Professional Documents

Culture Documents

Job Safety Analysis SEG 6.1 - Hotwork (Grinding, Cutting, and Welding) Rev.0

Job Safety Analysis SEG 6.1 - Hotwork (Grinding, Cutting, and Welding) Rev.0

Uploaded by

Jayvee Baradas ValdezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Safety Analysis SEG 6.1 - Hotwork (Grinding, Cutting, and Welding) Rev.0

Job Safety Analysis SEG 6.1 - Hotwork (Grinding, Cutting, and Welding) Rev.0

Uploaded by

Jayvee Baradas ValdezCopyright:

Available Formats

JOB SAFETY ANALYSIS # 3

Control Measures Example Table

Controls

Most Effective

Elimination

(Remove

the hazards)

Least

Effective

Engineering/Isolation

(Design people

effective

control

measures to protect

and

the environment)

Warning

(Alert people

of the hazards)

Administrative

(Provide training,

Procedures etc)

PPE Equipment)

(Personal Protective

Critical

Major

Moderate

Minor

1

6

Remove

damage

machine

fromtrailing

servicecords.

Provide power

outlets

to avoid

Use water-based

latex rather than

oil-based

paintsof organic solvents

Use

detergents

instead

Ventilation

Machine Guard

Enclosure

Signs

Backup Alarms

Work Rotation

Equipment

inspection

ELCB

LOTO

Platform/Guardrail

Horns

Labels

Beepers

Tags

Safety Glasses

Hearing

Protection

Severity Table

MD 510

F000-HS-HSSTA-2002

Examples

Make

connections

at ground

structure

to eliminate

height.level before erecting a

Substitution

(Replace the materials/process

hazardous

one) with a less

Severity

Level

Catastroph

ic

000.653.F0100

Form Job

Safety Analysis

Reduce energy,

such as speed, force, amperage,

pressure

and temperature.

Secondary Containment

Barriers

Improved

Lighting

High Visibility

Paint

Good housekeeping Practices

Harness and lanyard

Gloves

Respirator

High visibility vest

People

Multiple

or

single

fatality

Impact

Environment/Community

Long term

impact

to publicity/media

air,

surface/ground

water,

or soil;

or area/

Wide

spread

areas

including

offsite

community

affected;

orExtensive

adverse

coverage

Equipment/Property

Extensiveimpacts;

losses

oforLosses

high

value

equipment/property;Major

schedule

exceeding

1M

USD;

orSignificant

unplanned

financial

impacts to

business unit.

table

Likeliho

Proba

Chances

od Likelihood

bility

of100

Level

Occurren

ce

Very

2

1 in

Likely

5 1x10

Injury

or illness

resulting

in total

permanent

or

impartial

disability

Injury or illness

resulting

in

temporary

disability

or loss

of

function.

Injury

or illness

requiring

medical

attention.

Injury

or illness

requiring

first

aid only.

Lasting

(upto

toregulatory

one

year)impact

toOffsite

air,

surface/ground

water,

or authorities;

soil;

or

area/community

affected;

or events

that

reportable

or are

some

adverse

publicity/media

coverage.

Temporary

(up

towater,

one

impacts

to air,

surface/

ground

or

soil;

or or

significant

area

of the

project

sitemonth)

affected,

Breach

of

regulatory

requirement

or limit;

or

potential

for

adverse

Short-term

(up

to

onepublicity/media.

day)

impact

toand

air,

surface/

ground

water,

or

soil;

or

very

small

are

within

the

project

site

affected;

no

potential

for

adverse

publicity

or

media

coverage.

No

direct

impact

to

air,

surface/ground

water,

or

soil;

or

effects

restricted

within

the buildings

or containment

structures;

and

no potential

for adverse publicity/media

coverage.

Losses

of exceeding

equipment/property

that

cannot

be readily

replaced;

or losses

100k

USDon

or

significant

unplanned

impact

project

budget/schedule.

Loss of replaced;

equipment

that

can be

readily

or

losses

exceeding

10k

USD,

or

significant

unplanned

impact

on

project

budget.

Damage

to

equipment/

property

that

can

be

repaired

within

a

reasonable

timeframe;

exceeding

1k

USD

or

minor

impact

on the

budget. or losses

No

impact

on

equipment

functionality;

minor

cosmetic

damage;by

or

repair cost

easily

covered

normal

project

operation

budget.

Likely

Possibl

e

Unlikel

y

Very

Unlikel

y

4

3

2

1

3

1x10

4

1x10

5

1x10

6

1x10-

1 in 1,000

1 in 10,000

1 in 100,000

1 in

1,000,000

Seve

rity

Ver

Me

Ver

Ver

VerOverall Risk Rating

Hig

y

RiskPos

Matrix

y

Unli

Like

y

diu

sibl

ly

Like

y

Low

h

Hig

Catast Unli kely

e

m

kely

2

4

ly

rophic 16

3

32 48

64 80

Critica

Low 4-7

16h

1

5

8

16

24

32

40

Major

8-l -16

Note: Site/Construction

8

4

8 12 16 20

Moder

0-3

31 324

000.653.F0100

Form Job

MD 510

F000-H

Safety

Analysis

STA-2002

2

4

6

8

10

15

JOB

SAFETY

ANALYSIS

#

1

Minor

Manager

must

ate - 2

1

2

3

4

5

80Date:

Section

1 General

Information

Emergency Contact Name

Prepared

Jesus

B. Valdez

New __ Revised

By:

__

-1

Primary:

Liu Lian

JSA TITLE: personally review any

HOTWORK(GRINDING,

CUTTING, AN

WELDING)

Contact

Description:

Activities which has the highest probability to produce spar

Number:

items with a High or

Project HSE:

Jesus B. Valdez

High

risk

Contact

Location: Very Umm

Wualresidual

Package 6.15 TLUL

Laydown and Site.

Number:

Tools

Grinder, Oxy-Acetylene

Torch,and

Generators,

Welding Machine

Equipment

Used:and

score,

approve

by

Section

2

Does

this

job

requires

any

of

the

following

operations?

Yes

Yes

Areal Lift

Hazardous

Energy

Lead

Work

Respiratory

Control

hazards

signing

this

form. Yes

Asbestos

work

Hazardous

Materials

Limited

Roof

work

communication

Confined

Space

Hazardous

waste

Loading/Unloading

Site/Vehicle

traffic

operations

Material

Electrical

Hazards

X

Heavy

Equipment

X

Noise

exposure

X

Extreme

temperature

Emergency

Shutdown

High

Energy

Potentials

Powered

Industrial

Trucks

Excavation/Trenching

X

Hoisting

Rigging

and

Process

Cranes

instability/upset

First Line

Break

Hot

work

Radiation

area work

Grating/Floor

plate/Guardrail

Ladders

and

X

Remote

Location

Removal

Scaffolding

Section 3 AreYes

any of Task

these

Human Factors

to the Job?X

Human

Nature

Yes

Organizational

Demands

Yes Applicable

Work

Yes

Factors

Environment

Assumptions

Emphasis

on

High

workload

Changes

(inaccurate

schedule

(memory

departures

from

mental

picture)

requirement)

routine

Complacency

/

X

Lack

of

support

Interpretation

Confusing

Overconfidence

for

stop

work

requirement

display

or

authority

controls

Distraction

X

Personality

Irrecoverable

Hidden

system

Conflicts

acts

response

Habit Patterns

Poor

Lack

of or

Lack of

Communication

Unclear

Alternative

with

peers/

standards

indication

Supervisor

Inaccurate

risk

Unclear

goals,

Unexpected

perception

roles and

equipment

responsibilities

conditions

Limited

short

Workarounds/

term

memory

OOS

instruments

Mental

Shortcuts(bias

es)see)

Mindset(turne

d to

Stress(Limits

attention)

Maintenance/Chan

gesalone

Working

Work

at

height(1.5m)

Others

Individual

Capabilities

Hazardous

attitude

for

critical

task

Illness

fatigue

Imprecise

communication

habits

Indistinct

problem-solving

skills

Lack

of

knowledge

(Mental

Lackmode)

of

proficiency/

inexperience

Unfamiliarity

with

the

task/

first

time

JOB SAFETY ANALYSIS # 3

Activity/Step

1. Toolbox

Talk

2.

Preparation

Hazards

1.1

Unclear

information

1.2

Incomplete

STA

2.1

Sharp

Objects

2.22.3

Broken

tools

Broken

Equipment

2.4

Unauthorized

Personnel

Transportatio

n3.

of

Materials

3.

General

Hotwork

activities

3.1

Falling

objects

3.2

Trafficand

Hazards

3.3

Loading

Unloading

of

materials

3.1

hot

surfaces

3.2 pinch

sparks

3.3

points

3.4 slips/

fire hazards

3.5

trips/

falls

3.6

materials

3.7 scattered

Equipment

failure

/ electric

shock

Name

Lu Hongxing

Wang

Haitao

Section 4 Job Safety Analysis

English

Control

Measures

1.1.1

Permit

to work

must

beexecuting

secured

and

discussed

to

workers

before

the

activity.

The

activities

hazards

and

control

measures

must

be

known

to

the

workers.

1.2.1

Foreman

everyday

shall

discussed

3

points

for

the

activity

Construction/Quality

and

on

top

of it

Safetyin

and

shall

be written

the

details

the

STA.

2.1.1

Use

hand

protection

to

prevent

sharp

objects

to

cut

through

your

skin.

Safeguard

materials

(

Pipe

Edge,

Steel,

Metal

Sheets

etc.)Inspect

in

which

suspected

to before

be sharp.

2.2.1

tools

before

using;

look

for

damage,

cracks,

or

loose

parts

using.

2.2.2

Colour code

tools shall

according

to the

month.

2.3.1

Equipment

checklist

be filled

upto

by

the

Competent

Person

on daily

basis.

2.3.2

Third

party

certification

shall

be up

date

if

applicable.

2.4.1

Competent

persons

details

shall

be

posted

on

the

equipment.

3.1.1

Secure

the

materials(steel,

pipe,

metal

sheets

etc.) into

the or

trailer

bedtrailer/boom

by using

tie

ropes

slings.

3.2.1

Flagmen

shall

guide

the

truck

onprocedure

site.

3.3.1 Proper

mustMS)

be

followed

(SEErigging

LIFTING

AND RIGGING

SEG Management

Position

Project

Manager

HSE Manager

Section 5 Approvals and Signature

Signature

Name

Scott

Clark

Dick

Trembath

You might also like

- Evpn in The Data CenterDocument106 pagesEvpn in The Data CenterankitNo ratings yet

- Method of Statement For Installation of Pump (Submersible Pump and Deep Well Pump)Document4 pagesMethod of Statement For Installation of Pump (Submersible Pump and Deep Well Pump)Zin Ko Naing100% (2)

- Cessna 100 Series Service Manual 1963-1968Document262 pagesCessna 100 Series Service Manual 1963-1968Steve Huff100% (6)

- Application Form OSH PractitionerDocument3 pagesApplication Form OSH PractitionerJayvee Baradas Valdez100% (6)

- Model of Risk AssessmentDocument12 pagesModel of Risk AssessmentTony Gallacher60% (5)

- RABSDocument51 pagesRABSPrem Kumar100% (2)

- Automotive Instrument PanelsDocument59 pagesAutomotive Instrument PanelsGirijesh Patel100% (1)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- JSA Template 2017-05-30 Powder Actuated ToolsDocument19 pagesJSA Template 2017-05-30 Powder Actuated ToolsJayvee Baradas Valdez100% (2)

- 1911 ChecklistDocument2 pages1911 ChecklistGoNullYourself50% (2)

- Study of A Refrigeration Unit (R633)Document52 pagesStudy of A Refrigeration Unit (R633)mahbub133294% (17)

- Atlas Copco DKR-36 Rotary Hammer ManualDocument13 pagesAtlas Copco DKR-36 Rotary Hammer ManualSumit BhasinNo ratings yet

- Job Safety Analysis SEG 6.1 - Rebar and Formwork Fabrication and Installation Carpentry Works Rev.0Document2 pagesJob Safety Analysis SEG 6.1 - Rebar and Formwork Fabrication and Installation Carpentry Works Rev.0Jayvee Baradas Valdez25% (4)

- Construction Safety - Part 3 (Ppe)Document27 pagesConstruction Safety - Part 3 (Ppe)Henry TuraldeNo ratings yet

- Engineering & Technology PathwayDocument110 pagesEngineering & Technology PathwayNaveen S BasandiNo ratings yet

- CCPS - PHA For Combustible Dusts - FinalDocument29 pagesCCPS - PHA For Combustible Dusts - FinalHemendra Jani100% (2)

- CISSP - 5 Physical SecurityDocument29 pagesCISSP - 5 Physical SecurityRaj ShNo ratings yet

- 05 Hazard Control Hirearchy of Control PPEsDocument20 pages05 Hazard Control Hirearchy of Control PPEsImranNo ratings yet

- JSA G20 Scaffolding (Erection, Dismantling)Document4 pagesJSA G20 Scaffolding (Erection, Dismantling)Kanchalida Champathong92% (12)

- Control of Exposure Through Intervention (Final)Document62 pagesControl of Exposure Through Intervention (Final)Lauro CanceranNo ratings yet

- Ku Punyr Final Ouh YeayyyyyyDocument3 pagesKu Punyr Final Ouh YeayyyyyyAbdul QayyumNo ratings yet

- Risk Assessment FormDocument5 pagesRisk Assessment Formoadipphone7031No ratings yet

- Heat Exchanger Faillure ModesDocument5 pagesHeat Exchanger Faillure ModesCostynhaNo ratings yet

- IGC2 - QuestionsDocument27 pagesIGC2 - QuestionsAswin Magesh100% (3)

- Welding Safety Lectures: Know Your Worksite and SafetyDocument8 pagesWelding Safety Lectures: Know Your Worksite and SafetyNick PieperNo ratings yet

- Basic Safety DeffinationsDocument25 pagesBasic Safety DeffinationsmebuanaNo ratings yet

- Inherent SafetyDocument50 pagesInherent SafetyChing-Liang ChenNo ratings yet

- Unit 2Document11 pagesUnit 2KkkkkNo ratings yet

- Electric Hand Drill Risk AssessmentDocument4 pagesElectric Hand Drill Risk AssessmentTariq AkhtarNo ratings yet

- Hierarchy of ControlsDocument10 pagesHierarchy of ControlsJeanNo ratings yet

- JSA - Unloading & Positioning of Pre Action EquipmentDocument7 pagesJSA - Unloading & Positioning of Pre Action EquipmentRAJKUMAR MUTHINENINo ratings yet

- Igfa PPT 26 0 13 VC PilzDocument74 pagesIgfa PPT 26 0 13 VC PilzIGFAieNo ratings yet

- Seminar 1 - Cleanroom HVAC Design - KarachiDocument25 pagesSeminar 1 - Cleanroom HVAC Design - KarachituzlucayirNo ratings yet

- Battery Assembly: Oxide and GridDocument12 pagesBattery Assembly: Oxide and Grids9n9No ratings yet

- Example JSADocument3 pagesExample JSAnattwa2010No ratings yet

- Job Hazard AssessmentDocument2 pagesJob Hazard AssessmentSreekumarNo ratings yet

- Physical Sciences: Exvema Explosion Venting ManualDocument116 pagesPhysical Sciences: Exvema Explosion Venting ManualipliprensNo ratings yet

- Safe Work Method StatementDocument2 pagesSafe Work Method StatementFrank Barnes100% (1)

- Occupational Health and Safety-Ii: Asisst - Prof.Dr. Canan URAZ Assoc - Prof.Dr. Sevim KARAOĞLUDocument45 pagesOccupational Health and Safety-Ii: Asisst - Prof.Dr. Canan URAZ Assoc - Prof.Dr. Sevim KARAOĞLUdilsahNo ratings yet

- Disaster Management Safety OrientDocument55 pagesDisaster Management Safety OrientVishalNo ratings yet

- Lesson 08 Basic Occupational Safety and HealthDocument75 pagesLesson 08 Basic Occupational Safety and HealthJohn MaloneNo ratings yet

- Checklist PDFDocument5 pagesChecklist PDFAlfred Harvey ElacionNo ratings yet

- Clean Room - Clean Room & HVAC SystemsDocument74 pagesClean Room - Clean Room & HVAC Systemspchakravarty_2100% (8)

- Handouts Occupational Health and Safety 11 23 19Document3 pagesHandouts Occupational Health and Safety 11 23 19Edilbert Bonifacio GayoNo ratings yet

- Equipment in Hazardous AreaDocument7 pagesEquipment in Hazardous Areajay shahNo ratings yet

- JSA M36 Hydro Testing Spool Pieces & PipeworkDocument4 pagesJSA M36 Hydro Testing Spool Pieces & PipeworkMianNo ratings yet

- Book Reviews/Journal of Hazardous Materials 38 (1994) 329-348 339Document6 pagesBook Reviews/Journal of Hazardous Materials 38 (1994) 329-348 339Carlos PerdomoNo ratings yet

- HazardDocument10 pagesHazardElvin LstNo ratings yet

- Equipment: 8TB-ELEV-100 Turbine - BuildingDocument4 pagesEquipment: 8TB-ELEV-100 Turbine - BuildingIndah Mutiara DewiNo ratings yet

- ChE 534 - Module 2Document58 pagesChE 534 - Module 2Precious JamesNo ratings yet

- Controls Measure For OSHDocument16 pagesControls Measure For OSHricardo martinezNo ratings yet

- Safety in Chemical Process IndustriesDocument22 pagesSafety in Chemical Process IndustriesHimanshu SinghNo ratings yet

- Guideline On Air Handling On Food IndustryDocument6 pagesGuideline On Air Handling On Food IndustrysubirmeNo ratings yet

- Hardener H1Document7 pagesHardener H1Kate HdezNo ratings yet

- JSA 08 Laying of Conduit WiringDocument8 pagesJSA 08 Laying of Conduit Wiringsyed khaja misbhuddinNo ratings yet

- Personal Protective EquipmentDocument65 pagesPersonal Protective EquipmentDevashish SharmaNo ratings yet

- Demolition Toolbox TalkDocument4 pagesDemolition Toolbox TalkJomy JohnyNo ratings yet

- Personal Protective EquipmentDocument9 pagesPersonal Protective EquipmentM Ali JadoonNo ratings yet

- Basis of SafetyDocument2 pagesBasis of SafetyTen Dye MungwadziNo ratings yet

- Tugas K3Ll: Hazard Identification Risk Assessment and Mitigation Bengkel/Overhaul ShopDocument8 pagesTugas K3Ll: Hazard Identification Risk Assessment and Mitigation Bengkel/Overhaul ShopmartyNo ratings yet

- Exam Specifications PE Fire Oct 2012Document3 pagesExam Specifications PE Fire Oct 2012Jacqueline MoineNo ratings yet

- Isolation & Lock Out - Tag Out (LOTO)Document24 pagesIsolation & Lock Out - Tag Out (LOTO)Becha MouradNo ratings yet

- Pollution Control Handbook for Oil and Gas EngineeringFrom EverandPollution Control Handbook for Oil and Gas EngineeringNo ratings yet

- The Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationFrom EverandThe Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationRating: 1 out of 5 stars1/5 (1)

- Wind Turbines in Cold Climates: Icing Impacts and Mitigation SystemsFrom EverandWind Turbines in Cold Climates: Icing Impacts and Mitigation SystemsNo ratings yet

- Sinopec Status of Firstaid BoxDocument1 pageSinopec Status of Firstaid BoxJayvee Baradas ValdezNo ratings yet

- SINOPEC - RTR SOC Attendance Sheet 24-08-2021Document3 pagesSINOPEC - RTR SOC Attendance Sheet 24-08-2021Jayvee Baradas ValdezNo ratings yet

- 0002 Rev 00 Jsa TR Seg Piping ErectionDocument11 pages0002 Rev 00 Jsa TR Seg Piping ErectionJayvee Baradas ValdezNo ratings yet

- Saes T 555Document21 pagesSaes T 555Jayvee Baradas ValdezNo ratings yet

- 0001 Rev 00 Jsa TR Seg Structural ErectionDocument10 pages0001 Rev 00 Jsa TR Seg Structural ErectionJayvee Baradas ValdezNo ratings yet

- Sinopec-Tr-Safety Training Attendance SheetsDocument2 pagesSinopec-Tr-Safety Training Attendance SheetsJayvee Baradas ValdezNo ratings yet

- SDM 023 Attendance SheetDocument1 pageSDM 023 Attendance SheetJayvee Baradas ValdezNo ratings yet

- Powerline Pre Board Ree Sept 2010 PDFDocument14 pagesPowerline Pre Board Ree Sept 2010 PDFJayvee Baradas ValdezNo ratings yet

- Good Practices Guide To Dark Rooms OperationsDocument3 pagesGood Practices Guide To Dark Rooms OperationsJayvee Baradas Valdez0% (1)

- Content:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDocument8 pagesContent:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualJayvee Baradas ValdezNo ratings yet

- FGP SEG TR JSA 20 - Man Lift Operation Rev. 02Document15 pagesFGP SEG TR JSA 20 - Man Lift Operation Rev. 02Jayvee Baradas ValdezNo ratings yet

- Incident Root Cause Analysis - Nm060418 - Using The Ladder in Unsafe MannerDocument14 pagesIncident Root Cause Analysis - Nm060418 - Using The Ladder in Unsafe MannerJayvee Baradas ValdezNo ratings yet

- Contractor Environmental Monthly Returns: Monthly Air Quality Sampling Data AttachedDocument3 pagesContractor Environmental Monthly Returns: Monthly Air Quality Sampling Data AttachedJayvee Baradas ValdezNo ratings yet

- Powder Actuated ToolsDocument1 pagePowder Actuated ToolsJayvee Baradas ValdezNo ratings yet

- Safety Training Attendence List: Umm Wu'Al Phosphate Project U&I Multidiscipline PackageDocument1 pageSafety Training Attendence List: Umm Wu'Al Phosphate Project U&I Multidiscipline PackageJayvee Baradas ValdezNo ratings yet

- Duties and Responsibilities of HSE Supervisor (Oil and Gas Plant Construction)Document2 pagesDuties and Responsibilities of HSE Supervisor (Oil and Gas Plant Construction)Jayvee Baradas Valdez50% (2)

- Certificate of Appreciation: Sayyed Amjad Ullah ShahDocument6 pagesCertificate of Appreciation: Sayyed Amjad Ullah ShahJayvee Baradas ValdezNo ratings yet

- JSA Template 2017-05-31 Cable Tray InstallationDocument19 pagesJSA Template 2017-05-31 Cable Tray InstallationJayvee Baradas ValdezNo ratings yet

- RPB Astro Instruction ManualDocument20 pagesRPB Astro Instruction ManualJayvee Baradas ValdezNo ratings yet

- Married: Real Estate MortgageDocument1 pageMarried: Real Estate MortgageJayvee Baradas ValdezNo ratings yet

- Certficate of ExperienceDocument1 pageCertficate of ExperienceJayvee Baradas ValdezNo ratings yet

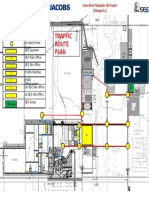

- Traffic PlanDocument1 pageTraffic PlanJayvee Baradas ValdezNo ratings yet

- Job Safety Analysis SEG 6.1 - Rebar and Formwork Fabrication and Installation Carpentry Works Rev.0Document2 pagesJob Safety Analysis SEG 6.1 - Rebar and Formwork Fabrication and Installation Carpentry Works Rev.0Jayvee Baradas Valdez25% (4)

- HMTS-80E Quick Manual-Ver27 - 20180327 (4 Mode)Document54 pagesHMTS-80E Quick Manual-Ver27 - 20180327 (4 Mode)kb mensurar100% (1)

- A Study On Warehouse Management of REB: A Case Study of Central Warehouse, DhakaDocument127 pagesA Study On Warehouse Management of REB: A Case Study of Central Warehouse, Dhakapravincs_007No ratings yet

- Coiled Tubing Technology MaureerDocument460 pagesCoiled Tubing Technology MaureerArt RodriguezNo ratings yet

- Deploying Oracle Database On Oracle Compute Cloud Service InstanceDocument30 pagesDeploying Oracle Database On Oracle Compute Cloud Service Instanceambipac@yahoo.comNo ratings yet

- 12.5 Oh GR CN ZDL SP Hdil CalDocument22 pages12.5 Oh GR CN ZDL SP Hdil CalStephanyNo ratings yet

- Book Nelems Bookdetails: Import Public Class Public Private IntDocument3 pagesBook Nelems Bookdetails: Import Public Class Public Private IntUSAMA SARWARNo ratings yet

- Chery Maintenance Manual For Oriental SonDocument13 pagesChery Maintenance Manual For Oriental SonAbbode HoraniNo ratings yet

- ISO Tolerances For HolesDocument4 pagesISO Tolerances For HolesMd Naushad RazaNo ratings yet

- Prime Faces Users Guide 140210Document350 pagesPrime Faces Users Guide 140210blub5234254No ratings yet

- Mautic Developer GuideDocument222 pagesMautic Developer GuideMorph DiainNo ratings yet

- IT Fundamentals Prelim ExamDocument3 pagesIT Fundamentals Prelim ExamBenjie Auza BereNo ratings yet

- Flow and Load Duration CurveDocument4 pagesFlow and Load Duration Curveyared sitotawNo ratings yet

- Basic Imaging Systems Colonydoc-ItDocument1 pageBasic Imaging Systems Colonydoc-ItNelson PerezNo ratings yet

- DBM Order Engine CookbookDocument60 pagesDBM Order Engine CookbookDavid Morales CespedeNo ratings yet

- AD-DC MotorDocument7 pagesAD-DC MotorJay Mark BalaneNo ratings yet

- Stun GunsDocument6 pagesStun Gunsdefensetechs100% (1)

- Northwestern Undergraduate ManualDocument50 pagesNorthwestern Undergraduate ManualBerhance GNo ratings yet

- 22 gr86 Brochure enDocument19 pages22 gr86 Brochure ensimpl yyNo ratings yet

- Raychem - PXE Resin Filled LV JointsDocument3 pagesRaychem - PXE Resin Filled LV JointsAdelAlcebaiNo ratings yet

- SCBA2Document12 pagesSCBA2deddy priambodoNo ratings yet

- INtern ShipDocument5 pagesINtern ShipMuhammad Talha AwanNo ratings yet

- S7-1200 SM 1231 8 X Analog Input - SpecDocument3 pagesS7-1200 SM 1231 8 X Analog Input - Specpryzinha_evNo ratings yet

- 2019 Artificial Neural Network Approach To Determine Elastic Modulus of Carbon Fiber-Reinforced LaminatesDocument9 pages2019 Artificial Neural Network Approach To Determine Elastic Modulus of Carbon Fiber-Reinforced Laminatesdhiraj.biswasNo ratings yet

- NadcapDocument21 pagesNadcapJHBernardoNo ratings yet