Professional Documents

Culture Documents

QW484

QW484

Uploaded by

Anonymous 4e7GNjzGWCopyright:

Available Formats

You might also like

- WPS For Structure Mild Steel Fillet WeldDocument2 pagesWPS For Structure Mild Steel Fillet WeldHarkesh Rajput76% (17)

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- Excel Construction Project Management Templates Construction Budget TemplateDocument19 pagesExcel Construction Project Management Templates Construction Budget TemplateAnonymous 4e7GNjzGW100% (3)

- Welder Performance Qualification-Interactive Form QW-484ADocument1 pageWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- Wps 316L SMAW+GTAW R00Document2 pagesWps 316L SMAW+GTAW R00Richard Periyanayagam87% (15)

- PWPS For Piping-API 1104Document6 pagesPWPS For Piping-API 1104Nguyen Tien Luong100% (1)

- Asme Ix QW PDFDocument183 pagesAsme Ix QW PDFAnonymous 4e7GNjzGW100% (4)

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- Wps A53 Gtaw R00Document2 pagesWps A53 Gtaw R00Richard PeriyanayagamNo ratings yet

- 653 WPS-PQR PDFDocument4 pages653 WPS-PQR PDFETSNo ratings yet

- WPSDocument2 pagesWPSJuli Agus50% (2)

- QW-482 WPS FormatDocument2 pagesQW-482 WPS FormatMardeOpamen100% (1)

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Aries MarteNo ratings yet

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 pageFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWNo ratings yet

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 pageFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWNo ratings yet

- Welding Defect - MACRO PDFDocument5 pagesWelding Defect - MACRO PDFAnonymous 4e7GNjzGWNo ratings yet

- Hydrostatic Test (Log) : Quality Control FormDocument22 pagesHydrostatic Test (Log) : Quality Control FormAnonymous 4e7GNjzGWNo ratings yet

- Suggested Wps Forms ASME - IX 2010Document5 pagesSuggested Wps Forms ASME - IX 2010Ajay ChodankarNo ratings yet

- Automatic, Manual, Machine, or Semi-Auto.Document10 pagesAutomatic, Manual, Machine, or Semi-Auto.ChE_MattNo ratings yet

- WPQ PDFDocument0 pagesWPQ PDFstanleyNo ratings yet

- Book 1Document3 pagesBook 1ansarmulla711No ratings yet

- mohanWPQ-1G 40NBDocument1 pagemohanWPQ-1G 40NBDeepakNo ratings yet

- Saravanan Wpq-5g 50nbDocument1 pageSaravanan Wpq-5g 50nbDeepakNo ratings yet

- BPVC Ix Qw-484aDocument1 pageBPVC Ix Qw-484aTC Capulcu Mustafa MNo ratings yet

- PQR REV. 2010a Interactive FormDocument2 pagesPQR REV. 2010a Interactive FormcosmicbunnyNo ratings yet

- Interactive Form QW-485 PDFDocument1 pageInteractive Form QW-485 PDFRama Krishna Reddy DonthireddyNo ratings yet

- Qw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )Document2 pagesQw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )essnelsonNo ratings yet

- Wps Gmaw SawDocument2 pagesWps Gmaw Sawupedro26No ratings yet

- QW484ADocument1 pageQW484AMohamed Ahmed MaherNo ratings yet

- PQRDocument3 pagesPQRnazirulhakimNo ratings yet

- WPS FormatDocument2 pagesWPS FormatAmit SarkarNo ratings yet

- 14033Document2 pages14033Priyanathan ThayalanNo ratings yet

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Document48 pagesQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- Welding Procedure Specification: Technip KT India LimitedDocument5 pagesWelding Procedure Specification: Technip KT India LimitedDeepak100% (1)

- Form Qw-485 Suggested Format For Demonstration of Standard Welding Procedure Specifications (SWPS) (See Article V)Document1 pageForm Qw-485 Suggested Format For Demonstration of Standard Welding Procedure Specifications (SWPS) (See Article V)durandm10No ratings yet

- P& E WPS Template Rev 00 - OfficialDocument3 pagesP& E WPS Template Rev 00 - OfficialRiaan PretoriusNo ratings yet

- QW 406 Asme CodeDocument3 pagesQW 406 Asme CodeMardeOpamenNo ratings yet

- Procedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingDocument6 pagesProcedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingNovita Dwi IsnaeniNo ratings yet

- WPQ Certificates Klis14Document8 pagesWPQ Certificates Klis14AdhicharanNo ratings yet

- WTCDocument57 pagesWTCSarah FrazierNo ratings yet

- BPVC Ix QW-483Document2 pagesBPVC Ix QW-483ganesh82No ratings yet

- Form Qw-484B Suggested Format B For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageForm Qw-484B Suggested Format B For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)viswamanojNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- Qw-483 (Back) : Specimen No. Width Thickness Area Ultimate Total Load Ultimate Unit Stress, (Psi or Mpa)Document8 pagesQw-483 (Back) : Specimen No. Width Thickness Area Ultimate Total Load Ultimate Unit Stress, (Psi or Mpa)Aries MarteNo ratings yet

- Valero Aruba Refinery Welding Procedure Specification: For Insert PatchesDocument3 pagesValero Aruba Refinery Welding Procedure Specification: For Insert PatchesRaymond de WeeverNo ratings yet

- WPS Format PDFDocument2 pagesWPS Format PDFHimansu Sekhar JenaNo ratings yet

- QW-483 BlankDocument2 pagesQW-483 BlankCraftyBob100% (1)

- BPVC Ix QW-482Document2 pagesBPVC Ix QW-482ganesh82No ratings yet

- Welder Operators Qualification TestDocument2 pagesWelder Operators Qualification Testlokifarad100% (1)

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Co D E)Document2 pagesQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Co D E)Vaibhav GuptaNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Name Name Name Name: To: CCDocument1 pageName Name Name Name: To: CCAnonymous 4e7GNjzGWNo ratings yet

- Shielded Metal Arc Welding (Smaw / "Stick") Shielded Metal Arc Welding (Smaw / Â Œstickâ )Document2 pagesShielded Metal Arc Welding (Smaw / "Stick") Shielded Metal Arc Welding (Smaw / Â Œstickâ )Anonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWNo ratings yet

- Weld Joint Preparation Weld Joint PreparationDocument1 pageWeld Joint Preparation Weld Joint PreparationAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldAnonymous 4e7GNjzGW100% (1)

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNo ratings yet

- Warrior Tech Spare Parts List 2Document1 pageWarrior Tech Spare Parts List 2Anonymous 4e7GNjzGWNo ratings yet

- Kafou Health Safety Loss Prevention ProgramDocument117 pagesKafou Health Safety Loss Prevention ProgramAnonymous 4e7GNjzGWNo ratings yet

- Bio Data-01.07.13Document2 pagesBio Data-01.07.13Anonymous 4e7GNjzGWNo ratings yet

- Numbering Format: Project DocumentationDocument1 pageNumbering Format: Project DocumentationAnonymous 4e7GNjzGWNo ratings yet

- SKTCO ISO 9001 2008 Gap Analysis ChecklistDocument17 pagesSKTCO ISO 9001 2008 Gap Analysis ChecklistAnonymous 4e7GNjzGWNo ratings yet

- QW484Document1 pageQW484Anonymous 4e7GNjzGWNo ratings yet

- Notes-Api Exams-Prathap DhasDocument7 pagesNotes-Api Exams-Prathap DhasAnonymous 4e7GNjzGWNo ratings yet

- Request For Inspection: Client: Contractor: Contract No. Rfi No. Project: Location: Date: Description of InspectionDocument2 pagesRequest For Inspection: Client: Contractor: Contract No. Rfi No. Project: Location: Date: Description of InspectionAnonymous 4e7GNjzGWNo ratings yet

- G. Std. ITP For Pipeline Job PDFDocument4 pagesG. Std. ITP For Pipeline Job PDFAnonymous 4e7GNjzGW100% (1)

- HSMC Employee Induction Procedure (Offices)Document3 pagesHSMC Employee Induction Procedure (Offices)Anonymous 4e7GNjzGWNo ratings yet

QW484

QW484

Uploaded by

Anonymous 4e7GNjzGWOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QW484

QW484

Uploaded by

Anonymous 4e7GNjzGWCopyright:

Available Formats

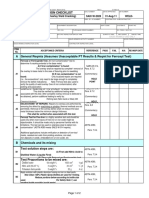

WELDER QUALIFICATION RECORD

Welder's Name:

Welding Process(es) Utilized:

SS#

Date:

Stamp #:

Type:

.

Welding Procedure Identification # Utlized by Welder for Qualification:

Base Material(s) Welded:

Thickness:

Manual or Semiatuomatic Variables for Each Process (QW-350)

Actual Values

Range Qualified

Actual Values

Range Qualified

Backing (metal, weld metal, welded from both sides, flux, etc. (QW-402)

ASME P-No.

to ASME P-No. (QW-403)

Plate

( )

Pipe (enter diameter if pipe)

( )

Filler metal specification (SFA):

Classification (QW-404)

Filler metal F- No.:

Consumable insert for GTAW or PAW:

Weld deposit thickness for each welding process

Welding position ( 1G, 5G, etc.) (QW-405)

Welding progression (uphill/downhill)

Backing gas fro GTAW, PAW, or GMAW; fuel gas for OFW (QW-408)

GMAW transfer mode (QW-409)

GTAW welding current type/polarity

Machine Welding Variable for the Process Used (QW-360)

Direct / remote visual control

Automatic voltage control (GTAW)

Automatic joint tracking

Welding position (1G, 5G, etc.)

Consumable insert

Backing (metal, weld metal, welded from both sides, flux, etc.)

Guided Bend Test Results

Guided Bend Tests Type

Type

) QW-462.2 (Side) Results

( )

QW-462.3a. (Trans. R&F) Type

Mandrel Dia. (mm)

Bend Angel

) QW-462.3b (Long, R&F) Results

Result

Visual examination results (QW-302.4)

Radiographic test results (QW-304 and QW-305)

(For alternative qualification of groove welds by radiography)

Fillet Weld - Facture test

Length & percent of defects

Macro Test Fusion

Fillet leg size

in.

Welding Test Conducted By:

Mechanical Tests Conducted By:

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and

tested in accordance with requirements of Section IX of the ASME Code.

in.

Organization:

By:

340953591.xls

WQR Blank

You might also like

- WPS For Structure Mild Steel Fillet WeldDocument2 pagesWPS For Structure Mild Steel Fillet WeldHarkesh Rajput76% (17)

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- Excel Construction Project Management Templates Construction Budget TemplateDocument19 pagesExcel Construction Project Management Templates Construction Budget TemplateAnonymous 4e7GNjzGW100% (3)

- Welder Performance Qualification-Interactive Form QW-484ADocument1 pageWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- Wps 316L SMAW+GTAW R00Document2 pagesWps 316L SMAW+GTAW R00Richard Periyanayagam87% (15)

- PWPS For Piping-API 1104Document6 pagesPWPS For Piping-API 1104Nguyen Tien Luong100% (1)

- Asme Ix QW PDFDocument183 pagesAsme Ix QW PDFAnonymous 4e7GNjzGW100% (4)

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- Wps A53 Gtaw R00Document2 pagesWps A53 Gtaw R00Richard PeriyanayagamNo ratings yet

- 653 WPS-PQR PDFDocument4 pages653 WPS-PQR PDFETSNo ratings yet

- WPSDocument2 pagesWPSJuli Agus50% (2)

- QW-482 WPS FormatDocument2 pagesQW-482 WPS FormatMardeOpamen100% (1)

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Aries MarteNo ratings yet

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 pageFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWNo ratings yet

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 pageFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWNo ratings yet

- Welding Defect - MACRO PDFDocument5 pagesWelding Defect - MACRO PDFAnonymous 4e7GNjzGWNo ratings yet

- Hydrostatic Test (Log) : Quality Control FormDocument22 pagesHydrostatic Test (Log) : Quality Control FormAnonymous 4e7GNjzGWNo ratings yet

- Suggested Wps Forms ASME - IX 2010Document5 pagesSuggested Wps Forms ASME - IX 2010Ajay ChodankarNo ratings yet

- Automatic, Manual, Machine, or Semi-Auto.Document10 pagesAutomatic, Manual, Machine, or Semi-Auto.ChE_MattNo ratings yet

- WPQ PDFDocument0 pagesWPQ PDFstanleyNo ratings yet

- Book 1Document3 pagesBook 1ansarmulla711No ratings yet

- mohanWPQ-1G 40NBDocument1 pagemohanWPQ-1G 40NBDeepakNo ratings yet

- Saravanan Wpq-5g 50nbDocument1 pageSaravanan Wpq-5g 50nbDeepakNo ratings yet

- BPVC Ix Qw-484aDocument1 pageBPVC Ix Qw-484aTC Capulcu Mustafa MNo ratings yet

- PQR REV. 2010a Interactive FormDocument2 pagesPQR REV. 2010a Interactive FormcosmicbunnyNo ratings yet

- Interactive Form QW-485 PDFDocument1 pageInteractive Form QW-485 PDFRama Krishna Reddy DonthireddyNo ratings yet

- Qw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )Document2 pagesQw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )essnelsonNo ratings yet

- Wps Gmaw SawDocument2 pagesWps Gmaw Sawupedro26No ratings yet

- QW484ADocument1 pageQW484AMohamed Ahmed MaherNo ratings yet

- PQRDocument3 pagesPQRnazirulhakimNo ratings yet

- WPS FormatDocument2 pagesWPS FormatAmit SarkarNo ratings yet

- 14033Document2 pages14033Priyanathan ThayalanNo ratings yet

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Document48 pagesQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- Welding Procedure Specification: Technip KT India LimitedDocument5 pagesWelding Procedure Specification: Technip KT India LimitedDeepak100% (1)

- Form Qw-485 Suggested Format For Demonstration of Standard Welding Procedure Specifications (SWPS) (See Article V)Document1 pageForm Qw-485 Suggested Format For Demonstration of Standard Welding Procedure Specifications (SWPS) (See Article V)durandm10No ratings yet

- P& E WPS Template Rev 00 - OfficialDocument3 pagesP& E WPS Template Rev 00 - OfficialRiaan PretoriusNo ratings yet

- QW 406 Asme CodeDocument3 pagesQW 406 Asme CodeMardeOpamenNo ratings yet

- Procedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingDocument6 pagesProcedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingNovita Dwi IsnaeniNo ratings yet

- WPQ Certificates Klis14Document8 pagesWPQ Certificates Klis14AdhicharanNo ratings yet

- WTCDocument57 pagesWTCSarah FrazierNo ratings yet

- BPVC Ix QW-483Document2 pagesBPVC Ix QW-483ganesh82No ratings yet

- Form Qw-484B Suggested Format B For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageForm Qw-484B Suggested Format B For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)viswamanojNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- Qw-483 (Back) : Specimen No. Width Thickness Area Ultimate Total Load Ultimate Unit Stress, (Psi or Mpa)Document8 pagesQw-483 (Back) : Specimen No. Width Thickness Area Ultimate Total Load Ultimate Unit Stress, (Psi or Mpa)Aries MarteNo ratings yet

- Valero Aruba Refinery Welding Procedure Specification: For Insert PatchesDocument3 pagesValero Aruba Refinery Welding Procedure Specification: For Insert PatchesRaymond de WeeverNo ratings yet

- WPS Format PDFDocument2 pagesWPS Format PDFHimansu Sekhar JenaNo ratings yet

- QW-483 BlankDocument2 pagesQW-483 BlankCraftyBob100% (1)

- BPVC Ix QW-482Document2 pagesBPVC Ix QW-482ganesh82No ratings yet

- Welder Operators Qualification TestDocument2 pagesWelder Operators Qualification Testlokifarad100% (1)

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Co D E)Document2 pagesQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Co D E)Vaibhav GuptaNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Name Name Name Name: To: CCDocument1 pageName Name Name Name: To: CCAnonymous 4e7GNjzGWNo ratings yet

- Shielded Metal Arc Welding (Smaw / "Stick") Shielded Metal Arc Welding (Smaw / Â Œstickâ )Document2 pagesShielded Metal Arc Welding (Smaw / "Stick") Shielded Metal Arc Welding (Smaw / Â Œstickâ )Anonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWNo ratings yet

- Weld Joint Preparation Weld Joint PreparationDocument1 pageWeld Joint Preparation Weld Joint PreparationAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldAnonymous 4e7GNjzGW100% (1)

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNo ratings yet

- Warrior Tech Spare Parts List 2Document1 pageWarrior Tech Spare Parts List 2Anonymous 4e7GNjzGWNo ratings yet

- Kafou Health Safety Loss Prevention ProgramDocument117 pagesKafou Health Safety Loss Prevention ProgramAnonymous 4e7GNjzGWNo ratings yet

- Bio Data-01.07.13Document2 pagesBio Data-01.07.13Anonymous 4e7GNjzGWNo ratings yet

- Numbering Format: Project DocumentationDocument1 pageNumbering Format: Project DocumentationAnonymous 4e7GNjzGWNo ratings yet

- SKTCO ISO 9001 2008 Gap Analysis ChecklistDocument17 pagesSKTCO ISO 9001 2008 Gap Analysis ChecklistAnonymous 4e7GNjzGWNo ratings yet

- QW484Document1 pageQW484Anonymous 4e7GNjzGWNo ratings yet

- Notes-Api Exams-Prathap DhasDocument7 pagesNotes-Api Exams-Prathap DhasAnonymous 4e7GNjzGWNo ratings yet

- Request For Inspection: Client: Contractor: Contract No. Rfi No. Project: Location: Date: Description of InspectionDocument2 pagesRequest For Inspection: Client: Contractor: Contract No. Rfi No. Project: Location: Date: Description of InspectionAnonymous 4e7GNjzGWNo ratings yet

- G. Std. ITP For Pipeline Job PDFDocument4 pagesG. Std. ITP For Pipeline Job PDFAnonymous 4e7GNjzGW100% (1)

- HSMC Employee Induction Procedure (Offices)Document3 pagesHSMC Employee Induction Procedure (Offices)Anonymous 4e7GNjzGWNo ratings yet