Professional Documents

Culture Documents

PTZ-BOX V2 Electronic Volume Converter: Documentation and Technical Specifications

PTZ-BOX V2 Electronic Volume Converter: Documentation and Technical Specifications

Uploaded by

N UlumOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PTZ-BOX V2 Electronic Volume Converter: Documentation and Technical Specifications

PTZ-BOX V2 Electronic Volume Converter: Documentation and Technical Specifications

Uploaded by

N UlumCopyright:

Available Formats

Gas - Measurement

PTZ-BOX V2 Electronic Volume Converter

Documentation and Technical Specifications

Advantages

Communication

Advanced conversion device for gas volume meters

(approved for custody transfer)

Relevant type approvals available

Low cost / high performance

Second pulse input for sensor check

Easy installation, operation and maintenance

Small size and weight

Software for Windows included

Extended communication options

Suitable for zone 1 and zone 2

The PTZ-BOX V2 can be easily configured using the software and a PC or notebook.

Available serial interfaces are infrared as well as RS 232 and

RS 485 cable connections. By means of these interfaces the

device can be connected directly to a computer or via line

modem, GSM modem, radio modem or GPRS connection.

Local read out can also be performed by using a handheld

computer (PDA).

In zone 1, RS 485 must be used in combination with an IS

barrier (see Additional Equipment).

The PTZ-BOX is designed to meet

EN 12405,

German DIN standards and the rigid German

regulations for custody transfer,

and other relevant international standards

The device can also be accessed by DCS or SCADA systems

via Modbus RTU or dedicated protocols.

Alarms

Display

The following error modes are registered:

Pressure or temperature

above maximum or below minimum

Gas meters actual flow rate above Qmax

Diagnostic status in case of an internal error

Battery capacity below 10 %

Setting log full

Gas meter manipulation (if connected)

Pulse sensor error (if 2 sensors are connected)

PTZ-BOX V2 is equipped with a 10 character numeric LCD.

This display is operated by pushing two buttons on the

front panel. It gives access to the current values, set values

and errors.

Operation

The PTZ-BOX V2 is a battery or line powered compact volume converter for gas volume measurement applications.

Applications are with gas flow meters like diaphragm

meters, turbine meters, rotary piston meters, and vortex

shedding meters.

Memory

The EEPROM memory provides storage capacity for

21 monthly records

8 years of daily records

25344 records (standard set of parameters) or 11264

records (extended set of parameters) settable at intervals

of 5 to 60 minutes (that is 34 months of information

with hourly intervals and standard set of parameters)

Status archives and setting archive

It is equipped with an energy-saving pressure transmitter

and a temperature probe. This equipment is supplied integrally with the converter.

The converter uses volume pulses generated by a gas meter,

measures pressure and temperature, and calculates the

compressibility factor Z of the gas as well as the conversion

factor C. From these input values given, it calculates the

volume at base conditions, the base flow rate and the

actual flow rate. The counted pulses from the gas meter

can be checked by connecting a second pulse sensor.

Power Supply

The standard power supply is a lithium battery. The life time

of that battery is a minimum 6 years, providing a measurement interval of 10 seconds or more and communication

via serial interface once a day. When the battery power is

below 10 %, it will generate an alarm for a battery change.

The volume measured at actual conditions is converted to

volume at base conditions according to EN 12405, complying with most other standards.

The compressibility factors Z and Zb may be fixed for all gas

types or calculated according to several methods for natural

gas:

Z/Zb = 1 (Ideal gas) or Z/Zb = const. 1

AGA NX 19 or AGA NX 19 mod

AGA 8 G1 or G2

SGERG 88

As an option, the PTZ-BOX V2 can be powered by an intrinsically safe power supply. The battery will provide power, in

case of line power failure.

Documentation

Initial Verification and Calibration

Each PTZ-BOX V2 is provided with the following

documentation:

IOM Installation, Operation and Maintenance Manual

(hardcopy)

CD-ROM with

IOM (manual as pdf-softcopy)

Software for configuration and read out

Specification data sheet with the preset

parameters of the device

The optional factory calibration certificate is often sufficient

when a calibration document is required.

NMi initial verification certificate can be supplied as an

option.

Legal calibration certificates for other countries are available

on request.

Optional Equipment

Installation

Infrared head for RS 232 serial interface, to be used for

easy read out and configuration via PC or notebook (USB

connection requires a converter), 2.5 m or 12 m cable

length

Cables for connecting RS 232 or RS 485, provided with

male plug (IP 65)

Intrinsically safe communication modules, barriers and

power supplies

Analogue output module 4 20 mA

Telemetric modules complete with power supply,

modems, barriers and safety modules, configuration

according to your specifications

Thermo-wells, thread-o-lets, three-way-valves and other

accessories

The PTZ-BOX V2 is delivered with equipment for wall

mounting or for mounting at the pipe upstream or downstream of the meter. A weldolet with thermo-well is also

supplied (common sizes and threads).

Pre-assembly in the factory is an alternative. The temperature probe needs a thermo-well close to the gas meter:

Downstream of a gas turbine meter or upstream of a rotary

gas meter. For custody transfer applications in many countries, you need a second thermo-well and a three-way-valve

in the pressure line. The vemm tec gas meters can be provided with a thermo-well in the meter body, but this is not

permitted by some local metrological services.

Electronic Volume Converter PTZ-BOX V2 with temperature probe Pt 1000

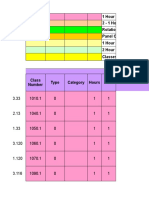

Table: Technical specifications PTZ-BOX V2

Power

Dedicated intelligent Lithium battery

Life time with battery power:

6 years minimum

(under specified conditions of use)

Optional: External power supply (IS)

4.7 to 10.0 V DC

Temperature

probe

1 or 2 LF contact inputs

(Reed or Wiegand)

100 / 10 / 1 / 0.1 / 0.01 m3/imp

with 4 Hz max. frequency

Contact, if available in gas meter

Piezo resistance sensor, mounted in the

casing, with the following ranges:

0.8 - 5.2 bar(a)

0.9 - 3.0 bar(a)

2.0 - 10 bar(a)

2.0 - 5.2 bar(a)

4.0 - 20 bar(a)

3.0 - 10 bar(a)

7.0 - 35 bar(a)

14 - 70 bar(a)

Other ranges on request

Connection: 6 mm Ermeto M12x1.5

Pt 1000 probe,

fixed to the device

Sample

frequency

Battery operation:

Line power:

Display

10 digits LCD, showing actual values,

settings and errors

Calculation

Compressibility calculation according to

EN 12405 and other standards:

AGA NX 19 (standard or mod)

AGA 8 G1 or G2

SGERG 88 or fixed value

Tamper switch

Pressure

transmitter

Accuracy

10 / 15 / 20 / 30 s

Every 2 seconds

Base volume:

< 0.15 % under reference conditions

< 0.50 % in the whole range of

pressure and temperature sensors

vemm tec Messtechnik GmbH

Gartenstrasse 20

14482 Potsdam-Babelsberg

Germany

Tel. +49 (0) 3 31 / 70 96 274

Fax +49 (0) 3 31 / 70 96 270

E mail: info@vemmtec.com

Internet: http://www.vemmtec.com

21 records of 12 values

3072 records (8 years) of 20 values

25344 records of 9 values or

11264 records of 20 values

(The custom archive can hold

34 months of information with

9 values stored at hourly intervals).

Intervals

Status archive

Setting archive

5 / 10 / 15 / 20 / 30 / 60 minutes

500 records of error messages

500 records of setting changes

Outputs

Pulse outputs

Unconverted flow (scalable)

Converted flow (scalable)

Alarms (settable pulse width)

Pulses are provided as pulse train at the

beginning of each measuring period.

Infra red port RS 232 (IS)

RS 232 port (not intrinsically safe) and

RS 485 port (IS) combined in one socket

with connector (IP 65)

Communication speed selectable:

19.2 / 9.6 / 4.8 kbit/s

Serial outputs

Alarms

Error status at high or low pressure or

temperature, high flow rate, low battery,

manipulation with gas meter, pulse error

and internal errors

Intrinsical

safety

II 2G EEx ia IIC T4/T3

FTZ 05 ATEX 0164X

Metrological

approvals

Netherlands Measurement Institute (NMi)

TC3572, T6794 and others

Protection

against

manipulation

A password is required to change the

settings. The sealable configuration switch

must be put to the set mode. The

device can be protected by seals

(user or metrological service).

Software

The included software package enables

configuration and read out of the device.

Values can be exported to several standard

software packages (Excel, Access, Paradox,

Foxpro) or to text formats or XML.

Data

exchange

Scada systems can access the device via

Modbus RTU or via optionally dedicated

protocols.

Jan. 2006

Temperature: -25 to +60 C (standard)

-40 to +60 C (optional)

Storage temperature: -40 to +60 C

Registers

Monthly

Daily

Custom

Changes in course of technical development are reserved.

Operating

conditions

Inputs

Pulses

Gas - Measurement

Dimensions: 100 x 120 x 70 mm

Weight: 1.2 kg

Material: Aluminium alloy

IP 65: According to EN 60529

092-002-001

Enclosure

You might also like

- Vega IiDocument6 pagesVega Iiganeshram2305No ratings yet

- MAG 8000 PresentationDocument16 pagesMAG 8000 PresentationMil ValenzuelaNo ratings yet

- Gas Metering System-Woodward - SwiftDocument4 pagesGas Metering System-Woodward - Swiftkats2404No ratings yet

- Vemmtec PTZ BoxDocument4 pagesVemmtec PTZ BoxHafikon Mitra sedayaNo ratings yet

- Ad00879m Nuflo Scanner 2200 Efm Data SheetDocument4 pagesAd00879m Nuflo Scanner 2200 Efm Data SheetCarlos Alberto MoviNo ratings yet

- MacBAT-5 Data-Sheet EN V9-PublisherDocument13 pagesMacBAT-5 Data-Sheet EN V9-PublisherSeka Vilar SorucoNo ratings yet

- TANCY TEC Type Volume Corrector Instruction ManualDocument9 pagesTANCY TEC Type Volume Corrector Instruction ManualSaleh AlomariNo ratings yet

- Scanner 2000 Technical Data SheetDocument4 pagesScanner 2000 Technical Data SheetDennis Espinoza Rospigliosi100% (1)

- BR Isk Mt375Document2 pagesBR Isk Mt375Javed HashmiNo ratings yet

- PLG C 3 Natural Gas ChromatographDocument4 pagesPLG C 3 Natural Gas ChromatographYuli_PribadiNo ratings yet

- NGC 8206 Data SheetDocument5 pagesNGC 8206 Data SheetMuhammad Darussalam HerdaniNo ratings yet

- PR Ve 0003Document16 pagesPR Ve 0003Procurement PardisanNo ratings yet

- Elster EK205: I Connected IndustrialDocument2 pagesElster EK205: I Connected IndustrialmohamedwalyNo ratings yet

- Monitor de BoquillasDocument4 pagesMonitor de BoquillasCM LanmatNo ratings yet

- FT Kistock KH210 RFDocument4 pagesFT Kistock KH210 RFHassan HoudoudNo ratings yet

- Acme PIUDocument4 pagesAcme PIUJay TrivediNo ratings yet

- Reakti̇f Güç Kontröl Rölesi̇ (RVT)Document8 pagesReakti̇f Güç Kontröl Rölesi̇ (RVT)iyilmaz1No ratings yet

- XFC EspecificacionsDocument19 pagesXFC Especificacionsadesa2013No ratings yet

- DS - VE - 0017 - EN - VEGA T Terminal MID 2.0Document7 pagesDS - VE - 0017 - EN - VEGA T Terminal MID 2.0moonnightwatcherNo ratings yet

- PR Ve 0004Document12 pagesPR Ve 0004Procurement PardisanNo ratings yet

- Ptz-Box 5.0 - e - 098-002-001 - 2019-11Document4 pagesPtz-Box 5.0 - e - 098-002-001 - 2019-11Nurdeny Hidayanto PribadiNo ratings yet

- Power Interface UnitDocument2 pagesPower Interface UnitPushkar MishraNo ratings yet

- TD - Datasheet TK400 NDDocument4 pagesTD - Datasheet TK400 NDSocaciu VioricaNo ratings yet

- Re95201 2007-11Document16 pagesRe95201 2007-11renatNo ratings yet

- Reason RPV311 Guideform Specification - v2 PDFDocument4 pagesReason RPV311 Guideform Specification - v2 PDFVíctor CasadoNo ratings yet

- Ds Ve 0024 En1390976235020390783Document10 pagesDs Ve 0024 En1390976235020390783Dusko ArsenovskiNo ratings yet

- MECi Flow ComputerDocument2 pagesMECi Flow ComputerykanchanamNo ratings yet

- Small On LIne DGA 3 Gas R2 Feb 2020Document5 pagesSmall On LIne DGA 3 Gas R2 Feb 2020Jitendra SinghNo ratings yet

- RMG Volume Corector EC 600Document6 pagesRMG Volume Corector EC 600aniyatiNo ratings yet

- DIRIS ADocument6 pagesDIRIS ARelief_EngineerNo ratings yet

- TB7300 Series Communicating Fan Coil Thermostats: 24 Vac For Commercial and Lodging Hvac ApplicationsDocument4 pagesTB7300 Series Communicating Fan Coil Thermostats: 24 Vac For Commercial and Lodging Hvac ApplicationsCarlos BarrazaNo ratings yet

- SCADAPack 350 DatasheetDocument6 pagesSCADAPack 350 DatasheetWiedNo ratings yet

- Prometer RDocument8 pagesPrometer RBitacora InternautaNo ratings yet

- Shark200 BrochureDocument8 pagesShark200 BrochureBryan Dela TorreNo ratings yet

- 852 318 Datasheet Usb OptionDocument4 pages852 318 Datasheet Usb OptionDaniel SubelzaNo ratings yet

- 505 - Itm - Ap M09 08a 01enDocument8 pages505 - Itm - Ap M09 08a 01enGuilherme Lopes SoledadeNo ratings yet

- Manual de BristolDocument16 pagesManual de BristolChristian Flores LozanoNo ratings yet

- ABB Chromatograph Gas NaturalDocument5 pagesABB Chromatograph Gas NaturalVRIMSANo ratings yet

- Correcteur CORUS PTZDocument4 pagesCorrecteur CORUS PTZosiris_apoloNo ratings yet

- Dresser Instruments Micro Corrector Specs.Document4 pagesDresser Instruments Micro Corrector Specs.davidNo ratings yet

- Chiller Plant Manager - McguayDocument4 pagesChiller Plant Manager - McguaysuathayriNo ratings yet

- 149-840 PICS For Part Number 550-492PKDocument7 pages149-840 PICS For Part Number 550-492PKMark Izsm AmersonNo ratings yet

- E7000 - Instruction Manual - v10Document38 pagesE7000 - Instruction Manual - v10edcooNo ratings yet

- Gallus 2000Document2 pagesGallus 2000@@ngNo ratings yet

- TTM-DS-00085-EN-01 TFX Ultra 07 09 13Document8 pagesTTM-DS-00085-EN-01 TFX Ultra 07 09 13Ahmed AbdelwaneesNo ratings yet

- Nomad 2Document2 pagesNomad 2sorin.piciu9051No ratings yet

- Floboss 103 Flow Manager: Fb103 Product Data SheetDocument7 pagesFloboss 103 Flow Manager: Fb103 Product Data SheetcartarNo ratings yet

- Bodas Controller RC: Series 22Document18 pagesBodas Controller RC: Series 22studskirby100% (2)

- Vortex KDocument5 pagesVortex KSylvain AguedaNo ratings yet

- Siprotec 7ke85 v7 ProfileDocument2 pagesSiprotec 7ke85 v7 ProfileJuan Carlos100% (1)

- Helmet MiniDocument56 pagesHelmet MiniSumanth VarmaNo ratings yet

- Data Sheet For EVC: ISO 9001-2015 CERITIFIEDDocument1 pageData Sheet For EVC: ISO 9001-2015 CERITIFIEDBrijesh YadavNo ratings yet

- Vortex: Gas Detection Control PanelDocument4 pagesVortex: Gas Detection Control PanelDanny YapNo ratings yet

- 509 ITM Back Deck March 2011 PDFDocument68 pages509 ITM Back Deck March 2011 PDFmartin zunigaNo ratings yet

- Gas Turbine Flow MeterDocument33 pagesGas Turbine Flow MeterKhabbab Hussain K-hNo ratings yet

- 002 - Gas ChromatographDocument52 pages002 - Gas Chromatographtubagus syariefNo ratings yet

- Elster-Instromet M2000 FCDocument0 pagesElster-Instromet M2000 FCsaid_rahmansyah4750No ratings yet

- E6000 InstructionManual v27Document42 pagesE6000 InstructionManual v27rommel76No ratings yet

- GL500-2-1 Global Logger: FeaturesDocument1 pageGL500-2-1 Global Logger: Featuresdrone jsnNo ratings yet

- Hydrocarbon Infrared SensorDocument9 pagesHydrocarbon Infrared SensorTuan CaoNo ratings yet

- Diaphragm Gas Meter-Goldcard Smart Group Co - LTDDocument5 pagesDiaphragm Gas Meter-Goldcard Smart Group Co - LTDRenato CastroNo ratings yet

- General Metering Products CatalogDocument4 pagesGeneral Metering Products Catalogemuno008No ratings yet

- Solving Instability IssuesDocument6 pagesSolving Instability IssuesHedi Ben MohamedNo ratings yet

- Custody TransferDocument6 pagesCustody TransferTHE TERMINATORNo ratings yet

- Brochure Dresser Series B3 MetersDocument4 pagesBrochure Dresser Series B3 Metersrahman ariwibowoNo ratings yet

- Slaa837a FAQ Ultrasonic Sensing Technology For Water and Gas Flow Metering With MSP430FR604x MCUsDocument16 pagesSlaa837a FAQ Ultrasonic Sensing Technology For Water and Gas Flow Metering With MSP430FR604x MCUsA N ArunkumarNo ratings yet

- Rotary Piston Gas Meter: National Accreditation of Certification BodiesDocument8 pagesRotary Piston Gas Meter: National Accreditation of Certification BodiesLuis CasasNo ratings yet

- CGDDocument72 pagesCGDKirtiVardhan100% (2)

- Comparison Bet Stds For Diaphragm Gas MetersDocument34 pagesComparison Bet Stds For Diaphragm Gas MetersRam SudheerNo ratings yet

- Hertz Inspection Service PVT LTD Irc1Document18 pagesHertz Inspection Service PVT LTD Irc1Rahul N PatelNo ratings yet

- Rotary Gas Meters: Rm16 - Soft MetricDocument2 pagesRotary Gas Meters: Rm16 - Soft MetricSanny HamdaniNo ratings yet

- PI FLOWSIC500 - enDocument16 pagesPI FLOWSIC500 - enShahnoza TorayevaNo ratings yet

- Essential Book Coriolis ExcerptDocument10 pagesEssential Book Coriolis ExcerptMIRCEA1305No ratings yet

- Imtm Turbine Meters 2" - 16" For Custody Transfer: High LightsDocument6 pagesImtm Turbine Meters 2" - 16" For Custody Transfer: High LightsaliNo ratings yet

- Volumetric Measurement of Gaseous Fuel Samples: Standard Test Methods ForDocument13 pagesVolumetric Measurement of Gaseous Fuel Samples: Standard Test Methods Forahmed100% (1)

- Fundamentals of Liquid MEasurement III - DynamicDocument11 pagesFundamentals of Liquid MEasurement III - DynamicCRT ServicesNo ratings yet

- OIML R 137-1 & 2: Nternational EcommendationDocument76 pagesOIML R 137-1 & 2: Nternational EcommendationAMY WEINo ratings yet

- Elster® TRZ2: I Connected Industrial I Connected IndustrialDocument4 pagesElster® TRZ2: I Connected Industrial I Connected Industrialnicoleta10No ratings yet

- DSFG Gateways C1 and C2 Series 2: Technical Documentation Function, Operation, Commissioning and MaintenanceDocument54 pagesDSFG Gateways C1 and C2 Series 2: Technical Documentation Function, Operation, Commissioning and MaintenancevishadkapadiaNo ratings yet

- Elster RABO Datasheet EN PDFDocument4 pagesElster RABO Datasheet EN PDFHuythuong NguyenNo ratings yet

- Calibrating Custody Transfer Gas Meter PDFDocument18 pagesCalibrating Custody Transfer Gas Meter PDFzohaibjamilNo ratings yet

- Basics of High-Pressure Measuring and Regulating Station DesignDocument8 pagesBasics of High-Pressure Measuring and Regulating Station DesignMelina SbhNo ratings yet

- Sensus Sonix - 12 - 16 - 25 Ultrasonic Meters LG-1021 PDFDocument2 pagesSensus Sonix - 12 - 16 - 25 Ultrasonic Meters LG-1021 PDFPaolita Auza BalderramaNo ratings yet

- E+H Entrained AirDocument4 pagesE+H Entrained Airaswin26No ratings yet

- Process Instrumentation Module 4Document68 pagesProcess Instrumentation Module 4ibuddhaNo ratings yet

- 028 Flare Gas Metering (English)Document12 pages028 Flare Gas Metering (English)Sergio A. Rdz. F.No ratings yet

- Manual Medidor RotativoDocument32 pagesManual Medidor RotativonduenasNo ratings yet

- 2014 Program ScheduleDocument329 pages2014 Program ScheduleKeerti S SNo ratings yet

- Fundamentals of Liquid Measurement IIIBDocument10 pagesFundamentals of Liquid Measurement IIIBmanuel_medcoNo ratings yet