Professional Documents

Culture Documents

Textile Chemical Finishing and Its Mechanisms: Mechanisms of The Softening Effect

Textile Chemical Finishing and Its Mechanisms: Mechanisms of The Softening Effect

Uploaded by

Farhan ParvaizOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Textile Chemical Finishing and Its Mechanisms: Mechanisms of The Softening Effect

Textile Chemical Finishing and Its Mechanisms: Mechanisms of The Softening Effect

Uploaded by

Farhan ParvaizCopyright:

Available Formats

Textile Chemical Finishing And Its Mechanisms

By :- AVM Chemical Industries.

In final finishing, with its great range of desired and undesired effects, the task of a textile

finisher can become demanding has to consider the compatibility of the different type of

finishing products and treatment, in particular their mutual influence on the desired

effects. With about different type of finishes and several finishing agents, most of which

are combined to give one-bath multipurpose finishes. Chemical finishing need a solid

basis of textile chemical knowledge and technical understanding as well as some practical

experience.

The term finishing, in a broad sense covers all the processes which the fabric undergoes

after leaving the loom or the knitting machine to the stage at which it enters the market.

This the term also includes bleaching, dyeing, mercerizing etc. but normally the term in

restricted to the final stage in the sequence of treatment of woven fabrics after bleaching

and dyeing. However fabrics which are neither bleached nor dyed are also finished. Some

finishing processes such as creping of silk and rayon, mercerization of cotton or crabbing

of wool are carried out a part of the fires phase of fabric treatment or over earlier, in the

form of yarn. Hence finishing is the term usually employed for processes. The

appearance may by qualitatively describe as clear or fibrous, fine or course, lustrous or

matt, plain or patterned and smooth or uneven.

These descriptions may be considered as the two extremes in each pair and the actual

fabric appearance may range between them. The fabric may not have the best in all these

pairs for example; a clear finished fabric can be either lustrous or matt. Similarly the

handle of fabric may be soft or crisp, flexible or stiff and fall or compact. The fabric

texture may be close or open light or heavy, loose or firm flat or raised and uniform or

varied. Clarity of fabrics is necessary to display colour, structure, and pattern or to

present a smooth plain appearance and uniform texture. A clear fabric should not have

any fiber ends protruding form its surface.

Mechanisms Of The Softening Effect.

Softeners provide their main effects on the surface of the fabrics. Small softener

molecules, in addition, penetrate the fiber and provide an internal plasticization of the

fiber forming polymer by reducing of the glass transition temperature. The physical

arrangement of the usual softener molecules on the fiber surface is important and shown

in Fig.-1. It depends on the ionic nature of the softener molecule and the relative

hydrophobicity of the fiber surface. cationic softeners orient themselves with their

positively charged ends toward the partially negatively charged fabrics (zeta

potential),creating a new surface of hydrophobic carbon chain that provide the

characteristic excellent softening and lubricity seen with cationic softeners. Anionic

softener, on the other hand, orients themselves with their negatively charged ends

repelled away from the negatively charged fiber surface. This leads to higher

hydrophilicity, but less softening than with cationic softeners. The orientation of non-

You might also like

- Textile Chemical Processing 11Document64 pagesTextile Chemical Processing 11vasiney50% (2)

- Study On Chemical FinishingDocument10 pagesStudy On Chemical FinishingZAyed100% (2)

- Compactor and StenterDocument9 pagesCompactor and StentertesNo ratings yet

- Resin Finishes On Cellulosic FabricsDocument28 pagesResin Finishes On Cellulosic FabricsHina Arif100% (7)

- Textile FinishingDocument11 pagesTextile Finishingmahen0177_268678881No ratings yet

- E CatalogueDocument26 pagesE CatalogueMuhammad Junaid AliNo ratings yet

- Mario Bros Grande CrochetDocument7 pagesMario Bros Grande CrochetLaura67% (3)

- Advancement in Textile FinishingDocument26 pagesAdvancement in Textile FinishingAbhishek Roy100% (1)

- Cotton FinishingDocument11 pagesCotton Finishingmahbub690No ratings yet

- Textile FinishingDocument21 pagesTextile FinishinganowartexNo ratings yet

- Packaging Textiles: The Use of Textile Materials in Consumer Packaging Is Exhibited in The Following ProductsDocument10 pagesPackaging Textiles: The Use of Textile Materials in Consumer Packaging Is Exhibited in The Following ProductsDewan Ajuad Hossain RifatNo ratings yet

- Assignment On Technical Textile... Sec..aDocument23 pagesAssignment On Technical Textile... Sec..aShamima akterNo ratings yet

- Denim FinishingDocument8 pagesDenim FinishingMuhammad Asad NawazNo ratings yet

- Textile Manufacturing Process Textile Manufacturing Process Is Done Some Regular ProcessesDocument5 pagesTextile Manufacturing Process Textile Manufacturing Process Is Done Some Regular Processesananthakumar100% (1)

- Presented By: Ruchi BhutaniDocument61 pagesPresented By: Ruchi BhutaniMonjur MorshedNo ratings yet

- Textile Finishing - Textile CentreDocument17 pagesTextile Finishing - Textile CentreashrafbookNo ratings yet

- Anticrease Finishing 1Document27 pagesAnticrease Finishing 1Sabrina SoniaNo ratings yet

- Fs Final AssignmentDocument21 pagesFs Final AssignmentAkanksha RamanNo ratings yet

- Textile FinishingDocument21 pagesTextile FinishinganowartexNo ratings yet

- Wool 482 582 12 T 15Document22 pagesWool 482 582 12 T 15KathirrveluSubramainanNo ratings yet

- Study On TEXtile FinishingDocument8 pagesStudy On TEXtile FinishingZAyed0% (1)

- Dry FinishingDocument3 pagesDry FinishingRonik JNo ratings yet

- Multi Component FabricsDocument25 pagesMulti Component Fabricsjubair hosenNo ratings yet

- Patent LeatherDocument10 pagesPatent LeathervinothjohnnashNo ratings yet

- Definitions:: Fabric CoatingDocument3 pagesDefinitions:: Fabric CoatingManoj KumarNo ratings yet

- Wrinkle Free Finishes: Assignment-1Document13 pagesWrinkle Free Finishes: Assignment-1Anushka SinghNo ratings yet

- FS PPT 1Document23 pagesFS PPT 1SHREYA TANEJANo ratings yet

- Surfactant SDocument12 pagesSurfactant SlitonrafiqNo ratings yet

- FINISHING OF WOVEN AND KNITTED FABRICS IN MicroModalDocument12 pagesFINISHING OF WOVEN AND KNITTED FABRICS IN MicroModalhamada2017No ratings yet

- BlendsDocument8 pagesBlendsAditi KNo ratings yet

- FINISHINGDocument32 pagesFINISHINGdyuti singhNo ratings yet

- Finishing of Nonwovens - For MajorsDocument2 pagesFinishing of Nonwovens - For MajorsDeepankerBhateja100% (1)

- Textile Finishing 1Document40 pagesTextile Finishing 1Mujahid MehdiNo ratings yet

- SoftenerDocument25 pagesSoftenerCr SamiNo ratings yet

- Textile Finishing: Bultan Sarkar Govt. College of Engg. & Textile Tech. BerhamporeDocument35 pagesTextile Finishing: Bultan Sarkar Govt. College of Engg. & Textile Tech. BerhamporeBULTAN SARKARNo ratings yet

- Eco FriendlyDocument8 pagesEco FriendlyShagun SinhaNo ratings yet

- Textile Design XII PDFDocument91 pagesTextile Design XII PDFJoan OziaasNo ratings yet

- Antimicrobial Finishes For Medical TextilesDocument28 pagesAntimicrobial Finishes For Medical TextilesDÃljït SīñghNo ratings yet

- Finishing of Non WovensDocument14 pagesFinishing of Non WovensGoutham RiyanNo ratings yet

- Chemical Finishing and Washing of Knit WearDocument7 pagesChemical Finishing and Washing of Knit WearHrishikesh DhawadshikarNo ratings yet

- SWSManual 2018 02 RefStateDocument7 pagesSWSManual 2018 02 RefStatekanzarkarss.tx.23No ratings yet

- Surface Modification Methods For Improving The Dyeability of Textile FabricsDocument20 pagesSurface Modification Methods For Improving The Dyeability of Textile Fabricshamidrahmany3657No ratings yet

- Softening FinishesDocument9 pagesSoftening FinishesAkanksha RamanNo ratings yet

- Fabric FinishesDocument12 pagesFabric FinishesJoelNo ratings yet

- Presentation On Textile FinishingDocument29 pagesPresentation On Textile Finishingdani87% (15)

- FGF Final PPT Resin FinishDocument25 pagesFGF Final PPT Resin FinishRajiv RanjanNo ratings yet

- Introduction To Chemical Processing: Pre-Treatments: Natural ImpuritiesDocument17 pagesIntroduction To Chemical Processing: Pre-Treatments: Natural ImpuritiesShah Sulaman100% (1)

- Polymer Matrix CompositesDocument84 pagesPolymer Matrix Compositesعلي الشمريNo ratings yet

- SoftenerDocument35 pagesSoftenerabid md rafiNo ratings yet

- Introduction To Chemical FinishingDocument20 pagesIntroduction To Chemical Finishingmdtawhiddewan1No ratings yet

- Properties of Textile Fibres: Exam - 2021Document9 pagesProperties of Textile Fibres: Exam - 2021Md. Mehedi Hasan MijanNo ratings yet

- Nonwovens HandoutsDocument9 pagesNonwovens HandoutsTamer Farouk KhalifaNo ratings yet

- 3 Softening FinishesDocument18 pages3 Softening Finisheszxlsmally100% (1)

- 27 1147 01Document8 pages27 1147 01ketchitoNo ratings yet

- FinishingDocument3 pagesFinishingTom KattoorNo ratings yet

- Project Report On MercerizationDocument39 pagesProject Report On MercerizationSaif Rahman90% (10)

- Introduction To Non Slip Finishes: Source: New Cloth MarketDocument4 pagesIntroduction To Non Slip Finishes: Source: New Cloth MarketanowartexNo ratings yet

- Functional FinishingDocument31 pagesFunctional Finishingsujal jhaNo ratings yet

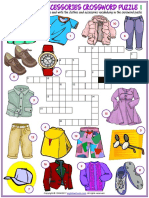

- Clothes and Accessories Vocabulary Esl Crossword Puzzle Worksheets For Kids PDFDocument6 pagesClothes and Accessories Vocabulary Esl Crossword Puzzle Worksheets For Kids PDFAndreia100% (1)

- 104 Jicr October 3344Document10 pages104 Jicr October 3344Krishna KumarNo ratings yet

- ASTM 3950 Testing Methods For Strapping Versie 2007 211007 PDFDocument7 pagesASTM 3950 Testing Methods For Strapping Versie 2007 211007 PDFNestor CzerwackiNo ratings yet

- Aditya Birla Group ProfileDocument15 pagesAditya Birla Group Profilemandhotra87No ratings yet

- CommercialInvoiceD100USO 221102143580Document4 pagesCommercialInvoiceD100USO 221102143580Christine TulangowNo ratings yet

- Synopsis - SPECIAL ROLE OF HANDICRAFT INDUSTRY IN THE ECONOMY OF RAJASTHAN - M K PandeyDocument23 pagesSynopsis - SPECIAL ROLE OF HANDICRAFT INDUSTRY IN THE ECONOMY OF RAJASTHAN - M K Pandeysakshi pandey100% (1)

- BD Test Textile Request FormDocument2 pagesBD Test Textile Request FormRezoanul Haque100% (1)

- Vastra Grah .Pvt. LTD: In-House Manufacturing FacaltyDocument2 pagesVastra Grah .Pvt. LTD: In-House Manufacturing FacaltySaurabh JainNo ratings yet

- Calentadores de BrazosDocument2 pagesCalentadores de Brazosclaudia_negrón_3No ratings yet

- Folus - Company ProfileDocument10 pagesFolus - Company Profilesales 1No ratings yet

- QuestionnaireDocument5 pagesQuestionnairetamiNo ratings yet

- Quality Control in Garment FactoryDocument15 pagesQuality Control in Garment FactoryMuhammad Ali100% (1)

- Carpet WeavingDocument9 pagesCarpet WeavingAnshu Singh100% (1)

- TIR Vardhman, Budhni (29 Dec 2020)Document36 pagesTIR Vardhman, Budhni (29 Dec 2020)Keshav AnandNo ratings yet

- Richemont Se 2014-JaarverslagDocument128 pagesRichemont Se 2014-JaarverslagNetwerk24SakeNo ratings yet

- Double Cross Me Necklace - EVRYJEWELSDocument1 pageDouble Cross Me Necklace - EVRYJEWELSgandino1031No ratings yet

- Istanbul High Streets 2015 enDocument14 pagesIstanbul High Streets 2015 enfbutteNo ratings yet

- COMEZ Tech Tex - enDocument23 pagesCOMEZ Tech Tex - enErkam AlpaslanNo ratings yet

- BRANDIXDocument70 pagesBRANDIXGreeshma33% (6)

- Synopsis FashionDocument5 pagesSynopsis FashionSharon Hepzibah100% (1)

- 2018 KOA Brand Program GuideDocument28 pages2018 KOA Brand Program GuideAmerican Hotel Register CompanyNo ratings yet

- Materials: Dr. Joseph Anbarasu 1Document8 pagesMaterials: Dr. Joseph Anbarasu 1Joseph Anbarasu100% (2)

- Praveen ChauhanDocument3 pagesPraveen ChauhansukhnagNo ratings yet

- Chapter 22 Outline A History of Western SocietyDocument7 pagesChapter 22 Outline A History of Western Societydrea4152No ratings yet

- Annual Report Prada 2016Document191 pagesAnnual Report Prada 2016claudia100% (1)

- Partsbook Racing MCA-18KDocument27 pagesPartsbook Racing MCA-18KMaskusyaniNo ratings yet

- Anita Goodesign Color GuideDocument29 pagesAnita Goodesign Color GuideAndreas D.100% (1)