Professional Documents

Culture Documents

Process Load Sheet For: Additive Tank 03-TA-05

Process Load Sheet For: Additive Tank 03-TA-05

Uploaded by

WawanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Load Sheet For: Additive Tank 03-TA-05

Process Load Sheet For: Additive Tank 03-TA-05

Uploaded by

WawanCopyright:

Available Formats

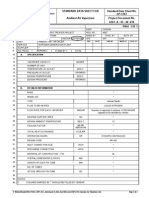

UPGRADING UNIT PRODUKSI PELUMAS JAKARTA

PROCESS LOAD SHEET FOR

ADDITIVE TANK

03-TA-05

DOC. NO.

DS-03-018-126

CLIENT

PT. PERTAMINA (Persero)

PROJECT TITLE

UPGRADING UNIT PRODUKSI PELUMAS JAKARTA PROJECT

LOCATION

TANJUNG PRIOK - JAKARTA

CONTRACT NO.

LATER

JOB. NO

2F1002

11-Mar-11

REV

DATE

Issued for Information

DESCRIPTION

SM/NK

AM/IRJ

IRJ

Prep'd

Check'd

Appr'd

By

Date

Client Approval

PROCESS - DATASHEET

ADDITIVE TANK

REV

B

ENGINEERING PROCUREMENT

CONSTRUCTION

DESCRIPTION

BY

CHK'D APP'D

DATE

SM/NK AM/IRJ

IRJ

11-Mar-11

Issued for Information

UUPPJ PROJECT

1

2

3

4

5

TAG NUMBER

SERVICE

NUMBER

P&ID

DOCUMENT NO

:

:

:

:

:

03-TA-05

ADDITIVE TANK

1 (ONE) UNIT

DS-03-018-126

OPERATING

N5

PROCESS DESIGN

N3

7

8

9

Pressure

Temperature

ATM

Full of Liquid

38 oC

48 oC

N4

N 11

MW 2

N6

10

11

12

13

Materials

Corrosion allow

Carbon Steel

Fluid

Viscosity

Specific Gravity

Vapor Pressure

Additive A18

o

2520 cSt @ 40 C

1.021 @ 15.6 oC

Insulation

Lining

Working Capacity

Nominal Capacity

Dimension (ID X H)

Addition :

- Flame Arrestor

- Breather Valve

Yes (2 m from bottom)

N/A

2000

m3

2182

m3

13.38

15.52

m x

N7

14

15

16

17

18

19

MW1

20

22

23

24

25

26

27

28

29

N9

N1

21

N10

N8

N2

No

Yes

30

31

32

Vessel Heating

Suction Heater c/w Hot Insulation

LIQUID LEVEL

NOZZLE DATA

33

Level (mm)

34

35

36

37

LLLL

LLL

HLL

500

550

14725

38

39

40

41

42

43

44

45

46

47

48

49

Notes :

1. Inlet nozzle size based on 400 m3/h (max. loading arm capacity)

Ref

Nb

MW1

MW2

N1

N2

N3

N4

N5

N6

N7

N8

N9

N10

N11

1

1

1

1

1

1

1

1

1

1

1

1

1

inch

24

24

10 (*1)

2

2

2

B

6

2

2

6

2

2

3

Rating-Facing

Service

150# - RF

150# - RF

150# - RF

150# - RF

150# - RF

150# - RF

150# - RF

150# - RF

150# - RF

150# - RF

150# - RF

150# - RF

150# - RF

Man Hole

Man Hole

Liquid Inlet

Manual Drain

Level Transmitter

Level Switch

Vent

Overflow

Temperature Transmitter

Liquid Outlet

Steam Coil Inlet

Steam Coil Outlet

Return Line

ATTACHMENT

1.

Basis of Calculation

2.

Calculation Sheet

3.

Nozzle Calculation

4.

Venting Calculation

UPGRADING UNIT PRODUKSI PELUMAS JAKARTA

BASIS OF CALCULATION - ADDITIVE TANK 03-TA-05

CLIENT

Page

PT. PERTAMINA (Persero)

LOCATION

TANJUNG PRIOK - JAKARTA

PROJECT

UPGRADING UNIT PRODUKSI PELUMAS JAKARTA PROJECT

PROJECT NO.

2F1002

DOC. NO.

DS-03-018-126

Prp.

Chk.

Apr.

Date

SM/NK

AM/IRJ

IRJ

11-Mar-11

BASIS OF CALCULATION - ADDITIVE TANK 03-TA-05

2

3

4

5

Objective

To size the Additive Tank

6

7

Basis

1. Density of Additive

2. Additive Filling rate capacity

3

1019.9 kg/m

400

m3/hr

(Max. Marine Loading Arm transfer rate capacity)

10

11

Assumption

12

1. Additive supply

13

2. Estimated holding time is

m3/hr

285.7 hr =

11.9

days

14

15

Calculations

16

1. Size of the Additive Tank

17

Required working volume

2000.0

m3

18

Margin 0%

2000.0

m3

19

20

The Working Volume of the Additive Tank Provided

2000

m3

21

Tank Volume / Capacity

2182

m3

22

23

24

25

26

27

28

29

30

31

32

of

Rev.

UPGRADING UNIT PRODUKSI PELUMAS JAKARTA

ADDITIVE TANK 03-TA-05 - CALCULATION

CLIENT

PT. PERTAMINA (Persero)

LOCATION

TANJUNG PRIOK - JAKARTA

PROJECT

UPGRADING UNIT PRODUKSI PELUMAS JAKARTA PROJECT

PROJECT NO.

2F1002

DOC. NO.

DS-03-018-126

Page

of

Rev.

Prp.

Chk.

Apr.

Date

SM/NK

AM/IRJ

IRJ

11-Mar-11

Calculations

2

3

4

H.L.L

h3

h3 =

vapor space

h2 =

height of working volume

6

7

8

h2

15520 mm

L.L.L

10

11

h1c

12

h1

13

h1 =

h1b

h1a

14

bottom to L.L.L space

Outlet nozzle

15

13380 mm

16

17

1.

h1 (Bottom to L.L.L space) calculation

(defined as per API 650)

6 in. NPS

18

Outlet nozzle diameter

19

h1a

200 mm

20

h1b

21

h1c

76.2 mm

152.4 mm

428.6 mm

h1

22

(From Table 3.6 API 650)

( = 0.5 * Nozzle OD)

( = 1 * Nozzle OD)

Take

h1

500 mm

23

24

2.

h2 (Height of working volume) calculation

2000.0 m3

Est. working volume

25

Take

1.063

26

27

H/D Ratio

1.101

28

Diameter

29

Height

13380 mm

14726 mm

30

31

3.

h3 (vapor space)

790 mm

32

33

Final Dimension

34

Diameter

35

Height

36

H/D check

37

Total Capacity

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

13380 mm

15520 mm

1.16

2182.2 m3

h2

13380 mm

14226 mm

Calc. working vol.

2000.25 m3

OK !

UPGRADING UNIT PRODUKSI PELUMAS JAKARTA

Page 3

ADDITIVE TANK 03-TA-05 - NOZZLE AND LIQUID LEVEL CALCULATION

CLIENT

LOCATION

PROJECT

PROJECT NO.

DOC. NO.

PT. PERTAMINA (Persero)

TANJUNG PRIOK - JAKARTA

UPGRADING UNIT PRODUKSI PELUMAS JAKARTA PROJECT

REV

BY

SM/NK

2F1002

DS-03-018-126

CHECK

AM/IRJ

APPR.

IRJ

Liquid Inlet

of

DATE

11-Mar-11

Liquid Outlet

Mass Flow =

Density =

Act Vol. Flow =

407,960 kg/hr

Mass Flow =

1019.9 kg/m3

400.00 m3/hr

7,139 kg/hr

Actual Vol. Flow =

1019.9 kg/m3

7.00 m3/hr

Design Pump Flow =

7.70 m3/hr

Density =

Design For One Tank:

Holding Time =

Liquid Volume =

LLLL =

285.7 hours

2000.0 m3

0.500 m

(LLLL~HLL)/D =

1.063

Tank Diameter =

13.38 m

LLLL~HLL =

14.225 m

Vapour space Height =

5.26 %

0.79 m

Tank Height =

15.52 m

Tank Volume =

H/D =

2182 m3

1.16

LLL Calculation

working vol. : 2000 m3

HLL

0.79

14.23

dL (in)

15.52

LLL

0.05 m

LLLL

h1c

0.50

h1b

h1a (mm) =

200

h1b (mm) =

76.2

h1c (mm) =

152.4

h1

428.6

(mm) =

Take LLLL(mm)

500

dL

h1a

LLLL~LLL Calc

13.38

#REF!

in

Hold time (min)

Liquid Inlet Nozzle diameter :

dF =

10 in

ID =

AF =

vF =

0.0511 m2

2.1756 m/s

vF =

FvF2 =

Take (mm)

10.039

4827.6090 kg/m.s2

FvF =

Liquid Outlet Nozzle diameter :

dF =

6 in

ID =

AF =

LLLL~LLL (mm)

OK!

6.063

0.0186 m2

0.1148 m/s

13.4484 kg/m.s2

OK!

5

4.56

50

UPGRADING UNIT PRODUKSI PELUMAS JAKARTA

ADDITIVE TANK 03-TA-05 - VENT SIZE CALCULATION

Page

CLIENT

PT. PERTAMINA (Persero)

LOCATION

TANJUNG PRIOK - JAKARTA

PROJECT

UPGRADING UNIT PRODUKSI PELUMAS JAKARTA PROJECT

PROJECT NO.

2F1002

DOC. NO.

DS-03-018-126

of

Rev.

Prep.

Chk.

Apr.

Date

SM/NK

AM/IRJ

IRJ

11-Mar-11

Vent Nozzle Size Calculation (Based on API 2000)

1

2

Tank Capacity (Nominal)

2182

m3

Liquid flash point

200

Liquid normal boiling point

Wetted surface area

100

619.00

3

4

m2

8

9

1.

Inbreathing

10

11

Q1 (Maximum Movement Out of Tank)

5.6

SCFH of Air

per

CFH of Liquid Outflow

12

(per section 4.3.2.1.1)

0.94

Nm3/hr of Air

per

m3/hr of Liquid Outflow

13

Outflow

14

Air inlet

(Table A.1 of API-2000 Ed 2009)

7.7 m3/hr

7.2 Nm3/hr

15

16

Q2 (Thermal Inbreathing)

17

(per section 4.3.2.1.2)

Total Vacuum Relief Required (Q)

12988 Nm3/hr

367.8 Nm3/hr

(Interpolation Table A.3 of API-2000 ed. 2009)

18

19

20

21

Q1

7.2 Nm3/hr

375.0 Nm3/hr

Q2

367.8 Nm3/hr

22

23

24

2.

Outbreathing - Pressure Relief

25

26

Q1 (Maximum Movement IntoTank)

SCFH of Air

per

CFH of Liquid Outflow

27

(per section 4.3.2.1.1)

1.01

Nm3/hr of Air

per

m3/hr of Liquid Outflow

28

Inflow

29

Air outlet

(Table A.1 of API-2000 Ed 2009)

400.0 m3/hr

404.0 Nm3/hr

30

31

Q2 (Thermal Outbreathing)

32

(per section 4.3.2.1.2)

Total Vacuum Relief Required (Q)

7787 ft3/hr

220.7 Nm3/hr

(Interpolation Table A.3 of API-2000 ed. 2009)

33

34

35

36

Q1

404.0 Nm3/hr

624.7 Nm3/hr

Q2

220.7 Nm3/hr

37

38

39

3.

Take the largest from (1) and (2) :

40

624.7

362.3

41

Maximum velocity at nozzle

42

Pipe size

Nm3/hr

Am3/hr

10.0 m/s

Q x4

0.8 x x 3600

43

44

45

113

mm

46

4.46

in

in

47

48

49

50

51

Take pipe size

(minimum 2 in)

You might also like

- Sample Calculation Drainage Design (Road Side Drain)Document3 pagesSample Calculation Drainage Design (Road Side Drain)Lokman Hakim100% (4)

- Boiler FoundationDocument36 pagesBoiler FoundationMochammad ShokehNo ratings yet

- How To Review PV Elite Design Report PDFDocument9 pagesHow To Review PV Elite Design Report PDFprocess process100% (1)

- API520 RVsizingDocument7 pagesAPI520 RVsizingdemem09100% (3)

- Awwa 1500m3 r6 18kDocument44 pagesAwwa 1500m3 r6 18kpertmaster100% (2)

- 2-4 Shell and Tube Heat Exchanger (Problem)Document35 pages2-4 Shell and Tube Heat Exchanger (Problem)Qamar Munir100% (1)

- Desain Pondasi Tanki 550 m3 Tahan GempaDocument37 pagesDesain Pondasi Tanki 550 m3 Tahan GempaYayan LesmanaNo ratings yet

- Weld Map Pressure VesselDocument32 pagesWeld Map Pressure Vesseljasmineamma100% (4)

- Water Demand CalculationDocument9 pagesWater Demand CalculationAsmatSalSabilaNo ratings yet

- Drift Test ProcedureDocument15 pagesDrift Test ProcedureNaPo ServiceNo ratings yet

- Lion Air Eticket (KNFEPG) - SetiadiDocument10 pagesLion Air Eticket (KNFEPG) - SetiadiWawanNo ratings yet

- CNC Book PDFDocument342 pagesCNC Book PDFDr V.Suresh Babu100% (4)

- Basic Cycles 40120519Document20 pagesBasic Cycles 40120519Pulkit SethiNo ratings yet

- Process Load Sheet For: Additive Tank 03-TA-02Document7 pagesProcess Load Sheet For: Additive Tank 03-TA-02WawanNo ratings yet

- Process Load Sheet For: Additive Tank 03-TA-01Document7 pagesProcess Load Sheet For: Additive Tank 03-TA-01WawanNo ratings yet

- Process Load Sheet For: Abb Swing Holding Tank 03-TH-02Document7 pagesProcess Load Sheet For: Abb Swing Holding Tank 03-TH-02WawanNo ratings yet

- Process Load Sheet For: Abb Swing Holding Tank 03-TH-05Document7 pagesProcess Load Sheet For: Abb Swing Holding Tank 03-TH-05WawanNo ratings yet

- T-502 Cover 3Document2 pagesT-502 Cover 3SriyonoNo ratings yet

- Doc. No. 01 - 42 10 002 - OCSDocument36 pagesDoc. No. 01 - 42 10 002 - OCSHerlambang sNo ratings yet

- M4 Deck DrawingsDocument544 pagesM4 Deck DrawingsVinay Kumar Neelam100% (1)

- Api 620 - 2002Document12 pagesApi 620 - 2002ductaiutc100% (1)

- 2phase Separator Size 2010 VerAADocument22 pages2phase Separator Size 2010 VerAAAnonymous a4Jwz14WNo ratings yet

- Fo System Revisi 1Document28 pagesFo System Revisi 1Panji Kresno WijanarkoNo ratings yet

- Design Calculation For Pipe SupportsDocument200 pagesDesign Calculation For Pipe Supportssanggytha100% (1)

- Steel Designer's Manual, 6th Edition, 2003 R20070821FDocument5 pagesSteel Designer's Manual, 6th Edition, 2003 R20070821Fsaad7159No ratings yet

- 00 BLANK Pipe Size Calc Sheet HWS - CWSDocument9 pages00 BLANK Pipe Size Calc Sheet HWS - CWSharoub_nasNo ratings yet

- Lista de Valvs PDFDocument5 pagesLista de Valvs PDFJose Alberto Uribe MinierNo ratings yet

- Va1 Tatl 00100 M M7 Cal 0001Document3 pagesVa1 Tatl 00100 M M7 Cal 0001hoangduythanhqbNo ratings yet

- Vessel'S Midnight Ullage ReportDocument33 pagesVessel'S Midnight Ullage ReportnawhiNo ratings yet

- 3 Phase - Overflow WeirDocument5 pages3 Phase - Overflow WeirAnonymous R23prjoKnoNo ratings yet

- Tonnage CalculationDocument5 pagesTonnage Calculationflip749wopNo ratings yet

- PSV - Folha de CalculosDocument4 pagesPSV - Folha de CalculosInspetor SoldagemNo ratings yet

- Pga1000998050010 01Document1 pagePga1000998050010 01Amit SaxenaNo ratings yet

- 8.8-Data Sheet EP-1103 (Ambient Air Vaporizers)Document1 page8.8-Data Sheet EP-1103 (Ambient Air Vaporizers)Fer VF100% (1)

- Natural Gas System Hydrualic Calculation: I.P.D.CDocument11 pagesNatural Gas System Hydrualic Calculation: I.P.D.CepbamdadNo ratings yet

- Larsen & Toubro Limited: 4/8/2012 A Issued For Review NSB BVR SDRDocument2 pagesLarsen & Toubro Limited: 4/8/2012 A Issued For Review NSB BVR SDRvrajan1988No ratings yet

- CCI Valve Technology AB: Rev Date Description SignDocument3 pagesCCI Valve Technology AB: Rev Date Description SignHumayun NawazNo ratings yet

- SC/V Pneumatic Piston Actuator Data Sheet: G E N E R A LDocument1 pageSC/V Pneumatic Piston Actuator Data Sheet: G E N E R A LHumayun NawazNo ratings yet

- Soil Stack 1: Calculation SheetDocument10 pagesSoil Stack 1: Calculation SheetSaviour UdoNo ratings yet

- Co Co: U-Trac U-TracDocument24 pagesCo Co: U-Trac U-Tracrudiskw456No ratings yet

- Mac LS 0 002 0Document4 pagesMac LS 0 002 0arifayee-1No ratings yet

- Reference Drawing/ Document:: 1. Jumpering of IO Signals at DCS End Shall Be Done by BHELDocument5 pagesReference Drawing/ Document:: 1. Jumpering of IO Signals at DCS End Shall Be Done by BHELarunNo ratings yet

- Design Project1Document19 pagesDesign Project1Syed Munawar Ali100% (1)

- CCI Valve Technology AB: Rev Date Description SignDocument3 pagesCCI Valve Technology AB: Rev Date Description SignHumayun NawazNo ratings yet

- Report Office FoundationDocument11 pagesReport Office FoundationMochammad ShokehNo ratings yet

- Local Private Funded Asphalt Surfacing Project: MaterialDocument12 pagesLocal Private Funded Asphalt Surfacing Project: MaterialAhamed Manazir HazzaanNo ratings yet

- Ivar Aasen Field Development Project - PDQDocument3 pagesIvar Aasen Field Development Project - PDQayemyothantNo ratings yet

- Vessel'S Midnight Ullage ReportDocument33 pagesVessel'S Midnight Ullage ReportnawhiNo ratings yet

- 32.0 M Dia Roof Design ReportDocument124 pages32.0 M Dia Roof Design ReportsndpinNo ratings yet

- (Page Chapter 5 - ACGIH) : Velocity Pressure Method Calculation SheetDocument2 pages(Page Chapter 5 - ACGIH) : Velocity Pressure Method Calculation SheetBukhory Tajudin0% (1)

- S 110 1224 0901S - 1 - 0001Document27 pagesS 110 1224 0901S - 1 - 0001duongtuongNo ratings yet

- Perhitungan Compressed Air System Untuk KapalDocument30 pagesPerhitungan Compressed Air System Untuk KapaldhearNo ratings yet

- Zetkin Wall Thickness CalculationsDocument59 pagesZetkin Wall Thickness CalculationsKarthik Channamsetty67% (3)

- VA1 TATL 00100 M M7 DSU 0022.air Heater Drawing For Silo 18 KWDocument2 pagesVA1 TATL 00100 M M7 DSU 0022.air Heater Drawing For Silo 18 KWhoangduythanhqbNo ratings yet

- 3119-Gear Box Data Sheet Rev.01Document4 pages3119-Gear Box Data Sheet Rev.01SAHTEESHKUMARNo ratings yet

- Vessel'S Midnight Ullage ReportDocument33 pagesVessel'S Midnight Ullage ReportnawhiNo ratings yet

- Material Take Off: Pt. Gunanusa Utama Fabricators Dept.: Engineering Section: Prod. EngineeringDocument1 pageMaterial Take Off: Pt. Gunanusa Utama Fabricators Dept.: Engineering Section: Prod. EngineeringLousianna MariaNo ratings yet

- Vessel'S Midnight Ullage ReportDocument33 pagesVessel'S Midnight Ullage ReportnawhiNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Intake Sistem 875,000,000: Uraian Pekerjaan Jumlah Harga Total Grand TotalDocument5 pagesIntake Sistem 875,000,000: Uraian Pekerjaan Jumlah Harga Total Grand TotalWawanNo ratings yet

- FEMCO Support LetterDocument1 pageFEMCO Support LetterWawanNo ratings yet

- CNG LPG Supply Scope Summary To Be Filled Up by Vendor (Check List), 220120Document4 pagesCNG LPG Supply Scope Summary To Be Filled Up by Vendor (Check List), 220120WawanNo ratings yet

- The Application of Magnetic Uids in Sealing Nodes Designed For Operation in Difficult Conditions and in Machines Used in Sea EnvironmentDocument11 pagesThe Application of Magnetic Uids in Sealing Nodes Designed For Operation in Difficult Conditions and in Machines Used in Sea EnvironmentWawanNo ratings yet

- TB - Kietrans 61, TK - Star Marine 2561Document2 pagesTB - Kietrans 61, TK - Star Marine 2561WawanNo ratings yet

- Babel 1Document1 pageBabel 1WawanNo ratings yet

- Po BBM Zarindo BeltimDocument1 pagePo BBM Zarindo BeltimWawanNo ratings yet

- Process Load Sheet For: Additive Tank 03-TA-02Document7 pagesProcess Load Sheet For: Additive Tank 03-TA-02WawanNo ratings yet

- CBU-summary Manday Services-8Document1 pageCBU-summary Manday Services-8WawanNo ratings yet

- MDS For ZA Weigher Feeder (81-WQ-316)Document2 pagesMDS For ZA Weigher Feeder (81-WQ-316)WawanNo ratings yet

- MDS For Filler Weigher Feeder (81-WQ-317)Document2 pagesMDS For Filler Weigher Feeder (81-WQ-317)WawanNo ratings yet

- Process Load Sheet For: Additive Tank 03-TA-01Document7 pagesProcess Load Sheet For: Additive Tank 03-TA-01WawanNo ratings yet

- Process Load Sheet For: Additive Tank 03-TA-01Document7 pagesProcess Load Sheet For: Additive Tank 03-TA-01WawanNo ratings yet

- 03-TA-03 Rev-ADocument7 pages03-TA-03 Rev-AWawanNo ratings yet

- Process Load Sheet For: Additive Tank 03-TA-02Document7 pagesProcess Load Sheet For: Additive Tank 03-TA-02WawanNo ratings yet

- Process Load Sheet For: Abb Swing Holding Tank 03-TH-02Document7 pagesProcess Load Sheet For: Abb Swing Holding Tank 03-TH-02WawanNo ratings yet

- Pt. Persada Cipta Perkasa (PCP) : Purchase OrderDocument1 pagePt. Persada Cipta Perkasa (PCP) : Purchase OrderWawanNo ratings yet

- Timesheet Alat123Document2 pagesTimesheet Alat123WawanNo ratings yet

- Process Load Sheet For: Abb Swing Holding Tank 03-TH-05Document7 pagesProcess Load Sheet For: Abb Swing Holding Tank 03-TH-05WawanNo ratings yet

- Biaya Visit Belitung BBRDocument3 pagesBiaya Visit Belitung BBRWawanNo ratings yet

- Qqquo (: 6uemejeyDocument1 pageQqquo (: 6uemejeyWawanNo ratings yet

- Engineering, Procurement & Construction Mechanical / Piping, Civil / Structure / Fire Protection SystemDocument1 pageEngineering, Procurement & Construction Mechanical / Piping, Civil / Structure / Fire Protection SystemWawanNo ratings yet

- Lect.3.Material Balances With Recycle and BypassDocument12 pagesLect.3.Material Balances With Recycle and BypassBa 4xNo ratings yet

- CS Kurt Vise TwoViseDocument5 pagesCS Kurt Vise TwoViseJavier SuarezNo ratings yet

- Design of Machine Tool GBDocument39 pagesDesign of Machine Tool GBrahul bachuteNo ratings yet

- WiiiDocument46 pagesWiiiJunior Rido KamagiNo ratings yet

- Tercer PeriodoDocument58 pagesTercer PeriodoYessica Amparo Parra PeñaNo ratings yet

- P3LA-ME-DSH-001-A4 Rev-0 IFC Data Sheet For MFO Storage Tank - 16 Mar 2018Document4 pagesP3LA-ME-DSH-001-A4 Rev-0 IFC Data Sheet For MFO Storage Tank - 16 Mar 2018Pascal MadhawaditomaNo ratings yet

- Airport DiagramDocument1 pageAirport DiagramPranav SatputeNo ratings yet

- NGEC 5-1 Nature of Math PDFDocument12 pagesNGEC 5-1 Nature of Math PDFRochelle Anne Lubat100% (1)

- The Bar Charts Illustrate Number of Passengers Drop Off: N1 N2 N3 N4 N5 N6Document23 pagesThe Bar Charts Illustrate Number of Passengers Drop Off: N1 N2 N3 N4 N5 N6Đăng TranNo ratings yet

- Reporte Caja 15-04-24Document25 pagesReporte Caja 15-04-24MarcosMarcosLimaPeruNo ratings yet

- ADRV9009-W PCBZ Schematic RevBDocument9 pagesADRV9009-W PCBZ Schematic RevBdocoodo123No ratings yet

- GA - PID CompressorDocument3 pagesGA - PID CompressorShanu kumarNo ratings yet

- Slot Wise TimeTable of UG I Year For AutumnSemester2021-22Document15 pagesSlot Wise TimeTable of UG I Year For AutumnSemester2021-22Harshil SajanNo ratings yet

- Proposal For Bush ClearingDocument8 pagesProposal For Bush ClearingGagalo IL100% (1)

- Chavani Company FolderDocument11 pagesChavani Company FolderMark KNo ratings yet

- Ic Replace IIDocument5 pagesIc Replace IILuis EstradaNo ratings yet

- Programe CNC Fanuc VerificateDocument55 pagesPrograme CNC Fanuc VerificateMITICA_VLADNo ratings yet

- Homework 4 SolutionsDocument16 pagesHomework 4 SolutionsAE ENo ratings yet

- A Readers Theater Adaptation of Chicken Big by Keith GravesDocument7 pagesA Readers Theater Adaptation of Chicken Big by Keith GravesJared MoyaNo ratings yet

- Public Super Shot BayTek Service ManualDocument67 pagesPublic Super Shot BayTek Service ManualEdward JANo ratings yet

- Chart UmurDocument21 pagesChart UmurRisman ChandraNo ratings yet

- Path Based Definitions-93-95Document3 pagesPath Based Definitions-93-95digital ali100% (1)

- U1 ATI BD Ejemplo Corresp.Document6 pagesU1 ATI BD Ejemplo Corresp.Jorege RangelNo ratings yet

- Flight Uuee LtaiDocument82 pagesFlight Uuee Ltairusik0463.terNo ratings yet

- Surface Roughness ConversionDocument1 pageSurface Roughness ConversionLuan Kien Tan100% (2)

- Nourice Type 1 - OutDocument83 pagesNourice Type 1 - OutsereNo ratings yet