Professional Documents

Culture Documents

Aircon Finals

Aircon Finals

Uploaded by

Justine AbanadorCopyright:

Available Formats

You might also like

- Jackson9 14Document2 pagesJackson9 14fawaadakhtar100% (1)

- Curved Beam ExperimentDocument2 pagesCurved Beam ExperimentPasindu Malith0% (1)

- Volume Holographic Gratings (VHG) in ZemaxDocument39 pagesVolume Holographic Gratings (VHG) in ZemaxLeandro Bertoluzzi100% (2)

- N2 Purging PDFDocument5 pagesN2 Purging PDFMohamed AdelNo ratings yet

- Marichem Instruction BookDocument11 pagesMarichem Instruction BookGeorgios Papakostas100% (1)

- Vaccum Approach Study-Nassim Haramein PDFDocument13 pagesVaccum Approach Study-Nassim Haramein PDFIVONNE GOETSCHNo ratings yet

- Study of A Single Pass Shell and Tube Heat ExchangerDocument21 pagesStudy of A Single Pass Shell and Tube Heat Exchangermahbub1332No ratings yet

- Tutorial Steam GenerationDocument2 pagesTutorial Steam GenerationAmanda KodippiliNo ratings yet

- Cyclone CalculatorDocument19 pagesCyclone CalculatornarsingrameshNo ratings yet

- Perhitungan Excel FluidaDocument13 pagesPerhitungan Excel FluidaSandi KurniawanNo ratings yet

- Halliburton Main MenuDocument160 pagesHalliburton Main Menumuki10100% (1)

- Cooling - Tower and Boiler CalculationDocument47 pagesCooling - Tower and Boiler CalculationDavid LambertNo ratings yet

- MEGAL TKM Tehnicke KarakteristikeDocument12 pagesMEGAL TKM Tehnicke Karakteristikezexi84No ratings yet

- C&D Front Acces PDFDocument0 pagesC&D Front Acces PDFPaul RasmussenNo ratings yet

- Perancangan CycloneDocument20 pagesPerancangan CycloneDavid LambertNo ratings yet

- Roof Calculation Book - UBC DESIGN PDFDocument70 pagesRoof Calculation Book - UBC DESIGN PDFStephanie CampbellNo ratings yet

- Study of Steam Condensation On A Single Vertical TubeDocument27 pagesStudy of Steam Condensation On A Single Vertical Tubemahbub1332No ratings yet

- SCLP SCMDocument6 pagesSCLP SCMsogetsu kazamaNo ratings yet

- Batteries Ni-CD Saft SCL P - SCMDocument6 pagesBatteries Ni-CD Saft SCL P - SCMULTG T3GALNo ratings yet

- TIP Application Manual Part 2 Draft PlanningDocument274 pagesTIP Application Manual Part 2 Draft PlanningStrahinja Vukovic100% (1)

- Of College of Chemical: Classical ClassDocument4 pagesOf College of Chemical: Classical Classنزار الدهاميNo ratings yet

- Midea 2005 Split Service ManualDocument359 pagesMidea 2005 Split Service ManualSotiris Ioannou60% (5)

- Mws Mec Ode TXT Runge4th Examples PDFDocument6 pagesMws Mec Ode TXT Runge4th Examples PDFeliasdu07No ratings yet

- Vol 1 - HVACDocument44 pagesVol 1 - HVACFarah DinaNo ratings yet

- L I G H TDocument4 pagesL I G H TPrem SharmaNo ratings yet

- L I G H TDocument4 pagesL I G H TPrem SharmaNo ratings yet

- L I G H TDocument4 pagesL I G H TPrem SharmaNo ratings yet

- Verification of Bernoulli'S Theorem ObjectivesDocument11 pagesVerification of Bernoulli'S Theorem Objectivesprakhar mishraNo ratings yet

- API 5L Line Pipe ODDocument2 pagesAPI 5L Line Pipe ODZainudinNo ratings yet

- Gas Steam SpecsDocument10 pagesGas Steam SpecsTriplx TriplexNo ratings yet

- L I G H TDocument4 pagesL I G H TPrem SharmaNo ratings yet

- Maintenance Chart and PriceDocument21 pagesMaintenance Chart and PriceDibas BaniyaNo ratings yet

- MV Lovely Falcon1278316856Document15 pagesMV Lovely Falcon1278316856Abdulachim EminNo ratings yet

- Air PurgingDocument14 pagesAir PurgingjgdberizoNo ratings yet

- Purge With NitrogenDocument5 pagesPurge With NitrogenSurya Kiran KNo ratings yet

- Wastewater Technical ManualDocument32 pagesWastewater Technical ManualagonzalezcordovaNo ratings yet

- How To Get Started Danfoss Compressors - BD SolarDocument12 pagesHow To Get Started Danfoss Compressors - BD SolarFEF777No ratings yet

- L I G H TDocument4 pagesL I G H TPrem SharmaNo ratings yet

- L I G H TDocument4 pagesL I G H TPrem SharmaNo ratings yet

- 12270r0 - Price SummaryDocument5 pages12270r0 - Price SummaryyulistanaNo ratings yet

- L I G H TDocument4 pagesL I G H TPrem SharmaNo ratings yet

- GgooDocument4 pagesGgooPrem SharmaNo ratings yet

- Valve CalculationDocument2 pagesValve Calculationjay_rajeshirkeNo ratings yet

- For Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Document4 pagesFor Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Prem SharmaNo ratings yet

- Praktikum Propulsi BDocument5 pagesPraktikum Propulsi BMokoNo ratings yet

- Modeling A Crude Vacuum System With Preheat TrainDocument6 pagesModeling A Crude Vacuum System With Preheat TrainELTIPAZONo ratings yet

- Experiment 5: Bernoulli's Equation: Murad Alshammas ID: 20161203013 EXP - DATE: 25/3/2019 DUE DATE: 1/4/2019Document7 pagesExperiment 5: Bernoulli's Equation: Murad Alshammas ID: 20161203013 EXP - DATE: 25/3/2019 DUE DATE: 1/4/2019Bandali TannousNo ratings yet

- Service Manual Hisens Premium Slim Design Super DC Inverter EngDocument37 pagesService Manual Hisens Premium Slim Design Super DC Inverter EngsaryanovichgNo ratings yet

- Tabla de DecaimientoDocument1 pageTabla de DecaimientoGregorioNo ratings yet

- Air Compressors, Screw Type, Altitude Corrections - 01 PDFDocument28 pagesAir Compressors, Screw Type, Altitude Corrections - 01 PDFluisbitron1527No ratings yet

- Assignment 1Document21 pagesAssignment 1Lim Chong SiangNo ratings yet

- Well No Depth (FT) Temperature at Depth (°F) Well #1 9100 225 Well #2 8100 209.6 Well #3 9500 232Document31 pagesWell No Depth (FT) Temperature at Depth (°F) Well #1 9100 225 Well #2 8100 209.6 Well #3 9500 232Deny Fatryanto EkoNo ratings yet

- Perhitungan CT, Hydrant, Dan BlowerDocument13 pagesPerhitungan CT, Hydrant, Dan BlowerNicholas GeorgeNo ratings yet

- JJJJDocument4 pagesJJJJPrem SharmaNo ratings yet

- L I G H TDocument4 pagesL I G H TPrem SharmaNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Case Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferFrom EverandCase Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferRating: 5 out of 5 stars5/5 (2)

- Advanced Plasma TechnologyFrom EverandAdvanced Plasma TechnologyRiccardo d'AgostinoNo ratings yet

- Hydroprocessing for Clean Energy: Design, Operation, and OptimizationFrom EverandHydroprocessing for Clean Energy: Design, Operation, and OptimizationNo ratings yet

- Fast Algorithm For DCTDocument20 pagesFast Algorithm For DCTsuhmudNo ratings yet

- Hach Pocket Pro TestersDocument4 pagesHach Pocket Pro TestersDavid Cruz ZamoraNo ratings yet

- Bone Ash Project 1-3 On Progress QaDocument26 pagesBone Ash Project 1-3 On Progress QaOshogbunu Onoriode ErnestNo ratings yet

- Exposer Anglais EnvironnementDocument4 pagesExposer Anglais EnvironnementAndrian100% (1)

- Ase 301 - HW1Document3 pagesAse 301 - HW1isaac tsaiNo ratings yet

- ME 231 All Instructors Whharris 11-9-17SOLUTIONDocument4 pagesME 231 All Instructors Whharris 11-9-17SOLUTIONEstebanGiraldoNo ratings yet

- Projet x60 Series Us 0Document4 pagesProjet x60 Series Us 0Ehab AlzabtNo ratings yet

- Bcs TheoryDocument18 pagesBcs Theoryanon_30981041No ratings yet

- 09 Light Reflection and Refraction Chapter Wise Important QuestionsDocument17 pages09 Light Reflection and Refraction Chapter Wise Important QuestionsKrsna JaiswalNo ratings yet

- Cement Process Engineering Vade Mecum: 2. StatisticsDocument15 pagesCement Process Engineering Vade Mecum: 2. StatisticsTamer FathyNo ratings yet

- Ansys LabDocument47 pagesAnsys LabPraveen KumarNo ratings yet

- WB-Mech 120 Ch03 AnalysisDocument55 pagesWB-Mech 120 Ch03 AnalysisMamu MachaNo ratings yet

- Y7 Energy TransfersDocument29 pagesY7 Energy Transfersjamie_venning_1No ratings yet

- MacrocosmDocument3 pagesMacrocosmMh Nurul Huda100% (1)

- L I::-.,: ,: L " j:'1.Document84 pagesL I::-.,: ,: L " j:'1.thermo2014No ratings yet

- 22-Year Clinical Evaluation of The Performance of Two Posterior Composites With Different Filler CharacteristicsDocument9 pages22-Year Clinical Evaluation of The Performance of Two Posterior Composites With Different Filler CharacteristicsAl-Kawthari As-SunniNo ratings yet

- Unit - 2 Optimal Design of DC Machine Unit-02/Lecture-01Document31 pagesUnit - 2 Optimal Design of DC Machine Unit-02/Lecture-01madeehaNo ratings yet

- For Questions 1 To 14, Fill in Your Answers in The Spaces ProvidedDocument4 pagesFor Questions 1 To 14, Fill in Your Answers in The Spaces Providedchaiseng yongNo ratings yet

- Keep 501Document13 pagesKeep 501Suriya ElangoNo ratings yet

- Guide To Magnifying GlassesDocument2 pagesGuide To Magnifying GlassesIndustry JunkieNo ratings yet

- CARB in Industrial FansDocument8 pagesCARB in Industrial FansJurun_Bidanshi100% (1)

- PD Diagnostics On Rotating Machines - Possibilities and Limitations - M. Hoof, S. Lanz - ABB - EIC - 1999Document6 pagesPD Diagnostics On Rotating Machines - Possibilities and Limitations - M. Hoof, S. Lanz - ABB - EIC - 1999tecolanzNo ratings yet

- H53015302 TRQ XXXDocument2 pagesH53015302 TRQ XXXTuTuy AnNo ratings yet

- 560Gti/660Gti: 60Th Anniversary EditionDocument20 pages560Gti/660Gti: 60Th Anniversary EditionDeepak SamNo ratings yet

- CT 4201304Document26 pagesCT 4201304shefalimathur91No ratings yet

Aircon Finals

Aircon Finals

Uploaded by

Justine AbanadorOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aircon Finals

Aircon Finals

Uploaded by

Justine AbanadorCopyright:

Available Formats

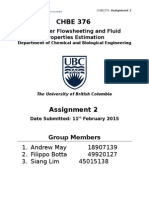

Republic of the Philippines

BSU Campus II, Alangilan, Batangas City

Mechanical Engineering Department

Final Exam ME 522 Air conditioning

2nd Semester 2013-14

Name:

______________________________________Section____________________Date____________

Instructions:

1. Maintain honest atmosphere in side examination room. Communication or any act of getting

the attention of seatmate is strictly prohibited. For necessary question refer to Instructor/

proctor.

2. In problem solving, work for a good solution and double check the answer.

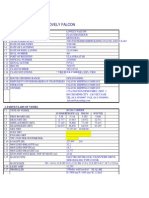

2.0 CHW piping:

FCU

FCU

10m

EV

15m

FCU

CHILLER-146.671 TR4m

2m 3m

P

10m

10m

10m

4m

5th Floor

FCU

FCU

4m

FCU

FCU

FCU

AAV

3m

A

1.5m

AHU-5TR

AHU-29.557TR

4m

3rd Floor

CHWR

12.0oC

All FCU-

3.0TR

4m

4m

10m

E

AHU-29.557TR

FCU

FCU

FCU

FCU

Ground Floor

6.0oC

AHU-29.557TR

4m

2nd Floor

CHWS

10m

10m

F

10m

G

FCU

FCU

FCU

15m

H

FCU

AAV

4m

3m

AHU-5TR

Required:

1.0 Calculate the volume flow rate handled by the chiller.

2.0 Calculate the volume flow rate carried by each AHUs and FCUs.

3.0 Prepare tabulated information to present the longest pipe run and the required information regarding

flow rate, pipe sizes DN, Velocity of Flow, pressures gradient, equivalent length and section pressure

drop.

4.0 Determine the total dynamic head of circulating chilled water pump if the chiller has 2.4Kpa pressure

drop and AHU-5TR has pressure drop of 1.4Kpa.

5.0 Calculate the brake power of chilled water pump if the pump efficiency is 72%.

6.0 Determine the volume of expansion vessel if the maximum static height is 20m and the total system

volume water content is 4.0m3 at a fill water temperature of 20 oC.

Engr. Ed F. Florindo

Asso. Professor III

Dr. Jessie A. Montalbo

Dean, CEAFA

Republic of the Philippines

BSU Campus II, Alangilan, Batangas City

Mechanical Engineering Department

Final Exam ME 522 Air conditioning

2nd Semester 2013-14

Prob.2.0 For Chilled water Piping:

Pipe Run

Q, Lit/sec

Pump- Chil

20.54

Chil A

20.54

AB

16.479

BC

12.34

CD

8.201

DE

4.062

EF

3.221

FG

2.381

GH

1.541

H AHU

0.7

DN,

ID=

100

102.3

100

102.3

100

102.3

75

77.92

75

77.92

50

52.51

50

50.51

50

50.51

40

40.9

35

35.04

2.5

Pres.Grad.

P/m

550

2.5

550

5 + 60.9 =65.9

2.00

360

1.5 + 19.513 = 21.013

7, 564.98

2.587

780

4.0 + 0.9 = 4.90

3,822.00

1.719

390

4 + 0.9 + 18.035 =22.935

8,944.65

1.875

710

8 + 2.7 = 10.7

7,597.00

1.606

590

10 + 0.6 = 10.6

6,254.00

1.188

330

10 + 4.171= 14.171

4,676.43

1.172

410

10 +1.05 = 11.05

4,530.50

0.7259

220

32 + 11.9 = 43.9

9,658.00

Vel.m/sec

Space for chilled water flow rate

calculation

146.671 3.5167 m 4.187

Equivalent Length, m

2 +85 = 87

Press drop,

Pa

47, 850

36, 245

Total Pressure Drop for Supply line 137,142.56

12.0 6 ;

29.557 3.5167 mw 4.187 12.0 6 ;

mw 20.531Kg / sec

vw 20.54l / sec chil

mw 4.1375 Kg / sec

vw 4.139l / sec ahu

5.0 3.5167 mw 4.187 12.0 6 ;

mw 0.6999 Kg / sec

3.0 3.5167 mw 4.187 12.0 6 ;

mw 0.41 995 Kg / sec

vw 0.7 / sec

AHU 5

vw 0.4201/ sec FCU

Pump disch arg e to chiller : 4 4.3 3 3.6 38 19 85m

chiller A : 3 4.3 3.6 38 6.4 60.9m

A B : TeeST 1.2 Ploss

2.587 2

2

999.6

B C : TeeST 0.9m; C D TeeST 0.9m Ploss

F G : TeeST 0.6m Ploss

G H : TeeST 0.5m Ploss

102.3

77.92

1.8752

2

52.51

1.1722

999.6

2

40.9

999.6

4

1.2

77.92

52.51

6592.982

19.513m

360

7034

1

0.9

18.935m

390

1178.68

1

0.6

4.171m

330

0.72592

40.9

999.6

2

35.04

225.5

1

0.5

1.05m

410

H AHU ; 4 1.2 1.6 5.5 11.9 m

4) TDH 137.14256 2 2.1 1.4

20.54

1000

9.806

72%

5) BPw 28.327 m

v Vs

6) Volev

Pa

P

a

vc

Po

Ph

277.785 Kpa

28.327 m

9.806

7.924 KW

1.7 0.06 4

101.325 101.325

0.0010017 297.185 378.73

Prob.1 Cooling and Dehumidifying coil:

Given: Qair =2.4m3/sec @ 29oCDB & 24oCWB;

hc =65W/m2-oK;

=52 KW

Coil; direct expansion type; Vf = 2.5m/sec

hr = 2050W/m2-oK

2

2

Coil air side heat transfer area = 15m /m Af/no. of row of tube

Required:

a )Coil face area

0.924m 3 92.47lit .

Ao/Ai =1.4 Cooling

Cap

tr = 7oC

Qa

2.4

0.96 m 2

Vf

2.5

@ 29oCDB and 24oCWB

ha =72.2KJ/Kg

Va

=0.87856m /Kg

Wa =0.01684Kg/Kg

Ps =2.671Kpa Cpm =1.0062+1.88(0.01684)

=1.0378KKJ/Kg

b)enthalpy of outlet air ; 52

2.4

72.2 ho ; ho 53.17 KJ / Kg ;

0.87856

ma 2.7325 Kg / sec

c) wetted surface temperature @ each sec tion of coil ;

1

2

ha1 =72.2KJ/Kg

ha2 = 62.685KJ/Kg

ha3=53.17KJ/Kg

hi1 =48.62KJ/Kg

ti1 =17.25oC

hi2 =43.1KJ/Kg

ti2 =15.38oC

hi3 =37.976KJ/Kg

ti3 =13.5oC

tr=7oC

tr =7oC

tr =7oC

ti t p

hc

A

65

14

x

0.4277

C pm hr Ai

1.03786 2050 1

ha hi

ti

7

2

3

ha 9.3625 1.7861ti 0.01135ti 0.00098855ti 0

0.4277

0.4277

ti

7

2

3

0.4277 0.4277 72.2 9.3625 1.7861ti 0.01135ti 0.00098855ti 0;

ti1 17.25o C

hi1 9.3625 1.7861 17.25 0.01135 17.25 0.00098855 17.25 48.62 KJ / Kg

2

ti

7

2

3

62.685 9.3625 1.7861ti 0.01135ti 0.00098855ti 0;

0.4277 0.4277

ti 2 15.38o C

hi 2 9.3625 1.7861 15.38 0.01135 15.38 0.00098855 15.38 43.1KJ / Kg

2

ti

7

2

3

0.4277 0.4277 53.17 9.3625 1.7861ti 0.01135ti 0.00098855ti 0;

ti 3 13.5o C

hi 3 9.3625 1.7861 13.50 0.01135 13.50 0.00098855 13.50 37.976 KJ / Kg

2

d )total surface area @ each sec tion of coil ;

Q1 2 2.7325 72.2 62.685 26.0 Kw

A1 2

65

1.0378

26000

18.382m 2

72.2 62.685 46.62 43.1

2

2

Q2 3 2.7325 62.685 53.17 26.0 Kw

26000

23.871m 2 ;

65 62.685 53.17 43.1 37.976

1.0378

2

2

A1 2

At 23.871 18.832 42.70m 2

e)no.of row of tube

No. of row

42.7 m 2 0.96

15

2.732;

use : 3row

You might also like

- Jackson9 14Document2 pagesJackson9 14fawaadakhtar100% (1)

- Curved Beam ExperimentDocument2 pagesCurved Beam ExperimentPasindu Malith0% (1)

- Volume Holographic Gratings (VHG) in ZemaxDocument39 pagesVolume Holographic Gratings (VHG) in ZemaxLeandro Bertoluzzi100% (2)

- N2 Purging PDFDocument5 pagesN2 Purging PDFMohamed AdelNo ratings yet

- Marichem Instruction BookDocument11 pagesMarichem Instruction BookGeorgios Papakostas100% (1)

- Vaccum Approach Study-Nassim Haramein PDFDocument13 pagesVaccum Approach Study-Nassim Haramein PDFIVONNE GOETSCHNo ratings yet

- Study of A Single Pass Shell and Tube Heat ExchangerDocument21 pagesStudy of A Single Pass Shell and Tube Heat Exchangermahbub1332No ratings yet

- Tutorial Steam GenerationDocument2 pagesTutorial Steam GenerationAmanda KodippiliNo ratings yet

- Cyclone CalculatorDocument19 pagesCyclone CalculatornarsingrameshNo ratings yet

- Perhitungan Excel FluidaDocument13 pagesPerhitungan Excel FluidaSandi KurniawanNo ratings yet

- Halliburton Main MenuDocument160 pagesHalliburton Main Menumuki10100% (1)

- Cooling - Tower and Boiler CalculationDocument47 pagesCooling - Tower and Boiler CalculationDavid LambertNo ratings yet

- MEGAL TKM Tehnicke KarakteristikeDocument12 pagesMEGAL TKM Tehnicke Karakteristikezexi84No ratings yet

- C&D Front Acces PDFDocument0 pagesC&D Front Acces PDFPaul RasmussenNo ratings yet

- Perancangan CycloneDocument20 pagesPerancangan CycloneDavid LambertNo ratings yet

- Roof Calculation Book - UBC DESIGN PDFDocument70 pagesRoof Calculation Book - UBC DESIGN PDFStephanie CampbellNo ratings yet

- Study of Steam Condensation On A Single Vertical TubeDocument27 pagesStudy of Steam Condensation On A Single Vertical Tubemahbub1332No ratings yet

- SCLP SCMDocument6 pagesSCLP SCMsogetsu kazamaNo ratings yet

- Batteries Ni-CD Saft SCL P - SCMDocument6 pagesBatteries Ni-CD Saft SCL P - SCMULTG T3GALNo ratings yet

- TIP Application Manual Part 2 Draft PlanningDocument274 pagesTIP Application Manual Part 2 Draft PlanningStrahinja Vukovic100% (1)

- Of College of Chemical: Classical ClassDocument4 pagesOf College of Chemical: Classical Classنزار الدهاميNo ratings yet

- Midea 2005 Split Service ManualDocument359 pagesMidea 2005 Split Service ManualSotiris Ioannou60% (5)

- Mws Mec Ode TXT Runge4th Examples PDFDocument6 pagesMws Mec Ode TXT Runge4th Examples PDFeliasdu07No ratings yet

- Vol 1 - HVACDocument44 pagesVol 1 - HVACFarah DinaNo ratings yet

- L I G H TDocument4 pagesL I G H TPrem SharmaNo ratings yet

- L I G H TDocument4 pagesL I G H TPrem SharmaNo ratings yet

- L I G H TDocument4 pagesL I G H TPrem SharmaNo ratings yet

- Verification of Bernoulli'S Theorem ObjectivesDocument11 pagesVerification of Bernoulli'S Theorem Objectivesprakhar mishraNo ratings yet

- API 5L Line Pipe ODDocument2 pagesAPI 5L Line Pipe ODZainudinNo ratings yet

- Gas Steam SpecsDocument10 pagesGas Steam SpecsTriplx TriplexNo ratings yet

- L I G H TDocument4 pagesL I G H TPrem SharmaNo ratings yet

- Maintenance Chart and PriceDocument21 pagesMaintenance Chart and PriceDibas BaniyaNo ratings yet

- MV Lovely Falcon1278316856Document15 pagesMV Lovely Falcon1278316856Abdulachim EminNo ratings yet

- Air PurgingDocument14 pagesAir PurgingjgdberizoNo ratings yet

- Purge With NitrogenDocument5 pagesPurge With NitrogenSurya Kiran KNo ratings yet

- Wastewater Technical ManualDocument32 pagesWastewater Technical ManualagonzalezcordovaNo ratings yet

- How To Get Started Danfoss Compressors - BD SolarDocument12 pagesHow To Get Started Danfoss Compressors - BD SolarFEF777No ratings yet

- L I G H TDocument4 pagesL I G H TPrem SharmaNo ratings yet

- L I G H TDocument4 pagesL I G H TPrem SharmaNo ratings yet

- 12270r0 - Price SummaryDocument5 pages12270r0 - Price SummaryyulistanaNo ratings yet

- L I G H TDocument4 pagesL I G H TPrem SharmaNo ratings yet

- GgooDocument4 pagesGgooPrem SharmaNo ratings yet

- Valve CalculationDocument2 pagesValve Calculationjay_rajeshirkeNo ratings yet

- For Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Document4 pagesFor Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Prem SharmaNo ratings yet

- Praktikum Propulsi BDocument5 pagesPraktikum Propulsi BMokoNo ratings yet

- Modeling A Crude Vacuum System With Preheat TrainDocument6 pagesModeling A Crude Vacuum System With Preheat TrainELTIPAZONo ratings yet

- Experiment 5: Bernoulli's Equation: Murad Alshammas ID: 20161203013 EXP - DATE: 25/3/2019 DUE DATE: 1/4/2019Document7 pagesExperiment 5: Bernoulli's Equation: Murad Alshammas ID: 20161203013 EXP - DATE: 25/3/2019 DUE DATE: 1/4/2019Bandali TannousNo ratings yet

- Service Manual Hisens Premium Slim Design Super DC Inverter EngDocument37 pagesService Manual Hisens Premium Slim Design Super DC Inverter EngsaryanovichgNo ratings yet

- Tabla de DecaimientoDocument1 pageTabla de DecaimientoGregorioNo ratings yet

- Air Compressors, Screw Type, Altitude Corrections - 01 PDFDocument28 pagesAir Compressors, Screw Type, Altitude Corrections - 01 PDFluisbitron1527No ratings yet

- Assignment 1Document21 pagesAssignment 1Lim Chong SiangNo ratings yet

- Well No Depth (FT) Temperature at Depth (°F) Well #1 9100 225 Well #2 8100 209.6 Well #3 9500 232Document31 pagesWell No Depth (FT) Temperature at Depth (°F) Well #1 9100 225 Well #2 8100 209.6 Well #3 9500 232Deny Fatryanto EkoNo ratings yet

- Perhitungan CT, Hydrant, Dan BlowerDocument13 pagesPerhitungan CT, Hydrant, Dan BlowerNicholas GeorgeNo ratings yet

- JJJJDocument4 pagesJJJJPrem SharmaNo ratings yet

- L I G H TDocument4 pagesL I G H TPrem SharmaNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Case Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferFrom EverandCase Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferRating: 5 out of 5 stars5/5 (2)

- Advanced Plasma TechnologyFrom EverandAdvanced Plasma TechnologyRiccardo d'AgostinoNo ratings yet

- Hydroprocessing for Clean Energy: Design, Operation, and OptimizationFrom EverandHydroprocessing for Clean Energy: Design, Operation, and OptimizationNo ratings yet

- Fast Algorithm For DCTDocument20 pagesFast Algorithm For DCTsuhmudNo ratings yet

- Hach Pocket Pro TestersDocument4 pagesHach Pocket Pro TestersDavid Cruz ZamoraNo ratings yet

- Bone Ash Project 1-3 On Progress QaDocument26 pagesBone Ash Project 1-3 On Progress QaOshogbunu Onoriode ErnestNo ratings yet

- Exposer Anglais EnvironnementDocument4 pagesExposer Anglais EnvironnementAndrian100% (1)

- Ase 301 - HW1Document3 pagesAse 301 - HW1isaac tsaiNo ratings yet

- ME 231 All Instructors Whharris 11-9-17SOLUTIONDocument4 pagesME 231 All Instructors Whharris 11-9-17SOLUTIONEstebanGiraldoNo ratings yet

- Projet x60 Series Us 0Document4 pagesProjet x60 Series Us 0Ehab AlzabtNo ratings yet

- Bcs TheoryDocument18 pagesBcs Theoryanon_30981041No ratings yet

- 09 Light Reflection and Refraction Chapter Wise Important QuestionsDocument17 pages09 Light Reflection and Refraction Chapter Wise Important QuestionsKrsna JaiswalNo ratings yet

- Cement Process Engineering Vade Mecum: 2. StatisticsDocument15 pagesCement Process Engineering Vade Mecum: 2. StatisticsTamer FathyNo ratings yet

- Ansys LabDocument47 pagesAnsys LabPraveen KumarNo ratings yet

- WB-Mech 120 Ch03 AnalysisDocument55 pagesWB-Mech 120 Ch03 AnalysisMamu MachaNo ratings yet

- Y7 Energy TransfersDocument29 pagesY7 Energy Transfersjamie_venning_1No ratings yet

- MacrocosmDocument3 pagesMacrocosmMh Nurul Huda100% (1)

- L I::-.,: ,: L " j:'1.Document84 pagesL I::-.,: ,: L " j:'1.thermo2014No ratings yet

- 22-Year Clinical Evaluation of The Performance of Two Posterior Composites With Different Filler CharacteristicsDocument9 pages22-Year Clinical Evaluation of The Performance of Two Posterior Composites With Different Filler CharacteristicsAl-Kawthari As-SunniNo ratings yet

- Unit - 2 Optimal Design of DC Machine Unit-02/Lecture-01Document31 pagesUnit - 2 Optimal Design of DC Machine Unit-02/Lecture-01madeehaNo ratings yet

- For Questions 1 To 14, Fill in Your Answers in The Spaces ProvidedDocument4 pagesFor Questions 1 To 14, Fill in Your Answers in The Spaces Providedchaiseng yongNo ratings yet

- Keep 501Document13 pagesKeep 501Suriya ElangoNo ratings yet

- Guide To Magnifying GlassesDocument2 pagesGuide To Magnifying GlassesIndustry JunkieNo ratings yet

- CARB in Industrial FansDocument8 pagesCARB in Industrial FansJurun_Bidanshi100% (1)

- PD Diagnostics On Rotating Machines - Possibilities and Limitations - M. Hoof, S. Lanz - ABB - EIC - 1999Document6 pagesPD Diagnostics On Rotating Machines - Possibilities and Limitations - M. Hoof, S. Lanz - ABB - EIC - 1999tecolanzNo ratings yet

- H53015302 TRQ XXXDocument2 pagesH53015302 TRQ XXXTuTuy AnNo ratings yet

- 560Gti/660Gti: 60Th Anniversary EditionDocument20 pages560Gti/660Gti: 60Th Anniversary EditionDeepak SamNo ratings yet

- CT 4201304Document26 pagesCT 4201304shefalimathur91No ratings yet