Professional Documents

Culture Documents

O-Cells at Kingdom Tower KSA

O-Cells at Kingdom Tower KSA

Uploaded by

Tony Chan0 ratings0% found this document useful (0 votes)

55 views1 pageO-cells at Kingdom Tower KSA

Original Title

O-cells at Kingdom Tower KSA - PPT

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentO-cells at Kingdom Tower KSA

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

55 views1 pageO-Cells at Kingdom Tower KSA

O-Cells at Kingdom Tower KSA

Uploaded by

Tony ChanO-cells at Kingdom Tower KSA

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

FUGRO LOADTEST

Kingdom Tower (1km High) Jeddah Saudi Arabia

Project

Owners Jeddah Economic Corporation and Kingdom

Holdings planned to build, what will be the Worlds tallest

tower at 1000 m, in Jeddah, Kingdom of Saudi Arabia. The

challenge of building such a tall tower in unknown ground

required a detailed investigation into the ground conditions

and load carrying capabilities of the soils at varying depths.

Geotechnical engineers Langan International was tasked

with providing guidance for the foundation design and

engaged Fugro Loadtest for a full scale load testing

program.

Foundation Testing Program

1000 m high Worlds Tallest Tower

Barrette reinforcing cage prior to

installation

Construction of the barrettes using

hydrofraise and bentonite slurry

Several questions were asked of the testing program. Which

would be the better option for the foundations, conventional

piles or a barrette foundation solution and what would be

the optimum depth of foundation? Would a bentonite or

polymer slurry be preferable over a natural water slurry? As

the tower would be situated in an active earthquake zone,

would the soil resistance degrade with cyclic loading? In

order to answer these questions, the foundation testing

program was designed into two phases.

Phase 1: A test program of 2 piles and 2 barrettes was

undertaken by Soletanche Bachy, one pile and barrette to

be 45 m length and the other pair to be 75 m in length

founding in siltstone and degraded sandstone deposits.

Each pile and barrette was constructed with a multi-level

O-cell arrangement consisting of two levels of loading and

cyclic loading was planned into the testing schedule to

ascertain the soil susceptibility to degradation under cyclic

loads.

Phase 2: A test program of 2 piles was undertaken by Huta

Foundation Works Ltd. The piles were 45 m and 75 m

length and constructed with a multi-level O-cell

arrangement. A fully instrumented lateral load test was also

performed on one of the test piles with 10 levels of

inclinometers to measure the lateral deflection. Lateral loads

were applied at the pile head using a calibrated jack and

load cell.

For the O-cell test piles, the excavation was calipered for

diameter, shape and verticality profile after final clean-out

using the SONICALIPER.

Pile reinforcing cage with O-cell

instrumentation

Testing, Results and Conclusions

Once the testing had been completed, an evaluation was

undertaken to enable a suitable foundation solution to be

found. The results indicated that piles would perform

adequately and that there was no indication of any friction

degradation of the deformed sandstone strata under cyclic

loading. Results of strain gauge analysis allowed the unit

friction to be assessed and a preferred foundation solution

to be put forward by Langan International based on the

findings for a hybrid pile raft of varying pile length.

Testing in progress

Copyright Fugro Loadtest 2014

www.fugro-loadtest.com

You might also like

- Geotechnical Investigations For DamsDocument2 pagesGeotechnical Investigations For DamsYudhi Febrian100% (2)

- Cantilever Column Systems SEAOCDocument5 pagesCantilever Column Systems SEAOCHirad GrivaniNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Coloane BetonDocument9 pagesColoane BetonAlexandru IonescuNo ratings yet

- Capitol Visitor Center Diaphragm WallDocument5 pagesCapitol Visitor Center Diaphragm WallTony ChanNo ratings yet

- Counterfort Retaing Wall of 6 M Height Design & CostDocument20 pagesCounterfort Retaing Wall of 6 M Height Design & CostDavid CruzaleguiNo ratings yet

- O-Cells in Jeddah KSADocument3 pagesO-Cells in Jeddah KSAArturo CusihuamanNo ratings yet

- Sea Construction Sep Oct 2013Document2 pagesSea Construction Sep Oct 2013Trần KhươngNo ratings yet

- Burj Khalifa FoundationDocument19 pagesBurj Khalifa FoundationKumail Murad75% (4)

- Burj KhalifaDocument8 pagesBurj KhalifaRASHA ANJUM RAJESHNo ratings yet

- PT61 Cove V1.inddDocument3 pagesPT61 Cove V1.inddGert-Jan RoelevinkNo ratings yet

- Six Rows of High Capacity Removable Anchors Support Deep Soil Mix Cofferdam Barley Payne Mcbarron European Conference Amsterdam 1999Document7 pagesSix Rows of High Capacity Removable Anchors Support Deep Soil Mix Cofferdam Barley Payne Mcbarron European Conference Amsterdam 1999Kenny CasillaNo ratings yet

- Protection of Public Beaches in Gibraltar by Stabilisation of Quarried Cliffs Using Rock Anchors Barley Burke Ice ConferenceDocument5 pagesProtection of Public Beaches in Gibraltar by Stabilisation of Quarried Cliffs Using Rock Anchors Barley Burke Ice ConferenceKenny CasillaNo ratings yet

- CS - P08-1186 International Tower Capital CentreDocument4 pagesCS - P08-1186 International Tower Capital Centrefrog15No ratings yet

- University of Salahaddin College of Engineering Civil DepartmentDocument17 pagesUniversity of Salahaddin College of Engineering Civil DepartmentStan JamelNo ratings yet

- Installation of Monopiles by Vibrohammers For The Riffgat ProjectDocument14 pagesInstallation of Monopiles by Vibrohammers For The Riffgat ProjectDoThanhTungNo ratings yet

- Naval Air StationDocument2 pagesNaval Air StationkbenjikaNo ratings yet

- Camp Porter PS PDFDocument0 pagesCamp Porter PS PDFMary FelicianoNo ratings yet

- 2015-TOOLS FOR MITIGATING AND MANAGING VDL LIMITATIONS IN CHALLENGING AUSTRALIAN SOIL AND ENVIRONMENTAL CONDITIONS Rev1Document13 pages2015-TOOLS FOR MITIGATING AND MANAGING VDL LIMITATIONS IN CHALLENGING AUSTRALIAN SOIL AND ENVIRONMENTAL CONDITIONS Rev1Neil PollockNo ratings yet

- Nondestructive Testing of Concrete Leg FoundationsDocument5 pagesNondestructive Testing of Concrete Leg Foundationsأحمد دعبسNo ratings yet

- Advanced Quality Assurance For Piling Works For The WICET Project in GladstoneDocument15 pagesAdvanced Quality Assurance For Piling Works For The WICET Project in GladstoneVetriselvan ArumugamNo ratings yet

- Heavy Tamping Part 2Document14 pagesHeavy Tamping Part 2Muhammad AfrasiyabNo ratings yet

- Deep Foundation Practice - BarrettesDocument9 pagesDeep Foundation Practice - Barrettesssi3k100% (1)

- ChaptersDocument29 pagesChapterscivilnaacpetwNo ratings yet

- Characteristics of Singapore Marine Clay at ChangiDocument11 pagesCharacteristics of Singapore Marine Clay at ChangichemodanNo ratings yet

- Challenges in Geotechnical FieldDocument32 pagesChallenges in Geotechnical FieldPrakash Singh RawalNo ratings yet

- Geotechnical Design For The Nakheel Tall TowerDocument5 pagesGeotechnical Design For The Nakheel Tall TowerLuca BrandiNo ratings yet

- Geomembranas ImpermeablesDocument20 pagesGeomembranas ImpermeablesEnzo Andres Gentile PachecoNo ratings yet

- Laboratory Investigation of Bearing Capacity Behavior of Strip Footing On Geogrid-Reinforced Sand SlopeDocument20 pagesLaboratory Investigation of Bearing Capacity Behavior of Strip Footing On Geogrid-Reinforced Sand Slopejavad khosraviNo ratings yet

- Diafragm Wall - The Marina BayDocument2 pagesDiafragm Wall - The Marina BaytortorpspNo ratings yet

- Recent Experiences With Bi-Directional Static Load Testing 040506Document9 pagesRecent Experiences With Bi-Directional Static Load Testing 040506Personal LearnNo ratings yet

- 2002 DrillTec - Shore Approach by Way of Horizontal Directional DrillingDocument4 pages2002 DrillTec - Shore Approach by Way of Horizontal Directional DrillingdmlsfmmNo ratings yet

- Sand Control and Frac PackDocument14 pagesSand Control and Frac PackImran SadiqNo ratings yet

- Assessment of Feasibility of Suction AnchorDocument11 pagesAssessment of Feasibility of Suction AnchorLale ÖnerNo ratings yet

- OTC-26671-MS The Design and Deployment of Open Hole Standalone Screens and Two Cased Hole Gravel Pack in Highly Deviated Well-A Case History With A Field in MalaysiaDocument8 pagesOTC-26671-MS The Design and Deployment of Open Hole Standalone Screens and Two Cased Hole Gravel Pack in Highly Deviated Well-A Case History With A Field in MalaysiaDarylNo ratings yet

- Paper Malbase Final ACMSDocument8 pagesPaper Malbase Final ACMSirfannshaikh11No ratings yet

- SPE 147247 Successful Discovery of Light Oil From An Unsuccessful Paleozoic Well Through Re-Entry - A Case Study of HPHT WellDocument8 pagesSPE 147247 Successful Discovery of Light Oil From An Unsuccessful Paleozoic Well Through Re-Entry - A Case Study of HPHT WellTheNourEldenNo ratings yet

- Successful Grout Curtain Installation Mean and MethodsDocument12 pagesSuccessful Grout Curtain Installation Mean and MethodsDarshan Babu AdhikariNo ratings yet

- Pile Load TestDocument6 pagesPile Load TestChristian JhansiNo ratings yet

- Exhumation and Design of Anchorages in Chalk Barley Mothersille Weerasinghe Ice Publication 2003Document22 pagesExhumation and Design of Anchorages in Chalk Barley Mothersille Weerasinghe Ice Publication 2003Kenny CasillaNo ratings yet

- Pile Load Test: IS: 2911 (Part 4) - 1985 IS: 14893-2001Document5 pagesPile Load Test: IS: 2911 (Part 4) - 1985 IS: 14893-2001Dwijendra Chanumolu100% (1)

- Ground Improvement Using The Vibro-Replacement Technique: March 2007Document13 pagesGround Improvement Using The Vibro-Replacement Technique: March 2007Javiera MoralesNo ratings yet

- Keller Frankie AseanDocument12 pagesKeller Frankie AseanaloysiusdeargaNo ratings yet

- The Use of Osterberg Cell Load Tests To Predict Piles ResistanceDocument6 pagesThe Use of Osterberg Cell Load Tests To Predict Piles Resistancedidiet noer affendiNo ratings yet

- EYGEC Paper - Time Effects On Pile Capacity - EKWDocument8 pagesEYGEC Paper - Time Effects On Pile Capacity - EKWBülent SarıalioğluNo ratings yet

- Effectiveness of Sand Column As A Ground Improvement TechniqueDocument5 pagesEffectiveness of Sand Column As A Ground Improvement TechniqueMuhammad IrfanNo ratings yet

- Foundation Design of Burj Khalifa: Sumit Vikram Singh 120107234 Term V (2014-15)Document13 pagesFoundation Design of Burj Khalifa: Sumit Vikram Singh 120107234 Term V (2014-15)azharahmadnazriNo ratings yet

- Bottom Line Benefits Justify Deepwater IWSDocument2 pagesBottom Line Benefits Justify Deepwater IWSVigna Ruban RamNo ratings yet

- 15 MFWRFocusDocument10 pages15 MFWRFocusAzlan AnzeriNo ratings yet

- Ground Improvement Using The Vibro-Replacement Technique: March 2007Document13 pagesGround Improvement Using The Vibro-Replacement Technique: March 2007Tsalis SalsabilaNo ratings yet

- The Construction of Oyster - A Nearshore Surging Wave Energy ConverterDocument7 pagesThe Construction of Oyster - A Nearshore Surging Wave Energy ConverterJasmeet Singh Loyal100% (1)

- Burj KhalifaDocument20 pagesBurj KhalifasonukuldeepNo ratings yet

- Berths 57, 58 and 59 Container Wharf at The Port of Oakland: Associate, Liftech Consultants IncDocument11 pagesBerths 57, 58 and 59 Container Wharf at The Port of Oakland: Associate, Liftech Consultants Incthinh_vu5218No ratings yet

- Climbing Robot For Steel Bridge Inspection: Design ChallengesDocument12 pagesClimbing Robot For Steel Bridge Inspection: Design ChallengesAbhishekNo ratings yet

- Contingency Measures During Dwall & Bpile ConstructionDocument3 pagesContingency Measures During Dwall & Bpile ConstructionAnonymous S7Cq7ZDgPNo ratings yet

- Efectiveness of Impulse CompactionDocument8 pagesEfectiveness of Impulse CompactionMagdalena PanekNo ratings yet

- Inst 5Document6 pagesInst 5ermvvNo ratings yet

- Highly Loaded Helical Piles in Compression and Tension Applications: A Case Study of Two ProjectsDocument4 pagesHighly Loaded Helical Piles in Compression and Tension Applications: A Case Study of Two ProjectstigertoobigNo ratings yet

- Ridgeway DeepsDocument15 pagesRidgeway Deepsalvaroaac4No ratings yet

- Micropile BrochureDocument8 pagesMicropile BrochureAmanjot Singh0% (1)

- 07 ParedesDocument16 pages07 Paredesi6vj5kpNo ratings yet

- Sand Control and Gravel Packing Techniques: It Never Rains in the Oil Field!From EverandSand Control and Gravel Packing Techniques: It Never Rains in the Oil Field!Rating: 5 out of 5 stars5/5 (1)

- Airblast Instrumentation in Surface MiningDocument58 pagesAirblast Instrumentation in Surface MiningTony ChanNo ratings yet

- BehrensDocument9 pagesBehrensTony ChanNo ratings yet

- 035 Reducing Negative Skin Friction With Bitumen Slip Layers PDFDocument3 pages035 Reducing Negative Skin Friction With Bitumen Slip Layers PDFTony ChanNo ratings yet

- BCE - Technical - Note - 3 - Relating Peak Particle Velocity and Acceleration To Moment Magnitude in Pasive Seismic MonitoringDocument5 pagesBCE - Technical - Note - 3 - Relating Peak Particle Velocity and Acceleration To Moment Magnitude in Pasive Seismic MonitoringTony ChanNo ratings yet

- Analysis of Axial Pile Load Test(s) On Large Bored Grouted and Instrumented PilesDocument14 pagesAnalysis of Axial Pile Load Test(s) On Large Bored Grouted and Instrumented PilesTony ChanNo ratings yet

- Autonomous Crack ComparometerDocument161 pagesAutonomous Crack ComparometerTony ChanNo ratings yet

- Geophones or Accelerometers BCE Technical Note 10Document3 pagesGeophones or Accelerometers BCE Technical Note 10Tony ChanNo ratings yet

- Probabilistic Analysis of Pile Deflection Under Lateral LoadsDocument8 pagesProbabilistic Analysis of Pile Deflection Under Lateral LoadsTony ChanNo ratings yet

- Filling of Abandoned Coal Mines Located Under The Ipswich MotorwayDocument10 pagesFilling of Abandoned Coal Mines Located Under The Ipswich MotorwayTony ChanNo ratings yet

- Toward The CFD Simulation of Sirocco Fans: From Selecting A Turbulence Model To The Role of Cell ShapesDocument12 pagesToward The CFD Simulation of Sirocco Fans: From Selecting A Turbulence Model To The Role of Cell ShapesGuyfawkesNo ratings yet

- Expansion Tank Design GuideDocument23 pagesExpansion Tank Design GuideShaik Bepari JakeerNo ratings yet

- Concrete Mix Design As Per IS10262-2009Document24 pagesConcrete Mix Design As Per IS10262-2009Prakash Singh RawalNo ratings yet

- Proposed Aquaculture Infrastructure Plumbing WorksDocument29 pagesProposed Aquaculture Infrastructure Plumbing WorksJysar ReubalNo ratings yet

- Battery Room FloorsDocument2 pagesBattery Room FloorsDaniel DediuNo ratings yet

- Stair Detail - ST - 03Document1 pageStair Detail - ST - 03Ram KrishnaNo ratings yet

- S-2.2 Proposed Filling Station (Caltex Station) : Girder Wide Flange Cutting LayoutDocument1 pageS-2.2 Proposed Filling Station (Caltex Station) : Girder Wide Flange Cutting LayoutCarmela Andrea BuenafeNo ratings yet

- An Improve Matematical Model Fo Shear Stress Robertson Stiff RheologyDocument6 pagesAn Improve Matematical Model Fo Shear Stress Robertson Stiff RheologyAgus Riza RomadlonNo ratings yet

- WSM V/S LSM IS:800-2007: Vishal A. NalwarDocument74 pagesWSM V/S LSM IS:800-2007: Vishal A. NalwarvishalnalwarNo ratings yet

- The Importance of Geology RawDocument13 pagesThe Importance of Geology RawRuby Anne LiwanagNo ratings yet

- Topographic Map of PoolvilleDocument1 pageTopographic Map of PoolvilleHistoricalMapsNo ratings yet

- Lat Short PileDocument1 pageLat Short PilemagdyamdbNo ratings yet

- Sustainable Drilling of Oil and Gas WellsDocument29 pagesSustainable Drilling of Oil and Gas Wellsnirbhaykumar100% (1)

- Wws Ten State Standards Waste WaterDocument102 pagesWws Ten State Standards Waste WaterLauren BowenNo ratings yet

- 12 Experiment #2: Bernoulli'S Theorem DemonstrationDocument12 pages12 Experiment #2: Bernoulli'S Theorem DemonstrationYasir A. Al-ShataifNo ratings yet

- CC-Q-17-066 - MR Ahmad Khadem - Mizhar First - G+1Document7 pagesCC-Q-17-066 - MR Ahmad Khadem - Mizhar First - G+1Fadi AlatrashNo ratings yet

- Structural Mechanics of Buried Pipes: Anderson, Loren Runar Et Al "RING DEFLECTION" Boca Raton: CRC Press LLC, 2000Document9 pagesStructural Mechanics of Buried Pipes: Anderson, Loren Runar Et Al "RING DEFLECTION" Boca Raton: CRC Press LLC, 2000Sheikh Mizanur RahmanNo ratings yet

- Alsan Trafik HP 500 Zero: Parking DeckDocument3 pagesAlsan Trafik HP 500 Zero: Parking DeckFatima PrezaNo ratings yet

- Boq CivilDocument13 pagesBoq CivilAnde Bhanu100% (1)

- Settlement Reducing Piles in Piled Basements and ShaftsDocument3 pagesSettlement Reducing Piles in Piled Basements and Shaftsvenkateswara rao pothinaNo ratings yet

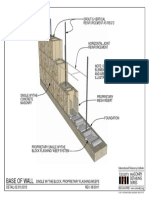

- 02.010.0313 Base of Wall Single Wythe Block Proprietary Flashing and WeepsDocument1 page02.010.0313 Base of Wall Single Wythe Block Proprietary Flashing and WeepsYolanda Leah UrbanoNo ratings yet

- Direct Analysis and Design Using Amplified First Order Analysis2part PDFDocument27 pagesDirect Analysis and Design Using Amplified First Order Analysis2part PDFPauloAndresSepulvedaNo ratings yet

- Er 0277Document27 pagesEr 0277NemkeNo ratings yet

- Acceptance Checklist: Elevator Machine Room And/or Control SpaceDocument4 pagesAcceptance Checklist: Elevator Machine Room And/or Control SpaceImran KhanNo ratings yet

- WTC2015 - Design and Construction Aspects of A Conventional Shallow Tunnel in Very Soft SoilDocument6 pagesWTC2015 - Design and Construction Aspects of A Conventional Shallow Tunnel in Very Soft SoilMapeixNo ratings yet

- Laminar or Viscous Flow 6Document26 pagesLaminar or Viscous Flow 6Sunil BagadeNo ratings yet

- Nepal National Building Code: Seismic Design of Buildings in NepalDocument34 pagesNepal National Building Code: Seismic Design of Buildings in Nepaladitya2053No ratings yet

- Building Code ViolationsDocument4 pagesBuilding Code ViolationsJulie Ann QuimingNo ratings yet