Professional Documents

Culture Documents

Value Chain: P. 70 Working With Our Suppliers P. 72 Working With Our Dealers

Value Chain: P. 70 Working With Our Suppliers P. 72 Working With Our Dealers

Uploaded by

TaVoVelaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Value Chain: P. 70 Working With Our Suppliers P. 72 Working With Our Dealers

Value Chain: P. 70 Working With Our Suppliers P. 72 Working With Our Dealers

Uploaded by

TaVoVelaCopyright:

Available Formats

NISSAN MOTOR COMPANY Sustainability Report 2013

68

Contents

Introduction

CEO MESSAGE

CoO MESSAGE

BLUE CITIZENSHIP: NISSAN'S CSR

Renault-Nissan Alliance

CSR DATA

Third-Party Comment

Environment

Safety

Philanthropy

Quality

Value Chain

Employees

Economic Contribution

Corporate Governance &

Internal Control

Value Chain

Together with its business partners, Nissan aims to achieve sustainable growth built on a foundation of mutual trust. We strive to listen

carefully to our suppliers and dealers on an equal footing and work hard together with them as partners, developing and maintaining

cooperative relations that enable us to implement best practices. Our value chain today extends around the globe due to the expansion

of the companys business interests. We endeavor to improve our CSR management by sharing our fundamental values and principles

with our business partners, thereby promoting consistency in the CSR activities undertaken throughout the supply chain.

Our Priorities

Key Figures

Working with Our Suppliers

p. 70

Working with Our Dealers

p. 72

Distribution of Renault-Nissan CSR Guidelines for

Suppliers

Distribution of Nissan Green Purchasing Guidelines

Environmental data of suppliers examined

Improvements recommended for compliance violations

(FY2012)

Nissan Green Shop certification* conferred

GRI G3 Indicators

EC6/EN26/PR2

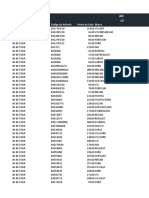

7,600 suppliers

3,000 parts and

materials suppliers

70% of global purchases

page_38

11

174 firms, approx. 2,800

outlets

* Click here for more

information on the Nissan

Green Shop certification.

NISSAN MOTOR COMPANY Sustainability Report 2013

69

Contents

Introduction

CEO MESSAGE

CoO MESSAGE

BLUE CITIZENSHIP: NISSAN'S CSR

Renault-Nissan Alliance

CSR DATA

Third-Party Comment

Environment

Safety

Philanthropy

Quality

Value Chain

Employees

Economic Contribution

Corporate Governance &

Internal Control

Nissans Approach to the Value Chain

page_91

* Click here for more

information on the Nissan

Global Code of Conduct.

Nissan uses a fair, impartial and completely transparent business process

when selecting suppliers. We provide a wide variety of opportunities for other

companies to do business with us, regardless of their nationality, size or

history with us. When making selections, the relevant Nissan divisions meet to

examine from a range of perspectives the proposals received from suppliers.

We explain our final decision to every supplier that has taken part in the

selection process.

We make every effort to maintain the highest standards of impartiality

and fairness in our business transactions, abiding by the Nissan Global Code

of Conduct* (item 4: Be Impartial and Fair). As well as maintaining close

communication in our day-to-day dealings with suppliers, we also take heed of

their ideas through regular questionnaires and direct meetings, checking our

business practices from an external perspective.

Nissan works hard to promote correct business practices throughout the

supply chain. We have disseminated internally a leaflet on guidelines for

appropriate business practices in the automobile industry, focusing on the

industrys principles of procurement and important points relating to

subcontracting and antimonopoly law, and we hold briefings with our suppliers

on these issues.

In fiscal 2012 we launched a new initiative incorporating environmental

concerns and compliance requirements, over which there is rising global

interest, in addition to continuing the disaster countermeasures in our supply

chain from the preceding year.

Fiscal 2012 Performance

n

Supply chain disaster countermeasures continued from previous year:

n

n

Database created to visualize supply-chain operations in Japan

Regions at risk of disaster identified; confirmation of suppliers provision systems at

main overseas locations

Joint activities implemented with suppliers in accordance with the Nissan

Green Program 2016 (NGP2016) mid-term environmental action plan

Preliminary investigation of suppliers' use of conflict minerals

Regarding sales companies: information security training conducted,

global social media policy crafted and shared with example policy

violations, anti-bribery regulations enhanced and re-disseminated

Future Measures

n

To enhance disaster risk preparedness:

Database creation to visualize supply-chain operations at main overseas locations

Creation of initial response duty flowcharts for main overseas locations

Diagnosis of supplier sites in high-risk areas in Japan

Introduction in Japan of simulation system for disaster forecasts

Continued examination of our suppliers environmental data to promote CO2

emission reductions and other environmental efforts in our supply chain

Investigation of use of conflict minerals in the supply chain and disclosure of

findings in our Sustainability Report and elsewhere

Continued information security training for our sales companies

NISSAN MOTOR COMPANY Sustainability Report 2013

70

Contents

Introduction

CEO MESSAGE

CoO MESSAGE

BLUE CITIZENSHIP: NISSAN'S CSR

Renault-Nissan Alliance

CSR DATA

Third-Party Comment

Environment

Safety

Philanthropy

Quality

Value Chain

Employees

Economic Contribution

Corporate Governance &

Internal Control

Working with Our Suppliers

All of Nissans suppliers are important business partners for the

company. We work with them to build relationships based on the

three values of trust (work fairly, impartially and professionally),

respect (honor commitments, liabilities and responsibilities) and

transparency (be open, frank and clear).

website

*1

*2

Click here to download The

Renault-Nissan Purchasing

Way and the RenaultNissan CSR Guidelines for

Suppliers.

References to the CSR

guidelines of the Japan

Automobile Manufacturers

Association, Inc. and the

Japan Auto Parts

Industries Association

were made in drafting the

Renault-Nissan CSR

Guidelines for Suppliers.

Renault-Nissan CSR Guidelines for Suppliers

Nissan and Renault have produced a booklet, The Renault-Nissan Purchasing

Way,*1 outlining the important values and processes to be adhered to when

doing business. This booklet has been shared with the primary suppliers of

Renault and Nissan since 2006. Furthermore, in May 2010, we published the

Renault-Nissan CSR Guidelines for Suppliers*2 in order to effectively

implement CSR practices across our globally expanding base of suppliers.

This was distributed to all primary suppliers worldwide with the aim of helping

them review their business activities from a CSR viewpoint and further instill

CSR activities. The guidelines explain Nissans CSR and procurement policies

in five main sections: safety and quality, human rights and labor, the

environment, compliance and information disclosure.

Since being published in 2010, the CSR guidelines have been provided

to suppliers for thoroughgoing implementation. In fiscal 2012, a number of

compliance violations that appeared to be in breach of relevant laws came to

light in the auto industry. In response to these developments, Nissan took rigid

measures with respect to the guidelines, and confirmations are being made of

suppliers steady compliance with all laws and regulations and their efforts to

organizationally strengthen CSR activities.

Activities to Improve Manufacturing Approaches

Nissan has been working to continually produce more competitive products

through its Monozukuri Activities program, a collaboration among suppliers

and Nissan that commenced in 2008. Since 2009, we have been expanding

these activities through the joint Thanks Activities initiative, which emphasizes

trust and cooperation between Nissan and its suppliers. With the goal of

working with our suppliers to become cost leaders in todays challenging

market conditions, we are striving to improve product quality, cut costs and

rationalize our manufacturing through measures that include increasing

production volume per part, promoting localization and improving logistics.

One important issue in the light of the substantial increases in global

production volume during 2012the second year of our Nissan Power 88

mid-term business planis building with our suppliers a system to ensure

steady supply. Working with our suppliers, we are enhancing our Monozukuri

Activities to establish such a system.

Responding to Disaster Risk

In addition to our supply chain business continuity plan (BCP) formulated for

Japan and Thailand, we expanded our scope of consideration to include

establishing similar supply chain BCPs for other operations (North America,

Europe, China and India). We are also promoting the visualization of the

supply chain via steps to ensure smooth initial response by ascertaining

supply chain conditions and measures to address anticipated risks in advance.

website

Click here for more

information on the quality

initiatives we undertake with

suppliers.

NISSAN MOTOR COMPANY Sustainability Report 2013

71

Contents

Introduction

CEO MESSAGE

CoO MESSAGE

BLUE CITIZENSHIP: NISSAN'S CSR

Renault-Nissan Alliance

CSR DATA

Third-Party Comment

Environment

Safety

Philanthropy

Quality

Value Chain

Employees

Economic Contribution

Corporate Governance &

Internal Control

Recognizing Supplier Contributions Worldwide

Each year Nissan recognizes the contributions of its suppliers with awards

presented in each of the regions where we operate, as well as with two

worldwide supplier awards, the Global Quality and Global Innovation

Awards. These are presented to suppliers that have contributed to our

business performance at the global level. This awards system aims to

encourage suppliers in the global supply chain to embrace our

management approach, which balances the economic activities of quality,

cost reduction and technological development with environmental concern

and social responsibility.

Global Quality Award recipients are selected by our purchasing, quality

and other divisions using standard criteria applied worldwide. Global

Innovation Award recipients are selected from suppliers nominated by our

production, development and quality divisions in the two categories of product

technology and process management. In fiscal 2012, three companies

received Global Quality Awards, and Global Innovation Awards went to seven

companies in the product technology category.

website

Click here to download the

revised version of the Nissan

Green Purchasing

Guidelines.

Revising Our Green Purchasing Guidelines

Nissan set forth the environmental standards for its suppliers in 2001 in the

Nissan Green Purchasing Guidelines, asking them to cooperate by reducing

their environmental impact. Prior to 2012, the guidelines had been updated

twice, expanding coverage to include the following items:

1 2008: Management of environment-impacting substances and

reductions of their use throughout the supply chain

2 2010: Promotion of environmental activities throughout the supply chain

in line with the Renault-Nissan CSR Guidelines for Suppliers

In 2012, the following items were added based on the Nissan Green

Program 2016:

1 Start gathering environmental data, including CO2 emissions and water

discharges, in the supply chain

2 Enhance management of environment-impacting substances in response

to the environmental regulations of various countries by expanding

regions and substances covered

3 Begin confirming with suppliers the setup for the management of

environment-impacting substances and items to be observed at the

stage of supplier selection

Policy on Conflict Minerals

In August 2012, bylaws were enacted in the United States requiring

companies to report the use of four minerals mined in the Democratic

Republic of the Congo and surrounding countries, which were potentially

believed to be sources of funds for armed insurgents. Agreeing with the spirit

of this legislation, Nissan decided, from a CSR viewpoint, to investigate the

supply chain for any use of conflict minerals and established a policy aimed at

preventing the use of conflict minerals.

Preliminary studies were conducted between October and December

2012, and full-scale investigations will begin in fiscal 2013. We plan to

disclose the findings of the study in our Sustainability Report and elsewhere.

NISSAN MOTOR COMPANY Sustainability Report 2013

72

Contents

Introduction

CEO MESSAGE

CoO MESSAGE

BLUE CITIZENSHIP: NISSAN'S CSR

Renault-Nissan Alliance

CSR DATA

Third-Party Comment

Environment

Safety

Philanthropy

Quality

Value Chain

Employees

Economic Contribution

Corporate Governance &

Internal Control

Working with Our Dealers

Nissan undertakes various measures to ensure that its approach to

compliance is shared with dealerships and to enhance its internal

controls. We aim to further improve our CSR management by

strengthening the lines of communication with dealers.

Working with Dealers for CSR Management

To promote consistency in the CSR management approaches taken by Nissan

and its dealers, we carry out activities on an ongoing basis aimed at helping

dealerships in Japan enhance their compliance.

As a specific measure, we organize self-inspection programs at all

dealerships to enable fuller understanding of and improvements to their

current compliance management status. The programs carried out during

fiscal 2012 have led to increased awareness and improvements on a

voluntary basis. To bolster compliance initiatives in cooperation with dealers,

we made an effort to familiarize them with our various programs and

undertook improvement activities during fiscal 2012. We aim to further

improve our CSR management by ensuring that our sense of compliance is

shared with dealerships and by working to build stronger internal controls.

Compliance Training for Sales Companies

Nissan offers the following compliance training programs for sales companies:

Information Security

Based on teaching materials that cover the same topics as those taught in

our e-learning courses, each sales company implements information security

training so as to avert risks arising from serious incidents occurring in the

course of daily activities, such as virus infections, unintended email

transmissions and information leaks due to misplaced or stolen PCs.

Global Social Media Policy

Examples of inappropriate posts on social networking services or blogs that

are in violation of Nissans global social media policy are shared with sales

companies. In an effort to enhance awareness and prevent a recurrence,

we also convey information on the potential adverse impact, not just to the

sales company but also to the Nissan Group as a whole, when such posts

are made.

Harassment

We provide training materials, particularly on power harassment, given the

growing social interest in abuses of authority and incidents of such abuse at

sales companies. Sales companies undertake training on such topics as

examples of acts and statements that constitute harassment, what impact

a harassment case can have, past incidents involving sales companies and

what steps should be taken when a case comes to light.

Prevent Bribery

We are making thoroughgoing efforts to prevent bribes involving Nissan

employees on a global basis, and we are asking sales companies, too, to

update existing rules and to inform their employees of the changes.

At the same time, we are also distributing materials based on the

detailed rules of the Nissan Groups Global Code of Conduct concerning

entertainment and gifts.

You might also like

- Manual de Taller Nissan Diesel Engines SD22-SD23-SD25-SD33Document52 pagesManual de Taller Nissan Diesel Engines SD22-SD23-SD25-SD33Patról15088% (32)

- Sony Global - Supply Chain ManagementDocument7 pagesSony Global - Supply Chain ManagementSamir SuljkanovicNo ratings yet

- Taiho Engine Bearing CatalogueDocument130 pagesTaiho Engine Bearing CatalogueJorge Luis Espino Cruz84% (19)

- 2004 Nissan MaximaDocument280 pages2004 Nissan Maximajunhe898No ratings yet

- Frenos ABS Nissan Frontier XEDocument1 pageFrenos ABS Nissan Frontier XEMiguel CortezNo ratings yet

- Adidas - Supply Chain ApproachDocument13 pagesAdidas - Supply Chain ApproachAlvaro Casas CobaledaNo ratings yet

- Yamaha Supply ChainDocument7 pagesYamaha Supply ChainkagneyNo ratings yet

- Samsung Sustainability Report 2011Document94 pagesSamsung Sustainability Report 2011CSRmedia.ro NetworkNo ratings yet

- Nissan Green Purchasing Guideline e PDFDocument22 pagesNissan Green Purchasing Guideline e PDFBelialShaunNo ratings yet

- Assignments - Business - Ethics - Governance-and-RiskDocument9 pagesAssignments - Business - Ethics - Governance-and-Riskcomputer.jaipur123No ratings yet

- Environment: NISSAN Sustainability Report 2011Document30 pagesEnvironment: NISSAN Sustainability Report 2011Ajay Roshan PNo ratings yet

- SVR 2010 Engl Sustainable OperationsDocument16 pagesSVR 2010 Engl Sustainable Operationshassanali007No ratings yet

- Our ReportingDocument51 pagesOur ReportingPatrick Ferguson AssuahNo ratings yet

- Practices of Good Governance ofDocument6 pagesPractices of Good Governance ofRosemarie Ű RodolfoNo ratings yet

- Ejemplo Supply ChainDocument6 pagesEjemplo Supply Chainsindy veraNo ratings yet

- CSR Alliance GuidelinesDocument11 pagesCSR Alliance GuidelinesRodrigo Moreno OchoaNo ratings yet

- 2010 Sustainabity PDFDocument48 pages2010 Sustainabity PDFWak MilNo ratings yet

- NikeDocument23 pagesNikeAnkitaKumar100% (2)

- ESGDocument48 pagesESGtariq.latifpkNo ratings yet

- Policy of Corporate Social ResponsibilityDocument4 pagesPolicy of Corporate Social ResponsibilityHimanshu OzaNo ratings yet

- 2016 Samsung Sustainability Report EngDocument216 pages2016 Samsung Sustainability Report EngFajar WidyaNo ratings yet

- GMS and Sustainability ST PaulDocument23 pagesGMS and Sustainability ST PaulamritamonaNo ratings yet

- Sdb2021e-Supply ChainDocument6 pagesSdb2021e-Supply Chainhameed hanifNo ratings yet

- Nike CRR Factory List CDocument32 pagesNike CRR Factory List CTrâm ChâuNo ratings yet

- Sustainable Supply ChainDocument12 pagesSustainable Supply Chainpratik9967No ratings yet

- NideraDocument56 pagesNideraFlorentina DragneNo ratings yet

- Ese BTB Yy 20231231Document39 pagesEse BTB Yy 20231231Emil RIJSEMUSNo ratings yet

- Concept of Sustainable Supply Chain2Document8 pagesConcept of Sustainable Supply Chain2sanzitNo ratings yet

- Como Criar Métricas ESG para Sua EmpresaDocument11 pagesComo Criar Métricas ESG para Sua Empresamb751086No ratings yet

- 2 BSR Case StudyDocument10 pages2 BSR Case StudyAamir WaseemNo ratings yet

- Corporate Social Responsibility SamsungDocument1 pageCorporate Social Responsibility SamsungGediya RockyNo ratings yet

- Corporate Governace (TY BBA 5th Practical Studies 2)Document16 pagesCorporate Governace (TY BBA 5th Practical Studies 2)Payal BhattNo ratings yet

- Sr10 Section Issues SupplyDocument31 pagesSr10 Section Issues SupplympashosNo ratings yet

- NFIR LecturesDocument9 pagesNFIR LecturesEliNo ratings yet

- Hankook Tire CSR Report 2011-12 - EngDocument92 pagesHankook Tire CSR Report 2011-12 - EngSam_Ha_100% (1)

- Nike's Strategy To Improve Conditions in Its Global Supply Chain A Mini-CaseDocument7 pagesNike's Strategy To Improve Conditions in Its Global Supply Chain A Mini-CaseHoai Thuong Le100% (1)

- What Is Supply Chain Sustainability?Document7 pagesWhat Is Supply Chain Sustainability?Shivam MishraNo ratings yet

- Supply Chain ManagementDocument10 pagesSupply Chain ManagementThuThuy BuiNo ratings yet

- Prequalification Document-Sindibad 2021 Word FileDocument73 pagesPrequalification Document-Sindibad 2021 Word FileSindibad Al BaherNo ratings yet

- BFN 427 - Emerging Issues in SFMDocument23 pagesBFN 427 - Emerging Issues in SFMgeorgeNo ratings yet

- 2019 Enve AllDocument160 pages2019 Enve AllNave2n adventurism & art works.No ratings yet

- Getting More Value Out of Sustainability ReportingDocument32 pagesGetting More Value Out of Sustainability ReportingIFC Sustainability100% (1)

- BCP Q6 - Group 7Document16 pagesBCP Q6 - Group 7Nitika AggarwalNo ratings yet

- About This Document: Adidas Group Sustainability Intro 1Document61 pagesAbout This Document: Adidas Group Sustainability Intro 1Akashdeep MukherjeeNo ratings yet

- Schneider Electric Supplier Code of Conduct PDFDocument8 pagesSchneider Electric Supplier Code of Conduct PDFAlia RedhaNo ratings yet

- WPP Sr12 IntroductionDocument5 pagesWPP Sr12 IntroductiondaniellemuntyanNo ratings yet

- WPP Sr12 Sustainability Report 2012 2013Document54 pagesWPP Sr12 Sustainability Report 2012 2013Vaibhav SharmaNo ratings yet

- Inspiring Change... Mitie Group PLC Sustainability Report 2014Document28 pagesInspiring Change... Mitie Group PLC Sustainability Report 2014edienewsNo ratings yet

- Environ FinalDocument21 pagesEnviron FinalPriti ChauhanNo ratings yet

- Supply Chain ManagementDocument11 pagesSupply Chain ManagementToufiq AmanNo ratings yet

- Business Ethics Governance & Risk-2Document11 pagesBusiness Ethics Governance & Risk-2OmeYadav100% (1)

- Nokia Supplier 06 WWWDocument12 pagesNokia Supplier 06 WWWanais_lee2010No ratings yet

- HRIR 201: Managing Human Resources & Industrial Relations: Week 9: Thursday 17 May 2012Document9 pagesHRIR 201: Managing Human Resources & Industrial Relations: Week 9: Thursday 17 May 2012Phuong HoNo ratings yet

- Accenture Sustainable ProcurementDocument2 pagesAccenture Sustainable ProcurementAnupriyaSaxenaNo ratings yet

- Supply ChainDocument9 pagesSupply ChainSwati RawatNo ratings yet

- Indira School of Business Studies: SR - No Name of Student Roll No. 1 2Document23 pagesIndira School of Business Studies: SR - No Name of Student Roll No. 1 2Roshan RajanNo ratings yet

- Submitted To: Md. Abdul Khaleque: Submitted By: Nazim Uddin 1721832 Sec:02Document9 pagesSubmitted To: Md. Abdul Khaleque: Submitted By: Nazim Uddin 1721832 Sec:02Md ShakilNo ratings yet

- HTTP://WWW - Slideshare.net/likhon143/performance Management and Appraisal of Cocacola#Document26 pagesHTTP://WWW - Slideshare.net/likhon143/performance Management and Appraisal of Cocacola#sheebaruksNo ratings yet

- Green Business - People - Planet - Profit - 2023/24: A Comprehensive Guide to Building & Managing A Sustainable Business.: Volume 1, #1From EverandGreen Business - People - Planet - Profit - 2023/24: A Comprehensive Guide to Building & Managing A Sustainable Business.: Volume 1, #1No ratings yet

- Responsible Business: How to Manage a CSR Strategy SuccessfullyFrom EverandResponsible Business: How to Manage a CSR Strategy SuccessfullyNo ratings yet

- Sustainability Reporting Frameworks, Standards, Instruments, and Regulations: A Guide for Sustainable EntrepreneursFrom EverandSustainability Reporting Frameworks, Standards, Instruments, and Regulations: A Guide for Sustainable EntrepreneursNo ratings yet

- Renault Nissan Strategic AllianceDocument15 pagesRenault Nissan Strategic AllianceMridul Dohutia100% (2)

- Nomuken Skyline R34Document8 pagesNomuken Skyline R34Fajar aldian FNo ratings yet

- Power Door Lock System Wiring Diagram - D/LOCK - : To EsmDocument6 pagesPower Door Lock System Wiring Diagram - D/LOCK - : To Esmricardo diazNo ratings yet

- Lista de Precios Suspensión y Aceite FramDocument1,566 pagesLista de Precios Suspensión y Aceite Framindependencia RNo ratings yet

- PC Bosal UniversaleDocument12 pagesPC Bosal Universalevali_monroeNo ratings yet

- JF015E Calibration Parte4Document4 pagesJF015E Calibration Parte4EdgarditoNo ratings yet

- Copia de Rodill. VehiculosDocument19 pagesCopia de Rodill. VehiculosMirian NacipuchaNo ratings yet

- Renault: Marca / Make Modello / Model Anno / Year OE P/N Delphi P/NDocument5 pagesRenault: Marca / Make Modello / Model Anno / Year OE P/N Delphi P/NLucian Cristian PintilieNo ratings yet

- FR 2021Document165 pagesFR 2021Bunny KanungoNo ratings yet

- NPW ToyotaDocument25 pagesNPW ToyotaDJ90RADIO100% (2)

- A Study On Customer'S Perception Towards Honda CarsDocument66 pagesA Study On Customer'S Perception Towards Honda CarsPankajPetwalNo ratings yet

- RE0F10A CVT Parts Catalogue 2019-07Document65 pagesRE0F10A CVT Parts Catalogue 2019-07Андрей ЛозовойNo ratings yet

- Vissan Case Group 7Document15 pagesVissan Case Group 7Nhi TuyếtNo ratings yet

- GP 9, Nissan CaseDocument17 pagesGP 9, Nissan CaseHumna Amna67% (3)

- Case AnalysisDocument7 pagesCase AnalysisPythia HecatleneNo ratings yet

- 1999 Nissan Pathfinder PDFDocument274 pages1999 Nissan Pathfinder PDFJosue FloresNo ratings yet

- Catalogo Kit de Tiempo IchibanDocument8 pagesCatalogo Kit de Tiempo IchibanPiero SánchezNo ratings yet

- ANNEXURE Ford PDFDocument3 pagesANNEXURE Ford PDFARSHU . SNo ratings yet

- NissanDocument2 pagesNissanIonut GrozaNo ratings yet

- Lista Actualizada de Delawer 11 de Noviembre 2021Document118 pagesLista Actualizada de Delawer 11 de Noviembre 2021jessica torresNo ratings yet

- Dbms Newex5 OutputDocument6 pagesDbms Newex5 OutputSruthisree R MNo ratings yet

- Production & Sale Data of Vehicles Passenger CarsDocument27 pagesProduction & Sale Data of Vehicles Passenger CarsFaysal MeghaniNo ratings yet

- Diagrama de Sincronizacion Nissan Cd17 ScribdDocument5 pagesDiagrama de Sincronizacion Nissan Cd17 Scribdnelson raul aranda roncal100% (1)

- EmployeesDocument19 pagesEmployeesAbhilash R MNo ratings yet

- Global Leadership Carlos GhosnDocument12 pagesGlobal Leadership Carlos GhosnRana ShakoorNo ratings yet

- ND Dealer - 29-06-21Document277 pagesND Dealer - 29-06-21Vicky ChoudharyNo ratings yet