Professional Documents

Culture Documents

Project Report: Submitted To: Sir Anees Ur Rehman

Project Report: Submitted To: Sir Anees Ur Rehman

Uploaded by

Muneeb Ur RehmanCopyright:

Available Formats

You might also like

- VLTD Fitment Certificate (Generated Online in VAHAN)Document1 pageVLTD Fitment Certificate (Generated Online in VAHAN)Siddhant BhandarkarNo ratings yet

- Anritsu MS2667C Service ID12869Document178 pagesAnritsu MS2667C Service ID12869sep cengNo ratings yet

- Kinesis One M5800-00Document34 pagesKinesis One M5800-00powerliftermiloNo ratings yet

- VMC ProgrammingDocument9 pagesVMC ProgrammingRatnakar Patil50% (10)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- 113 Canton Fair Buyers Database-Sample 0Document9 pages113 Canton Fair Buyers Database-Sample 0Fazal Ur RehmanNo ratings yet

- FILE - 20200415 - 220353 - NcEditor V12 Laser Cutting CNC System Manufacturer Manual-R1Document147 pagesFILE - 20200415 - 220353 - NcEditor V12 Laser Cutting CNC System Manufacturer Manual-R1Hoàng DêNo ratings yet

- MCX9M2D Mill Lesson 1Document14 pagesMCX9M2D Mill Lesson 1Anonymous shUWODvoNo ratings yet

- Manual de Referencia Rápida CNC Fagor8020Document9 pagesManual de Referencia Rápida CNC Fagor8020facu6116261No ratings yet

- Adaptive Headlight SystemDocument16 pagesAdaptive Headlight Systemmpankaj27No ratings yet

- G Force RPM Calculator - EndMemoDocument8 pagesG Force RPM Calculator - EndMemoBELINDA DCOSTA100% (1)

- JE MotorDocument231 pagesJE MotorFernando Lopez DiazNo ratings yet

- Tacx Flow ManualDocument17 pagesTacx Flow Manualfixie1979No ratings yet

- 06 JunioDocument152 pages06 Juniocristian GamaNo ratings yet

- Capsule Filling Machine: 16 March, 2010Document37 pagesCapsule Filling Machine: 16 March, 2010prakash67% (3)

- Introduction To Introduction To Computer Numerical Control: Computer Aided Manufacturing TECH 4/53350 1Document11 pagesIntroduction To Introduction To Computer Numerical Control: Computer Aided Manufacturing TECH 4/53350 1BabuRaoThellaNo ratings yet

- Cam Lab: AssignmentDocument5 pagesCam Lab: AssignmentMuneeb Ur RehmanNo ratings yet

- Heat and Mass Transfer Lab Topics For PresentationDocument2 pagesHeat and Mass Transfer Lab Topics For PresentationMuneeb Ur Rehman100% (1)

- Shandong Land Fitness Tech Co.,Ltd: LD-1000 Series QuotationDocument4 pagesShandong Land Fitness Tech Co.,Ltd: LD-1000 Series QuotationKrisNo ratings yet

- ALL CNC Printouts PROGRAMS PRINTOUTDocument26 pagesALL CNC Printouts PROGRAMS PRINTOUTGajananNo ratings yet

- MILL9Document220 pagesMILL9emaster1100% (1)

- H-1000-5021-06-B (E)Document53 pagesH-1000-5021-06-B (E)marioNo ratings yet

- Helical Gear Design PSG PDFDocument9 pagesHelical Gear Design PSG PDFMannam YashuNo ratings yet

- AL1717x Acer LCD Display PDFDocument15 pagesAL1717x Acer LCD Display PDFsylvan_No ratings yet

- Huabo Catalogue 12-300hpDocument11 pagesHuabo Catalogue 12-300hpAlexNo ratings yet

- Hedu e 19 2020Document43 pagesHedu e 19 2020D Venkatesan D Venkatesan100% (1)

- Kinematics of Machinery ManualDocument29 pagesKinematics of Machinery ManualShubham NaikNo ratings yet

- Design of Transmission Systems Question BankDocument27 pagesDesign of Transmission Systems Question BankbalajimetturNo ratings yet

- Joovv v. Mito Red Light - ComplaintDocument17 pagesJoovv v. Mito Red Light - ComplaintSarah BursteinNo ratings yet

- Cad Cam3 Unit NeelimaDocument96 pagesCad Cam3 Unit Neelimasatish86No ratings yet

- GPM32F011XBV10 Sensored FOC Control of PMSM Using GPM32F011xB User (English Version)Document39 pagesGPM32F011XBV10 Sensored FOC Control of PMSM Using GPM32F011xB User (English Version)ISHAK CHERGUINo ratings yet

- Uploading and Downloading Programs Using A Laptop ComputerDocument2 pagesUploading and Downloading Programs Using A Laptop ComputerseregeNo ratings yet

- PU-4010 ServiceManual RevBDocument96 pagesPU-4010 ServiceManual RevBmaivanthieuNo ratings yet

- CIMCO CNC-Calc 2 - User Guide With Tutorials 1-10Document156 pagesCIMCO CNC-Calc 2 - User Guide With Tutorials 1-10Alexandru IancuNo ratings yet

- Centroid cnc12 Oak Allin1dc Lathe Operator Manual v4.14Document269 pagesCentroid cnc12 Oak Allin1dc Lathe Operator Manual v4.14Cesar Augusto MontejoNo ratings yet

- Mill Lesson FBM 1Document34 pagesMill Lesson FBM 1saleem110110100% (1)

- Mill Lesson WCS Part 3Document12 pagesMill Lesson WCS Part 3WilfridoNo ratings yet

- D ME Parts II-&-IIIDocument79 pagesD ME Parts II-&-IIIprasenjitsayantanNo ratings yet

- Fsae DesignspecsDocument2 pagesFsae DesignspecsSureshMcNo ratings yet

- Super Mill ManualDocument77 pagesSuper Mill Manualshantanu kadamNo ratings yet

- REDESIGNATION OF AE As AEE PDFDocument2 pagesREDESIGNATION OF AE As AEE PDFVeera ChaitanyaNo ratings yet

- Summa Bigpaint 1500 Maintenance ManualDocument134 pagesSumma Bigpaint 1500 Maintenance ManualMo_DaviesUKNo ratings yet

- Step by Step Renishaw Retrofit PDFDocument4 pagesStep by Step Renishaw Retrofit PDFRizki AdhaNo ratings yet

- Machine Drawing - 15Me34D: Unit - 1 - Conventional RepresentationDocument22 pagesMachine Drawing - 15Me34D: Unit - 1 - Conventional Representationshreedhar sbNo ratings yet

- 23 13 SA V1 S1 - CncmachinesassDocument4 pages23 13 SA V1 S1 - Cncmachinesassamulya68No ratings yet

- mf70 PKGDocument19 pagesmf70 PKGCarlos RamirezNo ratings yet

- First Year Engineering/Technology Admission 2013-14 List of Eligible CandidatesDocument375 pagesFirst Year Engineering/Technology Admission 2013-14 List of Eligible CandidatesNikita PawarNo ratings yet

- User Manual: Cyptube Laser Cutting Control SystemDocument28 pagesUser Manual: Cyptube Laser Cutting Control Systemhữu tíbNo ratings yet

- KBLDocument16 pagesKBLRamKS80100% (1)

- Periodical Replacement Parts Rev1Document10 pagesPeriodical Replacement Parts Rev1Victor MartinezNo ratings yet

- CNC Programmer Job Description PostingDocument2 pagesCNC Programmer Job Description Postingsmith9krNo ratings yet

- GMN HF Spindles For Auto Tool Change PDFDocument45 pagesGMN HF Spindles For Auto Tool Change PDFsergioduarteNo ratings yet

- Huaxia Catalogue 12-300HPDocument11 pagesHuaxia Catalogue 12-300HPAlexNo ratings yet

- Upload 00387447 1564380640922Document264 pagesUpload 00387447 1564380640922Nouman wahidNo ratings yet

- BOM List Converter 60-12VDC - 18.05.20 - FinalDocument9 pagesBOM List Converter 60-12VDC - 18.05.20 - FinalNguyễn TínNo ratings yet

- HMS827 Manual 17-1298Document56 pagesHMS827 Manual 17-1298Kevin RoseNo ratings yet

- Project Report (Vikas Chandel)Document89 pagesProject Report (Vikas Chandel)Manju SharmaNo ratings yet

- Vehicle Suspension System Technology and DesignDocument11 pagesVehicle Suspension System Technology and DesignHarshraj Wani100% (1)

- GT30 ManualDocument83 pagesGT30 ManualJerry ReddenNo ratings yet

- SW-5.1 3005 Service ManualDocument17 pagesSW-5.1 3005 Service ManualBizoo76No ratings yet

- Monitor Sony Cpd-101vsDocument28 pagesMonitor Sony Cpd-101vspepitito22No ratings yet

- Cam Lab 12k708Document37 pagesCam Lab 12k708Nithish Kumar K MNo ratings yet

- Medical Fitness Certificate EdDocument1 pageMedical Fitness Certificate EdMuneeb Ur RehmanNo ratings yet

- Simple Easy Manufacturable Ventilator Design: Data Collection UnitDocument4 pagesSimple Easy Manufacturable Ventilator Design: Data Collection UnitMuneeb Ur RehmanNo ratings yet

- All SPD TESTS QuestionsDocument3 pagesAll SPD TESTS QuestionsMuneeb Ur RehmanNo ratings yet

- Mechanical Engineering Dept. HITEC 1Document23 pagesMechanical Engineering Dept. HITEC 1Muneeb Ur RehmanNo ratings yet

- Thermodynamics Lab Lab Report No: 06 Muhammad Hamza Abid 13-ME-093 Section: C SUBMISSION DATE: 13-04-2015 Submitted To: Sir Hafiz AbdullahDocument4 pagesThermodynamics Lab Lab Report No: 06 Muhammad Hamza Abid 13-ME-093 Section: C SUBMISSION DATE: 13-04-2015 Submitted To: Sir Hafiz AbdullahMuneeb Ur RehmanNo ratings yet

- Heat and Mass Transfer Lab Topics For PresentationDocument2 pagesHeat and Mass Transfer Lab Topics For PresentationMuneeb Ur Rehman100% (1)

- Lab Report 12Document3 pagesLab Report 12Muneeb Ur RehmanNo ratings yet

- Recomendations LetterSDocument1 pageRecomendations LetterSMuneeb Ur Rehman100% (1)

- Thermo Lab No 8Document3 pagesThermo Lab No 8Muneeb Ur RehmanNo ratings yet

- The LuxDocument1 pageThe LuxMuneeb Ur RehmanNo ratings yet

- Workshop Technology Lesson Plan (Rev.2)Document3 pagesWorkshop Technology Lesson Plan (Rev.2)Muneeb Ur RehmanNo ratings yet

- Machine DesignDocument1 pageMachine DesignMuneeb Ur RehmanNo ratings yet

- Home Tution Available: 3 Days Trial Available Contact#Document1 pageHome Tution Available: 3 Days Trial Available Contact#Muneeb Ur RehmanNo ratings yet

- TickDocument1 pageTickMuneeb Ur RehmanNo ratings yet

- Autocad 3dDocument1 pageAutocad 3dMuneeb Ur RehmanNo ratings yet

- InstructionsDocument1 pageInstructionsMuneeb Ur RehmanNo ratings yet

- English HS-101: Word Skills: Using The Right ToneDocument49 pagesEnglish HS-101: Word Skills: Using The Right ToneMuneeb Ur RehmanNo ratings yet

- Cam Lab: AssignmentDocument3 pagesCam Lab: AssignmentMuneeb Ur RehmanNo ratings yet

- Cam Lab: AssignmentDocument5 pagesCam Lab: AssignmentMuneeb Ur RehmanNo ratings yet

- DSE5120 Installation Instructions PDFDocument2 pagesDSE5120 Installation Instructions PDFeng_moh04No ratings yet

- Sambu: Engineering & Construction Co.,LtdDocument28 pagesSambu: Engineering & Construction Co.,LtdTanushree MishraNo ratings yet

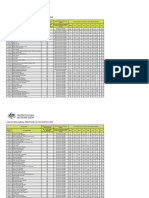

- Skills Priority List - September 2023Document39 pagesSkills Priority List - September 202311A8.01. Hoàng Phú AnNo ratings yet

- Rule: Federal Implementation Plan For The Billings/Laurel, MT, Sulfur Dioxide AreaDocument49 pagesRule: Federal Implementation Plan For The Billings/Laurel, MT, Sulfur Dioxide AreaJustia.comNo ratings yet

- 3G 2G Selection Reselection HandoverDocument50 pages3G 2G Selection Reselection HandoverMohammed Nazim100% (1)

- Epl SyllabusDocument2 pagesEpl SyllabuskaviinfoenggNo ratings yet

- BuildingsDocument173 pagesBuildingsmarella seshagiriNo ratings yet

- Kluber Lubrication Gear Greases: Portfolio and Grease SelectionDocument31 pagesKluber Lubrication Gear Greases: Portfolio and Grease SelectionErick AvilaNo ratings yet

- Operating Instructions: Bitzer KühlmaschinenbauDocument11 pagesOperating Instructions: Bitzer KühlmaschinenbauothmaniomarNo ratings yet

- Arc Welding: CarbonDocument3 pagesArc Welding: CarbonmanandpatelNo ratings yet

- Heat Treatment: Unit - 2Document75 pagesHeat Treatment: Unit - 2reza chamanfarNo ratings yet

- Planetary DrivesDocument277 pagesPlanetary DrivesalopezvillavicencioNo ratings yet

- Spare Parts: Gun, LS373Document2 pagesSpare Parts: Gun, LS373Pandel LucianNo ratings yet

- What'S New in Websphere Message Broker: Jonathan WoodfordDocument26 pagesWhat'S New in Websphere Message Broker: Jonathan WoodfordRajsekhar PillatuNo ratings yet

- Skytrans Charter Flight Schedule: Brisbane To Chinchilla & Taroom Return FlightsDocument1 pageSkytrans Charter Flight Schedule: Brisbane To Chinchilla & Taroom Return FlightsdewNo ratings yet

- 01CDT00330 - Lakeshore - 330 - ManualDocument104 pages01CDT00330 - Lakeshore - 330 - ManualSPMS_MELECNo ratings yet

- Battery Backup A Backup Battery For Hard-Wired Smoke Alarms Offers Security in Case of A Power Failure. All Battery-PoweredDocument11 pagesBattery Backup A Backup Battery For Hard-Wired Smoke Alarms Offers Security in Case of A Power Failure. All Battery-PoweredAndris AblaNo ratings yet

- Training ReportDocument20 pagesTraining ReportWaseem Ashraf100% (2)

- 1756-Pm008 Logix5000 Ladder DiagramDocument20 pages1756-Pm008 Logix5000 Ladder DiagramAnojan BalaNo ratings yet

- Vademecum Eiffel 2019 en PDFDocument8 pagesVademecum Eiffel 2019 en PDFMais OmarNo ratings yet

- 966F Series II and Electrical System 970F Wheel LoadersDocument2 pages966F Series II and Electrical System 970F Wheel Loadersdinny blanco rojasNo ratings yet

- WWTP-NY Prize 2015 Microgrid PDFDocument71 pagesWWTP-NY Prize 2015 Microgrid PDFSrirevathi BalapattabiNo ratings yet

- HNK NT - VTC CatalogDocument16 pagesHNK NT - VTC CatalogOleg Kuryan100% (1)

- Concepts of Metrology and Importance of CalibrationDocument19 pagesConcepts of Metrology and Importance of CalibrationDhruv PrajapatiNo ratings yet

- Walter Gropius: Bauhaus SchoolDocument19 pagesWalter Gropius: Bauhaus SchoolNiamul Hossain AdorNo ratings yet

- New Connection Forms For Electricity Distribution Companies of RajasthanDocument19 pagesNew Connection Forms For Electricity Distribution Companies of Rajasthanarpit85No ratings yet

- Eis29 - Control of Noise at Power PressesDocument4 pagesEis29 - Control of Noise at Power PressesButtsscribd9No ratings yet

- Syllabus MAN 5322 Technology & Operations Management (Core Courses)Document7 pagesSyllabus MAN 5322 Technology & Operations Management (Core Courses)Ardian SyahNo ratings yet

Project Report: Submitted To: Sir Anees Ur Rehman

Project Report: Submitted To: Sir Anees Ur Rehman

Uploaded by

Muneeb Ur RehmanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project Report: Submitted To: Sir Anees Ur Rehman

Project Report: Submitted To: Sir Anees Ur Rehman

Uploaded by

Muneeb Ur RehmanCopyright:

Available Formats

Muneeb 13-ME-136

Project Report

SUBMITTED TO:

Sir Anees Ur Rehman

SUBMITTED BY:

Muneeb Ur Rehman

REGISTRATION NO.

13-ME-136

SECTION : B

Muneeb 13-ME-136

CAM PROJECT (CNC Milling Machine)

INTRODUCTION:

This is a project on CNC simulator. The purpose of this project is to get some grip on CNC by

analyzing some physical drawings and then generating codes for CNC machines. Before inputting

programs for some parts on CNC we must know about syntax of G and M codes which are

necessary for operating CNC machines. So, this project on simulator helps student to get aware of

some G codes and M codes and their syntax. This project include some machining operation like

drilling, linear cutting and circular cutting etc. and complete simulation of part at the end.

Drawing (Approved drawing at the end)

Selected Parameters for CNC simulator

1) Box length in simulator

X-direction=150

Y-direction=150

Z-direction=10

2) Tool Diameters

Tool 1 =0.5mm

Tool 2= 8mm

Muneeb 13-ME-136

3) Zero point Register in CNC simulator

Set G54

X=25, Y=30, Z=0

CNC PROGRAM FOR GIVEN DRAWING

N10 G90 G54 G17 G40 G80 G21

N12 T01

N15 M03 S200

N20 G41 D0.5

N22 G00 X0 Y0 Z0

N25 G01 Z-8 F100

N30 G01 X0 Y90

N40 G01 X100 Y90

N50 G01 X100 Y0

N60 G01 X0 Y0

N80 G01 Z+8

N90 G00 X5 Y5

N100 G01 Z-6

N110 G01 X5 Y80.76

N120 G01 X9.24 Y85

N130 G01 X20 Y85

N140 G01 X46.08 Y79.15

N150 G03 X59.92 Y81.88 I4.14 J15.45

N160 G02 X91.55 Y49.32 R25

N170 G03 X95 Y29 I13.79 J-8.11

N180 G01 X95 Y5

N190 G01 X50 Y5

N200 G03 X20 Y5 R20

N205 G01 X5 Y5

N210 G01 Z+6

N215 G40

N220 M05

N225 T02

Muneeb 13-ME-136

N228 M03 S100

N230 G00 X62 Y74.39

N240 G81 X62 Y74.39 Z-8 R3 F100

N260 G00 X72.61 Y73.31

N270 G81 X72.61 Y73.31 Z-8 R3 F100

N280 G00 X81.31 Y64.61

N290 G81 X81.31 Y64.61 Z-8 R3 F100

N300 G00 X82.39 Y52.34

N310 G81 X82.39 Y52.34 Z-8 R3 F100

N320 M05

N330 T01

N335 M03 S200

N340 G41 D0.5

N350 G00 X46 Y29

N360 G01 Z-4

N370 G02 X46 Y29 I21 J0

N380 G01 Z+4

N390 G00 X10 Y9.5

N400 G01 Z-4

N410 G02 Y14.5 R2.5

N420 G01 X17.5

N430 G01 Y17

N110 G02 X22.5 R2.5

N120 G01 X22.5 Y12

N130 G02 X20 Y9.5 R2.5

N140 G01 X10

N150 G01 Z+4

N160 G00 X20 Y21.5

N170 G01 Z-4

N180 G02 Y26.5 R2.5

N190 G01 X27.5

N200 G01 Y29

N210 G02 X32.5 R2.5

N220 G01 Y24

N230 G02 X30 Y21.5 R2.5

Muneeb 13-ME-136

N240 G01 X20

N250 G01 Z+4

N260 G00 X30 Y33.5

N270 G01 Z-4

N280 G02 Y38.5 R2.5

N290 G01 X37.5 Y38.5

N300 G01 X37.5 Y41

N310 G02 X42.5 Y41 R2.5

N320 G01 X42.5 Y36

N330 G02 X40 Y33.5 R2.5

N340 G01 X30 Y33.5

N350 G01 Z+4

N360 G00 X36.17 Y46.37

N370 G01 Z-8

N380 G01 X16.85 Y51.55

N390 G02 X9.78 Y63.8 R10

N400 G01 X11.59 Y70.54

N410 G02 X23.84 Y77.61 R10

N420 G01 X43.16 Y72.42

N430 G02 X50.22 Y60.18 R10

N440 G01 X48.42 Y53.44

N450 G02 X36.17 Y46.37 R10

N460 G01 Z+8

N470 G00 X76.5 Y12.55

N480 G01 Z-8

N490 G02 X57.49 Y12.55 I-9.5 J16.45

N500 G02 X61.49 Y19.47 I2 J3.46

N510 G03 X72.51 Y19.47 I5.51 J14.53

N520 G02 X76.5 Y12.55 I2.01 J-3.46

N530 G01 Z+8

N540 G00 X78.01 Y29

N550 G01 Z-8

N560 G03 X72.5 Y38.54 I-11.01 J0

N570 G02 X76.49 Y45.46 I2 J3.46

N580 G02 X86 Y29 I-9.49 J-16.46

Muneeb 13-ME-136

N590 G02 X78.01 Y29 I-4 J0

N600 G01 Z+8

N610 G00 X61.5 Y38.54

N620 G01 Z-8

N630 G03 X55.99 Y29 I5.5 J-9.54

N640 G02 X48 Y29 I-3.99 J0

N650 G02 X57.51 Y45.46 I19 J0

N660 G02 X61.5 Y38.54 I1.99 J-3.46

N670 G01 Z+8

N680 G00 X0 Y0

N690 G40 G80

N700 M05

N710 M30

Simulated Part:

Muneeb 13-ME-136

CAD MODEL

OBSERVATIONS:

The course of this project is quite satisfactory and we learnt about CNC programming and in future

it will be helpful for us and as I was much interested in CNC programming and Pro-engineer and

waiting for this course. This gave us knowledge enough to compete with others in future. I am

interested to do work on CNC and CAD modeling simultaneously and also these are interlinked.

I have complete my project work so it means I got some skills on analyzing physical part and

generating CNC codes enough to compete in interviews and if we have to made some specimen

for our final year project then we will be able to generate their programs.

The difficulties we faced in my project work were on the finding of coordinates of tilt rectangle

and three parts inside the main circle but after hard work and with the help of pro engineer software

I succeed to get these coordinates leading to completion of my project.

I dont think so that there is annoying about computer aided manufacturing. It is very interesting

and parts we know are very accurate and this is what an engineer needs. But some things are

difficult like Maintance of complex parts and if face problem then we are more dependent on others

on this basis. I think we must work on this side.

If I have no restrictions then I will change the timing of working on CNC machines and we trained

some individuals to get best grip on Maintance of complete CNC machines and knowledge about

base of CNC machines.

Muneeb 13-ME-136

Muneeb 13-ME-136

You might also like

- VLTD Fitment Certificate (Generated Online in VAHAN)Document1 pageVLTD Fitment Certificate (Generated Online in VAHAN)Siddhant BhandarkarNo ratings yet

- Anritsu MS2667C Service ID12869Document178 pagesAnritsu MS2667C Service ID12869sep cengNo ratings yet

- Kinesis One M5800-00Document34 pagesKinesis One M5800-00powerliftermiloNo ratings yet

- VMC ProgrammingDocument9 pagesVMC ProgrammingRatnakar Patil50% (10)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- 113 Canton Fair Buyers Database-Sample 0Document9 pages113 Canton Fair Buyers Database-Sample 0Fazal Ur RehmanNo ratings yet

- FILE - 20200415 - 220353 - NcEditor V12 Laser Cutting CNC System Manufacturer Manual-R1Document147 pagesFILE - 20200415 - 220353 - NcEditor V12 Laser Cutting CNC System Manufacturer Manual-R1Hoàng DêNo ratings yet

- MCX9M2D Mill Lesson 1Document14 pagesMCX9M2D Mill Lesson 1Anonymous shUWODvoNo ratings yet

- Manual de Referencia Rápida CNC Fagor8020Document9 pagesManual de Referencia Rápida CNC Fagor8020facu6116261No ratings yet

- Adaptive Headlight SystemDocument16 pagesAdaptive Headlight Systemmpankaj27No ratings yet

- G Force RPM Calculator - EndMemoDocument8 pagesG Force RPM Calculator - EndMemoBELINDA DCOSTA100% (1)

- JE MotorDocument231 pagesJE MotorFernando Lopez DiazNo ratings yet

- Tacx Flow ManualDocument17 pagesTacx Flow Manualfixie1979No ratings yet

- 06 JunioDocument152 pages06 Juniocristian GamaNo ratings yet

- Capsule Filling Machine: 16 March, 2010Document37 pagesCapsule Filling Machine: 16 March, 2010prakash67% (3)

- Introduction To Introduction To Computer Numerical Control: Computer Aided Manufacturing TECH 4/53350 1Document11 pagesIntroduction To Introduction To Computer Numerical Control: Computer Aided Manufacturing TECH 4/53350 1BabuRaoThellaNo ratings yet

- Cam Lab: AssignmentDocument5 pagesCam Lab: AssignmentMuneeb Ur RehmanNo ratings yet

- Heat and Mass Transfer Lab Topics For PresentationDocument2 pagesHeat and Mass Transfer Lab Topics For PresentationMuneeb Ur Rehman100% (1)

- Shandong Land Fitness Tech Co.,Ltd: LD-1000 Series QuotationDocument4 pagesShandong Land Fitness Tech Co.,Ltd: LD-1000 Series QuotationKrisNo ratings yet

- ALL CNC Printouts PROGRAMS PRINTOUTDocument26 pagesALL CNC Printouts PROGRAMS PRINTOUTGajananNo ratings yet

- MILL9Document220 pagesMILL9emaster1100% (1)

- H-1000-5021-06-B (E)Document53 pagesH-1000-5021-06-B (E)marioNo ratings yet

- Helical Gear Design PSG PDFDocument9 pagesHelical Gear Design PSG PDFMannam YashuNo ratings yet

- AL1717x Acer LCD Display PDFDocument15 pagesAL1717x Acer LCD Display PDFsylvan_No ratings yet

- Huabo Catalogue 12-300hpDocument11 pagesHuabo Catalogue 12-300hpAlexNo ratings yet

- Hedu e 19 2020Document43 pagesHedu e 19 2020D Venkatesan D Venkatesan100% (1)

- Kinematics of Machinery ManualDocument29 pagesKinematics of Machinery ManualShubham NaikNo ratings yet

- Design of Transmission Systems Question BankDocument27 pagesDesign of Transmission Systems Question BankbalajimetturNo ratings yet

- Joovv v. Mito Red Light - ComplaintDocument17 pagesJoovv v. Mito Red Light - ComplaintSarah BursteinNo ratings yet

- Cad Cam3 Unit NeelimaDocument96 pagesCad Cam3 Unit Neelimasatish86No ratings yet

- GPM32F011XBV10 Sensored FOC Control of PMSM Using GPM32F011xB User (English Version)Document39 pagesGPM32F011XBV10 Sensored FOC Control of PMSM Using GPM32F011xB User (English Version)ISHAK CHERGUINo ratings yet

- Uploading and Downloading Programs Using A Laptop ComputerDocument2 pagesUploading and Downloading Programs Using A Laptop ComputerseregeNo ratings yet

- PU-4010 ServiceManual RevBDocument96 pagesPU-4010 ServiceManual RevBmaivanthieuNo ratings yet

- CIMCO CNC-Calc 2 - User Guide With Tutorials 1-10Document156 pagesCIMCO CNC-Calc 2 - User Guide With Tutorials 1-10Alexandru IancuNo ratings yet

- Centroid cnc12 Oak Allin1dc Lathe Operator Manual v4.14Document269 pagesCentroid cnc12 Oak Allin1dc Lathe Operator Manual v4.14Cesar Augusto MontejoNo ratings yet

- Mill Lesson FBM 1Document34 pagesMill Lesson FBM 1saleem110110100% (1)

- Mill Lesson WCS Part 3Document12 pagesMill Lesson WCS Part 3WilfridoNo ratings yet

- D ME Parts II-&-IIIDocument79 pagesD ME Parts II-&-IIIprasenjitsayantanNo ratings yet

- Fsae DesignspecsDocument2 pagesFsae DesignspecsSureshMcNo ratings yet

- Super Mill ManualDocument77 pagesSuper Mill Manualshantanu kadamNo ratings yet

- REDESIGNATION OF AE As AEE PDFDocument2 pagesREDESIGNATION OF AE As AEE PDFVeera ChaitanyaNo ratings yet

- Summa Bigpaint 1500 Maintenance ManualDocument134 pagesSumma Bigpaint 1500 Maintenance ManualMo_DaviesUKNo ratings yet

- Step by Step Renishaw Retrofit PDFDocument4 pagesStep by Step Renishaw Retrofit PDFRizki AdhaNo ratings yet

- Machine Drawing - 15Me34D: Unit - 1 - Conventional RepresentationDocument22 pagesMachine Drawing - 15Me34D: Unit - 1 - Conventional Representationshreedhar sbNo ratings yet

- 23 13 SA V1 S1 - CncmachinesassDocument4 pages23 13 SA V1 S1 - Cncmachinesassamulya68No ratings yet

- mf70 PKGDocument19 pagesmf70 PKGCarlos RamirezNo ratings yet

- First Year Engineering/Technology Admission 2013-14 List of Eligible CandidatesDocument375 pagesFirst Year Engineering/Technology Admission 2013-14 List of Eligible CandidatesNikita PawarNo ratings yet

- User Manual: Cyptube Laser Cutting Control SystemDocument28 pagesUser Manual: Cyptube Laser Cutting Control Systemhữu tíbNo ratings yet

- KBLDocument16 pagesKBLRamKS80100% (1)

- Periodical Replacement Parts Rev1Document10 pagesPeriodical Replacement Parts Rev1Victor MartinezNo ratings yet

- CNC Programmer Job Description PostingDocument2 pagesCNC Programmer Job Description Postingsmith9krNo ratings yet

- GMN HF Spindles For Auto Tool Change PDFDocument45 pagesGMN HF Spindles For Auto Tool Change PDFsergioduarteNo ratings yet

- Huaxia Catalogue 12-300HPDocument11 pagesHuaxia Catalogue 12-300HPAlexNo ratings yet

- Upload 00387447 1564380640922Document264 pagesUpload 00387447 1564380640922Nouman wahidNo ratings yet

- BOM List Converter 60-12VDC - 18.05.20 - FinalDocument9 pagesBOM List Converter 60-12VDC - 18.05.20 - FinalNguyễn TínNo ratings yet

- HMS827 Manual 17-1298Document56 pagesHMS827 Manual 17-1298Kevin RoseNo ratings yet

- Project Report (Vikas Chandel)Document89 pagesProject Report (Vikas Chandel)Manju SharmaNo ratings yet

- Vehicle Suspension System Technology and DesignDocument11 pagesVehicle Suspension System Technology and DesignHarshraj Wani100% (1)

- GT30 ManualDocument83 pagesGT30 ManualJerry ReddenNo ratings yet

- SW-5.1 3005 Service ManualDocument17 pagesSW-5.1 3005 Service ManualBizoo76No ratings yet

- Monitor Sony Cpd-101vsDocument28 pagesMonitor Sony Cpd-101vspepitito22No ratings yet

- Cam Lab 12k708Document37 pagesCam Lab 12k708Nithish Kumar K MNo ratings yet

- Medical Fitness Certificate EdDocument1 pageMedical Fitness Certificate EdMuneeb Ur RehmanNo ratings yet

- Simple Easy Manufacturable Ventilator Design: Data Collection UnitDocument4 pagesSimple Easy Manufacturable Ventilator Design: Data Collection UnitMuneeb Ur RehmanNo ratings yet

- All SPD TESTS QuestionsDocument3 pagesAll SPD TESTS QuestionsMuneeb Ur RehmanNo ratings yet

- Mechanical Engineering Dept. HITEC 1Document23 pagesMechanical Engineering Dept. HITEC 1Muneeb Ur RehmanNo ratings yet

- Thermodynamics Lab Lab Report No: 06 Muhammad Hamza Abid 13-ME-093 Section: C SUBMISSION DATE: 13-04-2015 Submitted To: Sir Hafiz AbdullahDocument4 pagesThermodynamics Lab Lab Report No: 06 Muhammad Hamza Abid 13-ME-093 Section: C SUBMISSION DATE: 13-04-2015 Submitted To: Sir Hafiz AbdullahMuneeb Ur RehmanNo ratings yet

- Heat and Mass Transfer Lab Topics For PresentationDocument2 pagesHeat and Mass Transfer Lab Topics For PresentationMuneeb Ur Rehman100% (1)

- Lab Report 12Document3 pagesLab Report 12Muneeb Ur RehmanNo ratings yet

- Recomendations LetterSDocument1 pageRecomendations LetterSMuneeb Ur Rehman100% (1)

- Thermo Lab No 8Document3 pagesThermo Lab No 8Muneeb Ur RehmanNo ratings yet

- The LuxDocument1 pageThe LuxMuneeb Ur RehmanNo ratings yet

- Workshop Technology Lesson Plan (Rev.2)Document3 pagesWorkshop Technology Lesson Plan (Rev.2)Muneeb Ur RehmanNo ratings yet

- Machine DesignDocument1 pageMachine DesignMuneeb Ur RehmanNo ratings yet

- Home Tution Available: 3 Days Trial Available Contact#Document1 pageHome Tution Available: 3 Days Trial Available Contact#Muneeb Ur RehmanNo ratings yet

- TickDocument1 pageTickMuneeb Ur RehmanNo ratings yet

- Autocad 3dDocument1 pageAutocad 3dMuneeb Ur RehmanNo ratings yet

- InstructionsDocument1 pageInstructionsMuneeb Ur RehmanNo ratings yet

- English HS-101: Word Skills: Using The Right ToneDocument49 pagesEnglish HS-101: Word Skills: Using The Right ToneMuneeb Ur RehmanNo ratings yet

- Cam Lab: AssignmentDocument3 pagesCam Lab: AssignmentMuneeb Ur RehmanNo ratings yet

- Cam Lab: AssignmentDocument5 pagesCam Lab: AssignmentMuneeb Ur RehmanNo ratings yet

- DSE5120 Installation Instructions PDFDocument2 pagesDSE5120 Installation Instructions PDFeng_moh04No ratings yet

- Sambu: Engineering & Construction Co.,LtdDocument28 pagesSambu: Engineering & Construction Co.,LtdTanushree MishraNo ratings yet

- Skills Priority List - September 2023Document39 pagesSkills Priority List - September 202311A8.01. Hoàng Phú AnNo ratings yet

- Rule: Federal Implementation Plan For The Billings/Laurel, MT, Sulfur Dioxide AreaDocument49 pagesRule: Federal Implementation Plan For The Billings/Laurel, MT, Sulfur Dioxide AreaJustia.comNo ratings yet

- 3G 2G Selection Reselection HandoverDocument50 pages3G 2G Selection Reselection HandoverMohammed Nazim100% (1)

- Epl SyllabusDocument2 pagesEpl SyllabuskaviinfoenggNo ratings yet

- BuildingsDocument173 pagesBuildingsmarella seshagiriNo ratings yet

- Kluber Lubrication Gear Greases: Portfolio and Grease SelectionDocument31 pagesKluber Lubrication Gear Greases: Portfolio and Grease SelectionErick AvilaNo ratings yet

- Operating Instructions: Bitzer KühlmaschinenbauDocument11 pagesOperating Instructions: Bitzer KühlmaschinenbauothmaniomarNo ratings yet

- Arc Welding: CarbonDocument3 pagesArc Welding: CarbonmanandpatelNo ratings yet

- Heat Treatment: Unit - 2Document75 pagesHeat Treatment: Unit - 2reza chamanfarNo ratings yet

- Planetary DrivesDocument277 pagesPlanetary DrivesalopezvillavicencioNo ratings yet

- Spare Parts: Gun, LS373Document2 pagesSpare Parts: Gun, LS373Pandel LucianNo ratings yet

- What'S New in Websphere Message Broker: Jonathan WoodfordDocument26 pagesWhat'S New in Websphere Message Broker: Jonathan WoodfordRajsekhar PillatuNo ratings yet

- Skytrans Charter Flight Schedule: Brisbane To Chinchilla & Taroom Return FlightsDocument1 pageSkytrans Charter Flight Schedule: Brisbane To Chinchilla & Taroom Return FlightsdewNo ratings yet

- 01CDT00330 - Lakeshore - 330 - ManualDocument104 pages01CDT00330 - Lakeshore - 330 - ManualSPMS_MELECNo ratings yet

- Battery Backup A Backup Battery For Hard-Wired Smoke Alarms Offers Security in Case of A Power Failure. All Battery-PoweredDocument11 pagesBattery Backup A Backup Battery For Hard-Wired Smoke Alarms Offers Security in Case of A Power Failure. All Battery-PoweredAndris AblaNo ratings yet

- Training ReportDocument20 pagesTraining ReportWaseem Ashraf100% (2)

- 1756-Pm008 Logix5000 Ladder DiagramDocument20 pages1756-Pm008 Logix5000 Ladder DiagramAnojan BalaNo ratings yet

- Vademecum Eiffel 2019 en PDFDocument8 pagesVademecum Eiffel 2019 en PDFMais OmarNo ratings yet

- 966F Series II and Electrical System 970F Wheel LoadersDocument2 pages966F Series II and Electrical System 970F Wheel Loadersdinny blanco rojasNo ratings yet

- WWTP-NY Prize 2015 Microgrid PDFDocument71 pagesWWTP-NY Prize 2015 Microgrid PDFSrirevathi BalapattabiNo ratings yet

- HNK NT - VTC CatalogDocument16 pagesHNK NT - VTC CatalogOleg Kuryan100% (1)

- Concepts of Metrology and Importance of CalibrationDocument19 pagesConcepts of Metrology and Importance of CalibrationDhruv PrajapatiNo ratings yet

- Walter Gropius: Bauhaus SchoolDocument19 pagesWalter Gropius: Bauhaus SchoolNiamul Hossain AdorNo ratings yet

- New Connection Forms For Electricity Distribution Companies of RajasthanDocument19 pagesNew Connection Forms For Electricity Distribution Companies of Rajasthanarpit85No ratings yet

- Eis29 - Control of Noise at Power PressesDocument4 pagesEis29 - Control of Noise at Power PressesButtsscribd9No ratings yet

- Syllabus MAN 5322 Technology & Operations Management (Core Courses)Document7 pagesSyllabus MAN 5322 Technology & Operations Management (Core Courses)Ardian SyahNo ratings yet