Professional Documents

Culture Documents

Unconvetional Machining Process

Unconvetional Machining Process

Uploaded by

maheshOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Unconvetional Machining Process

Unconvetional Machining Process

Uploaded by

maheshCopyright:

Available Formats

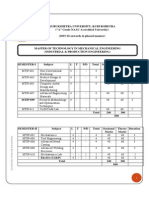

ME 317 - UNCONVENTIONAL MACHINING PROCESSES

Teaching Scheme:

Examination Scheme:

Lectures: 3 hrs/week

Tests -20 marks Mid-Sem. 30 marks

End Sem. Exam 50 marks

Objectives:

To learn about various unconventional machining processes, the various process

parameters and their influence on performance and their applications

Unit 1

[5 hrs]

Introduction

Unconventional machining Process Need classification Brief overview

Unit 2

[10 hrs]

Mechanical Energy Based Processes

Abrasive Jet Machining Water Jet Machining Abrasive Water Jet Machining - Ultrasonic

Machining. (AJM, WJM, AWJM and USM). Working Principles equipment used Process

parameters MRR-Variation in techniques used Applications.

Unit 3

[8 hrs]

Electrical Energy Based Processes

Electric Discharge Machining (EDM)- working Principle-equipments-Process

Parameters-Surface Finish and MRR- electrode / Tool Power and control Circuits-Tool

Wear Dielectric Flushing Wire cut EDM Applications.

Unit 4

[12 hrs]

Chemical Energy Based Processes

Chemical machining techniques of applying maskants-Process Parameters Surface finish and

MRR-Applications. Principles of ECM-equipments-Surface Roughness and MRR Electrical circuitProcess Parameters-ECG - Applications.

Unit 5

[10 hrs]

Thermal Energy Based Processes

Laser Beam machining and drilling (LBM), plasma arc machining (PAM) and Electron

Beam Machining (EBM). Principles Equipment Types - Beam control techniques

Applications

Unit 6

[6 hrs]

Electro-Chemical Energy Based Processes

Electro-Chemical machining (ECM)-Etchants maskant- techniques of applying maskants-Process

Parameters Surface finish and MRR-Applications. Principles of ECM-equipments-Surface

Roughness and MRR Electrical circuit-Process Parameters- ECH - Applications.

Text Books:

1. Vijay.K. Jain Advanced Machining Processes Allied Publishers Pvt. Ltd., New Delhi, 2007

Reference Books:

1. Benedict. G.F. Nontraditional Manufacturing Processes Marcel Dekker Inc., New

York (1987).

2. Pandey P.C. and Shan H.S. Modern Machining Processes Tata McGraw-Hill, New

Delhi (2007).

3. Mc Geough, Advanced Methods of Machining Chapman and Hall, London (1998).

4. Paul De Garmo, J.T.Black, and Ronald.A.Kohser, Material and Processes in

Manufacturing Prentice Hall of India Pvt. Ltd., New Delhi ,8th Edition,2001.

You might also like

- Electrochemical MACHININGDocument14 pagesElectrochemical MACHININGpramod_k100% (2)

- 02 Ucm SyllabusDocument1 page02 Ucm SyllabusSamuelHericNo ratings yet

- ME8073 - UNCONVENTIONAL MACHINING PROCESSES SyllabusDocument2 pagesME8073 - UNCONVENTIONAL MACHINING PROCESSES SyllabusP.N. MohankumarNo ratings yet

- Ucm SyllabusDocument5 pagesUcm SyllabusDhana MuruganNo ratings yet

- syllabus ucmpDocument1 pagesyllabus ucmprajesh_mech7419No ratings yet

- UCM Course InformationDocument14 pagesUCM Course InformationThiyagu SundaramNo ratings yet

- Syllabus PDF 1Document3 pagesSyllabus PDF 1gowrisankar32No ratings yet

- # 1 - IntroductionDocument42 pages# 1 - IntroductionRohan RautNo ratings yet

- Handouts: Kongunadu College of Engineering and Technology (Autonomous)Document59 pagesHandouts: Kongunadu College of Engineering and Technology (Autonomous)Akilesh SNo ratings yet

- Ucm SyllabusDocument2 pagesUcm Syllabusarun2386No ratings yet

- Unconventional Machining Process Session No Topics To Be CoveredDocument2 pagesUnconventional Machining Process Session No Topics To Be CoveredpmagrawalNo ratings yet

- Me 8073 UcmpDocument21 pagesMe 8073 UcmpAjay SriramNo ratings yet

- NTM Module 1Document19 pagesNTM Module 1RishiJpNo ratings yet

- UCM SylabusDocument4 pagesUCM SylabusajitsssNo ratings yet

- Production ElectivesDocument20 pagesProduction ElectivesAdhi ThyanNo ratings yet

- Ucm Two MarksDocument23 pagesUcm Two Marksarun kumarNo ratings yet

- Amp Qb.Document6 pagesAmp Qb.svkarthik83No ratings yet

- Ucmp NotesDocument46 pagesUcmp NotesAnonymous fowICTKNo ratings yet

- Me2026 UmpDocument74 pagesMe2026 Umpashoku24007No ratings yet

- 1.1 Introduction To Conventional and Non Conventional MachiningDocument42 pages1.1 Introduction To Conventional and Non Conventional MachiningDida KhalingNo ratings yet

- Ucmp R13 SyllDocument2 pagesUcmp R13 SyllN Dhanunjaya Rao BorraNo ratings yet

- Jawaharlal Nehru Technological University AnantapurDocument1 pageJawaharlal Nehru Technological University AnantapurManu RavuriNo ratings yet

- Energy Systems LM - 7 Credits: Main Objectives and Contents of The CourseDocument4 pagesEnergy Systems LM - 7 Credits: Main Objectives and Contents of The CourseAbhishek TiwariNo ratings yet

- Me6004 Unconventional Machining Processes Assignment 1,2,3,4,5Document5 pagesMe6004 Unconventional Machining Processes Assignment 1,2,3,4,5BIBIN CHIDAMBARANATHANNo ratings yet

- 1optimization of Micro-WireDocument33 pages1optimization of Micro-WireAman BansalNo ratings yet

- MMP NotesDocument81 pagesMMP NotestatiNo ratings yet

- Modern Manufacturing MethodsDocument3 pagesModern Manufacturing MethodsSree MurthyNo ratings yet

- Modern Optimization Techniques For Advanced MachiningDocument9 pagesModern Optimization Techniques For Advanced MachiningPrapto PraptNo ratings yet

- Experimental and Theoretical Investigations in ECDM Proc 2016 Procedia TechnDocument8 pagesExperimental and Theoretical Investigations in ECDM Proc 2016 Procedia TechnTanNguyễnNo ratings yet

- Ucmp-Question Bank - NewDocument4 pagesUcmp-Question Bank - New9966197483No ratings yet

- Our Official Android App - REJINPAUL NETWORK FromDocument1 pageOur Official Android App - REJINPAUL NETWORK FromNick “WWEXTRMEMENATOR” SpartaNo ratings yet

- Un Conventional Machining Processes SyllabusDocument2 pagesUn Conventional Machining Processes SyllabusKalai ArasanNo ratings yet

- Syllabus NON-TRADITIONAL MACHININGDocument1 pageSyllabus NON-TRADITIONAL MACHININGranjithkrajNo ratings yet

- Fluid Machinery & Fluid PowerDocument3 pagesFluid Machinery & Fluid Poweras2faasbujsacNo ratings yet

- Ucm - Unitwise Notes (r2017)Document168 pagesUcm - Unitwise Notes (r2017)A. AKASH 4001-UCE-TKNo ratings yet

- Review of Electrochemical and Electrodischarge Machining: Digitalcommons@University of Nebraska - LincolnDocument15 pagesReview of Electrochemical and Electrodischarge Machining: Digitalcommons@University of Nebraska - LincolnVignesh SunilNo ratings yet

- Review of Electrochemical and Electrodischarge MachiningDocument14 pagesReview of Electrochemical and Electrodischarge Machiningdinesh veerNo ratings yet

- UmpDocument7 pagesUmpRahul TechNo ratings yet

- Electrochemical Machining PDFDocument5 pagesElectrochemical Machining PDFBasavaraj HosurNo ratings yet

- BME Course Data SheetDocument5 pagesBME Course Data SheetBasilNo ratings yet

- 19EES113A CompressedDocument730 pages19EES113A CompressedYash AgrawalNo ratings yet

- UCM QUESTION BANK-min PDFDocument20 pagesUCM QUESTION BANK-min PDFBalaNo ratings yet

- Elect3 2Document2 pagesElect3 2pranav10dulkarNo ratings yet

- Ucmp First Mid Course FileDocument160 pagesUcmp First Mid Course FileAraveetiCSReddyNo ratings yet

- 084 - ME8073, ME6004 Unconventional Machining Processes - NotesDocument39 pages084 - ME8073, ME6004 Unconventional Machining Processes - NotesA. AKASH 4001-UCE-TKNo ratings yet

- Un Conventional Machining Process NotesDocument174 pagesUn Conventional Machining Process Notesban murthy0% (1)

- B Tech - Manufacturing Technology - 4th Year SyllabusDocument28 pagesB Tech - Manufacturing Technology - 4th Year SyllabusSuraj OjhaNo ratings yet

- ECDMDocument8 pagesECDMSaurabhBhardwajNo ratings yet

- Course Outline Fundamental F&C.docxDocument4 pagesCourse Outline Fundamental F&C.docxwondieNo ratings yet

- AIMTDR2016 - Full - Length PaperDocument6 pagesAIMTDR2016 - Full - Length PaperMM GoudNo ratings yet

- Amm Model Test Paper Q1. (A) State The Characteristics and Function of Dielectric Fluid Used in EDMDocument12 pagesAmm Model Test Paper Q1. (A) State The Characteristics and Function of Dielectric Fluid Used in EDMErin BarryNo ratings yet

- Modern Manufacturing TechnologyDocument15 pagesModern Manufacturing TechnologyTHE NORTHCAP UNIVERSITYNo ratings yet

- Soumya Seminar ReportDocument21 pagesSoumya Seminar ReportDillip MahakhudaNo ratings yet

- Supporting Document For Report - Wire Edm - HCHCR - For MuzammilDocument63 pagesSupporting Document For Report - Wire Edm - HCHCR - For MuzammilMUJA ICSNo ratings yet

- M.tech Mechanical Engg. (I &P)Document44 pagesM.tech Mechanical Engg. (I &P)Upender DhullNo ratings yet

- Ijstev2i12011 PDFDocument3 pagesIjstev2i12011 PDFIJSTENo ratings yet

- Nanoelectronics Devices: Design, Materials, and Applications (Part I)From EverandNanoelectronics Devices: Design, Materials, and Applications (Part I)No ratings yet

- Composite MaterialsDocument2 pagesComposite MaterialsmaheshNo ratings yet

- Control System EngineeringDocument2 pagesControl System EngineeringmaheshNo ratings yet

- Finite Elements in EngineeringDocument2 pagesFinite Elements in EngineeringmaheshNo ratings yet

- Composite Materials: Unit 1Document2 pagesComposite Materials: Unit 1maheshNo ratings yet

- Composite Materials: Unit 1Document2 pagesComposite Materials: Unit 1maheshNo ratings yet