings yet

- Panara, C. and de Becker, A. - The Role of The Regions in EU Governance PDFDocument350 pagesPanara, C. and de Becker, A. - The Role of The Regions in EU Governance PDFKypros SavvaNo ratings yet

- Direktiva 2004-54-EC o Minimalnim Sigurnosnim Uvjetima Za TuneleDocument21 pagesDirektiva 2004-54-EC o Minimalnim Sigurnosnim Uvjetima Za TuneleLudovikNo ratings yet

- Amarinth Technical Bulletin Specifying Reducing Measuring Pump Noise For Health Safety MP2615 100 RevADocument5 pagesAmarinth Technical Bulletin Specifying Reducing Measuring Pump Noise For Health Safety MP2615 100 RevAAsari Dear SNo ratings yet

- Celex 02003L0109-20110520 en TXTDocument22 pagesCelex 02003L0109-20110520 en TXTertanNo ratings yet