Professional Documents

Culture Documents

252BHL44K2 Exaust Tube Crack

252BHL44K2 Exaust Tube Crack

Uploaded by

Anthony PozoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

252BHL44K2 Exaust Tube Crack

252BHL44K2 Exaust Tube Crack

Uploaded by

Anthony PozoCopyright:

Available Formats

VOLVO CONSTRUCTION EQUIPMENT

SERVICE BULLETIN

Language Code

GB

Group

252

Product

No.

BHL

44 K

Version

Date

2011-11-30

Page

1/2

Applies to models

BL60, BL60B, BL61, BL61 PLUS, BL61B, BL70, BL70B, BL71, BL71 PLUS, BL71B

ONLY FOR DISTRIBUTORS / DEALERS

Exhaust flexible tube cracks on D5D engines

WARNING

Please pay attention to the safety instructions in the Operator's

and Service Manuals concerned.

This Service Bulletin is to be considered as technical information

only and is not subject to any reimbursement programs outside

normal warranty.

Cause

Due to stress applied from the engine on this flex tube, it can crack

due to vibrations.

Action

New assembly sequence and order has been reviewed and

introduced into production. Also new clamp has been

implemented according to serial No. in the table below.

Model

Serial No.

BL60B

2121223

BL61B

1202480

BL70B

2326058

BL71B

1415647

Required parts

Volvo Construction Equipment Germany GmbH

Max Planck Strae 1, DE-54329, Konz-Knen, Germany

Designation

Qty.

Part No.

Clamp

VOE 984659

Flex tube

VOE 15016325

Language Code

GB

Group

252

Product

No.

BHL

44 K

Version

Date

2011-11-30

Page

2/2

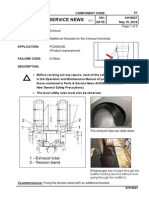

Work instructions

In the case of cracked flex tube (item 5), exchange it for the new

together with the new clamp (item 2).

Clamp tightening torque is 24 Nm 10% (17.7 lbf ft).

When assembling new flex tube, make sure that it fits to both ends

turbo charger studs and muffler without any stresses. It should

be possible to slide one flex tube end into muffler connection and

the other end on the 4 studs of turbo charger without any force or

twisting of the tube.

If its not possible to fit without force, access the muffler bracket

(item 3) and loosen the 4 screws (item 4). Adjust this bracket on

the slots to have free movement of the flex tube into the muffler.

Another adjusting point are 2 clamps (item 1) that, if loosened,

will allow twisting the muffler for better adjustment.

Fig.1

1

2

3

4

5

Clamps

Clamp

Muffler bracket

Screw

Flex tube

It is important to assembly and tighten new clamp (item 2) in a

way that its cut-out will be between slots of the muffler, see Fig.

2. It will avoid fume leaks.

Check if the clamp after assembled and torqued keeps the flex

tube in the muffler connection tight. The tube should not be pulled

from the muffler using hand force.

Fig.2

1 Clamp cut-out has to be placed between two

slots on the muffler inlet

You might also like

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Rating: 1 out of 5 stars1/5 (3)

- VW Transporter T4 Workshop Manual Diesel 2000-2004From EverandVW Transporter T4 Workshop Manual Diesel 2000-2004Rating: 5 out of 5 stars5/5 (3)

- X30592Document16 pagesX30592CTN2010No ratings yet

- ALGI BA-AZ 2 (E) - Elevator Control Blocks and Mounted ValvesDocument41 pagesALGI BA-AZ 2 (E) - Elevator Control Blocks and Mounted ValvesJonathan Bryant78% (9)

- Holden VT 2000 Service TechlinesDocument177 pagesHolden VT 2000 Service Techlinescosky071% (7)

- Tech Bulletin 0112 - Creaking Clicking of FrameDocument8 pagesTech Bulletin 0112 - Creaking Clicking of FrameRichard HagleyNo ratings yet

- SM60129 1Document12 pagesSM60129 1HENKO7659100% (1)

- TPI 2030685-5 - Oil Loss in Cylinder Head Areacylinder Head CoverDocument8 pagesTPI 2030685-5 - Oil Loss in Cylinder Head Areacylinder Head CoverDavianGiurcaNo ratings yet

- RT-124 Troubleshooting & Maintenance On Injection Control UnitDocument21 pagesRT-124 Troubleshooting & Maintenance On Injection Control UnitKhalid Najmi100% (2)

- Dunlop Hoses and Fittings CatalogDocument242 pagesDunlop Hoses and Fittings CatalogBrandon Troc50% (4)

- Manual Sbs OriginalDocument43 pagesManual Sbs OriginalNéstor José Pedrique Silva100% (1)

- Parts & Service News: Page 1 of 3 Exhaust Brackets For The Exhaust Manifolds PC4000/6D (Product Improvement)Document3 pagesParts & Service News: Page 1 of 3 Exhaust Brackets For The Exhaust Manifolds PC4000/6D (Product Improvement)Lucio Valderrama PeredaNo ratings yet

- 505 As Bas B 5052335Document11 pages505 As Bas B 5052335Bruno Alonso PachecoNo ratings yet

- FW Murphy Level Maintainer ManualDocument14 pagesFW Murphy Level Maintainer ManualIRWIN_DSOUZANo ratings yet

- 407-19-23 July 2019Document9 pages407-19-23 July 2019turboshaftNo ratings yet

- Injector InstalacionDocument6 pagesInjector Instalacionjose luis herreraNo ratings yet

- ASB 412-09-137A Page 1 of 10 Approved For Public ReleaseDocument10 pagesASB 412-09-137A Page 1 of 10 Approved For Public Releasesebastian eduardoNo ratings yet

- 30 - EC210B - MCV, Válvula Lógica EmperradaDocument4 pages30 - EC210B - MCV, Válvula Lógica EmperradaAparecidaMarquesNo ratings yet

- 206-19-42 July 2019Document9 pages206-19-42 July 2019turboshaftNo ratings yet

- Technical Guide JIBster KIT SWF 06 11 enDocument43 pagesTechnical Guide JIBster KIT SWF 06 11 enRonald FrancoNo ratings yet

- Warning: Installation Instructions For Level MaintainersDocument4 pagesWarning: Installation Instructions For Level MaintainersDiego Fernando Pedroza UribeNo ratings yet

- Collar Bolts in Shell and Tube Heat ExchangersDocument3 pagesCollar Bolts in Shell and Tube Heat ExchangersBaher ElsheikhNo ratings yet

- RTA-71 Retrofit For Fuel Injection Pump Block For RTA96C and C-B EnginesDocument14 pagesRTA-71 Retrofit For Fuel Injection Pump Block For RTA96C and C-B EnginesCatalin CataNo ratings yet

- L16/24 Mk. 2 Update Package: Service Letter SL12-560/SICDocument24 pagesL16/24 Mk. 2 Update Package: Service Letter SL12-560/SICTesta Bonaventura VincenzoNo ratings yet

- 2 Valves and Injectors Adjustment VEBDocument21 pages2 Valves and Injectors Adjustment VEBRuju RujuNo ratings yet

- Osn 407-19-23Document22 pagesOsn 407-19-23ferbmdNo ratings yet

- LA206001 Park Brake Lamp Illuminated PDFDocument4 pagesLA206001 Park Brake Lamp Illuminated PDFGino Pier100% (1)

- LPG Carbon Dioxide Fire Suppression System Installation Manual .Document50 pagesLPG Carbon Dioxide Fire Suppression System Installation Manual .hrhgk100% (1)

- Contents:: Choke Valve Installation & Maintenance ManualDocument10 pagesContents:: Choke Valve Installation & Maintenance Manualimam susantoNo ratings yet

- (Corus) SHS Jointing - Flowdrill and Hollo-BoltDocument13 pages(Corus) SHS Jointing - Flowdrill and Hollo-Bolt_at_to_No ratings yet

- SEB 27 04 T206H Elevator Trim Stop Block RelocationDocument8 pagesSEB 27 04 T206H Elevator Trim Stop Block RelocationKris Wuthrich BatarioNo ratings yet

- Biodiesel Pump - 115V - 20 GPMDocument4 pagesBiodiesel Pump - 115V - 20 GPMOrganic MechanicNo ratings yet

- BVR BOP: Technical Instruction ManualDocument9 pagesBVR BOP: Technical Instruction ManualGregory StewartNo ratings yet

- Torque Value PDFDocument8 pagesTorque Value PDF7761430No ratings yet

- Manuel de Servicio Tsm141 - 2revdDocument13 pagesManuel de Servicio Tsm141 - 2revdjairoNo ratings yet

- Shuttle Valve Switch Related Abs-Tc-Hdc Warning Lamp Illumination TroubleshootingDocument5 pagesShuttle Valve Switch Related Abs-Tc-Hdc Warning Lamp Illumination TroubleshootingTinashe HondovaNo ratings yet

- Technical Service Bulletin: 210-2418 Ed. 4 April 2006 AllDocument7 pagesTechnical Service Bulletin: 210-2418 Ed. 4 April 2006 AllPyro KDNo ratings yet

- SKF Manual de ApertosDocument44 pagesSKF Manual de ApertosA RNo ratings yet

- BPM800 BPM800 Repair - Rev 1Document7 pagesBPM800 BPM800 Repair - Rev 1api-3752216No ratings yet

- Class 10000 Fans Owner'S ManualDocument19 pagesClass 10000 Fans Owner'S ManualhaosfNo ratings yet

- RDCV - : Technical Instruction ManualDocument12 pagesRDCV - : Technical Instruction ManualGregory StewartNo ratings yet

- SPGP003vikingpump kk125Document16 pagesSPGP003vikingpump kk125Hector_Cornejo_5673No ratings yet

- 3S AWD Trans Service ManualDocument103 pages3S AWD Trans Service ManualMatt BushnellNo ratings yet

- Kit Number 57-0565: Volkswagen Transporter T4, 2.5L L5 TDI, 102 BHP, TUV Approved 1995-2003Document5 pagesKit Number 57-0565: Volkswagen Transporter T4, 2.5L L5 TDI, 102 BHP, TUV Approved 1995-2003danirialNo ratings yet

- Cylinder Liner - Install: Disassembly and AssemblyDocument4 pagesCylinder Liner - Install: Disassembly and AssemblysatyaNo ratings yet

- C107C1 - CAT TH580B Chain Shackles - Dist PDFDocument15 pagesC107C1 - CAT TH580B Chain Shackles - Dist PDFBart JohnNo ratings yet

- Tornamesas HolladDocument2 pagesTornamesas HolladJL OlivaNo ratings yet

- smhs 7727 Special Instruction-проверка установки гильз 3400Document5 pagessmhs 7727 Special Instruction-проверка установки гильз 3400Евгений АбрамовNo ratings yet

- HALFEN ConectoriDocument12 pagesHALFEN ConectoriSárközi Pál-ZoltánNo ratings yet

- 51-42-11-Taper LockDocument24 pages51-42-11-Taper LockFredNo ratings yet

- RB016 Tank Recall PDFDocument5 pagesRB016 Tank Recall PDFGino PierNo ratings yet

- Caterpillar Cat 330B L EXCAVATOR (Prefix 1JS) Service Repair Manual (1JS00001 and Up)Document26 pagesCaterpillar Cat 330B L EXCAVATOR (Prefix 1JS) Service Repair Manual (1JS00001 and Up)kfm8seuuduNo ratings yet

- Pump Repair ManualDocument17 pagesPump Repair ManualSergiSerrano100% (1)

- Enerpac BHP Puller SetsDocument36 pagesEnerpac BHP Puller SetsJorjinio7No ratings yet

- Modern Fuel SystemDocument13 pagesModern Fuel SystemthanhhungaudiNo ratings yet

- TP CSL A-2019Document9 pagesTP CSL A-2019turboshaftNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- Cobertura CAPDocument12 pagesCobertura CAPAnthony PozoNo ratings yet

- Service Bulletin: More Care. Built inDocument5 pagesService Bulletin: More Care. Built inAnthony Pozo100% (2)

- 3512 LocomotoraDocument4 pages3512 LocomotoraAnthony PozoNo ratings yet

- Cap Request FormDocument1 pageCap Request FormAnthony PozoNo ratings yet

- 223cosexcpatpawwlo6k GB PDFDocument2 pages223cosexcpatpawwlo6k GB PDFAnthony PozoNo ratings yet

- Chapter 02 - Application WalkaroundDocument7 pagesChapter 02 - Application WalkaroundAnthony PozoNo ratings yet

- Cobertura CAPDocument12 pagesCobertura CAPAnthony PozoNo ratings yet

- Service Bulletin: Volvo Construction EquipmentDocument1 pageService Bulletin: Volvo Construction EquipmentAnthony PozoNo ratings yet

- 421BHL125K1 New Drive Gear Dog Cluth PDFDocument2 pages421BHL125K1 New Drive Gear Dog Cluth PDFAnthony PozoNo ratings yet

- 372SSL20V3 Service Master Components PDFDocument2 pages372SSL20V3 Service Master Components PDFAnthony PozoNo ratings yet

- 366WLO384Kv2 GBDocument6 pages366WLO384Kv2 GBAnthony PozoNo ratings yet

- Leak Down Rates - BHLDocument2 pagesLeak Down Rates - BHLAnthony PozoNo ratings yet

- Wlo 874 6 PDFDocument1 pageWlo 874 6 PDFAnthony PozoNo ratings yet

- Product and Marketing Information: Volvo Construction Equipment FUEL CONSUMPTION - Volvo Construction EquipmentDocument7 pagesProduct and Marketing Information: Volvo Construction Equipment FUEL CONSUMPTION - Volvo Construction EquipmentAnthony PozoNo ratings yet

- Cap Request FormDocument1 pageCap Request FormAnthony PozoNo ratings yet