Professional Documents

Culture Documents

Coal Pillar Stability Considerations For Surface Protection

Coal Pillar Stability Considerations For Surface Protection

Uploaded by

Tony ChanCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Aloha Kitchen Troubleshooting GuideDocument24 pagesAloha Kitchen Troubleshooting GuideRicardo Paso GonzalezNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Capitol Visitor Center Diaphragm WallDocument5 pagesCapitol Visitor Center Diaphragm WallTony ChanNo ratings yet

- Final AccountDocument7 pagesFinal Accountswati100% (3)

- Airblast Instrumentation in Surface MiningDocument58 pagesAirblast Instrumentation in Surface MiningTony ChanNo ratings yet

- Autonomous Crack ComparometerDocument161 pagesAutonomous Crack ComparometerTony ChanNo ratings yet

- Analysis of Axial Pile Load Test(s) On Large Bored Grouted and Instrumented PilesDocument14 pagesAnalysis of Axial Pile Load Test(s) On Large Bored Grouted and Instrumented PilesTony ChanNo ratings yet

- BehrensDocument9 pagesBehrensTony ChanNo ratings yet

- 035 Reducing Negative Skin Friction With Bitumen Slip Layers PDFDocument3 pages035 Reducing Negative Skin Friction With Bitumen Slip Layers PDFTony ChanNo ratings yet

- BCE - Technical - Note - 3 - Relating Peak Particle Velocity and Acceleration To Moment Magnitude in Pasive Seismic MonitoringDocument5 pagesBCE - Technical - Note - 3 - Relating Peak Particle Velocity and Acceleration To Moment Magnitude in Pasive Seismic MonitoringTony ChanNo ratings yet

- Probabilistic Analysis of Pile Deflection Under Lateral LoadsDocument8 pagesProbabilistic Analysis of Pile Deflection Under Lateral LoadsTony ChanNo ratings yet

- Geophones or Accelerometers BCE Technical Note 10Document3 pagesGeophones or Accelerometers BCE Technical Note 10Tony ChanNo ratings yet

- Filling of Abandoned Coal Mines Located Under The Ipswich MotorwayDocument10 pagesFilling of Abandoned Coal Mines Located Under The Ipswich MotorwayTony ChanNo ratings yet

- Blibli Merchant API Documentation v-3.6.0 PDFDocument92 pagesBlibli Merchant API Documentation v-3.6.0 PDFKanto TerrorNo ratings yet

- Lab 5 - Archimedes PrincipleDocument13 pagesLab 5 - Archimedes PrincipleLance ShahNo ratings yet

- 15 Life Changing Lessons From Wayne DyerDocument6 pages15 Life Changing Lessons From Wayne Dyersaikumar selaNo ratings yet

- Fundamentals of Martial Arts RonelDocument2 pagesFundamentals of Martial Arts RonelRodne Badua RufinoNo ratings yet

- Annexure-IA Self Declaration Form For Application For Krishak Bandhu (Natun) SchemeDocument3 pagesAnnexure-IA Self Declaration Form For Application For Krishak Bandhu (Natun) SchemeSomnath Das YTNo ratings yet

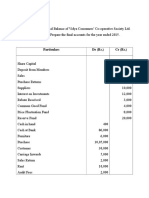

- Aeco136 - Final Term Report (Manatal Multipurpose Cooperatives)Document20 pagesAeco136 - Final Term Report (Manatal Multipurpose Cooperatives)JoyDianneGumatayNo ratings yet

- A Critical Analysis of The Beatitudes From The Gospel According To LukeDocument10 pagesA Critical Analysis of The Beatitudes From The Gospel According To LukejaketawneyNo ratings yet

- Write The Days in The Correct OrderDocument7 pagesWrite The Days in The Correct OrderRuth Yánez PadillaNo ratings yet

- 2841 A Watermark For Large LanguageDocument24 pages2841 A Watermark For Large LanguageAdithyaNo ratings yet

- Tort of NegligenceDocument10 pagesTort of NegligenceHETRAM SIYAGNo ratings yet

- Notes Ankita KashyapDocument49 pagesNotes Ankita Kashyapkharsatikevin92No ratings yet

- Domelux Series Manual de ServicioDocument43 pagesDomelux Series Manual de ServicioJohan LunaNo ratings yet

- Attracting and Dating A Partner For Marriag1Document21 pagesAttracting and Dating A Partner For Marriag1Isaac Abayomi OshinNo ratings yet

- Gpon - Vlan - Gem PortDocument5 pagesGpon - Vlan - Gem PortLe VuNo ratings yet

- Relationscapes Movement Art Philosophy by Erin Manning 2009 Cambridge Ma The Mit Press X 268 PP Images Notes Bibliography Index Dollar3200 HardcoverDocument4 pagesRelationscapes Movement Art Philosophy by Erin Manning 2009 Cambridge Ma The Mit Press X 268 PP Images Notes Bibliography Index Dollar3200 HardcoverHonglan HuangNo ratings yet

- 跟安德烈共餐 夢想照進現實Document49 pages跟安德烈共餐 夢想照進現實lamarckcanadaNo ratings yet

- Chavara Brochure Edited CompressedDocument13 pagesChavara Brochure Edited CompressedShameer ShajiNo ratings yet

- Online ExaminationDocument30 pagesOnline ExaminationArihant BothraNo ratings yet

- Ma History Dissertation StructureDocument7 pagesMa History Dissertation StructureCheapCustomPapersSingapore100% (1)

- GIAN Template-ProposalDocument4 pagesGIAN Template-ProposalRamesh GowdaNo ratings yet

- Fundamentals OF Accounting: Accounting by Meigs, Williams, Haka, BettnerDocument64 pagesFundamentals OF Accounting: Accounting by Meigs, Williams, Haka, BettnerAliya SaeedNo ratings yet

- TPA-Referenced Lesson Plan Teacher Candidate Name: Joe Birkholz Grade & Subject Area: 11-12 World History Date For Planned Lesson: TBA 1 DayDocument4 pagesTPA-Referenced Lesson Plan Teacher Candidate Name: Joe Birkholz Grade & Subject Area: 11-12 World History Date For Planned Lesson: TBA 1 Dayapi-347747740No ratings yet

- Presentation Class InglishDocument16 pagesPresentation Class Inglishmiralis gonzalezNo ratings yet

- Lesson 1 The Moral Agent: Camarines Norte State CollegeDocument4 pagesLesson 1 The Moral Agent: Camarines Norte State CollegeJeanNo ratings yet

- Macmillan Education Student - Great Thinkers B1+ - Student's Book 3Document1 pageMacmillan Education Student - Great Thinkers B1+ - Student's Book 3Rodrigo PequeñoNo ratings yet

- IB History IA SampleDocument14 pagesIB History IA SampleEscalusNo ratings yet

- Activity STSDocument1 pageActivity STSRalph ZeusNo ratings yet

- The Hydrothermal Alteration of Feldspars in Acid Solutions Between 300 Degrees and 400 Degrees CDocument12 pagesThe Hydrothermal Alteration of Feldspars in Acid Solutions Between 300 Degrees and 400 Degrees Ccristian camilo guisao palacioNo ratings yet

Coal Pillar Stability Considerations For Surface Protection

Coal Pillar Stability Considerations For Surface Protection

Uploaded by

Tony ChanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coal Pillar Stability Considerations For Surface Protection

Coal Pillar Stability Considerations For Surface Protection

Uploaded by

Tony ChanCopyright:

Available Formats

ABN 57 410 620 309

MINE SUBSIDENCE TECHNOLOGICAL SOCIETY

Reprint from

The Proceedings of the Sixth Triennial Conference

on

Subsidence Management Issues

Maitland

31 October to 2 November 2004

This document is available to members of the society at

www.mstsociety.org

Responsibility for the content of these papers rests with the Authors, and not the

Mine Subsidence Technological Society. Data presented and conclusions developed

by the authors are for information only and are not intended for use without

independent substantiating investigation on the part of potential users.

Apart from any fair dealing for the purpose of private study, research, criticism or

review, no part of these proceedings may be reproduced by any process without the

written permission of the Mine Subsidence Technological Society.

ISBN

0-9585779-2-7

Copyright MSTS

Coal Pillar Stability Considerations for Surface Protection

David Hill, Principal, Strata Engineering (Australia) Pty Ltd

Paul Buddery, Principal, Strata Engineering (Australia) Pty Ltd

Summary

More than two hundred years of underground coal mining in the Newcastle area have resulted

in large areas of ground supported on coal pillars, both in extensive old workings and current

drivages in active mining operations. Also, the continuing growth of civil infrastructure is

resulting in more surface development above old bord and pillar mines, as well as the

increasing need for mine development beneath existing, often sensitive, surface structures.

The result is greater possibility of conflict between mine operators, developers and regulatory

bodies, with the potential for sterilisation of coal resources and/or escalating surface

development / infrastructure protection costs.

Over the last forty years, there has also been significant improvement in the general level of

understanding of coal pillar behaviour and stability, both in Australia and overseas. This

paper examines some of the issues to be considered when undertaking either surface

development above old workings or mining beneath existing surface structures.

The methods currently available for the assessment of pillar stability are reviewed, including

some key geometrical, geological and statistical concepts associated with the probability of

coal pillar failure. Local and international experiences are examined for the purpose of

isolating critical variables. Some common concerns are addressed in the context of actual

practical experience, utilising a risk management approach.

Recent advances in methods for assessing coal pillar stability are highlighted, along with

critical issues to be researched and resolved in the interests of all stakeholders.

1. Introduction

Pillars in underground coal mines serve two

main roles: promoting the serviceability of

underground roadways adjacent to areas of

extraction (eg longwall chain pillars) and the

maintenance of long-term regional stability

(eg main headings pillars). The pillars are an

operational constraint, as they determine the

amount of roadway development required.

As such, there is a general need to minimise

pillar sizes wherever possible, noting that

overly-large coal pillars do not result in

significant improvements in serviceability or

enhanced regional stability. On the other

hand, inadequately-sized pillars can cause

major operational difficulties and large-scale

rock mass instability that may be manifested

as discernible surface ground movement (ie

subsidence), with potential impact on other

stakeholders.

Over 200 years of underground coal mining

in the Newcastle area has resulted in large

areas of ground supported on coal pillars,

including very extensive old workings in

generally inaccessible redundant mines and

current drivages in active mining operations.

Also, continuing growth (in terms of both

size and complexity) of civil infrastructure

is resulting in more surface development

above old bord and pillar mines, as well as

the increasing need for mine development

beneath existing, often sensitive, surface

structures. The result is greater possibility of

conflict between mine operators, developers

Proceedings of the 6th Triennial Conference on Mine Subsidence, 2004

209

and regulatory bodies, with the potential for

sterilisation of underground coal resources

and/or escalating surface development and

infrastructure protection costs.

One positive factor has been the significant

improvement in the general understanding

of coal pillar behaviour and stability over

the last forty years, both in Australia and

overseas. This paper examines the common

coal pillar stability issues relevant to surface

development above old workings or mining

beneath surface structures, commencing

with an outline of the most widely accepted

and understood empirical methodology.

2. Factor of Safety Methodology

The empirical pillar Factor of Safety (FoS)

approach is considered to represent the most

reliable methodology available for analysing

long-term stability of regular arrays of

pillars that are wide with respect to depth.

Alternative computer-based and numerical

approaches continue to be hampered by our

inability to accurately define rock mass

properties and to develop constitutive laws

that fully define their behaviour. The

inherent variability of the underground rock

mass (and specifically coal measures strata)

is also a challenge, in that system failure is

very often associated with an anomaly that

may be particularly difficult to model.

The FoS approach involves back-analysing

case histories (failures and successes) to

derive a means of estimating coal pillar

strength. FoS is simply the ratio of pillar

strength (S) to applied load (L). The great

merit of the empirical approach is that it

utilises full scale, four-dimensional models

(mines). The methodology draws inferences

directly from reality, whereas the alternative

numerical approaches draw inferences from

simplified simulations of reality.

Essentially, empirical approaches facilitate

the derivation of a probability of success in

a particular situation, based on the analysis

of prior successes and failures (ie intact and

collapsed pillars). Limitations of empirical

approaches are associated with the nature (ie

the extent and quality) of their underlying

databases. A historically common source of

difficulty is the utilisation of an empirical

relationship in a situation that is beyond the

experience quantified in the database. This

places the emphasis on the compilation of

reliable and relevant databases, as well as

their subsequent upkeep and extension.

With specific regard to general coal pillar

design in Australia, the formulae developed

in recent years by the UNSW (Salamon et

al 1996, Galvin et al 1998) are considered

to represent the current state of the art in

empirical FoS approaches. The formulae are

founded on extensively researched, broadly

based databases of coal mining experience.

The latest Australian formulae represent the

culmination to-date of the work commenced

some 40 years ago in South Africa by the

Chamber of Mines Research Organisation

following the Coalbrook disaster (Salamon

and Munro 1967). The UNSW has applied

the combined Australian and South African

database to the derivation of formulae that

are considered widely applicable.

The range of parameters within the UNSW

combined failed and unfailed pillar database

can be summarised as follows:

Depth: 20m to 510m

Mining Height: 1.0m to 9.2m

Smallest Pillar Dimension: 2m to 3.2m

Bord Width: 3.7m to 15.0m

Percentage Extraction: 30% to 90%

Width to Height Ratio: 0.9 to 11.2

Time to Failure: 0 to >80 years

The FoS derived using the UNSW formulae

can be related directly to the probability of

stability, as illustrated in Figure 1.

Proceedings of the 6th Triennial Conference on Mine Subsidence, 2004

210

Figure 1: Probability of a Stable Pillar

Geometry (after Galvin et al 1999)

iv) The presence and impact of weak

bands / discontinuities in the pillars.

v) The implications and potential nature

of a pillar collapse (surface impacts).

100

90

3. Pillar Width to Height Ratio

70

The role of increasing width to height ratio

in promoting enhanced pillar stability has

long been known. Back analysis of case

histories from South Africa and Australia, as

well as elsewhere in the world, has shown

that the width to height ratio exerts a major

influence on coal pillar strength.

60

50

40

30

20

10

0

0.5

1.5

2.5

Factor of Safety

Assuming full tributary area loading, it can

be seen from the figure that a probability of

stability of 99.9% is attained at a Factor of

Safety of 1.63. Further FoS increases have

diminishing effect, as the probability of

stability curve asymptotically approaches

100%. It follows that provided the workings

are designed to a minimum FoS of around

1.6, it is necessary to look beyond this

concept to obtain any further assurance of

stability that may be required. Further

increasing the FoS is not always the most

effective response from a risk management

perspective, given that the probability of

failure can only be reduced by <0.1%.

Additional factors that may require specific

attention include:

At low ratios (<3) overloaded coal pillars

tend to fail in a brittle, uncontrolled fashion,

whereas at higher ratios (>4) the overloaded

pillars demonstrate a more plastic form of

deformation: significant displacement may

take place in the form of convergence of the

roof and floor, as well as rib spall, but the

core of the pillar remains confined and tends

to retain its load carrying ability, generally

without failing in the commonly understood

sense. This was illustrated by Das (1986) in

tests on Indian coals, see Figure 2.

Figure 2: UCS Test Results for Coal

Samples (Das 1986)

Axial Stress (MPa)

Probability of a Stable Geometry (%)

80

i) Pillar width to height ratio.

ii) Future pillar loading history.

iii) The nature of the roof and floor.

Axial Strain (x10-3)

Proceedings of the 6th Triennial Conference on Mine Subsidence, 2004

211

International industry experience confirms

the importance of pillar width to height ratio

to coal pillar stability. Incidences of collapse

are concentrated at low ratios, see Figure 3.

The three databases are complimentary in

nature, reflecting the range of experiences of

their respective industries. For example, the

Australian data provides insight with regard

to pillar behaviour at relatively high w/h

ratios and furnishes the failed case at the

w/h ratio of 8. In contrast, the South African

industry has traditionally been characterised

by geometries that generally involve lower

w/h ratios, which is partly reflected in the

maximum w/h ratio of only 3.7 for a South

African failed case. Similarly, the CHM

pillar cases cover the lower end of the range

of w/h ratios, from 0.6 to 1.4.

Figure 3: Frequency of Collapses versus

Width to Height Ratio

20

Number of Pillar Collapses

18

Australia (Galvin et al, 1998)

16

South Africa (Madden and Hardman, 1992)

14

12

10

8

6

4

There are no failed cases in this combined

South African and Australian database with

a w/h ratio of greater than 8, even at a very

low Factor of Safety, and there is only one

failed case at a w/h ratio of greater than 5.

2

7.5-8.0

7.0-7.5

6.5-7.0

6.0-6.5

5.5-6.0

5.0-5.5

4.5-5.0

4.0-4.5

3.5-4.0

3.0-3.5

2.5-3.0

2.0-2.5

1.5-2.0

1.0-1.5

0-0.5

0.5-1.0

Pillar Width to Height Ratio

Width to height ratio, applied in conjunction

with other design criteria, such as FoS, is a

useful indicator of design reliability. This is

illustrated in Figure 4, which presents the

FoS versus pillar w/h ratio relationship for a

combined database of failed South African

and Australian bord and pillar panels, plus a

database of highwall mining (CHM)

failed pillar cases (UNSW 1995, Madden

and Hardman 1992, Strata Engineering,

2001).

The highest Factor of Safety assigned to a

bord and pillar collapse is 2.1 and this was

associated with a w/h ratio of only 2.2.

Although there are failed CHM pillars with

Factors of Safety of >3, all of them have

pillar width to height ratios of <2.

A limit envelope can be defined for the

database of failed cases, illustrated by the

curve and given by the following equation:

w/h ratio = 22.433e-1.1677*(Factor of Safety)

Figure 4: Database of Pillar Collapses

Width to Height Ratio versus FoS

Width to Height Ratio (w/h)

Beyond this envelope, there is no precedent

for failure within these databases. It is worth

noting that the exclusion of the CHM pillar

data would not materially change the shape

of this limit envelope.

Australian Highwall Mining Cases

South African Failed Cases (Madden and Hardman, 1992)

Australian Failed Cases (UNSW, 1995)

Limit Line of Failed Cases

7

6

5

4

3

2

1

0

0.5

1.5

2.5

In the case of long life (>5 years) pillars, if

it is reasonable to assume that the coal

pillars are, or will at some point in the

future, be subjected to full tributary area

loading, then it is generally considered

prudent to design the pillars to be outside (ie

above) the envelope defined by this

equation, even though there are many

examples of stable pillars that fall within it.

Factor of Safety (FoS)

Proceedings of the 6th Triennial Conference on Mine Subsidence, 2004

212

Furthermore, in the case of critical long-life

pillars, such as main headings, barriers or

those required for the purposes of surface

protection, it is considered prudent to allow

an additional margin beyond this curve.

designing to a FoS of 1.01 is not generally

acceptable, even though strength nominally

exceeds stress). Geological variability partly

accounts for the scatter in the population of

failed pillar cases and usually necessitates

design FoS values of >1.5, equivalent to

very low probabilities of failure.

4. Future Loading History

Back analysis indicates that cases of pillar

instability traditionally associated with weak

floor can very often be explained in terms of

the criteria outlined previously, notably in

terms of FoS plus w/h ratio. Even in known

weak floor environments, incidences of

pillar collapse are again concentrated at low

w/h ratios, see Figure 5.

5. Roof and Floor Properties

The South African and Australian databases

from which the UNSW coal pillar design

formulae have been derived cover a broad

range of roof and floor materials, including

mudrocks, coal, siltstones and sandstones.

Therefore, these materials and the variability

in pillar strength that may be associated with

them are implicitly recognised and catered

for within the Factor of Safety approach.

The uncertainty associated with the natural

variability in coal measures strata often

prohibits design to low Factors of Safety (eg

14

12

USA (Marino, 1989)

10

8

6

4

2

5.5-6.0

5.0-5.5

4.5-5.0

4.0-4.5

3.5-4.0

3.0-3.5

2.5-3.0

2.0-2.5

1.5-2.0

1.0-1.5

0

0.5-1.0

There are also circumstances that can have

potentially positive impacts on future pillar

loading conditions, such as buoyancy effects

associated with the gradual increase in the

water level in the old workings.

Figure 5: US Cases of Pillar Collapse in

Weak Floor Conditions (Marino and

Bauer 1989)

0-0.5

Inadequate coal pillar design associated with

uncertainties and inaccuracies regarding the

determination of abutment loads adjacent to

extraction areas has been associated with a

number of cases of instability, in Australia

and overseas. This puts an emphasis on the

understanding of system stiffness, the design

of barrier pillars, overall panel geometry and

panel width to depth ratio.

Number of Pillar Collapses

If the pillars are to be subject at some point

to stress increases due to ongoing mining

activities, it is usually the case that a design

to a higher FoS will be undertaken. In South

Africa, for example, coal pillars intended for

subsequent extraction are generally designed

to a minimum FoS of ~2.

Pillar Width to Height Ratio

Nonetheless, specific consideration should

be given to the application of these design

formulae in the presence of extremely weak

roof and floor materials. In Australia, the

Awaba Tuff (a claystone found in the Great

Northern Seam floor in the Lake Macquarie

area) has warranted particular attention. This

unit often has a high smectite content and

tends to swell and degrade in the presence of

moisture.

6. Discontinuities / Weak Bands

The potential impact of discontinuities (ie

localised structural defects), such as faults,

diminishes rapidly as the width to height

ratio of the pillars increases. Similarly, the

Proceedings of the 6th Triennial Conference on Mine Subsidence, 2004

213

Again, the database encompasses pillars in a

significant number of seams in different

geotechnical environments; consequently

the existence of pillar weaknesses is very

largely reflected and implicit within the

variability in the failed and intact pillar

cases, such that these weaknesses are very

largely catered for by adopting appropriate

FoS values.

Cases in which the competency of the coal

seam is specifically regarded as a critical

issue are rare and there are none known of

in Australia.

7. Surface Protection

Long-term panel stability may be critical for

a variety of reasons, including underground

coal resource access and surface protection.

In these circumstances, the most common

response is simply to increase the required

FoS. As previously stated, this is simplistic

and not necessarily optimal, as it ignores the

other factors involved.

In situations where the pillars are required to

be stable in the long-term due to surface

protection considerations, it has historically

been regarded as good practice in South

Africa to design the workings to a Factor of

Safety of 2 (Salamon and Oravecz 1976).

In Australia, long-life critical pillars (eg in

main headings and for surface protection)

are often (but not universally) designed to

an FoS of 2.11 (with no consideration of the

pillar width to height ratio), noting that this

equates to a probability of failure of only

one panel in a million. This reduces the

likelihood of instability to a level that would

be considered acceptable in other critical

fields of public interest.

Increasing pillar w/h ratio offers an added

safeguard. As indicated, the likelihood of

instability tends to reduce with increased

w/h ratio and the deformation characteristic

of the pillars changes from strain softening

to work hardening, such that the potential

for sudden collapse decreases markedly and

the more likely mode of failure (if at all)

becomes one of gradual creep.

The issue of the potential for very long-term

deterioration of workings leading to failure

is an important consideration with regard to

surface protection and this can again be

addressed in the context of these industry

databases. It can be seen from Figure 6 that

the great majority of pillar collapses occur

within a short period of mining. Within the

South African and Australian databases,

apart from one uncertain Australian case

history (ie at between 80 and 170 years) the

maximum recorded interval between mining

of the workings and subsequent failure is 52

years and the median time to failure is 4

years.

Experience from the USA is generally

consistent with this, even in unusually weak

floor conditions.

Figure 6: Time to Collapse for Australian

and South African Bord and Pillar Cases

40

Number of Collapsed Cases

influence of weak bands decreases as their

aspect ratio (length / width) increases with

increasing pillar width.

35

30

25

20

15

10

5

0

<10

>10, <20 >20, <30 >30, <40 >40, <50 >50, <60 >60, <70 >70, <80

>80

Time to Failure (Ten Year Ranges)

Expressed in the context of pillar FoS and

w/h ratio values, it can again be shown that

the likelihood of failure reduces markedly

with time, see Figures 7 and 8.

Proceedings of the 6th Triennial Conference on Mine Subsidence, 2004

214

Figure 7: Time to Collapse vs FoS

the contrary, the historical data suggests that

pillar deterioration (eg associated with spall

and weathering) tends to a limit over time.

Factor of Safety (FoS)

2.5

Australian Failed Cases

South African Failed Cases

Limit Line of Failed Cases

2.0

8. Data Interpretation

1.5

1.0

0.5

0

20

40

60

80

Time to Failure (Years)

Figure 8: Time to Collapse vs w/h Ratio

Pillar Width to Height Ratio

Australian Failed Cases

South African Failed Cases

Limit Line of Failed Cases

0

0

20

40

60

80

Time to Failure (Years)

Referring to Figure 7, it can be seen that

after an elapsed period of 20 years, there are

no cases of pillar collapse at FoS values of

>1.5. After 40 years, there are no failed

cases at FoS values of >1.4; after 80 years

no failures at an FoS of >1.1.

In assessing the stability of a mining layout

and particularly old workings underlying

proposed surface development, a sensitivity

analysis is often conducted with regard to

the impact of variations in geometry on the

FoS values. Whilst it is prudent to consider

the potential impact of changes in the

mining geometry on pillar stability, it must

be clearly understood that the South African

and Australian databases are based on a

combination of nominal (design) and actual

(as built) dimensions, which will differ in

practice. As with geological variability (see

Section 5), geometrical discrepancies are

inherent within the database and contribute

to the spread of values, such that it is

generally considered prudent to design to

Factors of Safety of significantly greater

than 1.

Salamon and Oravecz 1976 addresses this

issue as follows:

Since the pillar strength formula was

derived from practical mining data, in

which similar discrepancies were inherent,

a safety factor, chosen on the basis of the

previous discussion, will largely take into

account the errors arising from this source.

Referring to Figure 8, it can be seen that

after an elapsed period of 10 years, there are

no cases of collapse involving pillars with

width to height ratios of >3. After 40 years,

there are no failed cases at w/h ratios of >2.

Note that the previous discussion refers to

Factors of Safety of ~1.6.

The industry databases strongly suggest that

the majority of failures occur within a short

period of mining, due either to inappropriate

design or some local anomaly. As time

progresses, the actual likelihood of failure

continually decreases and those collapses

that do occur involve pillar designs that

would be considered increasingly marginal.

There is no evidence to suggest that failure

becomes increasingly likely over time. On

Furthermore, it is important to understand

that the database, the empirical strength

formulae and the associated probabilities of

stability are not founded on the likely actual

pillar geometry at the moment of collapse. It

is simply not rational to base an assessment

on what the actual pillar geometry may have

become after a period of time or may be at

some point in the future. To take such an

approach across the whole of the database

Proceedings of the 6th Triennial Conference on Mine Subsidence, 2004

215

(even if it could be rationally undertaken,

which it cannot) would simply mean that

smaller and/or higher coal pillars would be

associated with higher probabilities of

stability. In other words, assessing coal

pillar stability on the basis that some

unquantified (and frequently unquantifiable)

deterioration may well have taken place

over time to change the actual pillar

dimensions amounts to double dipping of

factors that are already inherently accounted

for within the database and is not logical.

Caution is therefore required in interpreting

the results of exercises aimed at gathering

data from inaccessible old workings, for

example, by means of surface drilling. Some

level of deterioration is common; this may

not be an indication of potential instability

and can result in an unduly conservative

assessment.

Salamon and Oravecz 1976 suggests that

as an additional precaution the discrepancy

between nominal and actual dimensions

should be examined, quoting an example of

a 0.3m difference in pillar width and height,

which is typical of the level of variation

between nominal and as built dimensions

that is frequently encountered underground.

They point out that the potential impact of

the discrepancy increases as the pillar design

dimensions get smaller and conclude that:

The derivation of Factor of Safety (FoS) and

an associated nominal probability of failure

using appropriate formulae and input values

is fundamental. It should also be evident that

a range of additional criteria can be used to

supplement an FoS-based assessment and

improve the overall understanding of the

potential for instability and the reliability of

a design; in this regard, minimum pillar

width to height ratio is a key parameter.

This paper has not considered subsidence

mechanisms or the consequences thereof.

Detailed site assessment should consider the

nature of potential subsidence, including the

mechanisms, magnitudes and strains

associated with ground displacements. The

mode of ground movement may not always

be a function of pillar collapse per se. For

example, at depths of <50m, the propensity

for a sink hole form of subsidence,

associated largely with intersection collapse

in weak roof conditions, increases markedly.

Finally, it should be apparent that there is

considerable international experience of coal

pillar design and stability issues, with a high

level of commonality. The derivation of the

next generation of design tools should aim

to build on this broad experience base.

10.

It is therefore recommended that special

care should be taken if small pillars are

used and, also, that no pillar width of less

than 3 metres should be used. Moreover, the

safety factor of pillars between 3.0 and 4.5m

in width should be at least 1.7.

9. Concluding Remarks

A range of issues relevant to long-term

pillar stability have been outlined. These are

relevant to both the mining operation and

any party involved in surface protection and

development.

References

Britten, T. and Frith, R.C. 2001 A Review

of the Geotechnical Design Aspects

Highwall Mining Based on a BackAnalysis of Australian Experiences.

Strata Engineering Report No. 00-001RCH/1 to Roche Mining.

Das, M.N. 1986 Influence of Width to

Height Ratio on Post-failure Behaviour of

Coal. International Journal of Mining and

Geological Engineering, Vol. 4, pp. 79-87.

Galvin, J.M., Hebblewhite, B.K., Salamon,

M.D.G. and Lin, B.B. 1998 Establishing

the Strength of Rectangular and Irregular

Proceedings of the 6th Triennial Conference on Mine Subsidence, 2004

216

Pillars. Final Report for ACARP Project

C5024.

Galvin, J.M., Hebblewhite, B.K. and

Salamon, M.D.G. 1999 UNSW Coal

Pillar Strength Determinations for

Australian and South African Mining

Conditions. Proc. of the 2nd International

Workshop on Coal Pillar Mechanics and

Design, Pittsburgh, NIOSH IC9448.

Madden, B.J. and Hardman, D.R. 1992

Long Term Stability of Bord and Pillar

Workings. Proceedings of Symposium on

Construction over Mined Areas, Pretoria.

Marino, G.G. and Bauer, R.A. 1989

Behaviour of Abandoned Room and

Pillar Mines in Illinois. International

Journal of Mining g and Geological

Engineering, Volume 7, pp. 271-281.

Salamon, M.D.G., Galvin, J.M., Hocking,

G. and Anderson, I. 1996 Coal Pillar

Strength from Back Calculation.

Research Report RP 1/96, JCB Strata

Control for Mine Design Project.

Salamon, M.D.G. and Munro, A.H. 1967

A Method of Designing Bord and Pillar

Workings. Journal of the South African

Institute of Mining and Metallurgy.

September 1967, Volume 68, no. 2, pp 68

- 78.

Salamon, M.D.G. and Oravecz, K.I. 1976

Rock Mechanics in Coal Mining.

Chamber of Mines of South Africa, P.R.D.

Series No. 198.

University of New South Wales 1995

Roadway

and

Pillar

Mechanics

Workshop - Stage 2 : Design Principles

and Practice (Course Notes).

Proceedings of the 6th Triennial Conference on Mine Subsidence, 2004

217

Proceedings of the 6th Triennial Conference on Mine Subsidence, 2004

218

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Aloha Kitchen Troubleshooting GuideDocument24 pagesAloha Kitchen Troubleshooting GuideRicardo Paso GonzalezNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Capitol Visitor Center Diaphragm WallDocument5 pagesCapitol Visitor Center Diaphragm WallTony ChanNo ratings yet

- Final AccountDocument7 pagesFinal Accountswati100% (3)

- Airblast Instrumentation in Surface MiningDocument58 pagesAirblast Instrumentation in Surface MiningTony ChanNo ratings yet

- Autonomous Crack ComparometerDocument161 pagesAutonomous Crack ComparometerTony ChanNo ratings yet

- Analysis of Axial Pile Load Test(s) On Large Bored Grouted and Instrumented PilesDocument14 pagesAnalysis of Axial Pile Load Test(s) On Large Bored Grouted and Instrumented PilesTony ChanNo ratings yet

- BehrensDocument9 pagesBehrensTony ChanNo ratings yet

- 035 Reducing Negative Skin Friction With Bitumen Slip Layers PDFDocument3 pages035 Reducing Negative Skin Friction With Bitumen Slip Layers PDFTony ChanNo ratings yet

- BCE - Technical - Note - 3 - Relating Peak Particle Velocity and Acceleration To Moment Magnitude in Pasive Seismic MonitoringDocument5 pagesBCE - Technical - Note - 3 - Relating Peak Particle Velocity and Acceleration To Moment Magnitude in Pasive Seismic MonitoringTony ChanNo ratings yet

- Probabilistic Analysis of Pile Deflection Under Lateral LoadsDocument8 pagesProbabilistic Analysis of Pile Deflection Under Lateral LoadsTony ChanNo ratings yet

- Geophones or Accelerometers BCE Technical Note 10Document3 pagesGeophones or Accelerometers BCE Technical Note 10Tony ChanNo ratings yet

- Filling of Abandoned Coal Mines Located Under The Ipswich MotorwayDocument10 pagesFilling of Abandoned Coal Mines Located Under The Ipswich MotorwayTony ChanNo ratings yet

- Blibli Merchant API Documentation v-3.6.0 PDFDocument92 pagesBlibli Merchant API Documentation v-3.6.0 PDFKanto TerrorNo ratings yet

- Lab 5 - Archimedes PrincipleDocument13 pagesLab 5 - Archimedes PrincipleLance ShahNo ratings yet

- 15 Life Changing Lessons From Wayne DyerDocument6 pages15 Life Changing Lessons From Wayne Dyersaikumar selaNo ratings yet

- Fundamentals of Martial Arts RonelDocument2 pagesFundamentals of Martial Arts RonelRodne Badua RufinoNo ratings yet

- Annexure-IA Self Declaration Form For Application For Krishak Bandhu (Natun) SchemeDocument3 pagesAnnexure-IA Self Declaration Form For Application For Krishak Bandhu (Natun) SchemeSomnath Das YTNo ratings yet

- Aeco136 - Final Term Report (Manatal Multipurpose Cooperatives)Document20 pagesAeco136 - Final Term Report (Manatal Multipurpose Cooperatives)JoyDianneGumatayNo ratings yet

- A Critical Analysis of The Beatitudes From The Gospel According To LukeDocument10 pagesA Critical Analysis of The Beatitudes From The Gospel According To LukejaketawneyNo ratings yet

- Write The Days in The Correct OrderDocument7 pagesWrite The Days in The Correct OrderRuth Yánez PadillaNo ratings yet

- 2841 A Watermark For Large LanguageDocument24 pages2841 A Watermark For Large LanguageAdithyaNo ratings yet

- Tort of NegligenceDocument10 pagesTort of NegligenceHETRAM SIYAGNo ratings yet

- Notes Ankita KashyapDocument49 pagesNotes Ankita Kashyapkharsatikevin92No ratings yet

- Domelux Series Manual de ServicioDocument43 pagesDomelux Series Manual de ServicioJohan LunaNo ratings yet

- Attracting and Dating A Partner For Marriag1Document21 pagesAttracting and Dating A Partner For Marriag1Isaac Abayomi OshinNo ratings yet

- Gpon - Vlan - Gem PortDocument5 pagesGpon - Vlan - Gem PortLe VuNo ratings yet

- Relationscapes Movement Art Philosophy by Erin Manning 2009 Cambridge Ma The Mit Press X 268 PP Images Notes Bibliography Index Dollar3200 HardcoverDocument4 pagesRelationscapes Movement Art Philosophy by Erin Manning 2009 Cambridge Ma The Mit Press X 268 PP Images Notes Bibliography Index Dollar3200 HardcoverHonglan HuangNo ratings yet

- 跟安德烈共餐 夢想照進現實Document49 pages跟安德烈共餐 夢想照進現實lamarckcanadaNo ratings yet

- Chavara Brochure Edited CompressedDocument13 pagesChavara Brochure Edited CompressedShameer ShajiNo ratings yet

- Online ExaminationDocument30 pagesOnline ExaminationArihant BothraNo ratings yet

- Ma History Dissertation StructureDocument7 pagesMa History Dissertation StructureCheapCustomPapersSingapore100% (1)

- GIAN Template-ProposalDocument4 pagesGIAN Template-ProposalRamesh GowdaNo ratings yet

- Fundamentals OF Accounting: Accounting by Meigs, Williams, Haka, BettnerDocument64 pagesFundamentals OF Accounting: Accounting by Meigs, Williams, Haka, BettnerAliya SaeedNo ratings yet

- TPA-Referenced Lesson Plan Teacher Candidate Name: Joe Birkholz Grade & Subject Area: 11-12 World History Date For Planned Lesson: TBA 1 DayDocument4 pagesTPA-Referenced Lesson Plan Teacher Candidate Name: Joe Birkholz Grade & Subject Area: 11-12 World History Date For Planned Lesson: TBA 1 Dayapi-347747740No ratings yet

- Presentation Class InglishDocument16 pagesPresentation Class Inglishmiralis gonzalezNo ratings yet

- Lesson 1 The Moral Agent: Camarines Norte State CollegeDocument4 pagesLesson 1 The Moral Agent: Camarines Norte State CollegeJeanNo ratings yet

- Macmillan Education Student - Great Thinkers B1+ - Student's Book 3Document1 pageMacmillan Education Student - Great Thinkers B1+ - Student's Book 3Rodrigo PequeñoNo ratings yet

- IB History IA SampleDocument14 pagesIB History IA SampleEscalusNo ratings yet

- Activity STSDocument1 pageActivity STSRalph ZeusNo ratings yet

- The Hydrothermal Alteration of Feldspars in Acid Solutions Between 300 Degrees and 400 Degrees CDocument12 pagesThe Hydrothermal Alteration of Feldspars in Acid Solutions Between 300 Degrees and 400 Degrees Ccristian camilo guisao palacioNo ratings yet