Professional Documents

Culture Documents

Galvany Shopprimer IZ182 (N) (Two-Component) : Product Description

Galvany Shopprimer IZ182 (N) (Two-Component) : Product Description

Uploaded by

Trịnh Minh KhoaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Galvany Shopprimer IZ182 (N) (Two-Component) : Product Description

Galvany Shopprimer IZ182 (N) (Two-Component) : Product Description

Uploaded by

Trịnh Minh KhoaCopyright:

Available Formats

Galvany Shopprimer

IZ182(N) (Two-Component)

Product

Description

Recommended Use

Galvany Shopprimer IZ182(N) is a self-curing, zinc filled inorganic coating. Liquid and Zinc

Paste mixed prior to application. It is a weldable inorganic primer. Welds made over Galvany

Shopprimer IZ182(N), coated steel are equal in every respect to welds joining uncoated steel

prior to fabrication.

It protects cathodically for periods exceeding 12 months in normal and marine environments.

Welds splatter does not adhere to damage the coating. Coated steel can be welded as quickly

and easily as bare steel at production line speeds, with no lows in strength of consistency of the

weld. Dry to touch paint and coatings.

Approved as a Prefabrication primer by Germanischer Lloyd (GL).

It is used as a shop (pre-construction) primer for the protection of steel from corrosion during

fabrication.

IZ182(N) that is not painting a top coat is applied to pH 5 ~ 10 condition.

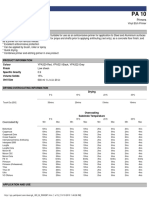

Physical Properties

Finish and Color

Drying Time

(with 65% R.H.)

Flat.

Gray

Substrate temp.

-18/0

4/40

16/60

27/80

38/100

Set to touch

2h

40min

15min

5min

3min

Dry through

5d

12h

6h

4h

2h

*The actual drying time is subject to the film thickness, ventilation, humidity etc., and drying time under other

temperature conditions should be checked and informed by KCC.

Solids by Volume

Approx. 35 %

Theoretical

Spreading Rate

23.3 /L in 15 dry film thickness on a smooth surface.

Specific Gravity

Approx. 1.34 for Mixture of Paste and Liquid.

Flash Point

Liquid : 12 /54 (Closed cup)

Paste : 4 /39 (Closed cup)

Application Details

Surface

Preparation

Application

Conditions

Remove any oil, grease, dirt and any other contaminant from the surface before painting by

proper method such as solvent cleaning and fresh water washing, etc.

* Steel : Blast cleaning to Sa2.5 to obtain 25 ~ 40 blast profile.

Normal

Min.

Max.

Substrate Temperature

4~43

-18

93

Relative Humidity

40%~80%

10%

85%

Special thinning and application techniques may be required in above or below normal conditions.

Mixing

Liquid : Paste = 5 : 5 (by volume).

Mix separately, then combine and mix the mixture thoroughly prior to application. Use the

mixture after filtering with 50 mesh screen.

Pot Life

24h at 20 /68 ,

Thinning

Under the temperature condition below 25/77 , diluted up to 40% by volume with Thinner

No. 0608. Under the temperature condition above 25 /77 or windy, use Thinner No.

0614.

Disclaimer : The information in this data sheet is believed to the best of our knowledge based on laboratory test and practical

experience. However, there are many factors affecting the performance of product and the product quality itself, so we are not

able to guarantee without the confirmation of the purpose of using the product from us in writing. We reserve the right to

change the data without notice and you should check that this data sheet is current prior to using the product.

KCC Corporation

Galvany Shopprimer IZ182(N) (Two-Components)

Application

Method

Special thinning and application techniques may be required above or below normal conditions.

Spray : Use adequate air volume for correct operation. Hold gun 8 ~ 10 inches from the

surface and at a right angle to the surface. Use a 50% overlap with each pass of the gun on

irregular surfaces, coat the edges first, making an extra pass later.

* For airless spray application ;

Nozzle orifice : 432 ~ 584 (0.017 ~ 0.023)

Output pressure : 9.6 ~ 12.4 MPa

Fan

: 45~ 90

* For conventional spray :

Use agitated pot and maximum 50 feet hose. Keep pot at same elevation as gun.

If spraying stops for more than 15 minutes, blow material from hose back into pot.

* For Brush or Roller ;

For minor touch-up coating only. Use medium bristled brush.

Apply with full brush and avoid rebrushing.

Typical

Film Thickness

Recoating Interval

15~25 dry.

Subsequent Coat

At 20 and above 60 % R.H., Minimum : 5h

Maximum : Free

May be topcoated with Galvany IZ 180(N), epoxies, epoxy tars, vinyls, acrylics, chlorinated

rubbers, silicones or according to specification.

Apply directly to the substrate compatibility with other coatings.

Shelf Life

12 months.

Heat resistance

Continuous

: 400 / 752

Non-continuous : 427 / 800

Chemical

Resistance

Acids

Alkalies

Solvents

Salts

Water

Splash & Spillage

Fair

Fair

Excellent

Excellent

Excellent

Fumes

Good

Good

Excellent

Excellent

Excellent

NR

Excellent

NR

NR

Immersion

NR

* NR : Not Recommended.

Standard

Unit

Remarks

Issued

Packing

18 L ( Liquid : 9 L, Zinc Paste : 9 L).

Automatic welding ;

About 48 inch per minutes of welding rod speed is recommended for Galvany Shopprimer

IZ182(N) applied steel. It is depends on the thickness of steel plate and welding rod.

This includes the following process;

1) Submerged arc.

2) Flux core.

3) Short arc.

4) Metal inert gas(MIG)

Manual welding :

Galvany Shopprimer IZ182(N) can be easily welded by all electrodes with MIL-E numbers

between 6010 and 10018.

Galvany Shopprimer IZ182(N) will skin if left in opened cans. Skin has no effect on

performance, but should be removed before using.

Clean tools with Thinner No. 0608 or No. 002 immediately after use.

Remove hardened material with 10 % caustic solution.

April, 2009

Disclaimer : The information in this data sheet is believed to the best of our knowledge based on laboratory test and practical

experience. However, there are many factors affecting the performance of product and the product quality itself, so we are not

able to guarantee without the confirmation of the purpose of using the product from us in writing. We reserve the right to

change the data without notice and you should check that this data sheet is current prior to using the product.

KCC Corporation

You might also like

- JSA For Fabrication WorkDocument11 pagesJSA For Fabrication WorkRanjan KumarNo ratings yet

- DX100 Operator's ManualDocument744 pagesDX100 Operator's ManualgotchiexNo ratings yet

- Cerakote H - C Series Training Manual 22316WEBDocument28 pagesCerakote H - C Series Training Manual 22316WEBRafael Nogueira RomãoNo ratings yet

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- KCC DATASHEET Galvany Shopprimer IZ182 (J) (IMO) (Two-Component) EngDocument3 pagesKCC DATASHEET Galvany Shopprimer IZ182 (J) (IMO) (Two-Component) EngIsabelo AbaoNo ratings yet

- KCC DataSheet IZ1990 (ENG)Document2 pagesKCC DataSheet IZ1990 (ENG)Trịnh Minh KhoaNo ratings yet

- Iz180 (N) 1184 (P)Document3 pagesIz180 (N) 1184 (P)anminsungNo ratings yet

- Carboweld 11P PDSDocument4 pagesCarboweld 11P PDS이선엽No ratings yet

- Rust O Cap: Surface Tolerant EpoxyDocument3 pagesRust O Cap: Surface Tolerant EpoxySanthana SaravanaNo ratings yet

- KCC - DATASHEET - Cerany IZ1990 (Two-Component) - EngDocument3 pagesKCC - DATASHEET - Cerany IZ1990 (Two-Component) - EngNguyen1987 TrungNo ratings yet

- Interzinc 52Document4 pagesInterzinc 52mirzaaliNo ratings yet

- Vinyl Ester-Glass Flake PaintDocument4 pagesVinyl Ester-Glass Flake PaintSimbu ArasanNo ratings yet

- Interzinc 52: Epoxy Zinc-RichDocument4 pagesInterzinc 52: Epoxy Zinc-RichKrishna VachaNo ratings yet

- Resist 78: Technical Data Sheet Application GuideDocument7 pagesResist 78: Technical Data Sheet Application GuideMohd YusriNo ratings yet

- PPG-Hi-Temp 1027 - PdsDocument6 pagesPPG-Hi-Temp 1027 - PdsqaNo ratings yet

- Carboguard 635 Thinned 50% - Sealer PDSDocument5 pagesCarboguard 635 Thinned 50% - Sealer PDSjakeNo ratings yet

- Ul Ul Ul Ultracote Tracote Tracote TracoteDocument3 pagesUl Ul Ul Ultracote Tracote Tracote TracoteJenniferValleNo ratings yet

- Apcoguard SF 725Document3 pagesApcoguard SF 725kiran vargheseNo ratings yet

- 113.007 - Zinc Clad Xi WB BR PDFDocument2 pages113.007 - Zinc Clad Xi WB BR PDFFernando VittoNo ratings yet

- Indium6.3 Water-Soluble Solder PasteDocument2 pagesIndium6.3 Water-Soluble Solder PastebrunizzaNo ratings yet

- Interplate 317: Zinc Silicate Shop PrimerDocument4 pagesInterplate 317: Zinc Silicate Shop PrimerMohamed NouzerNo ratings yet

- Zinc Anode 304 MZ Ds 099 02Document2 pagesZinc Anode 304 MZ Ds 099 02Power PowerNo ratings yet

- Carboguard 636 XT PDSDocument4 pagesCarboguard 636 XT PDSCarlos Rojas HandalNo ratings yet

- Carbothane+134+HG+PDS+3 11Document2 pagesCarbothane+134+HG+PDS+3 11James Everett AbdulNo ratings yet

- Thermaline 400 Finish PDSDocument3 pagesThermaline 400 Finish PDSQuy RomNo ratings yet

- Inorganic Zinc-Rich Silicate: IS 14946: Protective Coating World Wide ProductsDocument4 pagesInorganic Zinc-Rich Silicate: IS 14946: Protective Coating World Wide ProductsSubham SahuNo ratings yet

- Jazeera Barrel CoatingDocument2 pagesJazeera Barrel Coatingsalam nazarNo ratings yet

- Method Statement KACKC Steelguard MIDESCODocument4 pagesMethod Statement KACKC Steelguard MIDESCOTony KhouryNo ratings yet

- Epigard Zinc Rich Primer PDFDocument2 pagesEpigard Zinc Rich Primer PDFKarthimeena MeenaNo ratings yet

- Apcodur CF 699: Product DescriptionDocument4 pagesApcodur CF 699: Product DescriptionShravana PrasadNo ratings yet

- Pa 10Document3 pagesPa 10LymeParkNo ratings yet

- Jotun Resist 86 Data SheetDocument7 pagesJotun Resist 86 Data SheetKunal AjgaonkarNo ratings yet

- Interbond 1202UPC: Universal Pipe CoatingDocument4 pagesInterbond 1202UPC: Universal Pipe CoatingChennaNo ratings yet

- Amercoat 370Document3 pagesAmercoat 370Victor Hugo Bustos Beltran100% (1)

- Barrier ZEP: Technical Data Sheet Application GuideDocument7 pagesBarrier ZEP: Technical Data Sheet Application GuideNurmalinda SihombingNo ratings yet

- Carbo Zinc 11 HsDocument2 pagesCarbo Zinc 11 Hstyto_rmzNo ratings yet

- Carbomastic 15 LT: Selection & Specification DataDocument3 pagesCarbomastic 15 LT: Selection & Specification Datasrinath vNo ratings yet

- Carbomastic 15 PDSDocument2 pagesCarbomastic 15 PDSAnonymous 4fVUDODNo ratings yet

- PDS - EP-10 Etch PrimerDocument2 pagesPDS - EP-10 Etch Primercarlogeretto2No ratings yet

- Zinga Technical Data SheetDocument6 pagesZinga Technical Data SheetVikas TanejaNo ratings yet

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data Sheetajuhaseen100% (1)

- Resist 78: Technical Data Sheet Application GuideDocument7 pagesResist 78: Technical Data Sheet Application GuideEko Adi PutraNo ratings yet

- Interzinc 75V: Zinc-Rich EpoxyDocument4 pagesInterzinc 75V: Zinc-Rich EpoxyTrịnh Minh KhoaNo ratings yet

- Technical Data Sheets: Fluid FilmDocument5 pagesTechnical Data Sheets: Fluid FilmRAHULNo ratings yet

- 2K Etch Primer-Process Data SheetDocument3 pages2K Etch Primer-Process Data SheetmajaklipaNo ratings yet

- PS 22118Document2 pagesPS 22118omar.moradi3707No ratings yet

- Application Instructions Application InstructionsDocument5 pagesApplication Instructions Application InstructionsmameeranNo ratings yet

- GalvosilDocument5 pagesGalvosilAditya DasNo ratings yet

- Carboguard 880 MIO PDSDocument4 pagesCarboguard 880 MIO PDSHerman EngelbrechtNo ratings yet

- Intergard 269 DatasheetDocument4 pagesIntergard 269 DatasheetBalasubramanian AnanthNo ratings yet

- Carboguard 158 UP PDSDocument4 pagesCarboguard 158 UP PDSvihor94213No ratings yet

- PDS Admiline 354Document3 pagesPDS Admiline 354Angga Dwi PutrantoNo ratings yet

- Carbomastic 15 PDS 2013Document2 pagesCarbomastic 15 PDS 20134508366279No ratings yet

- 2006-008 (NXPowerLite)Document2 pages2006-008 (NXPowerLite)vijayakumar_samyNo ratings yet

- Pds Ipd Sikafast3121 Us MW 3.22.12Document4 pagesPds Ipd Sikafast3121 Us MW 3.22.12robox514No ratings yet

- DATA SHEET NO. 2006-008 Epigard HB Zinc Phosphate Primer Grey / RedDocument2 pagesDATA SHEET NO. 2006-008 Epigard HB Zinc Phosphate Primer Grey / Redvijayakumar_samyNo ratings yet

- Phenoline 1205 PDS 9-06 PDFDocument2 pagesPhenoline 1205 PDS 9-06 PDFttr_1947No ratings yet

- Plasite 7159 HAR: Selection & Specification DataDocument4 pagesPlasite 7159 HAR: Selection & Specification DataRobertoNo ratings yet

- 0091 Amercoat 91 PDS May 08Document2 pages0091 Amercoat 91 PDS May 08donaldoguerreroNo ratings yet

- Oasis QD Special PrimerDocument2 pagesOasis QD Special PrimerMaurice DavisNo ratings yet

- Galvacoat Data SheetDocument2 pagesGalvacoat Data Sheetabu.qckumyangNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Intertuf 654: Bleached EpoxyDocument4 pagesIntertuf 654: Bleached EpoxyTrịnh Minh KhoaNo ratings yet

- Intertuf 362: Epoxy AnticorrosiveDocument4 pagesIntertuf 362: Epoxy AnticorrosiveTrịnh Minh KhoaNo ratings yet

- Sigma Cover 256Document5 pagesSigma Cover 256Trịnh Minh KhoaNo ratings yet

- Intertuf 5003Document4 pagesIntertuf 5003Trịnh Minh KhoaNo ratings yet

- Interzinc 75V: Zinc-Rich EpoxyDocument4 pagesInterzinc 75V: Zinc-Rich EpoxyTrịnh Minh KhoaNo ratings yet

- Interzinc 22HSDocument4 pagesInterzinc 22HSTrịnh Minh KhoaNo ratings yet

- Interzone 101Document4 pagesInterzone 101Trịnh Minh KhoaNo ratings yet

- Sigmazinc 158Document6 pagesSigmazinc 158Trịnh Minh KhoaNo ratings yet

- Interzone 5140: Epoxy PrimerDocument4 pagesInterzone 5140: Epoxy PrimerTrịnh Minh KhoaNo ratings yet

- Interprime 820Document4 pagesInterprime 820Trịnh Minh KhoaNo ratings yet

- Intercryl 530 PDFDocument4 pagesIntercryl 530 PDFTrịnh Minh KhoaNo ratings yet

- Res Q SteelDocument4 pagesRes Q SteelTrịnh Minh KhoaNo ratings yet

- Interbond 600 PDFDocument4 pagesInterbond 600 PDFTrịnh Minh KhoaNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSTrịnh Minh KhoaNo ratings yet

- Interclene 165Document4 pagesInterclene 165Trịnh Minh KhoaNo ratings yet

- South Eastman English & Literacy Services: Unit 4: HealthDocument32 pagesSouth Eastman English & Literacy Services: Unit 4: HealthTrịnh Minh KhoaNo ratings yet

- Hempadur Fast Dry 17410 En-GbDocument2 pagesHempadur Fast Dry 17410 En-GbTrịnh Minh KhoaNo ratings yet

- Intersleek 425: Elastomeric Foul Release CoatingDocument4 pagesIntersleek 425: Elastomeric Foul Release CoatingTrịnh Minh KhoaNo ratings yet

- Formula 152 Topcoat (MILDTL-24441)Document4 pagesFormula 152 Topcoat (MILDTL-24441)Trịnh Minh KhoaNo ratings yet

- Carboguard 893 SG PDSDocument4 pagesCarboguard 893 SG PDSTrịnh Minh KhoaNo ratings yet

- Vocabulary Basics 100 Pictures and Words Food and DrinkDocument6 pagesVocabulary Basics 100 Pictures and Words Food and DrinkTrịnh Minh KhoaNo ratings yet

- Hand RailDocument5 pagesHand RailpandiangvNo ratings yet

- Welding Rod SpecDocument1 pageWelding Rod SpecMuhammad Hasbi AsidiqiNo ratings yet

- Stainless Steels - "300" Series Stainless Steels - "300" SeriesDocument3 pagesStainless Steels - "300" Series Stainless Steels - "300" SeriesTasneem VoraNo ratings yet

- Schedule of Rates MJPDocument13 pagesSchedule of Rates MJPSuhas Natu0% (1)

- pst6250 333lDocument12 pagespst6250 333luriac86No ratings yet

- Inspection Programs For Internal Corrosion in PipingDocument6 pagesInspection Programs For Internal Corrosion in PipingsajimaliNo ratings yet

- Manual UT of Pipeline DigsDocument112 pagesManual UT of Pipeline DigsTHIRU.SNo ratings yet

- SHS-WWW Polsteel Co - Uk-Nr-Str PDFDocument5 pagesSHS-WWW Polsteel Co - Uk-Nr-Str PDFMuhammad ArslanNo ratings yet

- Content Content Standard Performance Standard Learning Competencies Code Learning Materials Week Prepare Weld Materials (WM) LO 1. Set-Up Cutting EquipmentDocument9 pagesContent Content Standard Performance Standard Learning Competencies Code Learning Materials Week Prepare Weld Materials (WM) LO 1. Set-Up Cutting Equipmentlip100% (1)

- Cast Materials From KSB-DataDocument20 pagesCast Materials From KSB-DataHui ErdingerNo ratings yet

- Fro Bro Vs247317 EngDocument4 pagesFro Bro Vs247317 EngvonipkoNo ratings yet

- Non Destructive Testing Non Destructive TestingDocument74 pagesNon Destructive Testing Non Destructive TestingPrasant Kumar BeheraNo ratings yet

- GRLC Grayloc Installation Maintenance Bulletin Rev JDocument4 pagesGRLC Grayloc Installation Maintenance Bulletin Rev JlsgmzNo ratings yet

- Heavy-Duty Torch System: Heating Power PerformanceDocument8 pagesHeavy-Duty Torch System: Heating Power PerformanceNataliNo ratings yet

- Surface Preparation Specification No. 11: SSPC: The Society For Protective Coatings Power Tool Cleaning To Bare MetalDocument6 pagesSurface Preparation Specification No. 11: SSPC: The Society For Protective Coatings Power Tool Cleaning To Bare MetalDanielNo ratings yet

- Sample SpecsDocument137 pagesSample Specsprince francisNo ratings yet

- 33 KV Line Estimate Wardha LISDocument30 pages33 KV Line Estimate Wardha LISEr. Ajit SolankeNo ratings yet

- Curriculum Vitae: Oil & Gas Offshore & Onshore Client Qa/Qc RepresentativeDocument6 pagesCurriculum Vitae: Oil & Gas Offshore & Onshore Client Qa/Qc RepresentativeN S SivamNo ratings yet

- IAB-041-02 (IW Inspection Personnel)Document43 pagesIAB-041-02 (IW Inspection Personnel)Teddy TP100% (1)

- 50-83-02 Spec. For Arc & Capacitor Discharge Weldingt of Pr. & Non-Pr. PartsDocument6 pages50-83-02 Spec. For Arc & Capacitor Discharge Weldingt of Pr. & Non-Pr. PartsJKKNo ratings yet

- Installing Plastic Pipes: Butt Fusion Welding of PolypropyleneDocument6 pagesInstalling Plastic Pipes: Butt Fusion Welding of Polypropylenecrys suryo prayogoNo ratings yet

- Dril-Quip Welding Traceability RecordDocument11 pagesDril-Quip Welding Traceability Recordsankar123456789No ratings yet

- Stoody Super 20Document1 pageStoody Super 20JUAN DAVID ESPITIANo ratings yet

- TCAEMM EmptyvaluesdocumentDocument689 pagesTCAEMM EmptyvaluesdocumentJithinNo ratings yet

- Wabtec Freight 2 PDFDocument72 pagesWabtec Freight 2 PDFDeybi Ochoa100% (1)

- Manual FK2500 Cooling UnitDocument27 pagesManual FK2500 Cooling UnitGogzNo ratings yet

- Gfps 9200 Brochure CNC Automated Butt Fusion Machine Line enDocument8 pagesGfps 9200 Brochure CNC Automated Butt Fusion Machine Line enMohammed sabatinNo ratings yet

- Harger Grounding ProductsDocument24 pagesHarger Grounding ProductsAnonymous 1BdR0EQgbuNo ratings yet