Professional Documents

Culture Documents

Vitaulic Style 77 para Recubrimiento en Goma

Vitaulic Style 77 para Recubrimiento en Goma

Uploaded by

ALESSANDRO DEL PIEROOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vitaulic Style 77 para Recubrimiento en Goma

Vitaulic Style 77 para Recubrimiento en Goma

Uploaded by

ALESSANDRO DEL PIEROCopyright:

Available Formats

25.

10

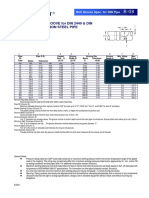

SPECIAL IPS GROOVE SPECIFICATIONS

Groove Dimensions for Rubber Lining

for corrosive services

RUBBER OR URETHANE LINED PIPE

Rubber or urethane lined pipe, connected with Victaulic couplings, has proven to be a most

practical and economical method of conveying corrosive fluids and slurries, showing savings

in maintenance cost over unlined metal pipe in such services. The use of rubber-lined metal

pipe combines the high-corrosive and abrasive-resistant properties of rubber or urethane with

the rigidity and strength of metal.

Urethane or rubber-lined pipe is available with Victaulic grooved ends from leading companies

in different types of linings for corrosive services. The type of lining selected for a particular

operation is determined by the conditions under which the system will operate. Request publication 25.03 for use of rubber lined fittings on abrasive services.

A

B

F

O.D.

O.D.

0.030" R

Nominal

Size

Inches

mm

Pipe

Outside Diameter

Inches/mm

Gasket Seat

A

Gasket Width

B

Basic

Tolerance

10

Dimensions Inches/millimeters

Groove Dia.

C

Tol.

Tol.

Tol.

F

E

H

+.000 +0.000 (Mean +0.030

+.000

+.000

G

Basic (+0.00) Basic (+0.00) Basic (+0.00) 0.030 Dia.) 0.000 (Ref.)

Min.

Allow.

Wall

Thick.

T

FOR CORROSION AND/OR

ABRASION RESISTANCE

1

25

1.315 +0.013 0.013 0.562 0.030 0.312 0.030 1.190 0.015 0.437

33.4 +0.33 0.33 14.27 0.76 7.92 0.76 30.23 0.38 11.10

1.190

30.23

0.188

4.78

0.250

6.35

0.133

3.38

NOTE: Dimensions apply to steel pipe and

Victaulic fittings. *Based on nominal dimensions

(without tolerances).

Column 1 Nominal IPS Pipe Size. Nominal

Metric (ISO) Pipe Size.

Column 2 IPS Outside Diameter. Metric (ISO)

Outside Diameter. The outside diameter of cut

grooved pipe shall not vary more than the tolerance listed. For IPS pipe, the maximum allowable

tolerance from square cut ends is 0.030" for 2 - 3 ";

0.045" for 4 - 6"; and 0.060" for sizes 8" O.D. and

above measured from true square line. For (ISO)

metric pipe, the maximum allowable tolerance

from square cut ends is 0,76 mm for sizes 20 - 80

mm; 1,14 mm for sizes 100 - 150 mm; and 1,52

mm for sizes 200 mm and above, measured

from the true square line.

Column 3 Gasket Seat. The pipe surface

shall be free from indentations and projections

from the end of the pipe to the groove, to

provide a leak-tight seat for the gasket. All loose

paint, scale, dirt, chips, grease, and rust must be

removed. Rubber lining must be ground flush

with pipe O.D. to a smooth finish for proper

gasket seating.

It continues to be Victaulics recommendation

that pipe be square cut. Beveled pipe may not

be used. Gasket seat A is measured from the

end of the rubber lining.

Column 4 Groove Width. Bottom of groove

to be free of loose dirt, chips, rust and scale that

may interfere with proper coupling assembly.

Maximum permissible radius at bottom of

groove is 0.025" (0,64 mm).

Column 5 Groove Diameter. The groove must

be of uniform depth for the entire pipe circumference. Groove must be maintained within the

C diameter tolerance listed.

Column 6 Lead edge of groove to end of pipe

after machining to allow rubber lining.

Column 7 Diameter of undercut at the pipe

end provided for lining overlap. (Corrosion and/

or abrasion only).

Column 8 Metal thickness between groove

and lining undercut. (This dimension must be

maintained for proper joint strength.)

Column 9 Length of undercut provided for lining overlap. (Corrosion and/or abrasion only). For

reference only. Dimension F must be maintained.

1

32

1.660 +0.016 0.013 0.562 0.030 0.312 0.030 1.535 0.015 0.437

42.2 +0.41 0.33 14.27 0.76 7.92 0.76 38.99 0.38 11.10

1.535

38.99

0.188

4.78

0.250

6.35

0.140

3.56

1

40

1.900 +0.019 0.019 0.562 0.030 0.312 0.030 1.775 0.015 0.437

48.3 +0.48 0.48 14.27 0.76 7.92 0.76 45.09 0.38 11.10

1.775

45.09

0.188

4.78

0.250

6.35

0.145

3.68

2

50

2.375 +0.024 0.024 0.562 0.030 0.312 0.030 2.250 0.015 0.437

60.3 +0.61 0.61 14.27 0.76 7.92 0.76 57.15 0.38 11.10

2.250

57.15

0.188

4.78

0.250

6.35

0.154

3.91

2

65

2.875 +0.029 0.029 0.562 0.030 0.312 0.030 2.720 0.018 0.437

73.0 +0.74 0.74 14.27 0.76 7.92 0.76 69.09 0.46 11.10

2.720

69.09

0.188

4.78

0.250

6.35

0.188

4.78

3 O.D.

3.000 +0.030 0.030 0.562 0.030 0.312 0.030 2.845 0.018 0.437

76.1 +0.76 0.76 14.27 0.76 7.92 0.76 72.26 0.46 11.10

2.845

72.26

0.188

4.78

0.250

6.35

0.188

4.78

3

80

3.500 +0.035 0.031 0.562 0.030 0.312 0.030 3.344 0.018 0.437

88.9 +0.89 0.79 14.27 0.76 7.92 0.76 84.94 0.46 11.10

3.344

84.94

0.188

4.78

0.250

6.35

0.188

4.78

3

90

4.000 +0.040 0.031 0.562 0.030 0.312 0.030 3.834 0.020 0.437

101.6 +1.02 0.79 14.27 0.76 7.92 0.76 97.38 0.51 11.10

3.834

97.38

0.188

4.78

0.250

6.35

0.188

4.78

4

100

4.500 +0.045 0.031 0.562 0.030 0.344 0.030 4.334 0.020 0.437 4.334 0.188

114.3 +1.14 0.79 14.27 0.76 8.73 0.76 110.08 0.51 11.10 110.08 4.78

0.250

6.35

0.203

5.16

5

125

5.563 +0.056 0.031 0.562 0.030 0.344 0.030 5.395 0.022 0.437 5.395 0.188

141.3 +1.42 0.79 14.27 0.76 8.73 0.76 137.03 0.56 11.10 137.03 4.78

0.250

6.35

0.203

5.16

6. O.D.

6.500 +0.063 0.031 0.562 0.030 0.344 0.030 6.330 0.022 0.437 6.330 0.188

165.1 +1.60 0.79 14.27 0.76 8.73 0.76 160.78 0.56 11.10 160.78 4.78

0.250

6.35

0.219

5.56

6

150

6.625 +0.063 0.031 0.562 0.030 0.344 0.030 6.455 0.022 0.437 6.455 0.188

168.3 +1.60 0.79 14.27 0.76 8.73 0.76 163.96 0.56 11.10 163.96 4.78

0.250

6.35

0.219

5.56

8

200

8.625 +0.063 0.031 0.625 0.030 0.469 0.030 8.441 0.025 0.500 8.441 0.219

219.1 +1.60 0.79 15.88 0.76 11.91 0.76 214.40 0.64 12.70 214.40 5.56

0.281

7.14

0.238

6.05

10

250

10.750 +0.063 0.031 0.625 0.030 0.469 0.030 10.562 0.027 0.500 10.562 0.219

273.0 +1.60 0.79 15.88 0.76 11.91 0.76 268.28 0.69 12.70 268.28 5.56

0.281

7.14

0.250

6.35

12

300

12.750 +0.063 0.031 0.625 0.030 0.469 0.030 12.531 0.030 0.500 12.531 0.219

323.9 +1.60 0,79 15.88 0.76 11.91 0.76 318.29 0.76 12.70 318.29 5.56

0.281

7.14

0.279

7.09

14

350

14.000 +0.063 0.031 0.938 0.030 0.500 0.030 13.781 0.030 0.813 13.781 0.344

355.6 +1.60 0.79 23.83 0.76 12.70 0.76 350.04 0.76 20.65 350.04 8.74

0.469

11.91

0.281

7.14

16

400

16.000 +0.063 0.031 0.938 0.030 0.500 0.030 15.781 0.030 0.813 15.781 0.344

406.4 +1.60 0.79 23.83 0.76 12.70 0.76 400.84 0.76 20.65 400.84 8.74

0.469

11.91

0.312

7.92

18

450

18.000 +0.063 0.031 1.000 0.030 0.500 0.030 17.781 0.030 0.875 17.781 0.344

457.2 +1.60 0.79 25.40 0.76 12.70 0.76 451.64 0.76 22.23 451.64 8.74

0.531

13.49

0.312

7.92

20

500

20.000 +0.063 0.031 1.000 0.030 0.500 0.030 19.781 0.030 0.875 19.781 0.344

508.0 +1.60 0.79 25.40 0.76 12.70 0.76 502.44 0.76 22.23 502.44 8.74

0.531

13.49

0.312

7.92

22

550

22.000 +0.063 0.031 1.000 0.060 0.500 0.030 21.656 0.030 0.875 21.656 0.344

559.0 +1.60 0.79 25.40 1.52 12.70 0.76 550.06 0.76 22.23 550.06 8.74

0.531

13.49

0.375

9.53

24

600

24.000 +0.063 0.031 1.000 0.060 0.500 0.030 23.656 0.030 0.875 23.656 0.344

610.0 +1.60 0.79 25.40 1.52 12.70 0.76 600.86 0.76 22.23 600.86 8.74

0.531

13.49

0.375

9.53

30

750

30.000 +0.063 0.031 1.750 0.060 0.625 0.030 29.500 0.063 1.625 29.500 0.563

762.0 +1.60 0.79 44.45 1.52 15.88 0.76 749.30 1.60 41.28 749.30 14.30

1.063

27.00

0.625

15.88

36

900

36.000 +0.093 0.031 1.750 0.060 0.625 0.030 35.500 0.063 1.625 35.500 0.563

914.4 +2.36 0.79 44.45 1.52 15.88 0.76 901.7 1.60 41.28 901.7 14.30

1.063

27.00

0.625

15.88

For complete contact information, visit www.victaulic.com

25.10

6920 REV A

UPDATED 09/2010

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. 2010 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

25.10

You might also like

- Steel Truss Design CalculatorDocument4 pagesSteel Truss Design CalculatorPrashant ShindeNo ratings yet

- Specification For Fired HeatersDocument17 pagesSpecification For Fired HeatersibadalamNo ratings yet

- Quizlet Table 6Document14 pagesQuizlet Table 6JosielynNo ratings yet

- Thesis - Effect of Pulverized Waste Terracotta Clay Pots From Pampanga As Partial Cement ReplacementDocument47 pagesThesis - Effect of Pulverized Waste Terracotta Clay Pots From Pampanga As Partial Cement ReplacementPamelaB.Hsu100% (1)

- 25.03 MRL For Abrasive ServiceDocument1 page25.03 MRL For Abrasive ServiceAnonymous LeC3YexoBoNo ratings yet

- Endseal Pipe Groove SpecificationsDocument4 pagesEndseal Pipe Groove SpecificationsJason MillerNo ratings yet

- 25.03 - Vitaulic RanuradoDocument3 pages25.03 - Vitaulic RanuradoABAD ALEXANDER MORENO ZÁRATENo ratings yet

- B-05 Standard Roll Groove-RevFDocument2 pagesB-05 Standard Roll Groove-RevFAgreen AnggadaNo ratings yet

- B-05 Standard Roll Groove-RevGDocument2 pagesB-05 Standard Roll Groove-RevGDeniNo ratings yet

- Sieve SizeDocument3 pagesSieve SizeSse SteelNo ratings yet

- Technical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40Document5 pagesTechnical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40mechmohsin4745No ratings yet

- Machining For Rubber Lining (MRL) : Rubber or Urethane Lined PipeDocument1 pageMachining For Rubber Lining (MRL) : Rubber or Urethane Lined PipeAnthony RamosNo ratings yet

- Ti Weight Tables - PipeDocument2 pagesTi Weight Tables - PipeOscar Soco Reuyan Jr.No ratings yet

- Sagar Engineering Works JaipurDocument6 pagesSagar Engineering Works JaipurSagarNo ratings yet

- Es Cut Groove Specifications 25.02Document3 pagesEs Cut Groove Specifications 25.02Mathew WolfNo ratings yet

- Din 2448Document1 pageDin 2448IsaacNo ratings yet

- Appendix B: Pipe Size DataDocument7 pagesAppendix B: Pipe Size DataSatyshikh SrivNo ratings yet

- Kaiser Aluminum Hard Alloy Drawn Seamless Tube CapabilitiesDocument7 pagesKaiser Aluminum Hard Alloy Drawn Seamless Tube CapabilitiesJM SVNo ratings yet

- Thread Data ChartDocument71 pagesThread Data ChartVishal BhanderiNo ratings yet

- Sound AttenuatorDocument4 pagesSound AttenuatorFareethAbdullahNo ratings yet

- 1core Aluminium Xlpe ArmouredDocument1 page1core Aluminium Xlpe Armouredrobinknit2009No ratings yet

- Metric Coarse Thread Data PDFDocument3 pagesMetric Coarse Thread Data PDFEndalkachew AbateNo ratings yet

- C Purlin FlyerDocument4 pagesC Purlin FlyerLer Kai HuiNo ratings yet

- Copper Cable Tech. DetailsDocument8 pagesCopper Cable Tech. DetailsDaya CheluvaNo ratings yet

- Final Correct Isolated FootingDocument20 pagesFinal Correct Isolated FootingK. S. Design GroupNo ratings yet

- Pipe Sizing & Specifications Methods For Joining Pipe Pipe Representation Pipe Fittings Buttwelded Branch Fittings Flanges Screwed FittingsDocument27 pagesPipe Sizing & Specifications Methods For Joining Pipe Pipe Representation Pipe Fittings Buttwelded Branch Fittings Flanges Screwed Fittingsrodhiba1No ratings yet

- NYY 1 X (1.5-500) MM 0.6/1 KVDocument5 pagesNYY 1 X (1.5-500) MM 0.6/1 KVFebi HerdianaNo ratings yet

- Tyler: ASTM Sieve Chart and EquivalentsDocument1 pageTyler: ASTM Sieve Chart and EquivalentsWilder CubaNo ratings yet

- Table 8 Commercial Pipe Sizes and Wall ThicknessesDocument1 pageTable 8 Commercial Pipe Sizes and Wall ThicknessesYahia Abou-ShoshaNo ratings yet

- Dimensions & Sizes For Mild Steel Pipes Confirming To IS: 1239 (PART I) - MS Pipes Sizes in IndiaDocument5 pagesDimensions & Sizes For Mild Steel Pipes Confirming To IS: 1239 (PART I) - MS Pipes Sizes in IndiaS. R. OvhalNo ratings yet

- 1 Core Copper Xlpe Armoured & Unarmoured Power CablesDocument1 page1 Core Copper Xlpe Armoured & Unarmoured Power CablesSikandar MirzaNo ratings yet

- Metric Screw Dimensions ISO FastenersDocument2 pagesMetric Screw Dimensions ISO FastenersHarshal JadhavNo ratings yet

- Copper Pipes To BS EN 1057Document12 pagesCopper Pipes To BS EN 1057wkcNo ratings yet

- Metric Screw Dimensions ISO Fasteners PDFDocument2 pagesMetric Screw Dimensions ISO Fasteners PDFHarshal JadhavNo ratings yet

- R2T Hose Data Sheet PDFDocument1 pageR2T Hose Data Sheet PDFNagarjunSHNo ratings yet

- KabelmetaDocument1 pageKabelmetaLinda Soraya SeptianaNo ratings yet

- Nyy - Iec PDFDocument5 pagesNyy - Iec PDFbenryNo ratings yet

- Civil Construction ActivitiesDocument3 pagesCivil Construction ActivitiessreeluNo ratings yet

- NYSYDocument5 pagesNYSYRinda_RaynaNo ratings yet

- Astm A53Document2 pagesAstm A53joseocsilvaNo ratings yet

- Concrete NotesDocument37 pagesConcrete Notesကိုနေဝင်းNo ratings yet

- Pipe Rack Load CalculationDocument3 pagesPipe Rack Load CalculationKrunalpanchalNo ratings yet

- Technical Details: WipersDocument4 pagesTechnical Details: WipersRPINILLA (EICO S.A.)No ratings yet

- PVC Insulated Heavy Duty Cables: Wiring The WorldDocument23 pagesPVC Insulated Heavy Duty Cables: Wiring The WorldPritam SinghNo ratings yet

- TEW/AWM 1015/ 1019/1020/1230 MTW: ApplicationsDocument2 pagesTEW/AWM 1015/ 1019/1020/1230 MTW: ApplicationsJesús SánchezNo ratings yet

- Tuberia A Presion Canal ChalluayacuDocument5 pagesTuberia A Presion Canal ChalluayacuWilder Lozano VivianNo ratings yet

- Drillmaster: Silicone Ventilation HoseDocument1 pageDrillmaster: Silicone Ventilation HoseG&GIndustrialNo ratings yet

- BS-5467 1Document2 pagesBS-5467 1Yazhar MuhammedNo ratings yet

- Well Tube 1050514Document12 pagesWell Tube 1050514Mustafa AlhoubaniNo ratings yet

- THDFRM 3Document1 pageTHDFRM 3AS BaizidiNo ratings yet

- Hydraulic Statement OverallDocument21 pagesHydraulic Statement OverallNeil AgshikarNo ratings yet

- Week 6 & 7-Specific Weight, Water-Absorption, Abrasion, DensityDocument27 pagesWeek 6 & 7-Specific Weight, Water-Absorption, Abrasion, DensitySamantha NamzugNo ratings yet

- ThreadsDocument11 pagesThreadsBuddha PrakashNo ratings yet

- Metric Screw Dimensions ISO Fasteners PDFDocument3 pagesMetric Screw Dimensions ISO Fasteners PDFEndalkachew AbateNo ratings yet

- 22 HDPE Pipe Oil GasDocument2 pages22 HDPE Pipe Oil GasArunkumar SelvamNo ratings yet

- Particle Size Conversion TableDocument2 pagesParticle Size Conversion TableVivi Oktavianti0% (1)

- Analisa Harga Satuan PlumbingDocument13 pagesAnalisa Harga Satuan PlumbingDaman Huri Wibowo100% (1)

- Catalog Profile Cu Pereti SubtiriDocument52 pagesCatalog Profile Cu Pereti Subtirinelutu12345100% (1)

- TABLE 1-2 Concrete ProportionDocument17 pagesTABLE 1-2 Concrete ProportionkifermaybzNo ratings yet

- NyaDocument1 pageNyaahmat kharisNo ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXXII, June, 1911 Water Purification Plant, Washington, D. C. Results of Operation.From EverandTransactions of the American Society of Civil Engineers, vol. LXXII, June, 1911 Water Purification Plant, Washington, D. C. Results of Operation.No ratings yet

- CCC2023 028Document7 pagesCCC2023 028majed sawanNo ratings yet

- (USBR) - 2011 - Chapter 8 Seepage PDFDocument186 pages(USBR) - 2011 - Chapter 8 Seepage PDFEvandro_JNo ratings yet

- Is Thicker Gasket Material Better Than ThinnerDocument2 pagesIs Thicker Gasket Material Better Than ThinnerSteven LiparotoNo ratings yet

- RCC54 Circular Column ChartingDocument13 pagesRCC54 Circular Column ChartingvaideehNo ratings yet

- Installation Manual: Split System Air ConditionersDocument20 pagesInstallation Manual: Split System Air ConditionersbenNo ratings yet

- Bridge Technical Note 2001 - 005 Approach SlabsDocument3 pagesBridge Technical Note 2001 - 005 Approach SlabsChen YishengNo ratings yet

- Juan de La Cruz: Registered Civil EngineerDocument2 pagesJuan de La Cruz: Registered Civil EngineerDA InhinyeraNo ratings yet

- Catalog Spesifikasi SDVDocument8 pagesCatalog Spesifikasi SDVAdi Kira YamatoNo ratings yet

- Building Wire Catalogue-Al FanarDocument34 pagesBuilding Wire Catalogue-Al FanarJabir QuadriNo ratings yet

- Design of Pile Cap For ESP Supports Unit 2 & 5 ModDocument84 pagesDesign of Pile Cap For ESP Supports Unit 2 & 5 Modasingh400No ratings yet

- DAFZ RegulationsDocument41 pagesDAFZ RegulationsRoger SchulpNo ratings yet

- Ductile Building DesignDocument3 pagesDuctile Building DesignroseNo ratings yet

- Twin Hearth FurnaceDocument3 pagesTwin Hearth Furnaceshreyasi_mahantyNo ratings yet

- Community Liaison Management PlanDocument26 pagesCommunity Liaison Management PlanJoseph EgonaNo ratings yet

- BICE-011 Drawing Sheet B. Tech. Civil Engineering (Btclevi) Term-End Examination December, 2013 Bice-011: Structural Analysis - IiDocument3 pagesBICE-011 Drawing Sheet B. Tech. Civil Engineering (Btclevi) Term-End Examination December, 2013 Bice-011: Structural Analysis - IiSri DNo ratings yet

- Septic Tank From The ConstructurDocument4 pagesSeptic Tank From The ConstructurTech BakeNo ratings yet

- Bill of Materials PoolDocument1 pageBill of Materials PoolJustine Yap100% (1)

- Ar20700942 Oth SchematicDocument6 pagesAr20700942 Oth SchematicMahela RupasingheNo ratings yet

- Autocalculator v. 16.00 i113001ENDocument53 pagesAutocalculator v. 16.00 i113001ENstikss100% (1)

- NASC-SG4 2022 Preventing Falls in Scaffolding OperatonsDocument74 pagesNASC-SG4 2022 Preventing Falls in Scaffolding OperatonsArdamit100% (2)

- A 297 - A 297M - 97 R98 Qti5ny05n1i5oaDocument3 pagesA 297 - A 297M - 97 R98 Qti5ny05n1i5oaJuan Sebastián Londoño MartínezNo ratings yet

- 02 ThermoPEXDocument38 pages02 ThermoPEXMohammad Rashad BarakatNo ratings yet

- Lecture 10 Electrical Design Considrations For Residential BuildingDocument11 pagesLecture 10 Electrical Design Considrations For Residential BuildingBUKENYA BEEE-2026100% (1)

- Seismic Resistance Steel Building StructuresDocument209 pagesSeismic Resistance Steel Building StructuresyahNo ratings yet

- Stetter M1 M225 - enDocument12 pagesStetter M1 M225 - enNandhagopalan KNo ratings yet