Professional Documents

Culture Documents

Sellador Elastico Autonivelante Alto Desempeno Sikaflex 2c SL

Sellador Elastico Autonivelante Alto Desempeno Sikaflex 2c SL

Uploaded by

Eleazar MendezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sellador Elastico Autonivelante Alto Desempeno Sikaflex 2c SL

Sellador Elastico Autonivelante Alto Desempeno Sikaflex 2c SL

Uploaded by

Eleazar MendezCopyright:

Available Formats

Product Data Sheet

Edition 5.5.2011

Sikaflex-2c SL

Sikaflex-2c SL

Two-component, self-leveling, polyurethane elastomeric sealant

Description

Sikaflex-2c SL is a 2-component, premium-grade, polyurethane-based, elastomeric sealant. It is principally

a chemical cure in a self-leveling consistency. Meets ASTM C-920, Type M, Grade P, Class 25, use T, NT,

M, G, A, O, I and Federal Specification TT-S-00227E, Type 1, Class A.

Where to use

n Intended

for use in all properly designed working joints with a minimum depth of 1/4 inch.

for horizontal applications.

n Placeable at temperatures as low as 40F.

n Adheres to most substrates commonly found in construction.

n Submerged conditions, such as canal and reservoir joints.

Advantages

n True

Construction

n Ideal

self-leveling properties.

of 50% joint movement.

n Chemical cure allows the sealant to be placed in non-moving joints exceeding 1/2 in. in depth.

n High elasticity with a tough, durable, flexible consistency.

n Exceptional cut and tear resistance.

n Exceptional adhesion to most substrates without priming.

n Available in 35 architectural colors.

n Color uniformity assured via Color-pak system.

n Available in pre-pigmented Limestone Gray (no Color-pak needed).

n Self-leveling consistency, easy to apply in horizontal joints.

n Easy to mix.

n Paintable with water-, oil-, and rubber-base paints.

n Jet fuel resistant.

n No color-pak needed in pre-pigmented Limestone.

Coverage

1 gal. yields 231 cu. in. or 154 lin. ft. of a 1/2 in. X 1/4 in. joint.

Packaging

1.5 gal. unit. 3 gal. units. Color-pak is purchased separately. Limestone Gray color available pre-pigmented.

n Capable

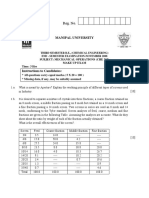

Typical Data (Material and curing conditions 73F (23C) and 50% R.H.)

Results may differ based upon statistical variations depending upon mixing methods and equipment,

temperature, application methods, test methods, actual site conditions and curing conditions.

Shelf life

One year in original, unopened containers.

Storage Conditions

Store dry at 40-95F (4-35C). Condition material to 65-75F

before using.

Colors

A wide range of architectural colors are available. Special colors available on request.

Application Temperature

Service Range

40 to 100F, ambient and substrate temperatures. Sealant should

be installed when joint is at mid-range of its anticipated movement.

-40 to 170F (-40-75C).

Curing Rate (ASTM C-679)

Tack-free Time 6-8 hrs.

Final Cure

3 days

Application Life

TT-S-00227E

4 hrs.

Tear Strength

ASTM D-624

100 lb./in.

Shore A Hardness

ASTM D-2240 40 5

Tensile Properties (ASTM D412)

Tensile Strength at Break

Tensile Elongation

100% Modulus

175 psi

650%

100 psi

Adhesion in Peel (Fed Spec. TT-S-00227E)

Substrate

Peel Strength

% Adhesion Loss

Concrete

30 lb.

Zero

Weathering Resistance

Excellent

Chemical Resistance Good resistance to water, diluted acids, diluted alkalines, and residential

sewage. Consult Technical Service for specific data.

How to Use

Surface Preparation All joint-wall surfaces must be clean, sound, and frost-free. Joint walls must

be free of oils, grease, curing compound residues, and any other foreign matter that might prevent bond. Ideally this should be accomplished by mechanical means. A roughened surface will also enhance bond. Bond breaker tape

or backer rod must be used in bottom of joint to prevent bond.

B70

Priming is typically not necessary. Most substrates only

require priming if sealant will be subjected to water

immersion after cure. Testing should be done, however,

on questionable substrates, to determine if priming is

needed.

Consult Technical Service or Sikaflex Primer Technical

Data Sheet for additional information on priming.

Linear Feet of Sealant per Gallon

Depth

Inches

1

/4

308.0

154.0

Width

Priming

77.0

4

102.7

51.3

Pour entire contents of Component B into pail of Component A. Add entire contents of Color-pak into pail and

1

77.0

38.5

mix with a low-speed drill (400-600 rpm) and Sikaflex

1

1 2

61.6

30.8

paddle. * Mix for 3-5 minutes to achieve a uniform color

and consistency. Scrape down sides of pail periodically.

1 34

51.3

25.7

Avoid entrapment of air during mixing.

Color-pak must be used with tint base. Note: When mixing 3

gal. unit, two containers of Component B and two color-paks must be used.

*For pre-pigmented Limestone base, just mix with low speed drill and Sikaflex paddle (no Color-pak needed).

Mixing

Application

Construction

Limitations

Caution

Recommended application temperatures 40-100F. Pre-conditioning units to approximately 70F is necessary when working at extremes. Move pre-conditioned units to work areas just prior to application.

Apply sealant only to clean, sound, dry, and frost-free substrates. Sikaflex-2c should be applied into joints

when joint slot is at mid-point of its designed expansion and contraction.

To place, pour or extrude the SL grade in one direction and allow it to flow and level as necessary. If extruding, load mixed sealant directly into bulk gun or use follower plate loading system. Place nozzle of gun into

bottom of joint and fill entire joint. Keeping the nozzle deep in the sealant, continue with a steady flow of

sealant preceding nozzle to avoid air entrapment. Also, avoid overlapping of sealant since this also entraps

air. Tool as necessary. Joint dimension should allow for 1/4 inch minimum and 1/2 inch maximum thickness

for sealant. Proper design is 2:1 width to depth ratio.

n The

ultimate performance of Sikaflex-2c, depends on good joint design and proper application.

depth in working joint is 1/4 in.

n Maximum expansion and contraction should not exceed 50% of average joint width.

n Do not cure in the presence of curing silicones.

n Avoid contact with alcohol and other solvent cleaners during cure.

n Allow 3 day cure before subjecting sealant to total water immersion.

n Avoid exposure to high levels of chlorine. (Maximum level is 5 ppm).

n Do not apply when moisture vapor transmission exists since this can cause bubbling within the sealant.

n Avoid over-mixing sealant.

White color tends to yellow slightly when exposed to ultraviolet rays.

Light colors can yellow if exposed to direct gas fired heating elements.

n When overcoating: an on-site test is recommended to determine actual compatibility.

n The minimum depth of sealant in horizontal joints subject to traffic is 1/2 inch.

n Do not tool with detergent or soap solution.

n Minimum

Component A; Irritant - Avoid contact. Product is a skin, respiratory and eye irritant. Use of safety

goggles and chemical resistant gloves recommended. Use of a NIOSH approved respirator required if PELs

are exceeded. Use with adequate ventilation.

Component B; Combustible; Sensitizer; Irritant - Contains Xylene. Keep away from heat, sparks and

open flame. Use with adequate ventilation. Product is a respiratory and skin sensitizer. Avoid contact.

Product is an eye, skin, and respiratory irritant. Use of safety goggles and chemical resistant gloves recommended. Use of a NIOSH approved respirator required if PELs are exceeded.

First Aid

In case of skin contact, wash thoroughly with soap and water. For eye contact, flush immediately with plenty

of water for at least 15 minutes; contact physician. For respiratory problems, remove to fresh air. Wash

clothing before re-use. Discard contaminated shoes.

Clean Up

Uncured material can be removed with approved solvent. Cured material can only be removed mechanically. For spillage, collect, absorb, and dispose of in accordance with current, applicable local, state, and

federal regulations.

KEEP CONTAINER TIGHTLY CLOSED KEEP OUT OF REACH OF CHILDREN NOT FOR INTERNAL CONSUMPTION FOR INDUSTRIAL USE ONLY

All information provided by Sika Corporation (Sika) concerning Sika products, including but not limited to, any recommendations and advice relating to the

application and use of Sika products, is given in good faith based on Sikas current experience and knowledge of its products when properly stored, handled

and applied under normal conditions in accordance with Sikas instructions. In practice, the differences in materials, substrates, storage and handling conditions, actual site conditions and other factors outside of Sikas control are such that Sika assumes no liability for the provision of such information, advice,

recommendations or instructions related to its products, nor shall any legal relationship be created by or arise from the provision of such information, advice,

recommendations or instructions related to its products. The user of the Sika product(s) must test the product(s) for suitability for the intended application

and purpose before proceeding with the full application of the product(s). Sika reserves the right to change the properties of its products without notice.

All sales of Sika product(s) are subject to its current terms and conditions of sale which are available at www.sikausa.com or by calling 800-933-7452.

Prior to each use of any Sika product, the user must always read and follow the warnings and instructions on the products most current Technical

Data Sheet, product label and Material Safety Data Sheet which are available online at www.sikausa.com or by calling Sika's Technical Service

Department at 800-933-7452. Nothing contained in any Sika materials relieves the user of the obligation to read and follow the warnings and

instruction for each Sika product as set forth in the current Technical Data Sheet, product label and Material Safety Data Sheet prior to product use.

LIMITED WARRANTY: Sika warrants this product for one year from date of installation to be free from manufacturing defects and to meet the

technical properties on the current Technical Data Sheet if used as directed within shelf life. User determines suitability of product for intended

use and assumes all risks. Buyers sole remedy shall be limited to the purchase price or replacement of product exclusive of labor or cost of labor.

No other warranties express or implied shall apply including any warranty of merchantability or fitness for a particular

purpose. Sikashallnot be liable underanylegaltheoryfor specialor consequentialdamages. SIKASHALLNOT BE RESPONSIBLE

FOR THE USE OF THIS PRODUCT IN A MANNER TO INFRINGE ON ANY PATENT OR ANY OTHER INTELLECTUAL PROPERTY RIGHTS HELD BY OTHERS.

Visit our website at www.sikausa.com

1-800-933-SIKA NATIONWIDE

Regional Information and Sales Centers. For the location of your nearest Sika sales office, contact your regional center.

Sika Corporation

Sika Canada Inc.

Sika Mexicana S.A. de C.V.

201 Polito Avenue

601 Delmar Avenue

Carretera Libre Celaya Km. 8.5

Lyndhurst, NJ 07071

Pointe Claire

Fracc. Industrial Balvanera

Phone: 800-933-7452

Quebec H9R 4A9

Corregidora, Queretaro

ISO 9001

Fax: 201-933-6225

Phone: 514-697-2610

C.P. 76920

RC 14001

Fax: 514-694-2792

Phone: 52 442 2385800

Sika and Sikaflex are registered trademarks.

Fax: 52 442 2250537

Printed in Canada.

Certificate # FM 69711

Certificate # RC 510999

You might also like

- Sikaflex 1ADocument4 pagesSikaflex 1Athe pilotNo ratings yet

- Sikaflex 2c NS EZ Mix UsDocument3 pagesSikaflex 2c NS EZ Mix Usتوان امتياس سامسدينNo ratings yet

- SikaGrout 328Document3 pagesSikaGrout 328jesica31No ratings yet

- Sikadur AnchorFix-1Document3 pagesSikadur AnchorFix-1Adam GreenlawNo ratings yet

- Sikaflex Construction DDocument3 pagesSikaflex Construction Dthe pilotNo ratings yet

- Sika Duoflex NS/SL: Two-Component, Polysulphide SealantDocument2 pagesSika Duoflex NS/SL: Two-Component, Polysulphide SealantAbu Vulkanik Al-JawiyNo ratings yet

- Sikaflex TS Plus PDSDocument4 pagesSikaflex TS Plus PDSMark CousinsNo ratings yet

- Sikaflex 11FCDocument3 pagesSikaflex 11FCthe pilotNo ratings yet

- SikaTop Seal 107 PDS (CE) PDFDocument4 pagesSikaTop Seal 107 PDS (CE) PDFSed BeelzeNo ratings yet

- Ipd Pds Sikaflex221 Us 1Document4 pagesIpd Pds Sikaflex221 Us 1Dennis UbillusNo ratings yet

- Pds CPD Sikadur301 UsDocument2 pagesPds CPD Sikadur301 UsGabriel MazariegosNo ratings yet

- SikaTop Seal 107 PDS (CE)Document5 pagesSikaTop Seal 107 PDS (CE)Vladimir StojanovicNo ratings yet

- CPD SikaLatexR UsDocument2 pagesCPD SikaLatexR UsFahad MohamedNo ratings yet

- Sika Seal 105Document2 pagesSika Seal 105Gabo Tellez100% (1)

- Interzone 101Document0 pagesInterzone 101hennawijayaNo ratings yet

- Sikaflex PRO 3 WFDocument4 pagesSikaflex PRO 3 WFfrahliaNo ratings yet

- Sika Seal 105Document2 pagesSika Seal 105the pilotNo ratings yet

- Sika PDS - E - Sikaflex Construction (NWE)Document4 pagesSika PDS - E - Sikaflex Construction (NWE)Pisut LeelalumlertNo ratings yet

- Conbextra Ep75Document4 pagesConbextra Ep75Sathiya SeelanNo ratings yet

- Sika PDS E Sikagard-950Document4 pagesSika PDS E Sikagard-950lwin_oo2435No ratings yet

- Acrabond KE45 Type RTV Silicone SealantDocument5 pagesAcrabond KE45 Type RTV Silicone SealantdrvikaasNo ratings yet

- Pds CPD Sikadur42GroutPak UsDocument2 pagesPds CPD Sikadur42GroutPak UsAHNo ratings yet

- B220 SikadurCombiflexSGSystem UsDocument3 pagesB220 SikadurCombiflexSGSystem Usengsam777No ratings yet

- Sikacrete 114 AEDocument4 pagesSikacrete 114 AEMicheal B HaizenNo ratings yet

- Sikacrete 114Document2 pagesSikacrete 114the pilotNo ratings yet

- Sikadur 31, Hi-Mod Gel 1 1 Mix Ratio-UsDocument2 pagesSikadur 31, Hi-Mod Gel 1 1 Mix Ratio-Usgrats_singcoNo ratings yet

- SikaGrout 212 Product Data B25956Document2 pagesSikaGrout 212 Product Data B25956Guillermo Garcia50% (2)

- Conbextra EP75Document4 pagesConbextra EP75Venkata Raju KalidindiNo ratings yet

- Pds CPD Sikadur22LM UsDocument2 pagesPds CPD Sikadur22LM Uspandavision76No ratings yet

- Interprime 198 PDFDocument4 pagesInterprime 198 PDFandreaju2013No ratings yet

- Sikaflex 252Document2 pagesSikaflex 252alexcus1539No ratings yet

- Sikasil - AP: Neutral Curing Silicone SealantDocument3 pagesSikasil - AP: Neutral Curing Silicone SealantLim VandoeunNo ratings yet

- Product Data 232 Ceilcote FlakelineDocument3 pagesProduct Data 232 Ceilcote FlakelineMohd MustafhaNo ratings yet

- Sika Rep FineDocument2 pagesSika Rep Finethe pilotNo ratings yet

- Sika Swell S-2 (Water Stop)Document2 pagesSika Swell S-2 (Water Stop)omar42170No ratings yet

- Sikadur31 TdsDocument4 pagesSikadur31 TdsFrederick Linsangan CruzNo ratings yet

- Sika PDS - E - Sarnafil G 410 LDocument4 pagesSika PDS - E - Sarnafil G 410 Llwin_oo2435No ratings yet

- Sika Floor Pronto 13Document7 pagesSika Floor Pronto 13Mohamed ShehataNo ratings yet

- Sonneborn NP2Document4 pagesSonneborn NP2Edward FlynnNo ratings yet

- Sika Grout 114Document5 pagesSika Grout 114Hassan MehmoodNo ratings yet

- Masterflex 700 PGDocument3 pagesMasterflex 700 PGHaresh BhavnaniNo ratings yet

- SikaTop 144Document2 pagesSikaTop 144trijokoadiyanto27No ratings yet

- Sika PDS - E - Sarnafil G 410 L FeltDocument4 pagesSika PDS - E - Sarnafil G 410 L Feltlwin_oo2435No ratings yet

- Tds CPD Sikalastic 621 TC UsDocument3 pagesTds CPD Sikalastic 621 TC UsTPNo ratings yet

- SikaTop Seal-109 MY 2012-08 - 1Document3 pagesSikaTop Seal-109 MY 2012-08 - 1Mashithah AhmadNo ratings yet

- Sikagard 75 Epocem: Superfine Epoxy-Cement Sealing MortarDocument4 pagesSikagard 75 Epocem: Superfine Epoxy-Cement Sealing MortarAnonymous v1blzDsEWANo ratings yet

- Sikadur 42 HSDocument2 pagesSikadur 42 HSthe pilotNo ratings yet

- SikaTop-Seal 107 PDFDocument4 pagesSikaTop-Seal 107 PDFSed BeelzeNo ratings yet

- Sika RepDocument2 pagesSika Repthe pilotNo ratings yet

- Formula 150 Primer (MILDTL-24441)Document4 pagesFormula 150 Primer (MILDTL-24441)Trịnh Minh KhoaNo ratings yet

- Sika PDS - E - SikaProof SB TH PDFDocument3 pagesSika PDS - E - SikaProof SB TH PDFlwin_oo2435No ratings yet

- Sika MonoTop 615 PDS (CE)Document6 pagesSika MonoTop 615 PDS (CE)Virah Sammy ChandraNo ratings yet

- Sikacryl SDocument2 pagesSikacryl Sthe pilotNo ratings yet

- Monotop 412 NFG PdsDocument4 pagesMonotop 412 NFG PdsJames MizziNo ratings yet

- Sika PDS E SikaProof MembraneDocument2 pagesSika PDS E SikaProof Membranelwin_oo2435No ratings yet

- SikalasticDuochem390 FpdsDocument4 pagesSikalasticDuochem390 FpdsHielene Corpin PaatNo ratings yet

- Sikafloor 357Document6 pagesSikafloor 357Jessica CaldwellNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Your Home Inspected: An Addendum for Residential Home Inspection ReportsFrom EverandYour Home Inspected: An Addendum for Residential Home Inspection ReportsNo ratings yet

- CTS+ Configuracion NW 7.3Document43 pagesCTS+ Configuracion NW 7.3Zou DisneyNo ratings yet

- How To Use GX Developer MelsecDocument43 pagesHow To Use GX Developer MelsecAlexia VargasNo ratings yet

- Klasifikasi Material: Myrna Ariati Wahyuaji Narottama PutraDocument49 pagesKlasifikasi Material: Myrna Ariati Wahyuaji Narottama Putrachink07No ratings yet

- FrictionDocument62 pagesFrictionchellamvNo ratings yet

- Mechanical Operations (CHE-205) (Makeup) (EngineeringDuniya - Com)Document3 pagesMechanical Operations (CHE-205) (Makeup) (EngineeringDuniya - Com)Cester Avila Ducusin100% (1)

- Catalog Bencomp Brosura Engleza 2018Document12 pagesCatalog Bencomp Brosura Engleza 2018sergiu9886No ratings yet

- Check Line MMX-6 Manual TI-25M-MMXDocument15 pagesCheck Line MMX-6 Manual TI-25M-MMXDragoș L. I. TeodorescuNo ratings yet

- Siemens Internship ReportDocument17 pagesSiemens Internship ReportmirfanbilalNo ratings yet

- Crouzet Switch CatalogDocument51 pagesCrouzet Switch Cataloghammondelec100% (2)

- CollisionDocument7 pagesCollisionboltuNo ratings yet

- H 99 Sec 8 D 1 App 1Document9 pagesH 99 Sec 8 D 1 App 1Benjamin Enmanuel Mango DNo ratings yet

- cs408 Finalterm Solved Mcqs With Reference PDFDocument18 pagescs408 Finalterm Solved Mcqs With Reference PDFMuzammil Siddique100% (1)

- 1308020EN Electrical EngineeringDocument20 pages1308020EN Electrical EngineeringamrehmaniNo ratings yet

- FCS-8005 User ManualDocument11 pagesFCS-8005 User ManualGustavo EitzenNo ratings yet

- SDD 048 ML 12xx DocumentDocument12 pagesSDD 048 ML 12xx DocumentRomiNo ratings yet

- Development and Testing of Sugarcane Juice Extractor: Agidi GbaboDocument5 pagesDevelopment and Testing of Sugarcane Juice Extractor: Agidi Gbabomekanic24100% (1)

- Class II Oral QuestionsDocument18 pagesClass II Oral QuestionsStewardGriffindorNo ratings yet

- MDV D80T2VN1 Ba5 PDFDocument2 pagesMDV D80T2VN1 Ba5 PDFJuan Carlos Soto OrihuelaNo ratings yet

- 1632 - Pbt-Pet Valox 815Document5 pages1632 - Pbt-Pet Valox 815Vinoth SekarNo ratings yet

- Guide Du Propriétaire Owner's Guide Guía Del Usuario: Robot Aspirateur Robot AspiradorDocument37 pagesGuide Du Propriétaire Owner's Guide Guía Del Usuario: Robot Aspirateur Robot AspiradoralelendoNo ratings yet

- Canopy Install TipsDocument1 pageCanopy Install Tipsengine wangNo ratings yet

- B. Tech. II - Class Time Table - 2023-24 - OddDocument2 pagesB. Tech. II - Class Time Table - 2023-24 - OddYusuf GoriawalaNo ratings yet

- What Is Nelco N5000-3032 BT PCBDocument5 pagesWhat Is Nelco N5000-3032 BT PCBjackNo ratings yet

- Ariston mtb45d2nf 81276250000Document21 pagesAriston mtb45d2nf 81276250000Cristian TeodorescuNo ratings yet

- PBA Therm Clad BrochureDocument2 pagesPBA Therm Clad BrochureJames DickinsonNo ratings yet

- At9000 GTX60GDocument9 pagesAt9000 GTX60Gjuan valderramaNo ratings yet

- IZenBridge PMI ACP Program PDFDocument4 pagesIZenBridge PMI ACP Program PDFadetolahNo ratings yet

- Lexmark C91x C912 5505 Service ManualDocument492 pagesLexmark C91x C912 5505 Service ManualMichael HanniganNo ratings yet

- Eye Movement-Based Human Computer Interaction TechniquesDocument5 pagesEye Movement-Based Human Computer Interaction TechniquesSreekanth MarlapatiNo ratings yet

- Coalbrookdale Darby Stove (Boiler Model) : Spare Parts ManualDocument7 pagesCoalbrookdale Darby Stove (Boiler Model) : Spare Parts ManualDavid Mark JonesNo ratings yet