Professional Documents

Culture Documents

1 SATIP-W-011-01 Welding of On-Plot Piping - Rev1 PDF

1 SATIP-W-011-01 Welding of On-Plot Piping - Rev1 PDF

Uploaded by

WIZKHALIFACopyright:

Available Formats

You might also like

- API 653 Above Ground Storage Tank InspectorDocument2 pagesAPI 653 Above Ground Storage Tank InspectorMohamed Hichem Guesmi0% (1)

- 1 SATIP-L-350-08 Shop Fab - Piping and Steel Structures-Rev1Document2 pages1 SATIP-L-350-08 Shop Fab - Piping and Steel Structures-Rev1skychurch100% (2)

- API 1104 PAUT Cal BlockDocument2 pagesAPI 1104 PAUT Cal BlockWIZKHALIFA100% (2)

- TOFD & PA Procedure For 301Document49 pagesTOFD & PA Procedure For 301WIZKHALIFA93% (14)

- 1 SATIP-A-004-02 Hydro Test of Plant Piping-Rev 1Document2 pages1 SATIP-A-004-02 Hydro Test of Plant Piping-Rev 1Ariel Anasco50% (2)

- SAIC-A-2020 Rev 2Document3 pagesSAIC-A-2020 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- 1 SATIP-W-016-01 Welding of S C R M & Duplex SS - Rev 1Document4 pages1 SATIP-W-016-01 Welding of S C R M & Duplex SS - Rev 1JithuJohnNo ratings yet

- PIPELINE Punch ListDocument2 pagesPIPELINE Punch ListTanveer Rajput EngrNo ratings yet

- Reduce Repair Rate of Welding ProcessesDocument3 pagesReduce Repair Rate of Welding ProcessesAnouar AbdelmoulaNo ratings yet

- Inspection and Test Plan For Valve: Before ManufacturingDocument2 pagesInspection and Test Plan For Valve: Before ManufacturingkarthikNo ratings yet

- Rotating Equipment PreservationDocument7 pagesRotating Equipment PreservationaamirapiNo ratings yet

- Installation Procedure For Gre PipeDocument14 pagesInstallation Procedure For Gre PipeNithin Mathai100% (1)

- Inspection Test Plan: Itp No: REV:1.0 DateDocument3 pagesInspection Test Plan: Itp No: REV:1.0 Datemohd as shahiddin jafriNo ratings yet

- Oman-India Fertilizer Project OIFDocument24 pagesOman-India Fertilizer Project OIFBassam Dahham83% (6)

- Enbridge Pipeline Repair Workplan Welding PDFDocument23 pagesEnbridge Pipeline Repair Workplan Welding PDFquiron2014No ratings yet

- Materials System SpecificationDocument13 pagesMaterials System SpecificationJeck MaquitedNo ratings yet

- Nozzle Fit-Up Inspection Report: Inspected & Prepared byDocument9 pagesNozzle Fit-Up Inspection Report: Inspected & Prepared byDaison PaulNo ratings yet

- Welding Repair ProcdureDocument16 pagesWelding Repair Procdureprem nautiyal100% (1)

- ED 00 CPL PRC 0021 Construction QC Procedure Rev.2Document24 pagesED 00 CPL PRC 0021 Construction QC Procedure Rev.2Rahmat Hidayat100% (1)

- O - (TOC) - SOP - 008 - R0 - SOP For Welding Consumables Handling and ControlDocument8 pagesO - (TOC) - SOP - 008 - R0 - SOP For Welding Consumables Handling and ControlMDhana SekarNo ratings yet

- Pressure Vessel RT TestDocument4 pagesPressure Vessel RT TestalokbdasNo ratings yet

- Technical SpecificationsDocument62 pagesTechnical SpecificationsRamu Nallathambi100% (1)

- Inspection of Testing Pipe SupportDocument44 pagesInspection of Testing Pipe Supportiran1362No ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 MechDocument15 pagesSaudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 Mechpookkoya thangalNo ratings yet

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapNo ratings yet

- Sa 6717Document1 pageSa 6717biplabpal2009No ratings yet

- Pipe Fit Up ReportDocument2 pagesPipe Fit Up ReportnguyenquanghiepNo ratings yet

- QAP ITP Bhogat - REV-01Document8 pagesQAP ITP Bhogat - REV-01Ramkunwar YadavNo ratings yet

- Specification For Fabrication and Erection ofDocument26 pagesSpecification For Fabrication and Erection ofEdgargarNo ratings yet

- PQR Asme Ix - CompletedDocument3 pagesPQR Asme Ix - CompletedCarlos Nombela Palacios100% (1)

- Saudi Aramco Typical Inspection PlanDocument3 pagesSaudi Aramco Typical Inspection PlanAnonymous S9qBDVkyNo ratings yet

- Risks in Facility Build Quality and Project Handover: What Happened?Document3 pagesRisks in Facility Build Quality and Project Handover: What Happened?musaismail8863No ratings yet

- Welding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldDocument2 pagesWelding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldAbdulmecit YetisNo ratings yet

- Saudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Document1 pageSaudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Mohammed Hamed BaganNo ratings yet

- 012 QualityNewsLetter - January2012Document8 pages012 QualityNewsLetter - January2012ரமேஷ் பாலக்காடுNo ratings yet

- ITP-Onshore-Pipeline PTMDocument2 pagesITP-Onshore-Pipeline PTMFerdie OSNo ratings yet

- Process Piping Inspection and Test PlanDocument6 pagesProcess Piping Inspection and Test Planmanoj thakkarNo ratings yet

- Butt JointsDocument21 pagesButt JointsRaj1-23No ratings yet

- ES.5.06.0001 RA - PressureVesselsDocument28 pagesES.5.06.0001 RA - PressureVesselsJagadeesh PuppalaNo ratings yet

- 13427-01weekly QAQC ReportDocument1 page13427-01weekly QAQC ReportShyam SinghNo ratings yet

- Co ., LT D.: ASME A-106/A-106M - 2019 EDITION Material Verification The Original Markings On ProductionDocument2 pagesCo ., LT D.: ASME A-106/A-106M - 2019 EDITION Material Verification The Original Markings On ProductionBalaji SelvarajNo ratings yet

- Tank Maintenance ITPDocument24 pagesTank Maintenance ITPthomas varugheseNo ratings yet

- Quality Assurance Audit For Piping FabricationDocument3 pagesQuality Assurance Audit For Piping Fabricationapply19842371No ratings yet

- METHOD STATEMENT FOR Pneumatic TestDocument11 pagesMETHOD STATEMENT FOR Pneumatic Testzahid100% (1)

- 8615 Nozzle Orientation Report 01Document4 pages8615 Nozzle Orientation Report 01Bsc Aditya Singh Dinkar100% (1)

- Nexteer Quality Alert: Response RequiredDocument1 pageNexteer Quality Alert: Response RequiredsimsonNo ratings yet

- 1 Imran Piping QC CVDocument4 pages1 Imran Piping QC CVkazim MirzaNo ratings yet

- Welding Terminology Dan Welding Positions PDFDocument52 pagesWelding Terminology Dan Welding Positions PDFRama TamaNo ratings yet

- Thickness Qualification Range For PQR and WPQDocument5 pagesThickness Qualification Range For PQR and WPQOuled BladiNo ratings yet

- Ug PipingDocument51 pagesUg PipingMuthu AlaguRaj100% (1)

- Inspection and Test Plan For Storage TankDocument7 pagesInspection and Test Plan For Storage TankABDELKADER BENABDALLAHNo ratings yet

- 5.1 - (ANX-1) Inspection Test Plan (ITP) ListDocument3 pages5.1 - (ANX-1) Inspection Test Plan (ITP) ListWinston BoxNo ratings yet

- Itp For Gasket - r1Document7 pagesItp For Gasket - r1Hamid Taghipour ArmakiNo ratings yet

- Test Pack SampleDocument12 pagesTest Pack SampleGomathyselviNo ratings yet

- Fabrication of ManifoldDocument2 pagesFabrication of Manifoldsarangpune100% (1)

- Welding Procedure Qualification Record (WPQR)Document8 pagesWelding Procedure Qualification Record (WPQR)Belin InversoNo ratings yet

- PIPE LINE Presentation PART 1Document33 pagesPIPE LINE Presentation PART 1kannan100% (1)

- 19 - Weld Fit Up Inspection Employee TrainingDocument10 pages19 - Weld Fit Up Inspection Employee TrainingManoj KumarNo ratings yet

- SQAE Velosi Interview PreparationDocument10 pagesSQAE Velosi Interview PreparationSebastian RajeshNo ratings yet

- 1 SATIP-W-017-01 Welding of API Tanks-Rev 1Document4 pages1 SATIP-W-017-01 Welding of API Tanks-Rev 1khalid764No ratings yet

- 1 SATIP-D-109-01 Shop Fab Storage Tank PDFDocument4 pages1 SATIP-D-109-01 Shop Fab Storage Tank PDFJithuJohnNo ratings yet

- Wiley Practitioner's Guide to GAAS 2023: Covering All SASs, SSAEs, SSARSs, and InterpretationsFrom EverandWiley Practitioner's Guide to GAAS 2023: Covering All SASs, SSAEs, SSARSs, and InterpretationsNo ratings yet

- 311d AP Se z3 Tmmk1a Kijun Rev1Document9 pages311d AP Se z3 Tmmk1a Kijun Rev1WIZKHALIFANo ratings yet

- NDT and IRIS Status RCON SD 2015extractedDocument9 pagesNDT and IRIS Status RCON SD 2015extractedWIZKHALIFA100% (1)

- Thanesh Kumar NagendranDocument3 pagesThanesh Kumar NagendranWIZKHALIFANo ratings yet

- 17 No Dues Certificate v2Document2 pages17 No Dues Certificate v2WIZKHALIFANo ratings yet

1 SATIP-W-011-01 Welding of On-Plot Piping - Rev1 PDF

1 SATIP-W-011-01 Welding of On-Plot Piping - Rev1 PDF

Uploaded by

WIZKHALIFAOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 SATIP-W-011-01 Welding of On-Plot Piping - Rev1 PDF

1 SATIP-W-011-01 Welding of On-Plot Piping - Rev1 PDF

Uploaded by

WIZKHALIFACopyright:

Available Formats

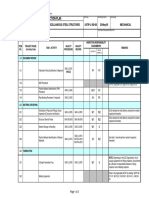

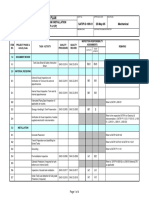

SAUDI ARAMCO ID/PID - REV 1 - 5/18/05 (Standards Cutoff - August 2004)

SATIP No.

SAUDI ARAMCO TYPICAL INSPECTION PLAN

WELDING OF ON-PLOT PIPING

APPROVED DATE

SATIP-W-011-01

PROJECT TITLE:

ITEM

NO.

1.0

PROJECT PHASE

25-May-05

MECHANICAL

CONTRACTOR/SUBCONTRACTOR

TASK / ACTIVITY

CHECKLIST

and/or

TEST RECORD

QUALITY

RECORD

INSPECTION RESPONSIBILITY

ASSIGNMENTS

CNTRCTR

SAUDI

ARAMCO

REMARKS

DOCUMENT REVIEW

1.1

Welding Procedure

Specifications/Welding Procedure

Qualification Record (WPS/WPQR)

SAIC-W-2001

RH1

RH1

1.2

Welder & Welding Operator

Certifications (and Issuance of JCC)

SAIC-W-2035

RH1

R1

1.3

Method Statement & WPS for Weld

Repair, ie:

a) Crack and other weld defects

b) Weld mis-alignments

SAIC-W-2002

RH1

RH1

1.4

Procedure for Weld Identification and

Weld Traceability (Original Welds and

modified/repaired welds)

SAIC-W-2008

RH1

RH1

SAIC-W-2003

RH1

RH1

SAIC-W-2012

RH1

RH1

SAIC-L-2004

RH1

RH1

Post Weld Heat Treatment (PWHT)

Procedure

Production Weld Hardness Testing

Procedure

Positive Material Identification Procedure

(Alloy Verification)

1.5

1.6

1.7

Refer to the respective SATIP for NDE (SATIP-NDEUT-01, LPT-01, MPT-01, RT-01)

1.8

Non-Destructive Testing Procedures

1.9

Procedure for Control of Welding

Consumables

SAIC-W-2009

2.1

Receiving Inspection and Verification of

Welding Consumables-(Properties, Type,

approve source, storage, etc.)

SAIC-W-2010

2.2

Welding Equipment Calibration

Verification

SAIC-W-2011

2.0

DISCIPLINE:

RH1

R1

SAIC-W-2010

SATR-W-2009

H1

W2

S. Aramco shall verify and inspect the first batch of

delivered consumables, then random inspection

thereafter.

SAIC-W-2011

SATR-W-2011

H1

W2

Random witnessing by S. Aramco at each calibration

cycle.

MATERIAL RECEIVING

Page 1 of 4

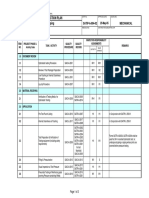

SAUDI ARAMCO ID/PID - REV 1 - 5/18/05 (Standards Cutoff - August 2004)

APPROVED DATE

SATIP No.

SAUDI ARAMCO TYPICAL INSPECTION PLAN

WELDING OF ON-PLOT PIPING

SATIP-W-011-01

PROJECT TITLE:

ITEM

NO.

PROJECT PHASE

3.0

3.1

3.2

TASK / ACTIVITY

3.4

Control of Welding ConsumablesStorage, Handling, Issuance &

Conditioning

3.7

CHECKLIST

and/or

TEST RECORD

QUALITY

RECORD

SAIC-L-2010

SAIC-L-2010

SATR-A-2012

SATR-A-2013

INSPECTION RESPONSIBILITY

ASSIGNMENTS

CNTRCTR

SAUDI

ARAMCO

H1

W1

Welding of Overlays & Clad Materials

(If Required)

Welding of Strip Linings

(If Required)

Welding of Special Corrosion-Resistant

Materials

(If Required)

3.6

MECHANICAL

REMARKS

Refer to Note 1 of the General Notes for S.Aramco

Inspection responsibility, afterwhich pre-arranged

witnessing shall be agreed upon.

INSTALLATION

3.3

3.5

25-May-05

CONTRACTOR/SUBCONTRACTOR

Positive Material Identification of Low

Alloy, Stainless Steel, Nickel & Copper

Based Materials (If Required)

2.3

DISCIPLINE:

Buttering or Weld Build-Up of Joints

Pre-Welding & Weld Joint Fit-Up

Inspection

In-Process Weld Inspection

See SATIP No: W-014-01

See SATIP N0: W-016-01 and other applicable SATIPW series (if required)

See SATIP No: W-016-01

SAIC-W-2032

SAIC-W-2033

SAIC-W-2005

SAIC-W-2006

SAIC-W-2032

SATR-W-2010

SAIC-W-2033

SATR-W-2006

SAIC-W-2005

SATR-W-2006

SAIC-W-2006

SATR-W-2007

Page 2 of 4

H1

H1

H1

W1

W1/H1

Saudi Aramco inspection responsibility varies from H1

to W1:

a) "W1" -for build-up thickness not exceeding 1/3 of

the metal thickness or 10mm whicever is less.

b) "H1" - for build-up thickness exceeding the above

and requiring CSD's approval.

W2/H1

(See

remarks)

S. Aramco's responsibilities varies as follows :

a) "W2" - for Welding on normal services at normal

conditions, refer to Note 1 of the General Notes.

b) "H1" - for critical welds, ie.; Tie-Ins, buttering, Hot

Taps, NDE-In-Lieu of Hydro & others as determined by

project requirements.

S/W2

(See

remarks)

S. Aramco's responsibilities varies as follows:

a) "S" - Generally is a surveillance activity for Saudi

Aramco, except in welding of stainless steel piping and

piping in low temp service.

b) "W2" - S. Aramco inspects and verifies Heat Input at

random or on routine basis for low temp service and

for stainless steel welding.

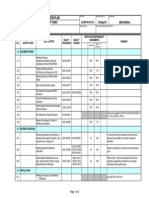

SAUDI ARAMCO ID/PID - REV 1 - 5/18/05 (Standards Cutoff - August 2004)

APPROVED DATE

SATIP No.

SAUDI ARAMCO TYPICAL INSPECTION PLAN

WELDING OF ON-PLOT PIPING

SATIP-W-011-01

PROJECT TITLE:

ITEM

NO.

PROJECT PHASE

25-May-05

MECHANICAL

CONTRACTOR/SUBCONTRACTOR

TASK / ACTIVITY

CHECKLIST

and/or

TEST RECORD

QUALITY

RECORD

INSPECTION RESPONSIBILITY

ASSIGNMENTS

CNTRCTR

SAUDI

ARAMCO

3.8

Inspect Welding of Socket Joint and Seal

Welding Threaded Jts.

SAIC-W-2037

SAIC-W-2037

H1

W1

3.9

Post-Welding Visual Inspection

SAIC-W-2007

SAIC-W-2007

SATR-W-2007

H1

W1

3.10

Repair of Weld Joints or Base Metal by

Welding (Prior to Weld Acceptance)

SAIC-W-2013

SAIC-W-2013

W1

3.11

DISCIPLINE:

Selection of Weld Joints for NDE

SAIC-W-2015

SATR-W-2007

H1

REMARKS

W1/W2

For Saudi Aramco Responsibility:

a) "W1" -PID Inspectors shall participate in the

seletion of weld to be radiographed.

b) "W2" - will be in effect once the level of

confidence to the QC is established.

* Use the applicable SATIPS:

a) SATIP-NDE-LT-01

b) SATIP-NDE-LPT-01

c) SATIP-NDE-MPT-01

d) SATIP-NDE-RT-01

e) SATIP-NDE-UT-01

**Refer to Note 1 of the General Notes for S.Aramco

Inspection responsibility, afterwhich

pre-arranged or random Witnessing shall be

agreed upon.

3.12

Verification of Non-Destructive

Examination Method Application and

Evaluation of Results

See Remarks

See Remarks

W1/RH1

W1/R1

3.13

Weekly reporting of the following:

a) Production Weld Status,

b) Welder & Project Repair Rate

c) Welder's Repair Assessment &

Tracer Welds

SAIC-W-2016

SAIC-W-2016

SATR-W-2013

SATR-W-2018

SATR-W-2019

H1

R1

3.14

Post Weld Heat Treatment Inspection

SAIC-W-2004

SAIC-W-2004

SATR-W-2005

H1

W1& R1

Refer to Note 1 of the General Notes for S.Aramco

Inspection responsibility, afterwhich pre-arranged

witnessing shall be agreed upon.

3.15

Verification of Hardness Testing

Application and Results

SAIC-W-2014

SAIC-W-2014

SATR-W-2012

H1

W1 & R1

Refer to Note 1 of the General Notes for S.Aramco

Inspection responsibility, afterwhich pre-arranged

witnessing shall be agreed upon.

Page 3 of 4

S. Aramco reviews on weekly basis.

SAUDI ARAMCO ID/PID - REV 1 - 5/18/05 (Standards Cutoff - August 2004)

APPROVED DATE

SATIP No.

SAUDI ARAMCO TYPICAL INSPECTION PLAN

WELDING OF ON-PLOT PIPING

SATIP-W-011-01

PROJECT TITLE:

ITEM

NO.

25-May-05

MECHANICAL

CONTRACTOR/SUBCONTRACTOR

PROJECT PHASE

TASK / ACTIVITY

CHECKLIST

and/or

TEST RECORD

QUALITY

RECORD

INSPECTION RESPONSIBILITY

ASSIGNMENTS

CNTRCTR

SAUDI

ARAMCO

3.16

Positive Material Identification (PMI) of

Deposited Weld for alloyed materials

within the scope of SAES-A-206.

SAIC-L-2010

SAIC-L-2010

SATR-A-2012

SATR-A-2013

H1

W\1 & R1

3.17

Weld Modification or Re-Work After Weld

Acceptance

SAIC-W-2036

SAIC-W-2036

H1

H1

SATR-W-2008

H1

R1

4.0

DISCIPLINE:

REMARKS

Refer to Note 1 of the General Notes for S.Aramco

Inspection responsibility, afterwhich pre-arranged

witnessing shall be agreed upon.

PRE-COMMISSIONING

Final Welding Inspection &

Documentation (Welding Summary

Report / Record & Weld Map)

4.1

Refer to Note 1 of the General Notes for S.Aramco

Inspection responsibility, afterwhich pre-arranged or

random Review shall be agreed upon.

GENERAL NOTES

1

The first three incidents of each Inspection or testing activity listed require 100 % participation by Saudi Aramco Site Inspection Personnel. After this period, Saudi Aramco Inspection may adjust the levels

of Saudi Aramco participation based upon the Contractors performance.

Surveillance: QA/QC organization to monitor work in progress without notice from Construction Organization

Witness:

QA/QC organization shall be notified of the timing of Inspection or test in advance. However, the inspection or test shall be performed as scheduled if the QA/QC organization representative

is not present.

Hold:

If the Main Contractor delegates the assigned responsibility to the Subcontractor, then the Main Contractor will have the same degree of responsibility as assigned to Saudi Aramco.

QA/QC organization shall be notified of the timing of inspection or test in advance. Inspection or test shall not be carried out without the QA/QC organization representative in attendance.

LEGEND

W1

100% Witness Inspection/Test

H2

Sample Hold Point for QC Inspection or Test

RH1

100% Review and Approval of Documents

W2

Sample Witness Inspection/Test

R1

100% Review of Documents

RH2

Sample Review and Approval of Documents

H1

100% Hold Point for QC Inspection or Test

R2

Sample Review of Documents

Page 4 of 4

Surveillance

You might also like

- API 653 Above Ground Storage Tank InspectorDocument2 pagesAPI 653 Above Ground Storage Tank InspectorMohamed Hichem Guesmi0% (1)

- 1 SATIP-L-350-08 Shop Fab - Piping and Steel Structures-Rev1Document2 pages1 SATIP-L-350-08 Shop Fab - Piping and Steel Structures-Rev1skychurch100% (2)

- API 1104 PAUT Cal BlockDocument2 pagesAPI 1104 PAUT Cal BlockWIZKHALIFA100% (2)

- TOFD & PA Procedure For 301Document49 pagesTOFD & PA Procedure For 301WIZKHALIFA93% (14)

- 1 SATIP-A-004-02 Hydro Test of Plant Piping-Rev 1Document2 pages1 SATIP-A-004-02 Hydro Test of Plant Piping-Rev 1Ariel Anasco50% (2)

- SAIC-A-2020 Rev 2Document3 pagesSAIC-A-2020 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- 1 SATIP-W-016-01 Welding of S C R M & Duplex SS - Rev 1Document4 pages1 SATIP-W-016-01 Welding of S C R M & Duplex SS - Rev 1JithuJohnNo ratings yet

- PIPELINE Punch ListDocument2 pagesPIPELINE Punch ListTanveer Rajput EngrNo ratings yet

- Reduce Repair Rate of Welding ProcessesDocument3 pagesReduce Repair Rate of Welding ProcessesAnouar AbdelmoulaNo ratings yet

- Inspection and Test Plan For Valve: Before ManufacturingDocument2 pagesInspection and Test Plan For Valve: Before ManufacturingkarthikNo ratings yet

- Rotating Equipment PreservationDocument7 pagesRotating Equipment PreservationaamirapiNo ratings yet

- Installation Procedure For Gre PipeDocument14 pagesInstallation Procedure For Gre PipeNithin Mathai100% (1)

- Inspection Test Plan: Itp No: REV:1.0 DateDocument3 pagesInspection Test Plan: Itp No: REV:1.0 Datemohd as shahiddin jafriNo ratings yet

- Oman-India Fertilizer Project OIFDocument24 pagesOman-India Fertilizer Project OIFBassam Dahham83% (6)

- Enbridge Pipeline Repair Workplan Welding PDFDocument23 pagesEnbridge Pipeline Repair Workplan Welding PDFquiron2014No ratings yet

- Materials System SpecificationDocument13 pagesMaterials System SpecificationJeck MaquitedNo ratings yet

- Nozzle Fit-Up Inspection Report: Inspected & Prepared byDocument9 pagesNozzle Fit-Up Inspection Report: Inspected & Prepared byDaison PaulNo ratings yet

- Welding Repair ProcdureDocument16 pagesWelding Repair Procdureprem nautiyal100% (1)

- ED 00 CPL PRC 0021 Construction QC Procedure Rev.2Document24 pagesED 00 CPL PRC 0021 Construction QC Procedure Rev.2Rahmat Hidayat100% (1)

- O - (TOC) - SOP - 008 - R0 - SOP For Welding Consumables Handling and ControlDocument8 pagesO - (TOC) - SOP - 008 - R0 - SOP For Welding Consumables Handling and ControlMDhana SekarNo ratings yet

- Pressure Vessel RT TestDocument4 pagesPressure Vessel RT TestalokbdasNo ratings yet

- Technical SpecificationsDocument62 pagesTechnical SpecificationsRamu Nallathambi100% (1)

- Inspection of Testing Pipe SupportDocument44 pagesInspection of Testing Pipe Supportiran1362No ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 MechDocument15 pagesSaudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 Mechpookkoya thangalNo ratings yet

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapNo ratings yet

- Sa 6717Document1 pageSa 6717biplabpal2009No ratings yet

- Pipe Fit Up ReportDocument2 pagesPipe Fit Up ReportnguyenquanghiepNo ratings yet

- QAP ITP Bhogat - REV-01Document8 pagesQAP ITP Bhogat - REV-01Ramkunwar YadavNo ratings yet

- Specification For Fabrication and Erection ofDocument26 pagesSpecification For Fabrication and Erection ofEdgargarNo ratings yet

- PQR Asme Ix - CompletedDocument3 pagesPQR Asme Ix - CompletedCarlos Nombela Palacios100% (1)

- Saudi Aramco Typical Inspection PlanDocument3 pagesSaudi Aramco Typical Inspection PlanAnonymous S9qBDVkyNo ratings yet

- Risks in Facility Build Quality and Project Handover: What Happened?Document3 pagesRisks in Facility Build Quality and Project Handover: What Happened?musaismail8863No ratings yet

- Welding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldDocument2 pagesWelding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldAbdulmecit YetisNo ratings yet

- Saudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Document1 pageSaudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Mohammed Hamed BaganNo ratings yet

- 012 QualityNewsLetter - January2012Document8 pages012 QualityNewsLetter - January2012ரமேஷ் பாலக்காடுNo ratings yet

- ITP-Onshore-Pipeline PTMDocument2 pagesITP-Onshore-Pipeline PTMFerdie OSNo ratings yet

- Process Piping Inspection and Test PlanDocument6 pagesProcess Piping Inspection and Test Planmanoj thakkarNo ratings yet

- Butt JointsDocument21 pagesButt JointsRaj1-23No ratings yet

- ES.5.06.0001 RA - PressureVesselsDocument28 pagesES.5.06.0001 RA - PressureVesselsJagadeesh PuppalaNo ratings yet

- 13427-01weekly QAQC ReportDocument1 page13427-01weekly QAQC ReportShyam SinghNo ratings yet

- Co ., LT D.: ASME A-106/A-106M - 2019 EDITION Material Verification The Original Markings On ProductionDocument2 pagesCo ., LT D.: ASME A-106/A-106M - 2019 EDITION Material Verification The Original Markings On ProductionBalaji SelvarajNo ratings yet

- Tank Maintenance ITPDocument24 pagesTank Maintenance ITPthomas varugheseNo ratings yet

- Quality Assurance Audit For Piping FabricationDocument3 pagesQuality Assurance Audit For Piping Fabricationapply19842371No ratings yet

- METHOD STATEMENT FOR Pneumatic TestDocument11 pagesMETHOD STATEMENT FOR Pneumatic Testzahid100% (1)

- 8615 Nozzle Orientation Report 01Document4 pages8615 Nozzle Orientation Report 01Bsc Aditya Singh Dinkar100% (1)

- Nexteer Quality Alert: Response RequiredDocument1 pageNexteer Quality Alert: Response RequiredsimsonNo ratings yet

- 1 Imran Piping QC CVDocument4 pages1 Imran Piping QC CVkazim MirzaNo ratings yet

- Welding Terminology Dan Welding Positions PDFDocument52 pagesWelding Terminology Dan Welding Positions PDFRama TamaNo ratings yet

- Thickness Qualification Range For PQR and WPQDocument5 pagesThickness Qualification Range For PQR and WPQOuled BladiNo ratings yet

- Ug PipingDocument51 pagesUg PipingMuthu AlaguRaj100% (1)

- Inspection and Test Plan For Storage TankDocument7 pagesInspection and Test Plan For Storage TankABDELKADER BENABDALLAHNo ratings yet

- 5.1 - (ANX-1) Inspection Test Plan (ITP) ListDocument3 pages5.1 - (ANX-1) Inspection Test Plan (ITP) ListWinston BoxNo ratings yet

- Itp For Gasket - r1Document7 pagesItp For Gasket - r1Hamid Taghipour ArmakiNo ratings yet

- Test Pack SampleDocument12 pagesTest Pack SampleGomathyselviNo ratings yet

- Fabrication of ManifoldDocument2 pagesFabrication of Manifoldsarangpune100% (1)

- Welding Procedure Qualification Record (WPQR)Document8 pagesWelding Procedure Qualification Record (WPQR)Belin InversoNo ratings yet

- PIPE LINE Presentation PART 1Document33 pagesPIPE LINE Presentation PART 1kannan100% (1)

- 19 - Weld Fit Up Inspection Employee TrainingDocument10 pages19 - Weld Fit Up Inspection Employee TrainingManoj KumarNo ratings yet

- SQAE Velosi Interview PreparationDocument10 pagesSQAE Velosi Interview PreparationSebastian RajeshNo ratings yet

- 1 SATIP-W-017-01 Welding of API Tanks-Rev 1Document4 pages1 SATIP-W-017-01 Welding of API Tanks-Rev 1khalid764No ratings yet

- 1 SATIP-D-109-01 Shop Fab Storage Tank PDFDocument4 pages1 SATIP-D-109-01 Shop Fab Storage Tank PDFJithuJohnNo ratings yet

- Wiley Practitioner's Guide to GAAS 2023: Covering All SASs, SSAEs, SSARSs, and InterpretationsFrom EverandWiley Practitioner's Guide to GAAS 2023: Covering All SASs, SSAEs, SSARSs, and InterpretationsNo ratings yet

- 311d AP Se z3 Tmmk1a Kijun Rev1Document9 pages311d AP Se z3 Tmmk1a Kijun Rev1WIZKHALIFANo ratings yet

- NDT and IRIS Status RCON SD 2015extractedDocument9 pagesNDT and IRIS Status RCON SD 2015extractedWIZKHALIFA100% (1)

- Thanesh Kumar NagendranDocument3 pagesThanesh Kumar NagendranWIZKHALIFANo ratings yet

- 17 No Dues Certificate v2Document2 pages17 No Dues Certificate v2WIZKHALIFANo ratings yet