Professional Documents

Culture Documents

Problem Statement 3. Causes & Possible Solutions

Problem Statement 3. Causes & Possible Solutions

Uploaded by

akbars.thasimaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Problem Statement 3. Causes & Possible Solutions

Problem Statement 3. Causes & Possible Solutions

Uploaded by

akbars.thasimaCopyright:

Available Formats

ON TIME DELIVERY SERVICE & PERFORMANCE IMPROVEMENT QUAD CHART

1. PROBLEM STATEMENT

3. CAUSES & POSSIBLE SOLUTIONS

Farnham's On Time Delivery To Request performance is currently at 80%. This is unacceptable

for Southco's customers

5a

Inventory Availability

Ontime To Request Date

OTD

TO REQUEST PERFORMANCE

1

Stock inaccuracy

Goal = Green line (95 %)

0.9

0.8

Percent

0.7

0.5

Supplier leadtimes

0.3

0.2

Poor supplier

quality

0.1

0

Feb

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

Lack of cross training

Develop EQDC

in supply chain review on

scorecard

Poor quality requires re-work

Poor delivery

performance to

PO

Contractors are

unreliable

Not shipping parts

to sub-con quick

enough

Feast & Famine to

subcontractors

Lack of consignment stock

arrangments (VMI/SOMI)

Dec

Transaction

Training

Incorrect

leadtime on subcon - H/T and

plate

Poor supplier

contracts

Jan

Queues behind

bottleneck processes

Lack of focus on

supplier delivery

performance

0.4

Capacity planning

incorrect

Poor transaction

discipline in booking

materials in / kitting

jobs

0.6

Introduce 2nd shift

for turning cell

Poor OEE on critical

machines

Accurate

Replenishment

model not yet

established

cross training to be

implemented in critical areas

14

Introduce daily milk run + order

new lorry

Insufficient capacity

on van

Poor employee

engagement/motiva

tion

Incorrect routings

15

Incorrect BOM / S

Specs

No penalty for

ordering within

leadtime

Hire temp to update routings &

BOMS & upload to ORBIT inc

links in Symix

Difficult to obtain

drws in Goods

Inwards

16

10

6 sigma project on

plating quality

Work not moved on

to next operation

Poor Quality

Systems

Orders placed

within lead-time

Lack of standard

work

Quality issues

resulting in rework

loops

Inventory puddles

between OPs

11

Incorrect

leadtime on subcon - H/T and

plate

12

Setup overdue meeting - expedite and

pareto route causes in date order

No FIFO in stores

Lack of front end

negotiation with

customer

Measure OEE on

bottleneck processes

Plan to

communicate LTs

to CSRs

Poor

communication with

CSRs

Update visual

loading charts in

Symix

Other 13

Global CI Teams?

Leadtime wrong on

Symix

Lack of flexibility on

working hours

Kanban Stocks not

in place

Orders placed

within lead-time

stock (40% complete)

for toggles

Machine availabiltiy

Introduce cycle

counting

procedure inc RC

Analysis.

Customer Demand

Lack of focus

5b

a Implementline-side

Feast or Famine

loading

Insufficient

component items

being held as

inventory

Customer requests inside

lead time for Panex kaizen req'd.

Capacity

17

Align QA to value

streams. Achieve

and sustain TS2

requirements

Use FMEA to risk assess

std work/control plan

where req'd

100% inspection

18

Shipping errors

Introduce daily milk run +

order new lorry

Root cause analysis and

preventative action for soft

errors

2. TARGET STATEMENT

Supply Chain

4. EASE Vs. BENEFIT CHART

High

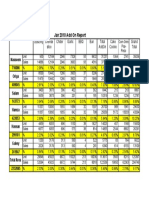

5. ACTIONS FOR OTD TO REQUEST PERFORMANCE IMPROVEMENT

12

Expected Improvement

(%)

Cause Area

Concern

Root Cause

Action Description

Start Date

Start of Savings

Date

Status

Actual

Improvement

(%)

1.5

Supply Chain

Parts being received late

from Sub-Con

No time allowance for

transport of parts to Subcon

Add 2 days to queue times to all

plated items

3/1/2006

31/04/06

25% 50% 75% 100%

1.5

12

1.5

SubContractors

Parts being received late

from Sub-Con + Feast &

Famine

Parts that miss weekly

delivery must wait until

following week

Intoduce daily Milk-round

4/1/2006

6/30/2006

25% 50% 75% 100%

Other

Continuous firefighting

with respect to OTD

performance

Lack of focus on route

causes of poor OTD

Review Overdues Meeting to

include route cause analysis &

follow up actions

5/12/2006

9/1/2006

25% 50% 75% 100%

All relevant personnel to undergo

Transaction Training

5/31/2006

7/30/2006

25% 50% 75% 100%

Start Cycle Counting program

throughout factory

5/31/2006

12/30/2006

25% 50% 75% 100%

2/1/2006

9/1/2006

25% 50% 75% 100%

5/1/2006

31/09/06

25% 50% 75% 100%

13

5b

2

13

1.0

10

1.0

Inventory

Availability

Incorrect part quantities

shown on Symix

Poor adherence and lack

of understanding of Symix

transactions procedures

2.0

Inventory

Availability

Incorrect part quantities

shown on Symix

Stock inaccuracies have

not been identified and

corrected on Symix

3

16

5b

15

17

In Process

Complete

Late

No.

5a

18

Impact on OTD Performance

Quality

Lead Time

Capability

Sub-Contractors

There has only been a gradual improvement in OTD to Request Year to date. Our

objective is to achieve a step change towards the stretch goal of 95 % OTD to Request

0.5

Capacity

18

1.0

Quality

5a

3.0

Capacity

High leadtime to customer

Plated parts held line-side ready for

Customer order triggers

for Diverse Toggle Latches

customer order + smaller batch

parts to go out for sub con.

(3 weeks)

sizes = leadtime of 3 days

Repetitive problems with

Soft Error issues, e.g.

incorrect shipping qty.

No root cause analysis of Root cause analysis and corrective

errors has been

actions for soft errors to be

undertaken

implemented for shipping process

Customer request dates High cycle times on auto

inside current leadtime for mills - CSRs not managing

Panex

customer expectations

Kaizen/step change to attack QT

lead time.

TBA

25% 50% 75% 100%

7

8

10

1.0

1.0

Capacity

SubContractors

Very high leadtime on

Tornos machines

Repeating problems with

quality of plating parts

Machines run out of work Introduce 2nd shift in turning to load

during lights off running

new jobs until morning

Variation in plating

process - process not

adhered to

Use 6 sigma tools to remove

variation in process. Work with D.

Foxall to sustain changes

Low

5/1/2006

9/1/2006

25% 50% 75% 100%

5/18/2006

10/1/2006

25% 50% 75% 100%

25% 50% 75% 100%

Hard

Ease of Completion

Easy

Total Expected

Improvement (%)

13.5

Expected OTD to

Request (%)

93.5

Total Actual

Improvement (%)

1.5

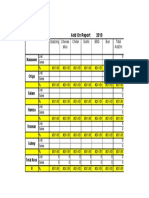

OTD to Request Graph

Date

Facility (%) Diverse (%) QT (%)

3-Apr

78

4-Apr

88

94

87

5-Apr

83.5

93.8

86.9

6-Apr

83

89

82

7-Apr

84

90

83

10-Apr

83

92

80

11-Apr

83

91

81

12-Apr

81

89

79

18-Apr

81

87

79

19-Apr

82

82

20-Apr

80

85

79

21-Apr

80

84

79

24-Apr

80.4

85

79

25-Apr

80

85

79

27-Apr

79

28-Apr

80

84

78

2-May

88.7

89

88.5

4-May

78.5

81

78

5-May

78.5

82.9

77.2

7-May

80.3

83

77

You might also like

- Proposal Compliance Matrix TemplateDocument1 pageProposal Compliance Matrix TemplateBobbyNicholsNo ratings yet

- 5S Technique DataDocument9 pages5S Technique DataMuhammad Luqman FarooquiNo ratings yet

- MGT 6720 - Implementing LEAN Operations at Caesars Casinos V2Document10 pagesMGT 6720 - Implementing LEAN Operations at Caesars Casinos V2simmayor100% (3)

- PBS & UpsDocument17 pagesPBS & UpsSRI PRAGATHINo ratings yet

- Matching Capacity and DemandDocument43 pagesMatching Capacity and Demanddesertrose188No ratings yet

- Date Requested Date Submitted: Block and LotDocument12 pagesDate Requested Date Submitted: Block and LotBotenes Mallorca RhonNo ratings yet

- Skill Matrix MaterialsDocument2 pagesSkill Matrix MaterialsRavikant PandeyNo ratings yet

- Quality Department Annual PlanDocument24 pagesQuality Department Annual PlanKumaravelNo ratings yet

- Internal Qualified Auditor ListDocument1 pageInternal Qualified Auditor ListvictorNo ratings yet

- Internal Customer SatisfactionDocument2 pagesInternal Customer SatisfactionKanagasabai VigneshNo ratings yet

- Audit MatrixDocument1 pageAudit MatrixsivamandoNo ratings yet

- OEE: Overall Equipment Efficiency: OrganizerDocument5 pagesOEE: Overall Equipment Efficiency: OrganizerSachin RamdurgNo ratings yet

- Internal / External Communication PlanDocument3 pagesInternal / External Communication PlanKumaravelNo ratings yet

- Sr. No. Metric Goal Data Source Base Line: TallbrosDocument3 pagesSr. No. Metric Goal Data Source Base Line: TallbrosVikas KashyapNo ratings yet

- Lot Management Sheet Quantity Tally ProcedureDocument4 pagesLot Management Sheet Quantity Tally ProcedureKumaravelNo ratings yet

- Cost of Quality Worksheet: Classification Examples # Totals Prevention CostsDocument2 pagesCost of Quality Worksheet: Classification Examples # Totals Prevention CostsvitortavaresNo ratings yet

- Project Management Using Excel - Gantt Chart TemplateDocument3 pagesProject Management Using Excel - Gantt Chart TemplatezapclinkNo ratings yet

- PT Jawa Tirtamarin Form Keselamatan, Kesehatan Kerja Dan Perlindungan Lingkungan Statistik Keselamatan Dan Kesehatan KerjaDocument1 pagePT Jawa Tirtamarin Form Keselamatan, Kesehatan Kerja Dan Perlindungan Lingkungan Statistik Keselamatan Dan Kesehatan Kerjaimam santosoNo ratings yet

- Six Sigma Process Map Template: Learn More About Smartsheet For Project ManagementDocument1 pageSix Sigma Process Map Template: Learn More About Smartsheet For Project ManagementDiana Carolina Chinchilla AngelNo ratings yet

- Customer Complaint Register 2017Document6 pagesCustomer Complaint Register 2017KumaravelNo ratings yet

- Supplier Scorecard GuidelinesDocument6 pagesSupplier Scorecard Guidelinesnasernaser741No ratings yet

- Company Name: Quality Management System (QMS)Document1 pageCompany Name: Quality Management System (QMS)Sachin RamdurgNo ratings yet

- M/s Qavi & Brothers: VIP Activity Plan & StatusDocument5 pagesM/s Qavi & Brothers: VIP Activity Plan & StatusMurtaza AhmedNo ratings yet

- MFG Procedure ManualDocument46 pagesMFG Procedure ManualAdinanNo ratings yet

- Process Check Sheet - Koyama IndiaDocument8 pagesProcess Check Sheet - Koyama IndiaKumaravelNo ratings yet

- SEML PresentationDocument47 pagesSEML PresentationalparathiNo ratings yet

- Customer Survey Form T2m 2009Document1 pageCustomer Survey Form T2m 2009Peracha EngineeringNo ratings yet

- QMS Risk & Opportunity RegisterDocument4 pagesQMS Risk & Opportunity Registernaveen yadavNo ratings yet

- Iatf 16949 Quality Management System RequirementsDocument42 pagesIatf 16949 Quality Management System RequirementsKiki AditamaNo ratings yet

- 01 Quality Objectives SummaryDocument2 pages01 Quality Objectives SummaryHelton MotaNo ratings yet

- Zero Defect GuidelinesDocument1 pageZero Defect GuidelinesSanjay KumarNo ratings yet

- Process Turtle - QMRDocument16 pagesProcess Turtle - QMRRavi javaliNo ratings yet

- Project Parameters: Project Participants: Hour Analysis Project PhasesDocument16 pagesProject Parameters: Project Participants: Hour Analysis Project PhasesMiha ElaNo ratings yet

- Chintamani Metal Udhoy Pvt. Ltd. 4M Change BoardDocument6 pagesChintamani Metal Udhoy Pvt. Ltd. 4M Change Boardcmu qmsNo ratings yet

- P2 Project Management Minimum Requirements Relevant For AssessmentDocument26 pagesP2 Project Management Minimum Requirements Relevant For AssessmentkssandeepNo ratings yet

- DS-04-01 R0 Competency Requirements of Internal AuditorsDocument2 pagesDS-04-01 R0 Competency Requirements of Internal AuditorsDhinakaranNo ratings yet

- Trailer IATF DocumentsDocument77 pagesTrailer IATF DocumentsSridharan VenkatNo ratings yet

- Name of Employee: Performance Evaluation FormDocument5 pagesName of Employee: Performance Evaluation FormShemu PlcNo ratings yet

- Trees Diagram System of Iso/Ts 14969: 2009Document8 pagesTrees Diagram System of Iso/Ts 14969: 2009AyuNo ratings yet

- Iso 9001 Internal Audit Checklist (EDocFind - Com)Document3 pagesIso 9001 Internal Audit Checklist (EDocFind - Com)anandthoriaNo ratings yet

- New Maitenance DB 22Document2 pagesNew Maitenance DB 22Senthilmani MuthuswamyNo ratings yet

- Mangement Review FormatsDocument7 pagesMangement Review FormatsAnkur DhirNo ratings yet

- Supplier Rating CalculatorDocument4 pagesSupplier Rating CalculatorsamcbsivNo ratings yet

- PFMEA EncodeDocument4 pagesPFMEA EncodeBooniz-bonice EliasNo ratings yet

- Manufactu Operational Risk 21Document14 pagesManufactu Operational Risk 21Senthilmani MuthuswamyNo ratings yet

- QMS Cross Audit 18Document4 pagesQMS Cross Audit 18rajesh sharmaNo ratings yet

- Tanya Gogia PDFDocument2 pagesTanya Gogia PDFSourabh SharmaNo ratings yet

- Value Stream Mapping: Project ExecutionDocument3 pagesValue Stream Mapping: Project ExecutionsrikarNo ratings yet

- Annexure 2 Change Control RegisterDocument1 pageAnnexure 2 Change Control Registerpuspa pharmaNo ratings yet

- FICQ2002 DairyProcessingEquipmentOperator V1.0Document43 pagesFICQ2002 DairyProcessingEquipmentOperator V1.0Abhilasha Rajeev Singh BaghelNo ratings yet

- 5.2 Process Capability Analysis Rev2ADocument8 pages5.2 Process Capability Analysis Rev2APollyNo ratings yet

- Key Documents Health 62.05%: # Document Satus Score % Notes / ObservationsDocument10 pagesKey Documents Health 62.05%: # Document Satus Score % Notes / ObservationsKhaledNo ratings yet

- 20040219-QMS Cycle - PpsDocument1 page20040219-QMS Cycle - PpsSanjay DhawasNo ratings yet

- BNC-Supplier Audit ProcedureDocument3 pagesBNC-Supplier Audit Procedurekyunjae JetomoNo ratings yet

- Supplier Corrective Action Report (Scar) : Characteristics Specification Actual RemarksDocument3 pagesSupplier Corrective Action Report (Scar) : Characteristics Specification Actual RemarksdysonNo ratings yet

- InProcess Rejection PPM.Document72 pagesInProcess Rejection PPM.Vikas KashyapNo ratings yet

- Performance Review TemplateDocument6 pagesPerformance Review TemplateDrAnand ShankarNo ratings yet

- Effectively Leading For Improving Quality - Look in The MirrorDocument29 pagesEffectively Leading For Improving Quality - Look in The MirrorendroNo ratings yet

- Salary Formation: Basic HRA Allowances Tel. Expense Food All. Spl. All. Monthly Salary PF Bonus LTA Perks Gross SalaryDocument1 pageSalary Formation: Basic HRA Allowances Tel. Expense Food All. Spl. All. Monthly Salary PF Bonus LTA Perks Gross SalaryNikunj SavaniNo ratings yet

- Adverse Event Log TemplateDocument2 pagesAdverse Event Log TemplateLore LopezNo ratings yet

- Type of Measure Measuring Key Performance Indicator World Class Target LevelDocument2 pagesType of Measure Measuring Key Performance Indicator World Class Target LevelHamza HafidiNo ratings yet

- Semester Project: ISE 250: Organizational Improvement Capabilities and SkillsDocument40 pagesSemester Project: ISE 250: Organizational Improvement Capabilities and SkillskeithwhitesideNo ratings yet

- Processes For The Production of Automobile Company Millat Tractors LimitedDocument4 pagesProcesses For The Production of Automobile Company Millat Tractors LimitedafansarimNo ratings yet

- Environmental ObjectivesDocument9 pagesEnvironmental Objectivesakbars.thasima0% (1)

- Ceo Kra-1Document222 pagesCeo Kra-1akbars.thasima0% (1)

- Management-Staff: Andy SampleDocument25 pagesManagement-Staff: Andy Sampleakbars.thasimaNo ratings yet

- Sample IDPDocument3 pagesSample IDPakbars.thasimaNo ratings yet

- Monitoring and Evaluation ToolkitDocument17 pagesMonitoring and Evaluation Toolkitakbars.thasima100% (1)

- Succession Planning TemplateDocument3 pagesSuccession Planning Templateakbars.thasimaNo ratings yet

- New Member OrientationDocument2 pagesNew Member Orientationakbars.thasimaNo ratings yet

- The Lean Canvas: Problem Solution Unique Value Prop. Unfair Advantage Customer SegmentsDocument7 pagesThe Lean Canvas: Problem Solution Unique Value Prop. Unfair Advantage Customer Segmentsakbars.thasimaNo ratings yet

- Branch: HRM&D: / Operational Reporting LevelDocument3 pagesBranch: HRM&D: / Operational Reporting Levelakbars.thasimaNo ratings yet

- KTA Payroll 0.9%Document2 pagesKTA Payroll 0.9%akbars.thasimaNo ratings yet

- The Michaelangelo Virus Source CodeDocument4 pagesThe Michaelangelo Virus Source Codeakbars.thasimaNo ratings yet

- Measures: Measure Classification (Dimensions)Document4 pagesMeasures: Measure Classification (Dimensions)akbars.thasimaNo ratings yet

- Checklist Audit: Auditor Dept/Process Tanggal Audit Referensi Pertanyaan No CatatanDocument2 pagesChecklist Audit: Auditor Dept/Process Tanggal Audit Referensi Pertanyaan No Catatanakbars.thasimaNo ratings yet

- 02 Cost of Sales Control Evaluation A4Document2 pages02 Cost of Sales Control Evaluation A4akbars.thasimaNo ratings yet

- Add On Report Blank 2010Document1 pageAdd On Report Blank 2010akbars.thasimaNo ratings yet

- Setting Ulang Scan FDocument6 pagesSetting Ulang Scan Fakbars.thasimaNo ratings yet

- Add On Report Jan 2010Document1 pageAdd On Report Jan 2010akbars.thasimaNo ratings yet

- Contoh EnvelopeDocument1 pageContoh Envelopeakbars.thasimaNo ratings yet

- 2006 Business Plan1Document15 pages2006 Business Plan1akbars.thasimaNo ratings yet

- June 2014 - Payroll Local, After TaxDocument13 pagesJune 2014 - Payroll Local, After Taxakbars.thasimaNo ratings yet

- Reading Material - Self Study Topic - Innovations in Supply ChainsDocument23 pagesReading Material - Self Study Topic - Innovations in Supply Chainsomverma0508No ratings yet

- Capacity PlanningDocument47 pagesCapacity PlanningTubagus FarizNo ratings yet

- Lesson 6 - Module 006 Location-Layout Facility DecisionsDocument14 pagesLesson 6 - Module 006 Location-Layout Facility DecisionsNoe AgubangNo ratings yet

- Quiz Pop MakeupDocument7 pagesQuiz Pop Makeuphpaiwbk7No ratings yet

- Capacity Loss Factors in Semiconductor Manufacturing: Jennifer Robinson, John Fowler, and Eileen NeacyDocument25 pagesCapacity Loss Factors in Semiconductor Manufacturing: Jennifer Robinson, John Fowler, and Eileen NeacyMichael GriouNo ratings yet

- The Six Minute Book Summary of The Goal by Eliyahu MDocument5 pagesThe Six Minute Book Summary of The Goal by Eliyahu Mfalconau100% (1)

- 4 Process - Analysis - Practice - Problem - SolutionsDocument7 pages4 Process - Analysis - Practice - Problem - SolutionsHEMANT KUMARNo ratings yet

- Theory of Constraints: Submitted by S. Madhula Roll No: 52 PGP 2010-12 Iim RaipurDocument6 pagesTheory of Constraints: Submitted by S. Madhula Roll No: 52 PGP 2010-12 Iim RaipurMadhula SathyamoorthyNo ratings yet

- Simulation Modeling and Analysis With Arena: Modeling of Production LinesDocument35 pagesSimulation Modeling and Analysis With Arena: Modeling of Production Linesjuli1652No ratings yet

- F5 Mapit Workbook Questions - Solutions PDFDocument206 pagesF5 Mapit Workbook Questions - Solutions PDFAmanda7100% (2)

- M13 Synchronizing and Balancing The ProcessDocument10 pagesM13 Synchronizing and Balancing The ProcessRheza Nugraha PrabareswaraNo ratings yet

- IDL Book Review The GOALDocument13 pagesIDL Book Review The GOALAnirudh KowthaNo ratings yet

- POM LectureDocument11 pagesPOM LecturemuneerppNo ratings yet

- Kristens Cookie CaseDocument4 pagesKristens Cookie CaseYichan WangNo ratings yet

- MGMT 208Document5 pagesMGMT 208Pio NguyenNo ratings yet

- Managing Accounting in A Changing Environment: MANAGEMENT ACCOUNTING - Solutions ManualDocument22 pagesManaging Accounting in A Changing Environment: MANAGEMENT ACCOUNTING - Solutions ManualBianca LizardoNo ratings yet

- Constraint Management: Eleventh EditionDocument38 pagesConstraint Management: Eleventh EditionOmer ChowdhuryNo ratings yet

- Industrial Training Course (APQ - Shivshyam (Shiv Shyaam) BindDocument570 pagesIndustrial Training Course (APQ - Shivshyam (Shiv Shyaam) BindpradeepNo ratings yet

- Section 2 Team 9 Business Plan Draft-1 1 CompressedDocument34 pagesSection 2 Team 9 Business Plan Draft-1 1 Compressedapi-635928069No ratings yet

- Self Reflection Opm 530Document2 pagesSelf Reflection Opm 530Markk MieyNo ratings yet

- Air Cannons: Powerful, Safe & Efficient Power To Put Materials in MotionDocument16 pagesAir Cannons: Powerful, Safe & Efficient Power To Put Materials in MotionJUAN CARLOSNo ratings yet

- Impact of Work Method & Line Balancing On The Produtivity of Steel Industry (Kidane Gemeda, August-2020)Document94 pagesImpact of Work Method & Line Balancing On The Produtivity of Steel Industry (Kidane Gemeda, August-2020)KidaneNo ratings yet

- OSCM Case InsightsDocument4 pagesOSCM Case InsightsMegha SenNo ratings yet

- Introduction To The Theory of Constraints (TOC) & Critical Chain Project Management (CCPM)Document16 pagesIntroduction To The Theory of Constraints (TOC) & Critical Chain Project Management (CCPM)M MaulanaNo ratings yet

- Optimización Industria de AlimentosDocument7 pagesOptimización Industria de AlimentoscamycazNo ratings yet

- OMM - Theory of Constraints - Nav17 - ChahatDocument38 pagesOMM - Theory of Constraints - Nav17 - ChahatNavneet NandaNo ratings yet