Professional Documents

Culture Documents

Step 1: Calculate The LMTD: HOT Cold

Step 1: Calculate The LMTD: HOT Cold

Uploaded by

tobyCopyright:

Available Formats

You might also like

- ME 307: Heat Transfer Equipment Design: (Arpachi-Ex-7.9)Document5 pagesME 307: Heat Transfer Equipment Design: (Arpachi-Ex-7.9)mz_haqNo ratings yet

- Heat Exchanger MathDocument8 pagesHeat Exchanger MathMasum ParvezNo ratings yet

- Question BankDocument11 pagesQuestion BankVenkadeshwaran KuthalingamNo ratings yet

- Shell and Tube Heat ExchangerDocument36 pagesShell and Tube Heat ExchangerSiti Nurshahira67% (3)

- Step 1: Calculate The LMTD: HOT ColdDocument34 pagesStep 1: Calculate The LMTD: HOT ColdFrancisca Hanna0% (2)

- Ejercicios PDFDocument4 pagesEjercicios PDFserepoesia10No ratings yet

- TUTORIAL 6 Heat ExchangerDocument4 pagesTUTORIAL 6 Heat ExchangerFikri Rahim50% (2)

- Practice Problems For Heat ExchangerDocument2 pagesPractice Problems For Heat ExchangerFour AyesNo ratings yet

- Numerical Problems LMTDDocument4 pagesNumerical Problems LMTDKhalidNo ratings yet

- Ihte Que BankDocument2 pagesIhte Que BankNikunj PatelNo ratings yet

- Assignment - IVDocument4 pagesAssignment - IVdivyanshu.221ch018No ratings yet

- Exercícios de EQ751Document3 pagesExercícios de EQ751Fernando MiyazakiNo ratings yet

- Heat ExchangerDocument1 pageHeat ExchangerArpit GoyalNo ratings yet

- Heat TransferDocument1 pageHeat TransferjacksonNo ratings yet

- FTFS Chap23 P054Document34 pagesFTFS Chap23 P054AbdulAbdulNo ratings yet

- 515MET02 HMT Unit 3 FinalDocument4 pages515MET02 HMT Unit 3 Finalntamilselvan.eecNo ratings yet

- Multipass Heat ExchangersDocument21 pagesMultipass Heat ExchangersBrando_BalagonNo ratings yet

- LMDTDocument6 pagesLMDThassnainiqbal11No ratings yet

- Basic Design MethodologyDocument4 pagesBasic Design MethodologySatya SuryaNo ratings yet

- Practica 3 PRQ 2203 I - 2024Document6 pagesPractica 3 PRQ 2203 I - 2024Cruz Paniagua Rene AngelNo ratings yet

- CL 351: Chemical Engineering Lab IIDocument9 pagesCL 351: Chemical Engineering Lab IIsagarchawla13No ratings yet

- Set 8 AnsDocument14 pagesSet 8 AnsMuhammad RomzuddinNo ratings yet

- 15.2 NewDocument12 pages15.2 NewindraNo ratings yet

- 3 Avaliacao Grupo1 PDFDocument3 pages3 Avaliacao Grupo1 PDFPedro Henrique Fauro De AraujoNo ratings yet

- Double Pipe Heat ExchangerDocument7 pagesDouble Pipe Heat ExchangerPriyanshiVadaliaNo ratings yet

- Homework #7Document3 pagesHomework #7Sebastián SantarrosaNo ratings yet

- C5 ExerciseDocument18 pagesC5 ExerciseHƯƠNG NGUYỄN LÊ NGỌCNo ratings yet

- Approach TemperaturesDocument4 pagesApproach TemperaturesrutabawellarsNo ratings yet

- 03 ME 6022 Design of Heat Transfer EquipmentsDocument1 page03 ME 6022 Design of Heat Transfer EquipmentsVenkitaraj K PNo ratings yet

- Tutorial Heat ExchangerDocument2 pagesTutorial Heat ExchangerAhmad Nor Fahmi WalidNo ratings yet

- Me8693 Heat and Mass Transfer - QBDocument5 pagesMe8693 Heat and Mass Transfer - QBmeckup123No ratings yet

- Sheet (3.1) Heat Exchangers Analysis Using LMTD MethodDocument2 pagesSheet (3.1) Heat Exchangers Analysis Using LMTD MethodAya Bekhet 1253No ratings yet

- Taller 2 2023-1Document8 pagesTaller 2 2023-1anderson ortizNo ratings yet

- Heat Exchanger (New)Document38 pagesHeat Exchanger (New)Rochie DiezNo ratings yet

- EKC 216 Wk13 Chapter 10 - Heat Exchanger L1 2017.keyDocument52 pagesEKC 216 Wk13 Chapter 10 - Heat Exchanger L1 2017.keySyazwan WanNo ratings yet

- Show A Simple Block Diagram of The Flash Tank Indicating The Different Streams 2. Calculate The Amount of Flash Steam Produced in The 3bar Flash TankDocument1 pageShow A Simple Block Diagram of The Flash Tank Indicating The Different Streams 2. Calculate The Amount of Flash Steam Produced in The 3bar Flash TankJamiel CatapangNo ratings yet

- Cryogenic EquipmentDocument36 pagesCryogenic Equipmentkeshavnandi1969No ratings yet

- Problem Set MassDocument3 pagesProblem Set MassSummer Wynn Dacwag0% (1)

- Tutorial 5 E BalanceDocument3 pagesTutorial 5 E BalanceYi Ying Hannie100% (1)

- Plate and Frame Heat ExchangersDocument6 pagesPlate and Frame Heat ExchangersAndrés Ramón Linares100% (1)

- Tut 4 Heat ExchangersDocument2 pagesTut 4 Heat ExchangersGomolemo BaarxxNo ratings yet

- Worked Problems Heat ExchangersDocument18 pagesWorked Problems Heat Exchangers521 Balaji ONo ratings yet

- Question Bank On Unit 6Document5 pagesQuestion Bank On Unit 6dongaNo ratings yet

- Tarea 4 CalorDocument2 pagesTarea 4 CalorDenisse M. ZamoraNo ratings yet

- Free Convection + Heat ExchangersDocument58 pagesFree Convection + Heat ExchangersSrinivasan 21BME1128No ratings yet

- Chemical Engineering Job QuestionsDocument9 pagesChemical Engineering Job QuestionsMunia AkterNo ratings yet

- Tutorial 3 - Revised SolutionDocument11 pagesTutorial 3 - Revised Solutionngoc.nguyenlamNo ratings yet

- Problems On VCRSDocument7 pagesProblems On VCRSFraol100% (1)

- Iitbombay: Me209 Thermodynamics: 2014 Jul-Dec Exercises Set FDocument5 pagesIitbombay: Me209 Thermodynamics: 2014 Jul-Dec Exercises Set FSunil SainiNo ratings yet

- Lab Report Heat Transfer in Laminar Flow and Turbulent Flow: Instructor: Prof. Vinod Narayanan Group 5Document11 pagesLab Report Heat Transfer in Laminar Flow and Turbulent Flow: Instructor: Prof. Vinod Narayanan Group 5Pawan KumarNo ratings yet

- Counter & ParallelDocument18 pagesCounter & ParallelHemapriyankaa PeriyathambyNo ratings yet

- Describe The Difference in The Temperature Profiles For Counter-Flow and Parallel Flow Heat Exchangers. Counter Flow Heat ExchangersDocument3 pagesDescribe The Difference in The Temperature Profiles For Counter-Flow and Parallel Flow Heat Exchangers. Counter Flow Heat Exchangersbyun baekNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

Step 1: Calculate The LMTD: HOT Cold

Step 1: Calculate The LMTD: HOT Cold

Uploaded by

tobyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Step 1: Calculate The LMTD: HOT Cold

Step 1: Calculate The LMTD: HOT Cold

Uploaded by

tobyCopyright:

Available Formats

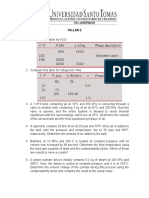

150,000 lb/h of SAE 30 oil is being cooled from 200 F to 175 F by 75,000 lb/h of water.

The water enters the

exchanger at 60 F and leaves at 168 F. The average viscosity of the water passing through the unit is 0.33

cP and the average viscosity of the oil in the unit is 215 cP. The maximum allowable pressure drop through the

plate heat exchanger is 15 psig on the hot and cold sides.

Step 1: Calculate the LMTD

Eq. (2)

Step 2: Calculate NTUHOT and NTUCOLD

Eq. (3)

Step 3: Read hHot from 0.25 < NTU < 2.0 chart for hydrocarbons

Although is there not a viscosity line for 215 cP, the line representing "100 cP" can be or viscosities up to about

400-500 cP. The heat exchanger will be pressure drop limited and the heat transfer coefficient will not change

appreciably over this viscosity range for plate and frame exchangers. Reading from the chart, a pressure drop of

15 psig corresponds to hHot @ 50 Btu/h ft2 F.

Step 4: Read hCold from 0.25 < NTU < 2.0 chart for water based liquids

Again, you will note that the exact viscosity line needed for pure water (0.33 cP) in this case is not available.

However, the "1.0 cP" line on the chart will provide a very good estimate of the heat transfer coefficient that pure

water will exhibit. Reading from the chart, a pressure drop of 15 psig corresponds to hCold @ 3000 Btu/h ft2 F.

Step 5: Calculate the Overall Heat Transfer Coefficient (OHTC)

Assume a stainless steel plate with a thickness of 0.50 mm is being used. 316 stainless steel has a thermal

conductivity of 8.67 Btu/h ft F.

Eq. (4)

Another Example

150,000 lb/h of water is being cooled from 200 F

by 150,000 lb/h of NaCl brine. The brine enters the exchanger at 50 F and leaves at 171 F. The average

viscosity of the water passing through the unit is 0.46 cP and the average viscosity of the brine in the unit is 1.10

cP. The maximum allowable pressure drop through the plate heat exchanger is 10 psig on the hot (water) side

and 20 psig on the cold (brine) side.

As before, the LMTD is calculated to be 38.5 F. NTUHotand NTUCold are calculated as 2.59 and 3.14

respectively. Reading hHot and hCold from the chart for 2.0 < NTU < 4.0 (water based), gives about 2000 Btu/h

ft2F and 2500 Btu/h ft2 F respectively. Although the material of choice may be Titanium or Palladium

stabilized Titanium, we will use the properties for stainless steel for our preliminary sizing. Calculating the OHTC

as before yields 918 Btu/h ft2 F.

You might also like

- ME 307: Heat Transfer Equipment Design: (Arpachi-Ex-7.9)Document5 pagesME 307: Heat Transfer Equipment Design: (Arpachi-Ex-7.9)mz_haqNo ratings yet

- Heat Exchanger MathDocument8 pagesHeat Exchanger MathMasum ParvezNo ratings yet

- Question BankDocument11 pagesQuestion BankVenkadeshwaran KuthalingamNo ratings yet

- Shell and Tube Heat ExchangerDocument36 pagesShell and Tube Heat ExchangerSiti Nurshahira67% (3)

- Step 1: Calculate The LMTD: HOT ColdDocument34 pagesStep 1: Calculate The LMTD: HOT ColdFrancisca Hanna0% (2)

- Ejercicios PDFDocument4 pagesEjercicios PDFserepoesia10No ratings yet

- TUTORIAL 6 Heat ExchangerDocument4 pagesTUTORIAL 6 Heat ExchangerFikri Rahim50% (2)

- Practice Problems For Heat ExchangerDocument2 pagesPractice Problems For Heat ExchangerFour AyesNo ratings yet

- Numerical Problems LMTDDocument4 pagesNumerical Problems LMTDKhalidNo ratings yet

- Ihte Que BankDocument2 pagesIhte Que BankNikunj PatelNo ratings yet

- Assignment - IVDocument4 pagesAssignment - IVdivyanshu.221ch018No ratings yet

- Exercícios de EQ751Document3 pagesExercícios de EQ751Fernando MiyazakiNo ratings yet

- Heat ExchangerDocument1 pageHeat ExchangerArpit GoyalNo ratings yet

- Heat TransferDocument1 pageHeat TransferjacksonNo ratings yet

- FTFS Chap23 P054Document34 pagesFTFS Chap23 P054AbdulAbdulNo ratings yet

- 515MET02 HMT Unit 3 FinalDocument4 pages515MET02 HMT Unit 3 Finalntamilselvan.eecNo ratings yet

- Multipass Heat ExchangersDocument21 pagesMultipass Heat ExchangersBrando_BalagonNo ratings yet

- LMDTDocument6 pagesLMDThassnainiqbal11No ratings yet

- Basic Design MethodologyDocument4 pagesBasic Design MethodologySatya SuryaNo ratings yet

- Practica 3 PRQ 2203 I - 2024Document6 pagesPractica 3 PRQ 2203 I - 2024Cruz Paniagua Rene AngelNo ratings yet

- CL 351: Chemical Engineering Lab IIDocument9 pagesCL 351: Chemical Engineering Lab IIsagarchawla13No ratings yet

- Set 8 AnsDocument14 pagesSet 8 AnsMuhammad RomzuddinNo ratings yet

- 15.2 NewDocument12 pages15.2 NewindraNo ratings yet

- 3 Avaliacao Grupo1 PDFDocument3 pages3 Avaliacao Grupo1 PDFPedro Henrique Fauro De AraujoNo ratings yet

- Double Pipe Heat ExchangerDocument7 pagesDouble Pipe Heat ExchangerPriyanshiVadaliaNo ratings yet

- Homework #7Document3 pagesHomework #7Sebastián SantarrosaNo ratings yet

- C5 ExerciseDocument18 pagesC5 ExerciseHƯƠNG NGUYỄN LÊ NGỌCNo ratings yet

- Approach TemperaturesDocument4 pagesApproach TemperaturesrutabawellarsNo ratings yet

- 03 ME 6022 Design of Heat Transfer EquipmentsDocument1 page03 ME 6022 Design of Heat Transfer EquipmentsVenkitaraj K PNo ratings yet

- Tutorial Heat ExchangerDocument2 pagesTutorial Heat ExchangerAhmad Nor Fahmi WalidNo ratings yet

- Me8693 Heat and Mass Transfer - QBDocument5 pagesMe8693 Heat and Mass Transfer - QBmeckup123No ratings yet

- Sheet (3.1) Heat Exchangers Analysis Using LMTD MethodDocument2 pagesSheet (3.1) Heat Exchangers Analysis Using LMTD MethodAya Bekhet 1253No ratings yet

- Taller 2 2023-1Document8 pagesTaller 2 2023-1anderson ortizNo ratings yet

- Heat Exchanger (New)Document38 pagesHeat Exchanger (New)Rochie DiezNo ratings yet

- EKC 216 Wk13 Chapter 10 - Heat Exchanger L1 2017.keyDocument52 pagesEKC 216 Wk13 Chapter 10 - Heat Exchanger L1 2017.keySyazwan WanNo ratings yet

- Show A Simple Block Diagram of The Flash Tank Indicating The Different Streams 2. Calculate The Amount of Flash Steam Produced in The 3bar Flash TankDocument1 pageShow A Simple Block Diagram of The Flash Tank Indicating The Different Streams 2. Calculate The Amount of Flash Steam Produced in The 3bar Flash TankJamiel CatapangNo ratings yet

- Cryogenic EquipmentDocument36 pagesCryogenic Equipmentkeshavnandi1969No ratings yet

- Problem Set MassDocument3 pagesProblem Set MassSummer Wynn Dacwag0% (1)

- Tutorial 5 E BalanceDocument3 pagesTutorial 5 E BalanceYi Ying Hannie100% (1)

- Plate and Frame Heat ExchangersDocument6 pagesPlate and Frame Heat ExchangersAndrés Ramón Linares100% (1)

- Tut 4 Heat ExchangersDocument2 pagesTut 4 Heat ExchangersGomolemo BaarxxNo ratings yet

- Worked Problems Heat ExchangersDocument18 pagesWorked Problems Heat Exchangers521 Balaji ONo ratings yet

- Question Bank On Unit 6Document5 pagesQuestion Bank On Unit 6dongaNo ratings yet

- Tarea 4 CalorDocument2 pagesTarea 4 CalorDenisse M. ZamoraNo ratings yet

- Free Convection + Heat ExchangersDocument58 pagesFree Convection + Heat ExchangersSrinivasan 21BME1128No ratings yet

- Chemical Engineering Job QuestionsDocument9 pagesChemical Engineering Job QuestionsMunia AkterNo ratings yet

- Tutorial 3 - Revised SolutionDocument11 pagesTutorial 3 - Revised Solutionngoc.nguyenlamNo ratings yet

- Problems On VCRSDocument7 pagesProblems On VCRSFraol100% (1)

- Iitbombay: Me209 Thermodynamics: 2014 Jul-Dec Exercises Set FDocument5 pagesIitbombay: Me209 Thermodynamics: 2014 Jul-Dec Exercises Set FSunil SainiNo ratings yet

- Lab Report Heat Transfer in Laminar Flow and Turbulent Flow: Instructor: Prof. Vinod Narayanan Group 5Document11 pagesLab Report Heat Transfer in Laminar Flow and Turbulent Flow: Instructor: Prof. Vinod Narayanan Group 5Pawan KumarNo ratings yet

- Counter & ParallelDocument18 pagesCounter & ParallelHemapriyankaa PeriyathambyNo ratings yet

- Describe The Difference in The Temperature Profiles For Counter-Flow and Parallel Flow Heat Exchangers. Counter Flow Heat ExchangersDocument3 pagesDescribe The Difference in The Temperature Profiles For Counter-Flow and Parallel Flow Heat Exchangers. Counter Flow Heat Exchangersbyun baekNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet