Professional Documents

Culture Documents

Super Precision Bearings - E

Super Precision Bearings - E

Uploaded by

PhanHathamCopyright:

Available Formats

You might also like

- Tata Toyo Case StudyDocument117 pagesTata Toyo Case StudyGokulraju Rangasamy0% (1)

- Gear Accuracy Class Comparison PDFDocument1 pageGear Accuracy Class Comparison PDFSaravanan DuraiNo ratings yet

- JLG T350 PDFDocument230 pagesJLG T350 PDFjhoanna nieves toroNo ratings yet

- Education & Training Guidance Manual PDFDocument133 pagesEducation & Training Guidance Manual PDFKESHAVA PRASAD SNo ratings yet

- Lean Six SigmaDocument84 pagesLean Six Sigmashamim hossainNo ratings yet

- Lect14r6oct 06 Pom World Class Manufacturing 110908135935 Phpapp01 PDFDocument80 pagesLect14r6oct 06 Pom World Class Manufacturing 110908135935 Phpapp01 PDFVivek KumarNo ratings yet

- Storm QCC: Welcomes You All For Our Second Project PresentationDocument89 pagesStorm QCC: Welcomes You All For Our Second Project Presentationapi-19901822100% (1)

- Engine Valves Production Summer PractiseDocument26 pagesEngine Valves Production Summer Practisestatica27100% (2)

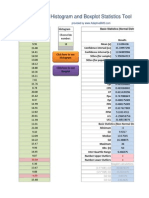

- Histogram Box Plot Statistics AdaptiveBMSDocument13 pagesHistogram Box Plot Statistics AdaptiveBMSashutoshrvNo ratings yet

- Teppi Tevet College Apply 3S: KaizenDocument60 pagesTeppi Tevet College Apply 3S: KaizenPunitha Paul0% (1)

- SQHDocument55 pagesSQHSreenivaasan SudharssanamNo ratings yet

- Case Analysis - Tisco Group 5Document11 pagesCase Analysis - Tisco Group 5Hitesh Khubchandani100% (1)

- Tata Steelium Case SolutionDocument9 pagesTata Steelium Case SolutionShailav Prakash100% (1)

- Step 0 and 1 Management Part 1Document14 pagesStep 0 and 1 Management Part 1murilocabriniNo ratings yet

- Woojin Plaimm Injection Molding MachineDocument10 pagesWoojin Plaimm Injection Molding MachineFauzi IskandarNo ratings yet

- Introduction To MTripleP IMetalDocument21 pagesIntroduction To MTripleP IMetalKrishna Mohan T.RNo ratings yet

- PMDocument92 pagesPMrogertbalancio100% (1)

- MTPDocument10 pagesMTPmurilocabriniNo ratings yet

- VSM Basics For CapacityDocument26 pagesVSM Basics For CapacityUriel Soto VarelaNo ratings yet

- Supplier Apqp Basic TrgudhayDocument39 pagesSupplier Apqp Basic TrgudhayVasudev DevNo ratings yet

- Quality Circle Presentation From Cheese PlantDocument36 pagesQuality Circle Presentation From Cheese Plantshivam singhNo ratings yet

- 30 November 2016 (Wednesday) : Japan Institute of Plant Maintenance (JIPM) Managing Director Satoshi SuzuokiDocument15 pages30 November 2016 (Wednesday) : Japan Institute of Plant Maintenance (JIPM) Managing Director Satoshi SuzuokiSelvaraj SimiyonNo ratings yet

- Chris Wilson - Market Trends ChallengesDocument29 pagesChris Wilson - Market Trends ChallengesAnbazhagan Sulur RamasamyNo ratings yet

- Gas Alarm System - KaizenDocument28 pagesGas Alarm System - KaizenShellender SinghNo ratings yet

- PT Vs SOP 17 Tooling RepairDocument7 pagesPT Vs SOP 17 Tooling RepairRidwanNo ratings yet

- Design Review Based On Failure Mode 1-Day Workshop by TetrahedronDocument2 pagesDesign Review Based On Failure Mode 1-Day Workshop by TetrahedrontetrahedronNo ratings yet

- IPC-SpecTree - IPC SpecTree 2014-09Document1 pageIPC-SpecTree - IPC SpecTree 2014-09edubrunno100% (1)

- b2 1 AndoDocument60 pagesb2 1 AndoSudhagarNo ratings yet

- Honing Stones English 07Document14 pagesHoning Stones English 07Shiri ShaNo ratings yet

- ChassisDocument30 pagesChassisRavi KiranNo ratings yet

- Grinding Process BoreDocument22 pagesGrinding Process Boremaulikgadara50% (2)

- 16 LossesDocument26 pages16 LossesAbhijit Bhattacherjee100% (1)

- Quality Function Deployment (QFD) : Mohan Khond Mechanical Engineering Department College of Engineering, PuneDocument18 pagesQuality Function Deployment (QFD) : Mohan Khond Mechanical Engineering Department College of Engineering, Punesan_02No ratings yet

- SscafDocument111 pagesSscafgabyroiceNo ratings yet

- 2018 Ims Manual Mechanical EngineeringDocument19 pages2018 Ims Manual Mechanical EngineeringMohamed IbrahimNo ratings yet

- Remanufacturing and Product DesignDocument77 pagesRemanufacturing and Product DesignALMusriALSudaniNo ratings yet

- An Introduction To ISO/TS 16949:2002: by George TaoDocument91 pagesAn Introduction To ISO/TS 16949:2002: by George Taogerald904640No ratings yet

- Manufacturing Process ImprovementDocument3 pagesManufacturing Process ImprovementgeniusMAHINo ratings yet

- 03 Knowledge Sharing 7 QC ToolsDocument107 pages03 Knowledge Sharing 7 QC Toolsravi javaliNo ratings yet

- 21 Storage System EbookDocument19 pages21 Storage System EbooksuriantoNo ratings yet

- QC Story - Toyota - Handbook of TQM and QCC - V1Document8 pagesQC Story - Toyota - Handbook of TQM and QCC - V1Venkatesh GogineniNo ratings yet

- WWW Vskills in Practice Lean Manufacturing Mock TestDocument34 pagesWWW Vskills in Practice Lean Manufacturing Mock TestRoopesh KesavarajuNo ratings yet

- DFMA MaterialsDocument19 pagesDFMA MaterialsdharmeshNo ratings yet

- Am Board DesignDocument1 pageAm Board DesignJoseph OrjiNo ratings yet

- MSA Example WorkbookDocument41 pagesMSA Example Workbookll vvNo ratings yet

- Technical Data Sheet - DST-DEGREEZ-6 - 2020 UKDocument1 pageTechnical Data Sheet - DST-DEGREEZ-6 - 2020 UKBala Sb0% (1)

- Seminar8july11-2 (Industrial Furnaces and Working)Document37 pagesSeminar8july11-2 (Industrial Furnaces and Working)Ankur Panwar0% (1)

- Industrial Fasteners, Nuts & BoltsDocument79 pagesIndustrial Fasteners, Nuts & BoltsMudduKrishna shettyNo ratings yet

- Kobetsu Kaizen: Maintenance ManagementDocument34 pagesKobetsu Kaizen: Maintenance ManagementMohammed Rushnaiwala100% (1)

- 16 LossesDocument2 pages16 LossesShekhar9No ratings yet

- MRM Report Format2Document1 pageMRM Report Format2cu4kissNo ratings yet

- Wide Belt Sanding Machines SANDTEQ W 300 700 en PDFDocument48 pagesWide Belt Sanding Machines SANDTEQ W 300 700 en PDFMesara Kod KokijaNo ratings yet

- Changeover Optimizer ChartDocument50 pagesChangeover Optimizer ChartBalaji SNo ratings yet

- IATF - International Automotive Task Force: Rules For Achieving and Maintaining IATF Recognition IATF Rules 5 EditionDocument30 pagesIATF - International Automotive Task Force: Rules For Achieving and Maintaining IATF Recognition IATF Rules 5 EditionAtul JoshiNo ratings yet

- Cost-Machine Shop Mar-15 (Ram-Assy)Document7 pagesCost-Machine Shop Mar-15 (Ram-Assy)azadsingh1No ratings yet

- Progress at TPM: Newsletter From CII TPM Club IndiaDocument18 pagesProgress at TPM: Newsletter From CII TPM Club IndiamurilocabriniNo ratings yet

- 2011 TPM Excellence Awards Winners (Outside Japan) : Award For World-Class TPM AchievementDocument3 pages2011 TPM Excellence Awards Winners (Outside Japan) : Award For World-Class TPM AchievementMatthew ColeNo ratings yet

- Hot ForgingDocument7 pagesHot ForgingPradeep Kumar BowmarajuNo ratings yet

- Agile Essentials You Always Wanted To Know: Self Learning ManagementFrom EverandAgile Essentials You Always Wanted To Know: Self Learning ManagementNo ratings yet

- De Chinh Thuc N3 PDFDocument95 pagesDe Chinh Thuc N3 PDFPhanHatham100% (1)

- 1001-Experimental Evaluation of A Digital Hydraulic Power Management SystemDocument15 pages1001-Experimental Evaluation of A Digital Hydraulic Power Management SystemPhanHathamNo ratings yet

- 0-Development of New Hybrid ExcavatorDocument9 pages0-Development of New Hybrid ExcavatorPhanHathamNo ratings yet

- 10 5445ir1000070929 PDFDocument239 pages10 5445ir1000070929 PDFPhanHathamNo ratings yet

- IndexDocument197 pagesIndexPhanHathamNo ratings yet

- English Rhetoric PDFDocument1 pageEnglish Rhetoric PDFPhanHathamNo ratings yet

- ZKL Brno Katalog 2007 enDocument74 pagesZKL Brno Katalog 2007 enPhanHathamNo ratings yet

- PDF Manuel ERREM Coupler 2012 1 UK PDFDocument7 pagesPDF Manuel ERREM Coupler 2012 1 UK PDFPhanHathamNo ratings yet

- General Brochure HESS Group EnglishDocument19 pagesGeneral Brochure HESS Group EnglishPhanHathamNo ratings yet

- TG17 - 15 Identification of EN74-1 CouplersDocument2 pagesTG17 - 15 Identification of EN74-1 CouplersPhanHathamNo ratings yet

- Study of Different Types of Pipe FittingsDocument17 pagesStudy of Different Types of Pipe FittingsIzi50% (2)

- 2012 - Phillips-Temro - Cold Weather Starting Products - LIT0350012 - 2012 - 95 PagesDocument95 pages2012 - Phillips-Temro - Cold Weather Starting Products - LIT0350012 - 2012 - 95 PagesJohn PagelsNo ratings yet

- 1 1 5 A GearsPulleyDrivesSprocketsPracticeProblemsDocument4 pages1 1 5 A GearsPulleyDrivesSprocketsPracticeProblemsJ. DunawayNo ratings yet

- Coastal Tug "Mhan Aung-4": Ministry of TransportDocument2 pagesCoastal Tug "Mhan Aung-4": Ministry of TransportnyaungzinNo ratings yet

- Soal Pre Test Efi Xii TKRDocument1 pageSoal Pre Test Efi Xii TKRAsep Dedi KurniadiNo ratings yet

- SRV210 - 250TC Spare PartsDocument2 pagesSRV210 - 250TC Spare PartsEnzo SovittiNo ratings yet

- Maintenance Interval Schedule 745C-LFKDocument4 pagesMaintenance Interval Schedule 745C-LFKfirman manaluNo ratings yet

- (Operator's Manual) (Operator's Manual) (Maintenance Manual) (Repair Manual P 106)Document21 pages(Operator's Manual) (Operator's Manual) (Maintenance Manual) (Repair Manual P 106)zahar222No ratings yet

- Motorized Rolling Shutter SynopsisDocument12 pagesMotorized Rolling Shutter SynopsisTanviNo ratings yet

- Royal GIII VENDOR (550 - 660 - 670 - 804) - 1Document48 pagesRoyal GIII VENDOR (550 - 660 - 670 - 804) - 1Christopher MeterNo ratings yet

- Uptime Maintenance Planner: Service IntervalsDocument3 pagesUptime Maintenance Planner: Service IntervalsBrian CareelNo ratings yet

- Vae Controls Group Vae Controls Group: Additive & Color Dosing EquipmentDocument2 pagesVae Controls Group Vae Controls Group: Additive & Color Dosing EquipmentSaravanan MathiNo ratings yet

- IR 7100 Datasheet PDFDocument4 pagesIR 7100 Datasheet PDFAnonymous TXOkcdyNo ratings yet

- NoteDocument2 pagesNoteMasoodMiyanNo ratings yet

- Governor ApparatusDocument14 pagesGovernor ApparatusHimanshu Kulshrestha100% (1)

- List of Drawings Order N 10828 - 39: Tel RDocument44 pagesList of Drawings Order N 10828 - 39: Tel RVinay Kumar Neelam0% (1)

- S.E.M.T. Pielstick.: Technical Data and DimensionsDocument3 pagesS.E.M.T. Pielstick.: Technical Data and Dimensionsammer alrayanNo ratings yet

- Review of Dual Clutch Transmission SystemsDocument7 pagesReview of Dual Clutch Transmission Systemselrobo0905No ratings yet

- F18ec - 2010-07-30Document4 pagesF18ec - 2010-07-30Mirko CoppiniNo ratings yet

- Pitanja Iz Engleskog-PrevodDocument1 pagePitanja Iz Engleskog-PrevodZvonimirDelićNo ratings yet

- Lecture 2 Degrees of FreedomDocument16 pagesLecture 2 Degrees of FreedomomarNo ratings yet

- c7 1 PDFDocument34 pagesc7 1 PDFTASHKEELNo ratings yet

- Case 695Document22 pagesCase 695ДмитрйиNo ratings yet

- 63ycy14-1b Hydraulic Axial Piston Pump ... Ial Piston Pump Product On AlibabaDocument8 pages63ycy14-1b Hydraulic Axial Piston Pump ... Ial Piston Pump Product On AlibabaElectroventica Electroventica100% (1)

- The New Firewall Forward Camshaft: PointDocument1 pageThe New Firewall Forward Camshaft: PointAndri OdeNo ratings yet

- Turbo Mueller PDFDocument31 pagesTurbo Mueller PDFAqleem AhmadNo ratings yet

- Electricity 22Document13 pagesElectricity 22christian foreroNo ratings yet

- Basic Civil and Mechanical-Unit-4-Ic Engines-Support Notes-Studyhaunters PDFDocument13 pagesBasic Civil and Mechanical-Unit-4-Ic Engines-Support Notes-Studyhaunters PDFSriram JNo ratings yet

- Coach & Bus EngineDocument2 pagesCoach & Bus EngineClegivaldoNo ratings yet

Super Precision Bearings - E

Super Precision Bearings - E

Uploaded by

PhanHathamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Super Precision Bearings - E

Super Precision Bearings - E

Uploaded by

PhanHathamCopyright:

Available Formats

IBC WLZLAGER GMBH

INDUSTRIAL BEARINGS AND COMPONENTS

Post box 1825 35528 WETZLAR (GERMANY)

Tel: +49/64 41/95 53-02

Fax: +49/64 41/5 30 15

e-mail: ibc@ibc-waelzlager.com

Corporate office

Industriegebiet Oberbiel

D-35606 Solms-Oberbiel

Super Precision Bearings

http://www.ibc-waelzlager.com

TI-I-5003.2 / E

IBC INDUSTRIAL BEARINGS

AND COMPONENTS AG

Tel: +41/32/6 52 83 53

Fax: +41/32/6 52 83 58

e-mail: ibc@ibcag.ch

Corporate office

Kapellstrasse 26

CH-2540 Grenchen

http://www.ibc-waelzlager.com

Location with Tradition

The headquarters in Solms-Oberbiel

is centrally located in Germany close to the

North/South and East/West highways which

also provides for a central location in Europe.

The international Airport Frankfurt approx.

80 km away serves as a worldwide link.

More of IBC . . .

Headquarter of the IBC Wlzlager GmbH at the industrial area of Solms-Oberbiel

Flexible and Reliable

Lieferprogramm

Hochgenauigkeits-Wlzlager

Przisionslagereinheiten Przisionsspannmuttern

TI-I-5000.0 / D

In the middle of 1996

we opened the central

computer controlled

high shelf warehouse with

more than 2.000 pallet places.

It is used for finsihed and

semi-finished products as well

as for large bearings.

This is in addition to our existing

two-storage computer controlled

service warehouse also with

more than 2.500 storage places.

Company Profile

(German)

(English)

Product Range

Super Precision Bearings

Product Range

Price List

T1-I-5000.0 / D (German)

T1-I-5000.0 / E (English)

Precise Logistics provide an

unequaled worldwide reliability

Both warehouse systems

provide together with our

distribution centre and

communication network precise

logistics and a worldwide

unequaled reliability.

Schrgkugellager 40

TI-I-4044.0 / D

Angular Contact Ball

Bearings 40

Linear Bearings

Telescopic Rails

T1-1-7001.2 / D (German)

T1-1-7005.1 / D (German)

T1-1-4044.0 / D (German)

T1-1-4044.0 / E (English)

Central Computer Controlled

High Shelf Warehouse Middle 1996

Precision with Future . . .

New plant in Asslar

We are future orientated.

We have the creativity and

vision to perform and provide.

This is our exact presentation

to solutions with precision.

IBC Wlzlager

mit ATCoat

Beschichtung

Wlzlager fr Kugelgewindetriebe

Axial-Schrgkugellager 60

Przisionslagereinheiten Przisionsspannmuttern

TI-1-5010.2/D

TI-I-5010.2 / D

Ball Screw Support Bearings

TI-I-5010.2 / D (German)

TI-I-5010.2 / E (English)

Super Precision Bearings

Service Catalog

ATCoated Bearings

TI-1-5010.2 / D (German)

T1-1-5003.1 / D (German)

T1-1-5003.2 / E (English)

Copyright 2006 IBC Wlzlager GmbH

The contents of this publication are the copyright of the publisher and may not be reproduced (even extracts)

unless permission is granted. Every care has been taken to ensure the accuracy of the information contained

in this publication but no liability can be accepted for any loss or damage whether direct, indirect or consequential arising out of the use of the information contained here in.

1.

Introduction

Permanent increase in demands on quality bearing systems is leading on to new developments of various technologies and new materials, to meet the high and very

specific technical and economical fields of application.

IBC is taking responsibility for this fact by continuous

increase in performance of products and technical

processes, as well as extension of product range.

IBC Wlzlager GmbH Industrial Bearings and Components,

has more than 30 years experience in the field of bearing

technologie. IBC continues the tradition of the 1918

founded Robert Kling Wetzlar GmbH.

Close customer contacts based on fair dialogues and

partnership achieve common aims and objectives together

with our customers.

The very intensive cooperation with universities, not only

in the field of research and development, but also practical

job training is a traditional and essential part of the scientific work of IBC Wlzlager GmbH.

The innovation is reflected in the intensive activities of

research and development. As an example we point out

the material variation of bearing components as a contributing factor to increase the efficiency of our products.

This combination of research and controlled processes is

leading to high precision bearings.

At the very first beginning special applications have been

the cause of hybrid ball bearings, and nowadays these

belong to our standard programme for the machine tool

and electric motor industry.

Modified materials for cages, as PEEK are used for

high-speed precision bearings and for high temperature

applications.

Lubricated high precision bearings, completed with sealed

versions allow for maintenance free operation with lifetime

lubrication. This makes a valuable contribution towards

easy mounting and design.

The IBC Wlzlager GmbH delivery programme is

enhanced by ATCoat thin dense chromium coated high

precision bearings for special applications. Prolongation

of usage, reduced wear and friction as well as reasonable

corrosion protection are the main value-added benefits of

ATCoat high precision bearings.

Depending on application high precision angular contact

ball bearings can be delivered with contact angle 15, 25,

30, 35, 40 or 60, with different diameters of balls out of

steel or ceramic, open or sealed. Direct lubrication by the

outer ring is another possible variation.

The most convenient bearings can be chosen depending

on the requirements regarding rotational speed, load

capacity, rigidity, and lubrication as well as any further surrounding parameters.

Many different and innovative principles granting a safe

floating bearing function can be found in IBCs product

range. Not only high precision cylindrical roller bearings

with its constructive floating function, but also the spring

loaded high precision deep groove ball bearings and high

precision angular contact ball bearings are worth mentioning. Bearings with ATCoat are representing an alternative

to avoid fretting corrosion and to grant a slide fit.

Further components of the bearing systems like precision

locknuts and labyrinth seals are essential parts of the

IBCs delivery programme for many years. They are mainly

used for preloading of spindle and ball screw support

bearings. A large variety of designs and dimensions

implies an optimization of economical efficiency for the

users.

Further more IBC is producing an extensive programme of

precision flange and pillow block units. In addition to the

standard design IBC is offering a large number of special

customized solutions.

Our quality management system is implemented and

accredited according DIN EN ISO 9001: 2000 for design,

development, production and sales of all kinds of rolling

bearings and linear motion bearings.

For any further details regarding the different bearing systems as well as how to select the right bearing for safe

integration in your individual design, please refer to our

corresponding catalogues and brochures. An overview is

indicated on the last page.

With this extensive delivery programme, you will find an

appropriate IBC high precision bearing for your special

application. For further details, our technical department is

pleased to be of your assistance and support at any time.

The following pages of this catalogue are showing the variety of products of high precision angular contact ball bearings (spindle bearings), high precision cylindrical roller

bearings, high precision single row deep groove ball bearings, completed by precision rolling bearings of special

design, i. e. for turbo charger bearings, compressors, separators and vacuum pumps.

IBC INDUSTRIAL BEARINGS AND COMPONENTS

2.

IBC Precision Products

Series

Designation

Page

Super Precision Angular Contact

Ball Bearings (Spindle Bearings)

Hybrid Bearings

Coated Bearings

Matched Sets of Bearings

40 Angular Contact Ball Bearings

19

Single Row Deep Groove Ball Bearings

24

Super Precision Cylindrical Roller Bearings

30

Thrust Ball Bearings

40

60 Super Precision Angular Contact

Thrust Ball Bearings

44

Super Precision Bearing Units with 60

Angular Contact Thrust Ball Bearings and

Floating End Supporting Units

49

Super Precision Pillow Block Bearing Units

52

Super Precision Locknuts and Labyrinth Seals

59

ATCoated Bearings; Cage versions

65

Tolerances, Gradings, Fits, BearLub Greases

68

IBC WLZLAGER GMBH

3.

Designation of IBC Super Precision Angular Contact Ball Bearings

CB

ACCB

Material

CB

ACACC-

H

H

70

70

719

70

72

719

14

16

10

12

13

16

.

.

.

.

.

.

E S . T

. P2A.

E

. T

. P4A.

E

. T

. P4A.

C

. T . 2RSZ . P2H.

E

. M

. P4A.

E

. T

. P2H.

X5

X7

X6

X2

X5

UL

. QBTM. GS32. V...

. UM .

GS34

. UL

. U40 . A11

. UL

Special specification

Steel balls 100 Cr6

Ceramic balls Si3N4

Rings ATCoated

Rings ATCoated + balls Si3N4

V..

Lubrication

Corrosion protected

G..

BearLub grease

Design

Standard design version B

H

High speed design

version C

Coating with ATCoat

A11

A15

Series

A 21

A 31

719.. 72..

70..

73..

Bore code

00 10 mm

01 12 mm

K..

Inner and outer ring ATCoated

Inner and outer ring ATCoated, rolling

elements and cage corrosion resistant*

Inner ring ATCoated

Outer ring ATCoated

Preload /universally faced bearings

UX

Extra light

UL

Light

UM

Medium

UH

High

U..

Special preload in daN

A..

Axial clearance with actual value

Bearing arrangements (sets) see page 6

02 15 mm

03 17 mm

At number 04 and upward x 5 [mm]

Contact angle

C 15

E 25

Sorting (bore and O.D.)

X1, X2, X3, X4, X5, X6, X7, X8, X9

see matrix page 6

Lubrication groove and bore

S Lubrication via outer ring

Precision

Cage

T(PA)

M

K

S

P

ABEC

ISO

DIN

P4, P4A, P2H, P2A

Fabric reinforced phenolic resin

Solid brass

PEEK

Stainless steel

PA6.6 Polyamide glass fibre reinforced

Sealing

2RSZ Non-contact seal, both sides

Designation system 51-900

*Corrosion protection depending on application, for further information please refer to main catalogue

IBC INDUSTRIAL BEARINGS AND COMPONENTS

3.1 Production Range of IBC Precision Angular Contact Ball Bearings

Production series

719...

d

mm

10

12

15

17

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

110

120

130

140

150

160

170

180

190

200

220

240

260

280

H 719...

D

B

mm

71900

71901

71902

71903

71904

71905

71906

71907

71908

71909

71910

71911

71912

71913

71914

71915

71916

71917

71918

71919

71920

71921

71922

71924

71926

71928

71930

71932

71934

71936

71938

71940

71944

71948

71952

71956

22

24

28

30

37

42

47

55

62

68

72

80

85

90

100

105

110

120

125

130

140

145

150

165

180

190

210

220

230

250

260

280

300

320

360

380

6

6

7

7

9

9

9

10

12

12

12

13

13

13

16

16

16

18

18

18

20

20

20

22

24

24

28

28

28

33

33

38

38

38

46

46

70...

D

mm

DI*

H 71905

H 71906

H 71907

H 71908

H 71909

H 71910

H 71911

H 71912

H 71913

H 71914

H 71915

H 71916

H 71917

H 71918

H 71919

H 71920

H 71921

H 71922

H 71924

42

47

55

62

68

72

80

85

90

100

105

110

120

125

130

140

145

150

165

9

9

10

12

12

12

13

13

13

16

16

16

18

18

18

20

20

20

22

B

mm

DI*

7000

7001

7002

7003

7004

7005

7006

7007

7008

7009

7010

7011

7012

7013

7014

7015

7016

7017

7018

7019

7020

7021

7022

7024

7026

7028

7030

7032

7034

7036

7038

7040

26

28

32

35

42

47

55

62

68

75

80

90

95

100

110

115

125

130

140

145

150

160

170

180

200

210

225

240

260

280

290

310

Table 14-302: Production Range of IBC Precision Angular Contact Ball Bearings

H 70...

8

8

9

10

12

12

13

14

15

16

16

18

18

18

20

20

22

22

24

24

24

26

28

28

33

33

35

38

42

46

46

51

mm

DI*

72...

B

H 7005

H 7006

H 7007

H 7008

H 7009

H 7010

H 7011

H 7012

H 7013

H 7014

H 7015

H 7016

H 7017

H 7018

H 7019

H 7020

H 7021

H 7022

H 7024

47

55

62

68

75

80

90

95

100

110

115

125

130

140

145

150

160

170

180

mm

DI*

12

13

14

15

16

16

18

18

18

20

20

22

22

24

24

24

26

28

28

73...

B

7200

7201

7202

7203

7204

7205

7206

7207

7208

7209

7210

7211

7212

7213

7214

7215

7216

7217

7218

7219

7220

7221

7222

7224

7226

7228

30

32

35

40

47

52

62

72

80

85

90

100

110

120

125

130

140

150

160

170

180

190

200

215

230

250

D B

mm

DI*

9

10

11

12

14

15

16

17

18

19

20

21

22

23

24

25

26

28

30

32

34

36

38

40

40

42

7304

7305

7306

7307

7308

7309

7310

7311

7312

7313

7314

7315

52

62

72

80

90

100

110

120

130

140

150

160

15

17

19

21

23

25

27

29

31

33

35

37

*DI: sealed version

IBC WLZLAGER GMBH

3.2 Arrangements, assorting of Precision Angular Contact Ball Bearings

Sets out of single bearings of same preload (indication of main load in V-direction):

Arrangements, advantages of bearing sets, mounting

According to different needs spindle bearings are used in

various arrangements.

IBC supplies single bearings as well as sets with an overall

V-marking over the outer rings.

(The V-mark on a single bearing points in the direction, from

which side the axial load is applied at the inner ring).

Sets with V-marking are advantageous in several aspects for

the customer:

a. The diameter tolerance of the inner and outer rings of the

bearings is within a selected close tolerance spectrum.

(See matrix).

This allows for a more even support of the shafts and housings for the whole set.

It eases the combination with shafts and housings to

achieve the same fits for a greater lot.

For fast moving spindles it means a better speed behaviour.

b. The V-marking eases the mounting especially with sealed

bearings, where the sealing hides the view into the bearing,

which makes it more difficult to put the bearings into the

right order based on the main load direction.

The overall V-marking on the set of the outer rings shows

the main load direction acting on the inner rings of the set.

c. The V-marking also shows the point of highest material

thickness or highest radial eccentricity of the outer ring.

d. A marked ring at one side face of the bearing shows the

highest material thickness or highest radial eccentricity of

the inner ring. Even these points should be lined up

before mounting.

e. A compensation of eccentricities on bearing rings, shaft

and housing can be achieved by following before mounting the hints according to c and d in that way that the

markings for highest points of the inner rings will be

arranged opposite to the smallest diameter of the shaft

and at the same time the outer ring markings are in line

with the biggest diameter of the housing. Thus enables

best running accuracy.

Housing

Dm

0

0

Dm

X6

X4

X1

Dmp

0

X6

X1

X7

X5

X2

X8

X3

X8

X9

X3

total tolerance

dm

<5m

total tolerance

Matrix: combination of arrangement groups for

dm

dm and

>5m

Dm

IBC INDUSTRIAL BEARINGS AND COMPONENTS

dmp

Shaft

3.3 IBC Super Precision Angular Contact Ball Bearings

Primary dimensions

1)

Basic

designation

Dimensions

ramax

rbmax

kg

Precision

locknut

page 60

10.8

12.4

20.9

13.0

13.0

24.0

15.0

15.0

0.3

0.3

0.3

0.3

0.3

0.3

0.6

0.6

0.15

0.15

0.15

0.15

0.15

0.15

0.3

0.3

0.015

0.018

0.010

0.019

0.020

0.019

0.028

0.030

MMR 8

MMR 9

MMR 10

MMR 10

MMR 10

MMRB 10

MMR 10

MMR 10

21.5

25.0

25.0

24.7

27.5

27.5

27.9

22.7

15.0

15.0

26.0

16.8

16.8

29.0

0.3

0.3

0.3

0.3

0.6

0.6

0.6

0.15

0.15

0.15

0.15

0.3

0.3

0.3

0.011

0.024

0.025

0.020

0.038

0.040

0.035

MMR 12

MMR 12

MMR 12

MMRB 12

MMR 12

MMR 12

MMRB 12

17.5

18.5

18.5

17.0

19.5

19.5

18.0

25.5

28.5

28.5

28.2

28.2

30.5

31.0

26.7

18.5

18.5

30.0

30.0

19.8

32.0

0.3

0.3

0.3

0.3

0.6

0.6

0.6

0.15

0.15

0.15

0.15

0.3

0.3

0.3

0.016

0.028

0.030

0.029

0.048

0.050

0.043

MMR 15

MMR 15

MMR 15

MMRB 15

MMR 15

MMR 15

MMRB 15

22.2

22.2

23.1

23.1

24.4

24.3

24.3

26.5

19.0

19.0

21.0

21.0

19.0

22.5

22.5

20.0

27.5

27.5

31.0

31.0

30.7

34.5

34.5

35.0

28.0

28.0

20.2

20.2

33.0

22.4

22.4

37.0

0.3

0.3

0.3

0.3

0.3

0.6

0.6

1.0

0.15

0.15

0.15

0.15

0.15

0.3

0.3

0.3

0.016

0.017

0.037

0.040

0.039

0.067

0.070

0.063

MMR 17

MMR 17

MMR 17

MMR 17

MMRB 17

MMR 17

MMR 17

MMRB 17

26.7

26.7

27.5

27.5

29.0

28.8

28.8

31.0

30.9

22.0

22.0

25.0

25.0

23.0

26.5

26.5

25.0

25.0

33.5

33.5

37.0

37.0

37.8

40.5

40.5

41.8

45.3

35.0

35.0

23.4

23.4

39.0

26.6

26.6

42.0

47.0

0.3

0.3

0.6

0.6

0.6

1.0

1.0

1.0

1.0

0.15

0.15

0.3

0.3

0.3

0.6

0.6

0.6

0.6

0.034

0.036

0.065

0.070

0.065

0.106

0.110

0.106

0.144

MMR 20

MMR 20

MMR 20

MMR 20

MMRB 20

MMRB 20

MMRB 20

MMRB 20

MMRB 20

d21)/Db

mm

D1

Dpi

da

Da

12.8

14.3

14.0

15.3

15.3

14.7

17.3

17.3

17.5

19.0

18.1

21.0

21.0

21.4

23.0

23.0

12.7

14.2

14.8

15.2

15.2

16.5

16.3

16.3

11.0

12.5

12.5

13.0

13.0

12.0

14.5

14.5

19.5

21.0

19.5

23.0

23.0

22.7

25.5

25.5

0.15

0.15

0.15

0.15

0.3

0.3

0.3

15.8

17.3

17.3

16.7

19.3

19.3

18.3

20.2

23.0

23.0

23.4

25.0

25.0

26.1

16.7

17.2

17.2

18.5

18.4

18.4

20.4

14.5

15.0

15.0

14.0

16.5

16.5

15.0

0.3

0.3

0.3

0.3

0.6

0.6

0.6

0.15

0.15

0.15

0.15

0.3

0.3

0.3

19.2

20.8

20.8

20.2

22.3

22.3

21.1

23.8

26.5

26.5

26.9

28.0

28.0

29.1

20.3

20.7

20.7

21.9

21.3

21.3

23.4

CB 71903

71903

CB 7003 CC

7003 CC

7003

CB 7203 CC

7203 CC

7203

0.3

0.3

0.3

0.3

0.3

0.6

0.6

0.6

0.15

0.15

0.15

0.15

0.15

0.3

0.3

0.3

20.8

20.8

22.9

22.9

22.7

25.4

25.4

24.1

26.3

26.3

29.5

29.5

29.4

32.0

32.0

33.0

CB 71904

71904

CB 7004 CC

7004 CC

7004

CB 7204 CC

7204 CC

7204

7304

0.3

0.3

0.6

0.6

0.6

1.0

1.0

1.0

1.0

0.15

0.15

0.3

0.3

0.3

0.6

0.6

0.6

0.6

25.3

25.3

27.0

27.0

26.6

29.9

29.9

29.2

29.6

31.8

31.8

35.5

35.5

35.5

37.5

37.5

37.9

41.1

r12min

r34min

d1

mm

Abutment and fillet dimensions

D

mm

8

9

10

10

10

10

10

10

22

24

22

26

26

26

30

30

7

7

6

8

8

8

9

9

708 CC

709 CC

71900

CB 7000 CC

7000 CC

7000

CB 7200 CC

7200 CC

0.3

0.3

0.3

0.3

0.3

0.3

0.6

0.6

0.15

0.15

0.15

0.15

0.15

0.15

0.3

0.3

12

12

12

12

12

12

12

24

28

28

28

32

32

32

6

8

8

8

10

10

10

71901

CB 7001 CC

7001 CC

7001

CB 7201 CC

7201 CC

7201

0.3

0.3

0.3

0.3

0.6

0.6

0.6

15

15

15

15

15

15

15

28

32

32

32

35

35

35

7

9

9

9

11

11

11

71902

CB 7002 CC

7002 CC

7002

CB 7202 CC

7202 CC

7202

17

17

17

17

17

17

17

17

30

30

35

35

35

40

40

40

7

7

10

10

10

12

12

12

20

20

20

20

20

20

20

20

20

37

37

42

42

42

47

47

47

52

9

9

12

12

12

14

14

14

15

Weight

Only valid for CC-Bearings.

IBC WLZLAGER GMBH

Contact angle 15

Basic

designation

Contact angle 25

Basic load ratings

C

mm

C0

N

Speed ratings

nb

Grease

Oil-air

min-1

Basic

designation

Basic load ratings

C

mm

C0

N

Speed ratings

nb

Grease

Oil-air

min-1

708.CC

3 600

1 540

84 000

135 000

709.CC

3 900

1 800

79 000

127 000

71900.C

CB 7000.CC

7000.CC

7000.C

CB 7200.CC

7200.CC

5

6

6

6

7

7

3 100

4 950

4 950

5 710

5 850

5 850

1 600

2 250

2 250

2 770

2 950

2 950

70 000

80 000

68 000

57 000

72 500

60 800

111 000

145 800

108 000

88 000

123 000

93 000

71900.E

2 900

1 500

63 000

96 000

7000.E

5 520

2 670

47 400

73 000

71901.C

CB 7001.CC

7001.CC

7001.C

CB 7201.CC

7201.CC

7201.C

5

6

6

7

8

8

8

3 300

5 450

5 450

6 180

6 300

6 300

8 600

1 800

2 600

2 600

3 180

3 450

3 450

4 320

60 000

72 500

57 000

52 000

72 500

51 000

47 000

86 000

119 000

88 000

80 000

106 000

79 000

72 500

71901.E

3 100

1 700

57 000

85 000

7001.E

5 940

3 070

43 000

66 000

7201.E

10

8 320

4 190

39 200

60 000

71902.E

4 500

2 500

49 000

71 000

7002.E

10

6 670

3 830

36 400

56 000

7202.E

12

9 010

4 880

34 800

53 500

9

9

4 510

4 510

2 590

2 900

49 700

36 800

76 300

56 500

7003.E

11

6 980

4 250

33 700

51 000

71902.C

CB 7002.CC

7002.CC

7002.C

CB 7202.CC

7202.CC

7202.C

6

7

7

8

9

9

9

4 700

6 300

6 300

6 970

6 300

6 300

9 370

2 700

3 400

3 400

4 010

3 450

3 450

5 050

50 000

61 000

48 700

44 200

58 000

45 700

41 600

75 000

100 000

75 000

68 000

94 000

70 000

64 000

CB 71903.C

71903.C

CB 7003.CC

7003.CC

7003.C

CB 7203.CC

7203.CC

7203.C

7

7

8

8

9

10

10

10

4 740

4 900

8 300

8 300

7 320

8 300

8 300

11 600

2 710

2 900

4 550

4 550

4 440

4 700

4 700

6 400

59 700

44 200

58 000

47 000

39 600

50 800

40 000

36 400

91 800

68 000

90 000

75 000

61 000

83 000

61 000

56 000

CB 71903.E

71903.E

7203.E

13

11 100

6 200

31 000

47 700

CB 71904.C

71904.C

CB 7004.CC

7004.CC

7004.C

CB 7204.CC

7204.CC

7204.C

7304.C

8

8

9

9

10

11

11

12

12

6 940

6 940

12 200

12 200

9 830

10 600

10 600

13 600

17 100

4 240

4 240

6 650

6 650

5 450

6 200

6 200

7 250

8 750

49 100

36 400

46 000

34 700

33 100

43 000

34 000

31 300

24 700

75 600

56 000

72 000

53 000

51 000

71 000

53 000

48 300

38 000

CB 71904.E

71904.E

11

11

6 600

6 600

4 050

4 050

41 900

31 000

64 400

47 700

7004.E

13

9 400

5 200

29 300

45 100

7204.E

7304.E

15

16

13 000

16 500

7 000

8 500

27 500

22 300

42 300

34 300

IBC INDUSTRIAL BEARINGS AND COMPONENTS

3.3 IBC Super Precision Angular Contact Ball Bearings

Primary dimensions

1)

Basic

designation

Dimensions

ramax

rbmax

kg

Precision

locknut

page 60

40.0

40.0

28.5

28.5

44.0

30.4

30.4

47.3

57.0

0.3

0.3

0.6

0.6

0.6

1.0

1.0

1.0

1.0

0.2

0.15

0.3

0.3

0.3

0.6

0.6

0.6

0.6

0.040

0.042

0.074

0.080

0.075

0.127

0.135

0.128

0.236

MMR 25

MMR 25

MMR 25

MMR 25

MMRB 25

MMRB 25

MMRB 25

MMRB 25

MMRB 25

43.5

43.5

48.0

48.0

49.8

56.8

65.0

45.0

45.0

50.0

50.0

50.0

57.0

67.0

0.3

0.3

1.0

1.0

1.0

1.0

1.0

0.2

0.15

0.6

0.6

0.6

0.6

0.6

0.045

0.048

0.127

0.130

0.118

0.197

0.348

MMR 30

MMR 30

MMRB 30

MMRB 30

MMRB 30

MMRB 30

MMRB 30

38.0

38.0

40.0

40.0

40.0

40.0

42.5

50.8

50.8

55.0

55.0

56.8

65.5

71.3

52.0

52.0

57.0

57.0

57.0

67.0

72.5

0.6

0.6

1.0

1.0

1.0

1.0

1.5

0.3

0.3

0.6

0.6

0.6

0.6

0.8

0.071

0.076

0.165

0.170

0.154

0.290

0.473

MMR 35

MMR 35

MMRB 35

MMRB 35

MMRB 35

MMRB 35

MMRB 35

49.0

49.0

51.8

51.8

51.5

56.1

43.0

43.0

45.0

45.0

45.0

45.0

57.6

57.6

60.5

60.5

62.3

73.3

59.0

59.0

63.0

63.0

63.0

75.0

0.6

0.6

1.0

1.0

1.0

1.0

0.3

0.3

0.6

0.6

0.6

0.6

0.101

0.108

0.214

0.220

0.194

0.363

MMR 40

MMR 40

MMRB 40

MMRB 40

MMRB 40

MMRB 40

61.1

61.1

64.0

64.0

64.7

72.4

54.5

54.5

57.8

57.8

57.2

61.0

48.0

48.0

50.0

50.0

50.0

50.0

63.3

63.3

67.5

67.5

69.0

78.3

65.0

65.0

70.0

70.0

70.0

80.0

0.6

0.6

1.0

1.0

1.0

1.0

0.3

0.3

0.6

0.6

0.6

0.6

0.120

0.128

0.251

0.260

0.245

0.408

MMR 45

MMR 45

MMRB 45

MMRB 45

MMRB 45

MMRB 45

65.6

65.6

69.0

69.0

69.9

76.8

59.0

59.0

62.6

62.6

62.3

66.1

53.0

53.0

55.0

55.0

55.0

55.0

67.8

67.8

72.5

72.5

74.3

83.3

69.0

69.0

75.0

75.0

75.0

85.0

0.6

0.6

1.0

1.0

1.0

1.0

0.3

0.3

0.6

0.6

0.6

0.6

0.121

0.129

0.280

0.290

0.264

0.476

MMR 50

MMR 50

MMRB 50

MMRB 50

MMRB 50

MMRB 50

d21)/Db

mm

D1

Dpi

da

Da

30.3

30.3

32.0

32.0

32.6

34.3

34.3

34.7

38.7

37.0

37.0

40.5

40.5

41.3

43.0

43.0

43.3

49.9

31.8

31.8

32.5

32.5

34.6

33.4

33.4

36.4

41.0

27.0

27.0

30.0

30.0

28.0

31.5

31.5

30.0

30.0

38.5

38.5

42.0

42.0

43.5

45.5

45.5

47.0

55.0

0.2

0.15

0.6

0.6

0.6

0.6

0.6

35.3

35.3

39.6

39.6

38.5

41.2

45.1

41.8

41.8

45.5

45.5

46.4

51.8

59.0

36.7

36.7

40.6

40.6

40.1

43.3

48.1

32.0

32.0

35.0

35.0

35.0

35.0

35.0

0.6

0.6

1.0

1.0

1.0

1.0

1.5

0.3

0.3

0.6

0.6

0.6

0.6

0.8

41.5

41.5

45.1

45.1

44.5

47.9

50.5

48.6

48.6

52.0

52.0

53.0

59.7

64.7

43.2

43.2

45.3

45.3

46.2

50.3

53.3

CB 71908

71908

CB H7008

H7008

7008

7208

0.6

0.6

1.0

1.0

1.0

1.0

0.3

0.3

0.6

0.6

0.6

0.6

46.7

46.7

50.6

50.6

49.7

53.4

55.6

55.6

57.5

57.5

58.5

66.8

12

12

16

16

16

19

CB 71909

71909

CB H7009

H7009

7009

7209

0.6

0.6

1.0

1.0

1.0

1.0

0.3

0.3

0.6

0.6

0.6

0.6

52.2

52.2

56.1

56.1

55.3

57.5

12

12

16

16

16

20

CB 71910

71910

CB H7010

H7010

7010

7210

0.6

0.6

1.0

1.0

1.0

1.0

0.3

0.3

0.6

0.6

0.6

0.6

56.7

56.7

61.1

61.1

60.5

63.5

r12min

r34min

d1

mm

Abutment and fillet dimensions

D

mm

25

25

25

25

25

25

25

25

25

42

42

47

47

47

52

52

52

62

9

9

12

12

12

15

15

15

17

CB 71905

71905

CB 7005 CC

7005 CC

7005

CB 7205 CC

7205 CC

7205

7305

0.3

0.3

0.6

0.6

0.6

1.0

1.0

1.0

1.0

0.2

0.15

0.3

0.3

0.3

0.6

0.6

0.6

0.6

30

30

30

30

30

30

30

47

47

55

55

55

62

72

9

9

13

13

13

16

19

CB 71906

71906

CB H7006

H7006

7006

7206

7306

0.3

0.3

1.0

1.0

1.0

1.0

1.0

35

35

35

35

35

35

35

55

55

62

62

62

72

80

10

10

14

14

14

17

21

CB 71907

71907

CB H7007

H7007

7007

7207

7307

40

40

40

40

40

40

62

62

68

68

68

80

12

12

15

15

15

18

45

45

45

45

45

45

68

68

75

75

75

85

50

50

50

50

50

50

72

72

80

80

80

90

Weight

Only valid for CC-Bearings.

10

IBC WLZLAGER GMBH

Contact angle 15

Basic

designation

Contact angle 25

Basic load ratings

C

mm

C0

N

Speed ratings

nb

Grease

Oil-air

min-1

Basic

designation

Basic load ratings

C

mm

C0

N

Speed ratings

nb

Grease

Oil-air

min-1

CB 71905.C

71905.C

CB 7005.CC

7005.CC

7005.C

CB 7205.CC

7205.CC

7205.C

7305.C

9

9

10

10

11

13

13

13

14

7 510

7 510

13 100

13 100

11 700

14 300

14 300

14 700

23 400

4 400

5 100

6 600

7 750

7 500

8 000

9 400

8 550

13 700

43 000

31 400

40 300

30 700

29 300

37 600

30 000

27 800

20 300

65 200

48 300

64 000

47 000

45 200

63 000

47 000

42 800

31 200

CB 71905.E

71905.E

12

12

7 120

7 120

4 100

4 820

37 300

27 500

57 100

42 300

7005.E

15

11 100

7 150

26 000

40 000

7205.E

7305.E

17

19

14 000

22 500

8 150

13 200

24 600

18 300

37 900

28 200

CB 71906.C

71906.C

CB H7006.C

H7006.C

7006.C

7206.C

7306.C

10

10

12

12

12

14

16

8 000

8 000

9 000

9 000

15 100

23 300

33 800

5 100

5 950

5 300

7 450

10 200

14 400

20 300

37 700

27 900

46 800

36 000

26 000

24 200

17 200

58 100

43 000

70 200

52 000

40 000

37 300

26 500

CB 71906.E

71906.E

CB H7006.E

H7006.E

7006.E

7206.E

7306.E

14

14

17

17

17

19

22

7 550

7 550

8 500

8 500

14 400

22 400

32 500

4 500

5 600

4 950

7 050

9 800

13 900

19 600

33 200

24 600

41 600

32 000

22 900

21 400

15 600

51 200

37 900

63 500

47 000

35 200

33 000

23 900

CB 71907.C

71907.C

CB H7007.C

H7007.C

7007.C

7207.C

7307.C

11

11

14

14

14

16

18

11 000

11 000

12 000

12 000

18 300

30 400

40 300

7 300

8 550

7 100

10 100

12 700

20 100

25 700

33 300

24 700

41 600

32 000

23 200

21 200

15 100

51 300

38 000

62 800

46 500

35 800

32 700

23 300

CB 71907.E

71907.E

CB H7007.E

H7007.E

7007.E

7207.E

7307.E

16

16

19

19

19

21

24

10 400

10 400

11 300

11 300

17 400

29 100

38 800

6 900

8 100

6 700

9 550

12 200

19 100

24 800

29 400

21 800

33 800

26 000

20 500

18 500

13 700

45 200

33 500

55 200

40 900

31 500

28 500

21 100

CB 71908.C

71908.C

CB H7008.C

H7008.C

7008.C

7208.C

13

13

15

15

15

17

14 000

14 000

12 800

12 800

19 700

36 400

9 500

11 100

8 200

11 700

15 000

23 800

30 100

22 300

36 400

28 000

21 000

18 900

46 300

34 300

56 800

42 100

32 400

29 100

CB 71908.E

71908.E

CB H7008.E

H7008.E

7008.E

7208.E

18

18

20

20

20

23

13 200

13 200

12 100

12 100

18 700

34 900

9 100

10 600

8 470

11 000

14 200

22 800

26 300

19 500

33 200

25 500

18 400

16 500

40 500

30 000

49 500

36 700

28 300

25 500

CB 71909.C

71909.C

CB H7009.C

H7009.C

7009.C

7209.C

14

14

16

16

16

18

14 700

14 700

15 900

15 900

23 400

38 600

10 800

12 600

10 300

14 600

18 100

26 600

2 700

20 000

31 200

24 000

18 800

17 300

41 700

30 900

50 900

37 700

29 000

26 700

CB 71909.E

71909.E

CB H7009.E

H7009.E

7009.E

7209.E

19

19

22

22

22

25

13 900

13 900

15 000

15 000

22 200

36 900

10 200

11 900

9 700

13 800

17 200

25 400

23 800

17 600

31 200

24 000

16 500

15 200

36 500

27 000

44 700

33 100

25 500

23 500

CB 71910.C

71910.C

CB H7010.C

H7010.C

7010.C

7210.C

14

14

17

17

17

20

14 900

14 900

16 600

16 600

24 100

42 800

11 400

13 400

11 200

16 000

19 500

31 700

25 100

18 600

28 600

22 000

17 300

15 700

38 600

28 600

46 800

34 700

26 700

24 200

CB 71910.E

71910.E

CB H7010.E

H7010.E

7010.E

7210.E

20

20

23

23

23

27

14 100

14 100

15 600

15 600

22 800

40 800

10 800

12 600

10 920

15 000

18 600

30 300

22 000

16 300

26 000

20 000

15 200

14 000

33 800

25 000

41 200

30 500

23 500

21 500

IBC INDUSTRIAL BEARINGS AND COMPONENTS

11

3.3 IBC Super Precision Angular Contact Ball Bearings

Primary dimensions

Basic

designation

Dimensions

rbmax

kg

75.0

75.0

85.0

85.0

85.0

92.5

1.0

1.0

1.0

1.0

1.0

1.5

0.6

0.6

0.6

0.6

0.6

0.6

0.175

0.186

0.416

0.430

0.390

0.627

MMR 55

MMR 55

MMRB 55

MMRB 55

MMRB 55

MMRB 55

80.0

80.0

85.5

85.5

88.3

101.5

80.0

80.0

90.0

90.0

90.0

102.5

1.0

1.0

1.0

1.0

1.0

1.5

0.6

0.6

0.6

0.6

0.6

0.8

0.188

0.200

0.446

0.460

0.418

0.795

MMR 60

MMR 60

MMRB 60

MMRB 60

MMRB 60

MMRB 60

70.0

70.0

70.0

70.0

70.0

72.5

85.0

85.0

90.5

90.5

93.5

110.5

85.0

85.0

95.0

95.0

95.0

112.5

1.0

1.0

1.0

1.0

1.0

1.5

0.6

0.6

0.6

0.6

0.6

0.8

0.201

0.215

0.465

0.480

0.443

1.008

MMR 65

MMR 65

MMRB 65

MMRB 65

MMRB 65

MMRB 65

82.2

82.2

87.0

87.0

86.3

92.0

75.0

75.0

75.0

75.0

75.0

77.5

94.3

94.3

99.0

99.0

102.5

115.8

95.0

95.0

105.0

105.0

105.0

117.5

1.0

1.0

1.0

1.0

1.0

1.5

0.6

0.6

0.6

0.6

0.6

0.8

0.323

0.345

0.649

0.670

0.617

1.107

MMR 70

MMR 70

MMRB 70

MMRB 70

MMRB 70

MMRB 70

94.8

94.8

100.1

100.1

101.8

111.6

87.2

87.2

92.0

92.0

91.7

97.0

80.0

80.0

80.0

80.0

80.0

82.5

99.3

99.3

104.0

104.0

107.8

120.8

100.0

100.0

110.0

110.0

110.0

122.5

1.0

1.0

1.0

1.0

1.0

1.5

0.6

0.6

0.6

0.6

0.6

0.8

0.343

0.367

0.688

0.710

0.657

1.216

MMR 75

MMR 75

MMRB 75

MMRB 75

MMRB 75

MMRB 75

99.7

99.7

108.1

108.1

109.7

121.5

92.2

92.2

99.2

99.2

98.3

105.7

85.0

85.0

85.0

85.0

85.0

90.0

104.3

104.3

112.5

112.5

116.8

130.0

105.0

105.0

120.0

120.0

120.0

131.5

1.0

1.0

1.0

1.0

1.0

2.0

0.6

0.6

0.6

0.6

0.6

1.0

0.364

0.390

0.931

0.960

0.881

1.451

MMR 80

MMR 80

MMRB 80

MMRB 80

MMRB 80

MMRB 80

Dpi

da

Da

63.7

63.7

68.1

68.1

67.4

70.1

71.6

71.6

77.0

77.0

78.5

85.0

65.3

65.3

69.7

69.7

69.6

73.1

60.0

60.0

60.0

60.0

60.0

62.5

75.0

75.0

80.5

80.5

83.8

92.5

0.6

0.6

0.6

0.6

0.6

0.8

68.7

68.7

73.1

73.1

72.1

76.8

76.6

76.6

82.0

82.0

83.1

93.4

70.2

70.2

74.7

74.7

74.2

80.1

65.0

65.0

65.0

65.0

65.0

67.5

1.0

1.0

1.0

1.0

1.0

1.5

0.6

0.6

0.6

0.6

0.6

0.8

73.7

73.7

78.1

78.1

77.2

84.4

81.5

81.5

87.0

87.0

88.3

101.8

75.2

75.2

79.7

79.7

79.4

87.9

CB71914

71914

CB H7014

H7014

7014

7214

1.0

1.0

1.0

1.0

1.0

1.5

0.6

0.6

0.6

0.6

0.6

0.8

80.4

80.4

85.2

85.2

83.8

88.4

89.8

89.8

95.0

95.0

96.4

106.6

16

16

20

20

20

25

CB 71915

71915

CB H7015

H7015

7015

7215

1.0

1.0

1.0

1.0

1.0

1.5

0.6

0.6

0.6

0.6

0.6

0.8

85.4

85.4

90.2

90.2

89.1

93.4

16

16

22

22

22

26

CB 71916

71916

CB H7016

H7016

7016

7216

1.0

1.0

1.0

1.0

1.0

2.0

0.6

0.6

0.6

0.6

0.6

1.0

90.4

90.4

97.2

97.2

95.5

101.7

D

mm

55

55

55

55

55

55

80

80

90

90

90

100

13

13

18

18

18

21

CB 71911

71911

CB H7011

H7011

7011

7211

1.0

1.0

1.0

1.0

1.0

1.5

0.6

0.6

0.6

0.6

0.6

0.6

60

60

60

60

60

60

85

85

95

95

95

110

13

13

18

18

18

22

CB 71912

71912

CB H7012

H7012

7012

7212

1.0

1.0

1.0

1.0

1.0

1.0

65

65

65

65

65

65

90

90

100

100

100

120

13

13

18

18

18

23

CB 71913

71913

CB H7013

H7013

7013

7213

70

70

70

70

70

70

100

100

110

110

110

125

16

16

20

20

20

24

75

75

75

75

75

75

105

105

115

115

115

130

80

80

80

80

80

80

110

110

125

125

125

140

12

ramax

Precision

locknut

page 60

D1

r12min

r34min

d1

mm

Abutment and fillet dimensions

Dbmax

mm

Weight

IBC WLZLAGER GMBH

Contact angle 15

Basic

designation

Contact angle 25

Basic load ratings

C

mm

C0

N

Speed ratings

nb

Grease

Oil-air

min-1

Basic

designation

Basic load ratings

C

mm

C0

N

Speed ratings

nb

Grease

Oil-air

min-1

CB 71911.C

71911.C

CB H7011.C

H7011.C

7011.C

7211.C

16

16

19

19

19

21

18 500

18 500

20 500

20 500

32 800

52 900

14 400

16 900

14 200

20 200

27 000

39 900

22 400

16 600

26 000

20 000

15 400

14 200

34 600

25 600

41 900

31 000

23 800

21 900

CB 71911.E

71911.E

CB H7011.E

H7011.E

7011.E

7211.E

22

22

26

26

26

29

17 500

17 500

19 400

19 400

31 100

50 500

13 600

15 900

13 000

18 900

25 700

38 200

19 700

14 600

23 400

18 000

13 400

12 400

30 400

22 500

36 100

26 700

20 600

19 000

CB 71912.C

71912.C

CB H7012.C

H7012.C

7012.C

7212.C

16

16

20

20

20

23

19 400

19 400

20 800

20 800

33 800

60 900

15 900

18 600

14 700

21 000

29 000

45 500

20 800

15 400

24 700

19 000

14 200

12 800

32 000

23 700

38 300

28 400

21 900

19 700

CB 71912.E

71912.E

CB H7012.E

H7012.E

7012.E

7212.E

23

23

27

27

27

31

18 300

18 300

19 600

19 600

32 000

58 100

14 800

17 400

13 800

19 600

27 600

43 700

18 100

13 400

22 100

17 000

12 400

11 000

27 800

20 600

33 300

24 700

19 000

16 900

CB 71913.C

71913.C

CB H7013.C

H7013.C

7013.C

7213.C

17

17

20

20

20

24

20 200

20 200

21 500

21 500

34 700

66 400

17 200

20 200

15 800

22 500

31 000

51 000

19 200

14 200

23 400

18 000

13 300

11 500

29 600

21 900

36 200

26 800

20 600

17 800

CB 71913.E

71913.E

CB H7013.E

H7013.E

7013.E

7213.E

25

25

28

28

28

33

19 100

19 100

20 200

20 200

32 800

63 300

16 000

18 800

14 700

20 900

29 400

48 600

16 700

12 400

19 500

15 000

11 400

9 600

25 700

19 000

30 600

22 700

17 500

14 900

CB 71914.C

71914.C

CB H7014.C

H7014.C

7014.C

7214.C

19

19

22

22

22

25

27 300

27 300

26 100

26 100

43 700

75 800

22 600

26 600

19 500

27 800

38 600

60 000

17 300

12 800

21 500

16 500

11 900

10 800

26 600

19 700

32 300

23 900

18 400

16 700

CB 71914.E

71914.E

CB H7014.E

H7014.E

7014.E

7214.E

28

28

31

31

31

35

25 700

25 700

24 600

24 600

41 400

72 300

21 200

24 900

18 200

25 900

36 800

57 500

14 700

10 900

18 200

14 000

10 100

9 000

22 700

16 800

27 000

20 000

15 500

13 900

CB 71915.C

71915.C

CB H7015.C

H7015.C

7015.C

7215.C

20

20

23

23

23

26

28 600

28 600

27 000

27 000

46 500

79 300

24 700

29 000

20 800

29 600

43 500

64 500

16 100

11 900

20 800

16 000

11 100

10 100

24 800

18 400

30 200

22 400

17 200

15 600

CB 71915.E

71915.E

CB H7015.E

H7015.E

7015.E

7215.E

29

29

32

32

32

37

26 900

26 900

25 400

25 400

43 900

75 400

23 100

27 100

19 400

27 600

41 200

61 500

13 600

10 100

16 900

13 000

9 300

8 500

21 000

15 500

25 200

18 700

14 400

12 600

CB 71916.C

71916.C

CB H7016.C

H7016.C

7016.C

7216.C

21

21

25

25

25

28

29 800

29 800

31 500

31 500

56 700

88 500

26 700

31 400

24 300

34 700

52 500

72 500

15 000

11 100

19 500

15 000

10 200

9 200

23 200

17 200

27 600

20 400

15 700

14 300

CB 71916.E

71916.E

CB H7016.E

H7016.E

7016.E

7216.E

30

30

35

35

35

39

28 100

28 100

29 600

29 600

53 700

84 300

24 900

29 200

22 700

32 300

49 900

69 500

12 600

9 300

16 300

12 500

8 700

8 200

19 300

14 300

22 400

16 600

12 800

11 500

IBC INDUSTRIAL BEARINGS AND COMPONENTS

13

3.3 IBC Super Precision Angular Contact Ball Bearings

Primary dimensions

Basic

designation

Dimensions

ramax

rbmax

kg

Precision

locknut

page 60

115.0

115.0

125.0

125.0

125.0

140.0

1.0

1.0

1.0

1.0

1.0

2.0

0.6

0.6

0.6

0.6

0.6

1.0

0.518

0.554

0.989

1.020

0.921

1.872

MMR 85

MMR 85

MMRB 85

MMRB 85

MMRB 85

MMRB 85

118.3

118.3

126.5

126.5

131.8

147.5

120.0

120.0

132.5

132.5

132.5

150.0

1.0

1.0

1.5

1.5

1.5

2.0

0.6

0.6

0.8

0.8

0.8

1.0

0.540

0.581

1.164

1.210

1.189

2.336

MMR 90

MMR 90

MMRB 90

MMRB 90

MMRB 90

MMRB 90

100.0

100.0

102.5

102.5

102.5

105.0

123.3

123.3

131.5

136.5

136.5

157.3

125.0

125.0

137.5

137.5

137.5

160.0

1.0

1.0

1.5

1.5

1.5

2.0

0.6

0.6

0.8

0.8

0.8

1.0

0.573

0.616

1.303

1.350

1.245

2.794

MMR 95

MMR 95

MMRB 95

MMRB 95

MMRB 95

MMRB 95

116.3

116.3

121.1

121.1

120.8

132.3

105.0

105.0

107.5

107.5

107.5

110.0

132.5

132.5

136.5

136.5

141.3

166.5

135.0

135.0

142.5

142.5

142.5

170.0

1.0

1.0

1.5

1.5

1.5

2.0

0.6

0.6

0.8

0.8

0.8

1.0

0.766

0.826

1.349

1.400

1.288

3.312

MMR 100

MMR 100

MMRB 100

MMRB 100

MMRB 100

MMRB 100

131.4

131.4

141.3

162.9

121.3

121.3

127.4

140.7

110.0

110.0

115.0

115.0

137.5

137.5

150.0

175.0

140.0

140.0

150.0

180.0

1.0

1.0

2.0

2.0

0.6

0.6

1.0

1.0

0.781

0.844

1.550

3.845

MMR 105

MMR 105

MMRB 105

MMRB 105

123.8

123.8

129.0

129.0

142.1

136.4

136.4

151.1

151.1

170.0

126.4

126.4

134.4

134.4

147.7

115.0

115.0

120.0

120.0

120.0

142.5

142.5

159.3

159.3

184.3

145.0

145.0

160.0

160.0

190.0

1.0

1.0

2.0

2.0

2.0

0.6

0.6

1.0

1.0

1.0

0.785

0.850

1.990

1.990

4.710

MMR 110

MMR 110

MMRB 110

MMRB 110

MMRB 110

0.6

0.6

1.0

1.0

1.0

135.5

135.5

140.6

140.6

153.9

149.7

149.7

159.6

159.6

182.8

138.3

138.3

144.4

144.4

160.0

125.0

125.0

130.0

130.0

130.0

156.3

156.3

169.3

169.3

196.8

160.0

160.0

170.0

170.0

205.0

1.0

1.0

2.0

2.0

2.0

0.6

0.6

1.0

1.0

1.0

10.070

1.160

2.190

2.190

5.710

MMR 120

MMR 120

MMRB 120

MMRB 120

MMRB 120

0.6

0.6

1.0

1.0

1.0

147.2

147.2

154.4

154.4

164.8

163.0

163.0

175.8

175.8

195.6

150.4

150.4

158.7

158.7

170.9

137.5

137.5

140.0

140.0

142.5

170.8

170.8

186.8

186.8

211.5

172.5

172.5

190.0

190.0

217.5

1.0

1.0

2.0

2.0

2.5

0.6

0.6

1.0

1.0

1.0

1.540

1.540

3.340

3.340

6.380

MMR 130

MMR 130

MMRB 130

MMRB 130

MMRB 130

r34min

d1

mm

D1

Dpi

da

Da

Dbmax

mm

D

mm

85

85

85

85

85

85

120

120

130

130

130

150

18

18

22

22

22

28

CB 71917

71917

CB H7017

H7017

7017

7217

1.0

1.0

1.0

1.0

1.0

2.0

0.6

0.6

0.6

0.6

0.6

1.0

97.1

97.1

102.2

102.2

101.0

107.3

108.2

108.2

113.1

113.1

115.3

127.9

99.3

99.3

104.2

104.2

103.9

111.4

90.0

90.0

90.0

90.0

90.0

95.0

113.3

113.3

117.5

117.5

122.3

138.3

90

90

90

90

90

90

125

125

140

140

140

160

18

18

24

24

24

30

CB 71918

71918

CB H7018

H7018

7018

7218

1.0

1.0

1.5

1.5

1.5

2.0

0.6

0.6

0.8

0.8

0.8

1.0

102.1

102.1

108.7

108.7

108.1

115.3

113.1

113.1

121.6

121.6

123.9

136.7

104.3 95.0

104.3 95.0

111.1 97.5

111.1 97.5

111.2 97.5

119.6 100.0

95

95

95

95

95

95

130

130

145

145

145

160

18

18

24

24

24

32

CB 71919

71919

CB H7019

H7019

7019

7219

1.0

1.0