Professional Documents

Culture Documents

BS 215 1 Aluminum Conductors Aluminum Conductors Steel Reinforced For Overhead Power Transmission Aluminum Stranded Conductors PDF

BS 215 1 Aluminum Conductors Aluminum Conductors Steel Reinforced For Overhead Power Transmission Aluminum Stranded Conductors PDF

Uploaded by

annuvyas0 ratings0% found this document useful (0 votes)

123 views13 pagesOriginal Title

BS-215-1-Aluminum-Conductors-Aluminum-Conductors-Steel-Reinforced-for-Overhead-Power-Transmission-Aluminum-Stranded-Conductors.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

123 views13 pagesBS 215 1 Aluminum Conductors Aluminum Conductors Steel Reinforced For Overhead Power Transmission Aluminum Stranded Conductors PDF

BS 215 1 Aluminum Conductors Aluminum Conductors Steel Reinforced For Overhead Power Transmission Aluminum Stranded Conductors PDF

Uploaded by

annuvyasCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 13

SPECIFICATION FOR

ALUMINIUM CONDUCTORS AND

ALUMINIUM CONDUCTORS,

STEEL-REINFORCED

FOR OVERHEAD POWER TRANSMISSION

Part 1. Aiuminium stranded conductors

BRITISH . STANDARDS INSTITUTION

Incorporated by Royal Charter

British Standards House, 2 Park Street, London, WIY 44A

“Telegrams: Standards London WI ‘Telephone: 01-629 9000

UDC 621,315.55 : 669.71

‘ ECEIVED.

o 04 MAR 1999

1 approved by the BS 215: Part 1: 1970

is Committee, was

Exccalve Board oo oe

Page

cooperating organizations 4

Foreword. : s

SPECIFICATION

; 1. GENERAL,

. 1a Seape ‘

1 Definition 6

tothe fact hat his oo 13 Standard for ard-rawnalmiium wire 7

wee seeesary 2. MATERIAL 7

2. DIMENSIONS AND CONSTRUCTIONS

eee en 34 Standard sizes of wire 1

eee 32 standart ofluminiumstandedconducors 7

ces harged wah 2 m= 1

yt 3.) Surening ;

“coag over S80, 5.5 compete constr

isos of each wil

ok, which may be 4.1 Serection of test samples 3

oS ee pases | °

2 iautons, of extng

¢ following, Bish «84 Cente of compliance 9

ical engineering. APPENDICES

at purposes, Wie [A. Noten the calelation of Table 3 2

Note on modal of elastic and coefiient

“yy eee ee “

ea tat “i . Cade ames for standard alomsiom stranded

— conductors, “

: ‘D. Non-standard constructions: 1s

| ‘TABLES

1. Lay ratios for aluminium stranded conductors 8

2. Aluminium wires used in the construction of

imstranded conductors. 10

vork on this standard:

(foe comment 6429131 standard alumi

43. Standard aluminium stranded conductors Ut

2

4, Stranding constants

ener ee coe co

PR RER

~eaptten c en e ena

ZATIONS

sadards Committe,

Se Standard was

fom the following

fe" and: industri

turers? Association

See Asioeistion

High Condvctivity

‘omobile Division)

ners Ltd.

Vile and industria

in the above Ist

aly represented on

ion of this

1 Genecaung Board

Niater

BS 25: Part 1: 1970

BRITISH STANDARD SPECIFICATION FOR

ALUMINIUM CONDUCTORS AND ALUMINIUM

CONDUCTORS, STEEL-REINFORCED

FOR OVERHEAD POWER TRANSMISSION

Part 1. Aluminium stranded conductors

FOREWORD

British Standard was frst published as BS 215: Part

s ‘conductors

ndctors, now cove:

1956; previously

inchnded "agate?

fn the one publication,

Tn this revision all dimensions are included in metric units and the

requirements of ire stancare have teen amended to conform suestantialy wisn

those of IEC Pue.cation 207, ‘ Aluminium stranded conductors

(As a result shecr ace 22

xternal diamets- 9f

hitherto, The basis “or calculating conductor breaking icads has eeu aver.

Values of the mocull of elasticity quoted in an appendix are practical values

obtained dy tesi, which are considered to be of more practical significance tas

the caleulated values formerly quoted.

In the course of metrication the sizes of standard conductors, of which the

‘umber has been restricted, have been maintained unchanged except for

epligible diferences due (0 the expression of wice diameters in millimetres.

‘The ses of conductors are designated by nominal aluminium areas (mm) in

place of the formerly used nominal copper areas (in'). For convenience the

Frominal aluminium areas have been taken as being numerically 1000 times the

previous nominal copper areas.

"At the present time there isan increasing use of conductors of constructions

other than those covered in this standard. To facilitate standardization of these

‘constructions lay ratio limite and the appropriate stranding factors are included

in an appendix.

‘Detailed requirements for aluminium wires are not included in this standard,

but are specified in BS 2627, *Wrought aluminium for electrical purposes.

Wire

‘All stresses are quoted in terms of the hectobar (hbar*).

© phar = 10. MNfn# = 10 N/m.

BS 215: Part 1 : 1970

Other British Standards dealing with aluminium conductors for overhead

lines are listed below:

BS 215: ‘Aluminium conductors and alumini

teinforced for overhead power transmission.

Part 2, Aluminium conductors, stee-reinforced.

conductors, steel-

BS 3242, Aluminium alloy stranded conductors for overhrad power

transmission.

SPECIFICATION

1, OE

Pat [of t's British sf roolies to aluminium stranded conductors ier

coveriead power transmission.

112 DEFINITIONS

For the purposes of this Part of this British Standard the following definitions

apply:

‘Stranted conductor, A conductor consisting of seven or more aluminium

wires of the same nominal diameter twisted together in concentric layers, When

the conductor consists of more than one layer, successive layers are twisted in

‘opposite directions.

‘Diameter. ‘The mean of two measurements at right angles taken at the

‘same cross section.

Direction of lay. The direction of lay is defined as right-hand or leftthand.

‘With right-hand lay, the wires conform to the direction of the central part of

the leer Z when the conductor is held vertically. With left-hand lay, the wires

‘conform to the direction of the central part of the letter $ when the conductor

is held vertically.

Lay ratio. The ratio of the axial length of a complete turn of the helix

formed by an individual wie in a stranded conductor to the external diameter

of the helix

‘For other definitions reference should be made to BS 205°.

+ 85 205," Glonary of terms sed in electrical engineer

‘

head

steel-

ven

ain

» the

‘and.

tof

actor

helix

eter

BS 215; Part 1 : 1970

1.3 STANDARDS FOR HARD-DRAWN ALUMINIUM WIRE,

LAA Resistivity, The resistivity of aluminium wire depends upon its purity

and its physical condition, For the purposes of this British Standard the maximary

ate permitted is 28264 wl em at 20°C, and this value shall also be used a9

the standard resistivity for the purpose of ealculation.

1.22 Density. At temperature of 20°C the density of hard-drawn aluminium

wire isto be taken as 2703 glen.

1.3.3 Coefficient of linear expansion. The coefficient of linear expansion of

hhard-drawn aluminium ig to be taken as 23 x 10-4/°C.

1.3.4 Constantemass temperature cooficlent, Ata temperature of 20°C the

tGonstant mass” temsperaiure ccetcient of eesistance of naedecavwn alumi

syize, rreasured between two potential points rigily fixed to the wire, is taken

as 960 OY°C.

Gik in the 19 ov:

By agreement

evenly throug

Jhout the feng: of the conduct.

3. DIMENSIONS AND CONSTRUCTION

‘1 STANDARD SIZES OF WIRES

‘The sluminium wices for the standard constructions covered by this specification

shall have the diameters specified in Table 2.

42 STANDARD SIZES OF ALUMINIUM STRANDED CONDUCTORS

432.1 The sizes of standard aluminium stranded conductors are given in Table 3.

13.2.2 The masses (excluding the mass of grease for corrosion protection) and

Tesiatances may be taken as being in accordance with Table 3.

33 JOINTS IN WIRES

‘3.3.1 Conductors containing seven wires. There shall be no joints in any wire

‘ra stranded conductor containing seven wires, except those made in the base

fod of wire before final drawing.

3.32 Conductors containing more than seven wires. In stranded conductors

Containing more than zeven wires, joints in individual wires are permitted in

Sedition to those made in the base rod or wire before final drawing, but no two

+ 2627, Wrought aluminium for electrical purposes. Wie

1

us 215 : Pact 1217

such joins shall be less than 15 m apart in the complete stranded conductor,

Such pins shal be made by resistance or cold-pressure butowelding, They are

fot required to fulfil the mechanical requirements for unjinted wires. Joints

Jade by resistance buttovelding shal, subsequent to welding, be annealed over

ft distance of at least 200 mm on each side of the joint.

134 STRANDING

ast The wice used in the construction of a stranded conductor shall, before

stranding, satisfy all the relevant requirements of this standard.

342 The lay ratio of the different layers shall be within the limits given in

‘Table 1. ’

NOTE: iis important to note that ny rato is now defined a the ratio ofthe ala ent

MYO ote tam ofthe helix formed by an individoal wire in a stranded conductor tothe 1

hiernal Gameter of he be G4

3:43 in all cons

of lay, the outerest

evealy and closely 3

344 In aluminis

3 COMPLETED CONDUCTOR

“The completed conductor shall be free from dirt, grit, excessive amounts of

drawing oil and other foreign deposits.

i RES

EES

mich si i AN A

See

Jed conductor.

iding. They are

wires. Joints

‘annealed over

oe shall, before

of the anit est

3 of Wie, 6

sive amounts of

BS 215 : Part 1: 1970

4, TESTS

‘41 SELECTION OF TEST SAMPLES

‘4d Samples forthe tests specified in 4.3, shall be taken by the manufacturer

before stranding, from not les than 10 % ofthe individual lengths of aluminium

‘wire which willbe included in any one consignment of stranded conductor.

‘One supe, sufficient to provide one test specimen foreach ofthe appropriate

tests, shall be taken from each of the selected lengths of wire.

4:12 Alternatively, when the purchaser states at the time of ordering shat he

‘sizes tests to be made in the presence of his representative, samples of wite

‘hall be taken from lengths of stranded conductor zelectea ‘rom approximately

10 % of the lengths included in any one consignment.

‘ne sample, sulfcient to provide one specimen for eaca of ihe spprops

casts, shail be taken from eaea of aa agraeu 2.5 7

in each of the selected Ie

ate

Untess otherwise agreed between the purchaser and the manufacturer at the

time of ordering, all tests shail be made at the manuiscturer's works.

43 TESTS,

-The test samples taken under 4.11 shall be subjected to the following tes in

cvordance with BS 2627" and shall meet the requirements of that standard:

“Tensile test.

Wrapping test

Resistivity test.

‘Test samples taken under 4.1.2 shall be subjected to the same test, but in

the case ofthe tensile test the tensile strength of the specimen shall be not less

than 95 % ofthe appropriate minimum value specified in BS 2627.

{44 CERTIFICATE OF COMPLIANCE

‘When the purchaser does not call for tests on wires taken from the stranded

conductor, the manufacturer shall if requested, furnish him with a certificate

fiving the results of the tests made on samples taken in accordance with 4.11.

+ 2627, Weoueht aluminium for eletial purpose. Wire",

9

BS 215 : Part 1: 1970

TABLE 2. ALUMINIUM WIRES USED IN THE CONSTRUCTION OF!

‘STANDARD ALUMINIUM STRANDED CONDUCTORS

[NOTE The velues given in Columns 2t0 5

10

ONSTRUCTION OF

"NDUCTORS.

scier

ioe

‘ation onl.

ys2is: Part:

TABLE 3. STANDARD ALUMINIUM STRANDED CONDUCTORS

20 m

888

1s | 906s) RIO |

1

in of this able re Append A

rade cotton ithe sum of tbe crosses

NOTE 2 The eetona ates oat

Shite iia es

sr Ntention soca <9 the fet tha the secdonal areas of standand conics

the nominal aluminium aes by witch thy ato

‘anulctored exstly 10

BS 215 : Part 1: 1970

APPENDIX A” =

NOTES ON THE CALCULATION OF TABLE 3

‘A.A Increase in length due to stranding. When straightened out, each wire in

‘ny particular layer of a stranded conductor, except the central wire, is lange?

thorthe stranded conduetor by an amount depending on the fay ratio of that

layer.

'Ad Resistance and mass of conductor. ‘The resistance of any length ofa stranded

Mhehetor isthe resistance of the same length of say one wire multiplied By 3

constant, as set out in Table 4.

tea done of zarh sven in any partinlar faver of stranded conductor, except

will be greater than that of an equal length of sa

stants in Table 4, the mean lay ratio, .€ 12e

‘mes and rvaniinnm values in Tabte t, 8s

‘been assumed for each layer

'A3 Calculated breaking load of conductor. The breaking load of an aluminium

‘Sandel conductor containing not more than 37 wires, in terms of the strengths

Of the individual component wires, may be taken to be 95% of the sum of the

Strengths of the individval aluminium wires caleuated from the specified

minimum tensile strength.

TABLE 4, STRANDING CONSTANTS:

Sheath Renetangs RUIN Sy Se

BS 215 ; Part 1 : 1970

APPENDIX B

a NOTE ON MODULUS OF ELASTICITY AND COEFFICIENT OF

: LINEAR EXPANSION

ATION OF TABLE 3 |The practical moduli of elasticity given below are based on an analysis of the

| inno determined rom age numberof shar term eS)

‘yen straightened out, each wire in ane tbe aken as applying to conductors sessed between 15% and

acept the central wire, Tonger are teeaking load ofthe conductor. They may be regarded as being accurate

{depending on the lay ratio ofthat to within + 300 hbar*,

Peat | litte | Sree

ssi) of any length ofa stranded otra | ceils | oe

ihc. one wire multiplied by & cy | exeamioal

ayer of stranded concucicr, except

stan equal Tength of straight wie | moxie

dhat lave: (ee ALT above). The erat \

ad conductor is, therefor, ootained = { 250 x 10-*

cr ainishe aire by an ag2rupriste a | Boo

NOTE, Thee value aro gen for oi sn840H OH

. The breaking load of aa aluminiuea

fhan 37 wires, in terms of the strengths

se taken to be 95 % of the sum of the

“vines calculated from the specified

#1 Nour = 10 MNjn# = 10 N/mm’

BS 215 : Part 1: 1970

APPENDIX C

CODE NAMES FOR STANDARD ALUMINIUM STRANDED

CONDUCTORS

“NOTE, These code names re not an essential part ofthe tandard, They are given or com>

Yenience im ordering conductor.

emia!

sKtettn | stranding | Code ame

‘rea

resem

seaNeUe rae HN

ee RC nt Se te

CRRA ETI

Cc

ALUMINIUM STRANDED

RS

at he standard, They ate given for ome

BS 215 : Part 1 21970

APPENDIX D

NON-STANDARD CONSTRUCTIONS

Dal Lay ratios and stranding constants

0016 76

weltolas 10] 14) —|—|_ 62s

chestectyelecligtar! exon | omnes

div ual component wires, may be taken to be50 % of ke.

forthe indivigual aluminium vres cueuaied ifein sae specs

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 05 Switchgear and SubstationsDocument82 pages05 Switchgear and Substationsemy1188No ratings yet

- Claulation For Check Suitability of IPSDocument45 pagesClaulation For Check Suitability of IPSannuvyas100% (1)

- 220 KV Sag Tension Calculation - ThyottarDocument13 pages220 KV Sag Tension Calculation - Thyottarannuvyas100% (3)

- GTP of 400kv CVT Rev 01 - D 98Document3 pagesGTP of 400kv CVT Rev 01 - D 98annuvyasNo ratings yet

- Annexure IV - ET-P26-G1 Guidelines For Protection Energy Meter Requirements For Power Supply To B PDFDocument72 pagesAnnexure IV - ET-P26-G1 Guidelines For Protection Energy Meter Requirements For Power Supply To B PDFannuvyas0% (1)

- 838 E3023 PDFDocument8 pages838 E3023 PDFannuvyasNo ratings yet

- Pgcil - Spacers For Bersimis - 400kv & 220kv - Type Test ReportDocument7 pagesPgcil - Spacers For Bersimis - 400kv & 220kv - Type Test ReportannuvyasNo ratings yet

- 132kv Malana Ekd-Section-Rev01 ModifiedDocument1 page132kv Malana Ekd-Section-Rev01 ModifiedannuvyasNo ratings yet

- NEMA CC 1 2009 Contains 2012Document67 pagesNEMA CC 1 2009 Contains 2012Marco Vassão100% (1)

- RAL Colour IdendificationDocument9 pagesRAL Colour IdendificationannuvyasNo ratings yet

- Wind Calculation ManDocument12 pagesWind Calculation ManannuvyasNo ratings yet

- CT SizingDocument14 pagesCT SizingHassenLNo ratings yet

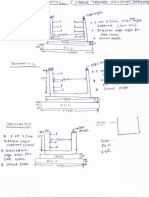

- Cable Trench Section DrawingDocument2 pagesCable Trench Section DrawingannuvyasNo ratings yet