Professional Documents

Culture Documents

Tutorial 4 Aspen Plus Using Heat Transfer With A Plug Flow Reactor

Tutorial 4 Aspen Plus Using Heat Transfer With A Plug Flow Reactor

Uploaded by

Andreea IoanaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tutorial 4 Aspen Plus Using Heat Transfer With A Plug Flow Reactor

Tutorial 4 Aspen Plus Using Heat Transfer With A Plug Flow Reactor

Uploaded by

Andreea IoanaCopyright:

Available Formats

Uploaded by:

Ebooks Chemical Engineering

(https://www.facebook.com/pages/Ebooks-Chemical-Engineering/238197077030)

For More Books, softwares & tutorials Related to Chemical Engineering

Join Us

@google+: http://gplus.to/ChemicalEngineering

@facebook: https://www.facebook.com/AllAboutChemcalEngineering

@facebook: https://www.facebook.com/groups/10436265147/

@facebook: https://www.facebook.com/pages/Ebooks-ChemicalEngineering/238197077030

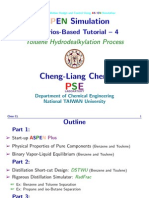

Aspen Plus Tutorial 4

1/8

Aspen Plus Tutorial 4:

Using Heat Transfer with a Plug Flow Reactor

This is an adjustment of Aspen Tutorial 3. In that tutorial, we assumed the reactor would operate

isothermally. Now we want to make sure that it does by adding heat transfer. Start from Aspen

Tutorial 3 and add the "HEATX" heat exchanger and the water cooling streams indicated in the

flowsheet below. The screenshots below illustrate how do configure such a system in Aspen Plus.

An assignment is given below.

http://www.che.utexas.edu/~che473k/aspen/aspentutor4.htm

2005-2-24

Aspen Plus Tutorial 4

2/8

http://www.che.utexas.edu/~che473k/aspen/aspentutor4.htm

2005-2-24

Aspen Plus Tutorial 4

3/8

http://www.che.utexas.edu/~che473k/aspen/aspentutor4.htm

2005-2-24

Aspen Plus Tutorial 4

4/8

http://www.che.utexas.edu/~che473k/aspen/aspentutor4.htm

2005-2-24

Aspen Plus Tutorial 4

5/8

http://www.che.utexas.edu/~che473k/aspen/aspentutor4.htm

2005-2-24

Aspen Plus Tutorial 4

6/8

http://www.che.utexas.edu/~che473k/aspen/aspentutor4.htm

2005-2-24

Aspen Plus Tutorial 4

7/8

http://www.che.utexas.edu/~che473k/aspen/aspentutor4.htm

2005-2-24

Aspen Plus Tutorial 4

8/8

Assignment:

You'll probably find that the conversion of VA is pretty low. The conversion can be increased by

reducing the feed stream inlet to 10000 lbmol/hr and increasing the pipe diameter to 2 inches. Make

modifications to your system reflecting these changes while still maintaining a relatively isothermal

reactor. It is a good idea to try to get your cooling water stream "COOL_OUT" to be all vapor at the

same temperature of its input counterpart. Also be sure you have enough cooling water to cool the

coolant stream. (Note: the cold water is very cold; it would be difficult to get a utility provider to

inexpensively sell you this stream) In one page, summarize the following (you won't be able to do

this with a simple printout from Aspen):

z

z

z

z

Changes (if any) in reactor temperature (inlet vs. outlet).

VA production, overall reaction ratio (2*VAout/CO2out), and reactor conversion

(VAout/AAin).

Coolant and cooling water flowrates.

Heat exchanger configuration.

http://www.che.utexas.edu/~che473k/aspen/aspentutor4.htm

2005-2-24

You might also like

- Sintesis de Urea Con AspenDocument11 pagesSintesis de Urea Con AspenOlfer Claros0% (1)

- Jump Start Aspen Custom Modeler V8 PDFDocument26 pagesJump Start Aspen Custom Modeler V8 PDFAlessandro TrigilioNo ratings yet

- Project 6 AmmoniaDocument10 pagesProject 6 AmmoniaAhmed AliNo ratings yet

- ASPEN PLUS Example ProblemDocument5 pagesASPEN PLUS Example ProblemAlbert Powa0% (1)

- f23690472 Rate-Based Model of The CO2 Capture Process by K2CO3 Using Aspen PlusDocument23 pagesf23690472 Rate-Based Model of The CO2 Capture Process by K2CO3 Using Aspen PlusAhmed Sohaib0% (1)

- Ammonia Synthesis Loops Variables Investigated by Steady-State SimulationDocument14 pagesAmmonia Synthesis Loops Variables Investigated by Steady-State Simulationpolonium2310No ratings yet

- Aspen Case 4 RDocument137 pagesAspen Case 4 RItxaso Villanueva OraaNo ratings yet

- Brian JR Geoffroy CHNG 3012 Part II PDFDocument103 pagesBrian JR Geoffroy CHNG 3012 Part II PDFjanelle ramdahinNo ratings yet

- Aspen Plus DEPG ModelDocument23 pagesAspen Plus DEPG ModelAmir JoonNo ratings yet

- Aspen Custom ModelerDocument4 pagesAspen Custom ModelerJemar LimNo ratings yet

- Plant Design Project FinalDocument221 pagesPlant Design Project FinalYasser AshourNo ratings yet

- Design of Acetone HYSYSDocument6 pagesDesign of Acetone HYSYSlockas222100% (1)

- Simulation and ParametricDocument12 pagesSimulation and ParametricAmiruddin KubikNo ratings yet

- Simulation of Methanol Synthesis in Packed Bed Reactor Based On Gas From Biomass GasificationDocument9 pagesSimulation of Methanol Synthesis in Packed Bed Reactor Based On Gas From Biomass GasificationHaris Surya HidayatNo ratings yet

- Steam Methane Reforming Reaction Process Intensification by Using A ReactorDocument14 pagesSteam Methane Reforming Reaction Process Intensification by Using A ReactorserchNo ratings yet

- Simulation of Steam Reformers For MethaneDocument6 pagesSimulation of Steam Reformers For Methanedashali1100% (1)

- FoamingDocument3 pagesFoamingkarthickNo ratings yet

- Modeling and Simulation of Ammonia Synthesis Reactor PDFDocument9 pagesModeling and Simulation of Ammonia Synthesis Reactor PDFRaúl RivasNo ratings yet

- Reactor (PFR) PDFDocument10 pagesReactor (PFR) PDFHien Ngo ThiNo ratings yet

- Ammonia Converter DesignnnDocument4 pagesAmmonia Converter DesignnnHumaira NoorNo ratings yet

- Exercise-3 CSTR Dynamic PDFDocument16 pagesExercise-3 CSTR Dynamic PDFNima LufiaNo ratings yet

- Chapter One 1.1. BackgroundDocument16 pagesChapter One 1.1. Backgroundchisom100% (1)

- AmmoniaDocument24 pagesAmmonianghiemta18100% (2)

- Production of 20 000 MTPD of Methyl Tertiary Butyl Ether From Methanol and Butylenes by Catalytic ConversionDocument177 pagesProduction of 20 000 MTPD of Methyl Tertiary Butyl Ether From Methanol and Butylenes by Catalytic ConversioniffatNo ratings yet

- A Review of The Water Gas Shift Reaction KineticsDocument35 pagesA Review of The Water Gas Shift Reaction KineticsRickyWisaksono100% (1)

- REACTOR DESIGN - Docx Fyp MyDocument5 pagesREACTOR DESIGN - Docx Fyp Myabdul rehmanNo ratings yet

- 2009 Water-Gas Shift Kinetics Over FeCr-Based Catalyst - Sel...Document18 pages2009 Water-Gas Shift Kinetics Over FeCr-Based Catalyst - Sel...Taniadi SuriaNo ratings yet

- Adiabatic and Non-Isothermal Reactor DesignDocument35 pagesAdiabatic and Non-Isothermal Reactor DesignTesfaye Kassaw100% (1)

- Bubble Column ReactorDocument21 pagesBubble Column ReactorMuhammad Hamzah SyahrirNo ratings yet

- Chemcad Reactor Design TutorialDocument4 pagesChemcad Reactor Design TutorialErich EscobarNo ratings yet

- Plug FlowDocument17 pagesPlug FlowNurshahirahSapianNo ratings yet

- Aspen Plus Simulation of Saponification of Ethyl Acetate in The Presence of Sodium Hydroxide in A Plug Flow ReactorDocument8 pagesAspen Plus Simulation of Saponification of Ethyl Acetate in The Presence of Sodium Hydroxide in A Plug Flow ReactorSoumajit SenNo ratings yet

- Data Regression Analysis in Aspen Plus For CO2 Absorption Process Using MEA Final 3Document15 pagesData Regression Analysis in Aspen Plus For CO2 Absorption Process Using MEA Final 3Piyush Priyadarshi0% (1)

- 2 Thermodynamic Property Methods in Aspen PlusDocument10 pages2 Thermodynamic Property Methods in Aspen PlusNorman_Mpofu21100% (1)

- Simple Reactor DesignDocument30 pagesSimple Reactor DesignSehry SyedNo ratings yet

- (1)Document119 pages(1)Virginia Rosales OlmosNo ratings yet

- CRE Notes 13-A Methanol ReactorDocument11 pagesCRE Notes 13-A Methanol ReactorjoeNo ratings yet

- Case Study 109 Ammonia OxidationDocument9 pagesCase Study 109 Ammonia OxidationkaalkankNo ratings yet

- Development of An ASPEN PLUS Physical Property Database For Biofuels ComponentsDocument36 pagesDevelopment of An ASPEN PLUS Physical Property Database For Biofuels ComponentsoslemmNo ratings yet

- Aspen Hysys Reactive DistillationDocument10 pagesAspen Hysys Reactive DistillationAGP100% (1)

- Chemical Engineering Science Volume 1 Issue 4 1952 (Doi 10.1016/0009-2509 (52) 87011-3) D. Annable - Application of The Temkin Kinetic Equation To Ammonia Synthesis in Large-Scale ReactorsDocument10 pagesChemical Engineering Science Volume 1 Issue 4 1952 (Doi 10.1016/0009-2509 (52) 87011-3) D. Annable - Application of The Temkin Kinetic Equation To Ammonia Synthesis in Large-Scale Reactorsmade hNo ratings yet

- HYSYS - Multiple Reactions - Styrene Prepared by Robert P. Hesketh Spring 2005 Styrene Reactor SystemDocument9 pagesHYSYS - Multiple Reactions - Styrene Prepared by Robert P. Hesketh Spring 2005 Styrene Reactor SystemCarlos GonzalezNo ratings yet

- Cumene Process, Prod - CBIDocument2 pagesCumene Process, Prod - CBIChris LindseyNo ratings yet

- NCCPS 2018 ProceedingsDocument151 pagesNCCPS 2018 ProceedingsShyamPanthavoorNo ratings yet

- Design Project On Nitric Acid ProductionDocument152 pagesDesign Project On Nitric Acid Productionحاتم غيدان خلف100% (1)

- Aspen Energy Analyzer Reference Guide v7Document148 pagesAspen Energy Analyzer Reference Guide v7Francois VoeuxNo ratings yet

- The Dry Reforming of Methane To Syngas and Subsequent Products PDFDocument107 pagesThe Dry Reforming of Methane To Syngas and Subsequent Products PDFIntan Clarissa SophianaNo ratings yet

- Optimization of The Acetone Plant Using CHEMCADDocument24 pagesOptimization of The Acetone Plant Using CHEMCADshahed IasirNo ratings yet

- Module#3-Heat ExchangersDocument19 pagesModule#3-Heat ExchangersLa Casa JordanNo ratings yet

- Aspen Plus Sulfuric Acid ModelDocument16 pagesAspen Plus Sulfuric Acid ModelStanley WoonNo ratings yet

- Propane Dehydrogenation in Modified Membrane Porous ReactorDocument7 pagesPropane Dehydrogenation in Modified Membrane Porous ReactorNoezran AzwarNo ratings yet

- Aspen Estimating Physical PropertiesDocument12 pagesAspen Estimating Physical PropertiesStheh Ka Nkosi100% (1)

- Aspen Plus, Reaction Engineering and DesignDocument45 pagesAspen Plus, Reaction Engineering and Designnikhilgoyal4100% (1)

- التعديل النهائي محمد احمد علي عبدالله 22130011 PDFDocument115 pagesالتعديل النهائي محمد احمد علي عبدالله 22130011 PDFRojan Pradhan0% (1)

- Methane Oxidation To Acetic AcidDocument31 pagesMethane Oxidation To Acetic AcidАндрей КолесниковNo ratings yet

- Simulation of Fluid Catalytic CrackerDocument62 pagesSimulation of Fluid Catalytic CrackerAhmed Ali100% (1)

- Design of A 90 MTPD Methanol Production Plant FinalDocument147 pagesDesign of A 90 MTPD Methanol Production Plant FinalFardin Faruk KhanNo ratings yet

- Fluid Mechanics, Heat Transfer, Thermodynamics Design Project Production of StyreneDocument12 pagesFluid Mechanics, Heat Transfer, Thermodynamics Design Project Production of StyrenezarceloNo ratings yet

- Acrylic Acid ProductionDocument8 pagesAcrylic Acid ProductionAhmad MuzammilNo ratings yet

- (CH) Choh (CH) Co + HDocument14 pages(CH) Choh (CH) Co + HAhmad AlkhateebNo ratings yet