Professional Documents

Culture Documents

Steel Sheet Piling Design Manual

Steel Sheet Piling Design Manual

Uploaded by

Addrien DanielCopyright:

Available Formats

You might also like

- Sheet Pile DesignDocument5 pagesSheet Pile DesignnileshbhusariNo ratings yet

- Shore Pile DesignDocument30 pagesShore Pile DesignMuhammad Mynul Hossain100% (13)

- Cantilever Sheet Pile DesignDocument14 pagesCantilever Sheet Pile DesignMaltesh H100% (3)

- Settlement (N Values)Document6 pagesSettlement (N Values)Hiranya VarmaNo ratings yet

- Fe Sheet Pile WallDocument22 pagesFe Sheet Pile WallBogie Prastowo MahardhikaNo ratings yet

- Sheet Pile Wall DesignDocument7 pagesSheet Pile Wall DesignSavy VannNo ratings yet

- Example Cantilever Soldier Piles: Ca, Active CP, Passive Coefficient CoefficientDocument2 pagesExample Cantilever Soldier Piles: Ca, Active CP, Passive Coefficient CoefficientVinh DuongNo ratings yet

- Pile DesignDocument56 pagesPile Designsamwong87100% (3)

- H4135A eDocument6 pagesH4135A earunkuriankNo ratings yet

- Pile SpringDocument6 pagesPile Springkaleswara_tellakula100% (2)

- CV6313 - AY2019-20 L4 - Lateral Response of A Single PileDocument53 pagesCV6313 - AY2019-20 L4 - Lateral Response of A Single PileLordM00nNo ratings yet

- Design of Sheet PileDocument14 pagesDesign of Sheet PileRifka AmaliaNo ratings yet

- Sheet Pile 1Document13 pagesSheet Pile 1belacewNo ratings yet

- Properties of Pile: 4.0 Design Calculation of Pile Foundations Calculation of Pile InputDocument15 pagesProperties of Pile: 4.0 Design Calculation of Pile Foundations Calculation of Pile InputARUN RAWATNo ratings yet

- Pile Design CalculationDocument69 pagesPile Design Calculationhessian123No ratings yet

- Desing Report - Temporary Sheet PileDocument6 pagesDesing Report - Temporary Sheet PileHafiz KamarudinNo ratings yet

- Wallap Input Data Bada Chauraha Station Top Down Grid 08-11-750mm CS at 8.15mDocument18 pagesWallap Input Data Bada Chauraha Station Top Down Grid 08-11-750mm CS at 8.15msumit rawatNo ratings yet

- BH 1 UploadDocument8 pagesBH 1 UploadTee Bun PinNo ratings yet

- Sachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997Document14 pagesSachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997sitheeqNo ratings yet

- Pile DesignDocument12 pagesPile DesignRaxKitNo ratings yet

- 9.3 Strut Design ISMB (Hor)Document7 pages9.3 Strut Design ISMB (Hor)24x7civilconsultantNo ratings yet

- Bearing Capacity of SoilDocument7 pagesBearing Capacity of SoilAsad Hayat WarraichNo ratings yet

- Dynamic Calculation For Retaining WallDocument6 pagesDynamic Calculation For Retaining WallSabrina ImloulNo ratings yet

- Design - BorepileDocument10 pagesDesign - BorepileSumedha MayadunnaNo ratings yet

- Analysis and Design of Cantilever Retaining Walls On Staad ProDocument12 pagesAnalysis and Design of Cantilever Retaining Walls On Staad ProCamilo TercerosNo ratings yet

- Cantilever Soldier Pile DesignDocument1 pageCantilever Soldier Pile DesignSAEED NegarNo ratings yet

- Design Retaining WallDocument98 pagesDesign Retaining WallAnkush SharmaNo ratings yet

- Design of Pile FoundationDocument16 pagesDesign of Pile FoundationD SRINIVASNo ratings yet

- Calculation Manhole Type - 02Document25 pagesCalculation Manhole Type - 02ameena ahamedNo ratings yet

- Retaining Wall DesignDocument5 pagesRetaining Wall DesignbharatNo ratings yet

- SQ RC Driven Pile Capacity CalculationDocument251 pagesSQ RC Driven Pile Capacity Calculationsaravanan100% (1)

- Winkler Spring Calculation ForAbutment BoredPileDocument1 pageWinkler Spring Calculation ForAbutment BoredPileVal Beltran100% (2)

- Drain Cum Retaining WallDocument12 pagesDrain Cum Retaining WallvivekNo ratings yet

- Lateral Geotechnical Capacity of Pile 350x350mm Free HeadDocument12 pagesLateral Geotechnical Capacity of Pile 350x350mm Free HeadPriodeep ChowdhuryNo ratings yet

- Ceng3143 Fge-III Ext Chapter5Document122 pagesCeng3143 Fge-III Ext Chapter5ABAMELANo ratings yet

- Sheet Pile Design SampleDocument4 pagesSheet Pile Design SampleMarvin SabadoNo ratings yet

- Bearing Capacity VesicDocument13 pagesBearing Capacity VesicZhenhe SongNo ratings yet

- Pile Conditions: Input Quantities Value Units CommentDocument16 pagesPile Conditions: Input Quantities Value Units CommentMarcos MaNo ratings yet

- Shoring Design - Contiguous Pile, Soldier Piles System, Secant Piles SystemDocument53 pagesShoring Design - Contiguous Pile, Soldier Piles System, Secant Piles Systemျမတ္ သူ ေအာင္No ratings yet

- Lateral Pile Capacity - BromsDocument2 pagesLateral Pile Capacity - Bromscalky117100% (1)

- Chapter - 2 - Sheet PileDocument28 pagesChapter - 2 - Sheet PilebeleteNo ratings yet

- Project: Pilipinas Kao Inc.: Slope StabilityDocument5 pagesProject: Pilipinas Kao Inc.: Slope StabilityclarkgaguiNo ratings yet

- Sheet Pile Calculation REF Calculations OutputDocument7 pagesSheet Pile Calculation REF Calculations OutputAgboola OluwasolaNo ratings yet

- Design of Retaining Wall..Document9 pagesDesign of Retaining Wall..Sovan PramanickNo ratings yet

- B1-2A Pile ShearDocument8 pagesB1-2A Pile ShearFranklyn P. GenoveNo ratings yet

- Pile Capacity Calculation With Bore-Logs Method (Meyerhof Equation)Document82 pagesPile Capacity Calculation With Bore-Logs Method (Meyerhof Equation)mathuNo ratings yet

- Lateral Force For One-Story Wall Based On IBC 2006: G G I G G Q W C C V C C KKKDocument3 pagesLateral Force For One-Story Wall Based On IBC 2006: G G I G G Q W C C V C C KKKLivian TeddyNo ratings yet

- Rock Socket EC 7 Template Rev 00Document42 pagesRock Socket EC 7 Template Rev 00Vistash BuharyNo ratings yet

- King PostDocument9 pagesKing PostNyan OoNo ratings yet

- Deep Beam CheckDocument10 pagesDeep Beam CheckNikhil AgrawalNo ratings yet

- PPTDocument21 pagesPPTKunwarKhaliqeAhmadNo ratings yet

- Pile CapacityDocument6 pagesPile Capacityhemantkle2u100% (2)

- Pile FundationDocument49 pagesPile FundationFranklyn GenoveNo ratings yet

- Rectangular DuctDocument67 pagesRectangular DuctAUCE9802100% (3)

- Sheet Stair Design UOL Class Lectrure Project SubjectDocument3 pagesSheet Stair Design UOL Class Lectrure Project Subjecthafiz zain saeedNo ratings yet

- Structural ReviewDocument46 pagesStructural ReviewNicholas Thompson100% (1)

- Footing Design Calculations TowerDocument37 pagesFooting Design Calculations TowersetuinfNo ratings yet

- Static Model BraDocument27 pagesStatic Model BraPatranNo ratings yet

- Tributary Load and Load PathDocument14 pagesTributary Load and Load PathPandal RajNo ratings yet

- Erc - Valve Pit CalculationDocument30 pagesErc - Valve Pit Calculationisaacjoe77No ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Calculation & Formuals: ReferenceDocument3 pagesCalculation & Formuals: ReferenceAddrien DanielNo ratings yet

- Reference Output Calculations & FormulasDocument4 pagesReference Output Calculations & FormulasAddrien DanielNo ratings yet

- Solutions To Assignment 4 MATH110BDocument8 pagesSolutions To Assignment 4 MATH110BAddrien DanielNo ratings yet

- Blockwork PDFDocument11 pagesBlockwork PDFAddrien DanielNo ratings yet

- Done By: CHK By: Revision: Output Title: Calculations & Formulas X-DirectionDocument5 pagesDone By: CHK By: Revision: Output Title: Calculations & Formulas X-DirectionAddrien DanielNo ratings yet

- Z PurlinDocument2 pagesZ PurlinAddrien DanielNo ratings yet

- Cold-Formed Steel Structures To The AISI Specification - 0824792947Document405 pagesCold-Formed Steel Structures To The AISI Specification - 0824792947irdl92% (12)

- Gec8 PDFDocument293 pagesGec8 PDFAddrien DanielNo ratings yet

- Structural SlabDocument3 pagesStructural SlabAddrien DanielNo ratings yet

- SI UnitsDocument4 pagesSI UnitsAddrien DanielNo ratings yet

- Formula Sheet 4-Concrete DesignDocument7 pagesFormula Sheet 4-Concrete DesignAddrien DanielNo ratings yet

- Columb Soil CoefficientDocument2 pagesColumb Soil CoefficientAddrien DanielNo ratings yet

- Formula Sheet 5-Slabs, Compositie Beams, Prestress Concrete Design, Steel ConnectionDocument14 pagesFormula Sheet 5-Slabs, Compositie Beams, Prestress Concrete Design, Steel ConnectionAddrien DanielNo ratings yet

- ASTM A992: Output Calculations & FormulasDocument1 pageASTM A992: Output Calculations & FormulasAddrien DanielNo ratings yet

- Combined FootingDocument4 pagesCombined FootingAddrien DanielNo ratings yet

- Overall Equipment Effectiveness in Coal Mining Company: A Case StudyDocument6 pagesOverall Equipment Effectiveness in Coal Mining Company: A Case StudyRohis Al - MijanNo ratings yet

- Conference Program USFQ SISE IIN2019Document10 pagesConference Program USFQ SISE IIN2019Andres SanchezNo ratings yet

- LMN20040R-RC12000W Ultra Large Laser Cutting Machine Technical ParametersDocument20 pagesLMN20040R-RC12000W Ultra Large Laser Cutting Machine Technical ParametersTaha TitoNo ratings yet

- Flyer Culticam - 2023 en DataDocument5 pagesFlyer Culticam - 2023 en DataEvgen WoofNo ratings yet

- Pretest, RC Part 2 PDFDocument1 pagePretest, RC Part 2 PDFleanne DespaNo ratings yet

- The Kenya Universities and Colleges Central Placement Service (Kuccps) InstituDocument3 pagesThe Kenya Universities and Colleges Central Placement Service (Kuccps) InstituJacksonNo ratings yet

- 07-Relay TechnologyDocument13 pages07-Relay Technologyapi-3769988No ratings yet

- Engineering Design ShowcaseDocument36 pagesEngineering Design ShowcaseHarisSafiNo ratings yet

- JFZ-22F Split-Phase Auxiliary Relay Equipment - MANUAL (0SF.459.017E) - V2.2Document44 pagesJFZ-22F Split-Phase Auxiliary Relay Equipment - MANUAL (0SF.459.017E) - V2.2duonzaNo ratings yet

- SNR - Engineering - 19 - Unit3 - Ia1 - Ass - Inst - Project PDFDocument9 pagesSNR - Engineering - 19 - Unit3 - Ia1 - Ass - Inst - Project PDFPaul TatelNo ratings yet

- 2021 LWRC W40 007Document1 page2021 LWRC W40 007Jay ar TenorioNo ratings yet

- Metrology Chapter 9Document83 pagesMetrology Chapter 9Sweekar KhadkaNo ratings yet

- 2post Car Lifter - Sheet2Document2 pages2post Car Lifter - Sheet2pavansvgp2003No ratings yet

- Distributed Control SystemDocument8 pagesDistributed Control SystemParth ShethNo ratings yet

- CAIP Part IDocument914 pagesCAIP Part ILeoLaureatte100% (5)

- Pile Foundation#2 PDFDocument79 pagesPile Foundation#2 PDFErwin Nur WicaksonoNo ratings yet

- Recommended OilsDocument8 pagesRecommended OilsAhmad Faishal LuthfiNo ratings yet

- By Awad S. Hanna, Ph. D., P. E. The University of Wisconsin, MadisonDocument28 pagesBy Awad S. Hanna, Ph. D., P. E. The University of Wisconsin, MadisontechethiocomNo ratings yet

- Piling Practices Under Eurocode 7 (Contractor Point of View) PDFDocument42 pagesPiling Practices Under Eurocode 7 (Contractor Point of View) PDFBatu GajahNo ratings yet

- Some Critical Issues 4 Injection MoldingDocument280 pagesSome Critical Issues 4 Injection MoldingMiralles Martínez JordiNo ratings yet

- B.Tech in AI and Data ScienceDocument23 pagesB.Tech in AI and Data ScienceMan mNo ratings yet

- The Benefits of The Incremental LaunchingDocument24 pagesThe Benefits of The Incremental LaunchingmrlobboNo ratings yet

- E.naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - V2.0.2Document2 pagesE.naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - V2.0.2Max100% (1)

- Project of Design by Group 3Document54 pagesProject of Design by Group 3etayhailu100% (4)

- ELF GLOBAL Solutions ProfileDocument6 pagesELF GLOBAL Solutions Profile987_bbbNo ratings yet

- 6ELTswagelok+Tube Weld Fittings For High Temp UseDocument2 pages6ELTswagelok+Tube Weld Fittings For High Temp UseRifai Idris50% (2)

- Building - Codes and HousingDocument53 pagesBuilding - Codes and HousingVeronica HernandezNo ratings yet

- Study On The Strength of EarthbagsDocument28 pagesStudy On The Strength of EarthbagsZherrinore Rasay100% (1)

- Seminar Report State Load Despatch Centre (RRVPNL) : Mr. Subhash Swami Hemraj Gurjar (15EAOEE013)Document40 pagesSeminar Report State Load Despatch Centre (RRVPNL) : Mr. Subhash Swami Hemraj Gurjar (15EAOEE013)HEMRAJ KHATANANo ratings yet

Steel Sheet Piling Design Manual

Steel Sheet Piling Design Manual

Uploaded by

Addrien DanielOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Sheet Piling Design Manual

Steel Sheet Piling Design Manual

Uploaded by

Addrien DanielCopyright:

Available Formats

Page 1 of 6

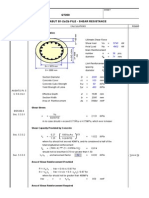

REFERENCE

U.S.S

DESIGN CALCULATIONS & FORMULAS

Lup=4ft.

Steel Sheet Piling

Uniform Surcharge = 300 p.s.f

Design Manual

A

Ha=5ft.

Anchor Pull ,T

H1=12ft.

low water level

low water level

Hw=20ft. Ht=27ft.

Dredge line

C1

C2

y

D

D

D1

Height of wall above wt. Lvl

Height of w.t Lvl

Height of tension-rod above Dredge line

Height of Anchor rod below Gr. Lvl

Uniform surcharge

Line load

Perpendicular distance of line load

Height of w.t lag behind wall

Height of w.t behind behind wall

H1 =

Hw=

H t=

Ha=

=

Lu=

Lup=

Hl=

hbw

12

20

27

5

300

4000

4

2

10

ft.

ft.

ft.

ft.

lb/ft2

lb/ft

ft.

ft.

ft.

=

'=

110

60

0

34

0.28

lb/ft3

lb/ft3

65

6.63

0.26

36

-0.4

6.37

lb/ft3

Backfill Properties Above Dredge Line :

=

=

Ka=

Backfill Properties Below Dredge Line :

'=

Kp'=

Ka'=

=

/=

Kp'-Ka'=

Output

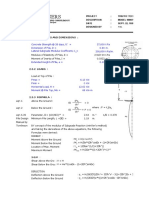

Page 2 of 6

REFERENCE

DESIGN CALCULATIONS & FORMULAS

Pressures On Wall :

=

1

+

1

+

=

308

lb/ft2

466.4

lb/ft2

1+

802.4

lb/ft2

661.648

lb/ft2

414.05

(D1)

Pressure On Wall Due To Surcharge

Above C --

84

lb/ft2

Below C --

'=

78

lb/ft2

=

= 0.55

Location of resultant =

0.125

2200

0.6 (H)

lb

19.2 ft. from the dredge line

The location of (y)

1.60

ft.

= H1 PB =

1540

lb.

6776

lb.

158.4

lb.

3168

lb.

3360

Resultant Of Pressures

1

2

=(

= Hl

+ )PB =

+

= [

+

5

= [

= [

(+ ) =

(+ ) =

2]

529.3184

PE [D1] =

207.025

+

1

[D12]

2688

lb.

130

+ (78)D1

Output

Page 3 of 6

REFERENCE

DESIGN CALCULATIONS & FORMULAS

Output

Solving For D Using Mat

Element

1

Force

1540

Arm

-1.67

Moment

-2567

6776

16.0

108416

158

20.3

3220.8

3168

17.00

53856

3360

20.33

68320

529

27.53

14574

7(PASSIVE)

207.025[D12]

27+1.6+ [2(D1)/3 ]

-[138(D1^3)+5921(D1^2)]

SUR(+C)

2688

11.00

29568

SUR(-C)

130+ (78)D1

LINE LOAD

2200

[D1+ 1.6 + 27 ]/ 2

39[D1^2]+1180.4[D1]+1859

7.8

(+M)

39[D1^2]+1180.4[D1]+296974

(-M)

138(D1^3)+5921(D1^2)+2567

17160

And

(+M)

NOW SOLVING FOR D WITH:

[D1^3] + 42.62[D1^2] -8.1[D1] - 2133.38= 0

D1 =

Total penetration = D1 + y =

To provide a margin of Safety ,increase D by a factor of =

6.7

ft

8.30

ft.

40

Dmin =

11.62

Use D=

18

ft.

The Tie Rod Tension Force

T= P1 + P2 + P3 + P4 + Psur.(+C)+ Psur.(-C)+P5+LineLoad =

For Sizing The Tie Rod Size Increase By

9578.96615 lb.

33

Use T= 12740.025 lb.

Maximum Moment

(-M)

Page 4 of 6

REFERENCE

DESIGN CALCULATIONS & FORMULAS

By Letting the Point Of Zero Shear Be At (x) Feet Below Low Water Level

Output

[x^2] + 37[x] -695= 0

T=P1+LineLoad +PB(x) + Ka '(x)2 =

x=

20.3

ft.

Design Moments

-37422

-P1 (x + H1) =

=

- Ka '(x)2

ft-lb

-63461.86 ft-lb

-23423.1956 ft-lb

T[(x) + (H1-Ha)]= 261505.776 ft-lb

Line load x [x+H1-(H1+H2)-(0.6H)] =

-42900

ft-lb

Max. Moment = M= 94298.7203 ft-lb

1131.58464 k-in

Grade Steel 50

Using

Allowable Stress =

32

ksi.

Mmax= FyS= 1131.58464 k-in

=

Sreq'd =

35.3620201 in3/ft of wall.

AZ- 26 Section (Grade 50)

Use

With S=

57.1

in3/ft/wall

>

3

35.362 in /ft/wall

O.k

Using Rowe's Theory Of Reduction

Calculating P =

For the sheet pile Sections below

P=

Pile Sections

S (per foot)( in3)

I (per foot)(in4)

Ratio =

Mdesign = Ratio[Mmax]

Stress =

Ratio

Mdesign (kips)

Stress(ksi)

E=

3E+07

psi

4320

/I

AZ-26

57.1

437.3

0.8

905.3

15.9

AZ-28

AZ-24

53.3

408.8

0.78

882.6

16.6

60.9

465.9

0.8

905.3

14.9

Based on Rowe's Theory Of Moment Reduction The Following Sheet Pile Section May Be used :

AZ-24

AZ-26

AZ-28

ASTM A572 Grade 50

ASTM A572 Grade 50

ASTM A572 Grade 50

fs=

fs=

fs=

16.6 ksi.

15.9 ksi.

14.9 ksi.

<

<

<

32

32

32

ksi

ksi

ksi

O.k

O.k

O.k

Page 5 of 6

REFERENCE

DESIGN CALCULATIONS & FORMULAS

Output

Tie Rod Design

Tie Rod Design Force Tact=

9578.96615 lb

Anchor rod length ,al =

65

ft

Anchor rod decline ,ad =

0

ft.

Anchor rod spacing ,d =

9

ft.

Using

A50

Steel ;Allowable stress =

= tan-1

86210.6954 lb./tie rod

Ap=

33000 psi.

Increasing by

Apdesign=

Tie rod Req'd x-x area =

30

112073.904 lb./tie rod

2

3.39617891 in /rod.

2

4.90625 in /rod.

2.5

in. Rod

A36

Steel ;Allowable stress =

Use a

Asprov.=

>

2

3.39618 in /rod.

O.k

Wale Design

2

For Maximum Moment Using Mmax=

Using

22000 psi.(bending )

Mmax = 86210.6954 ft.-lb

S x-x=

47.0240156 in3

3

S x-x= 23.5120078 in /Channel

Use --

S x-x=

2 -C10X20

Use --

1 in. Bolts

Use --

3 in. clear distance between channel.

&

31.6 in3/Channel

>

3

23.51 in /Channel

O.k

1.5 in. pipe separators to bolt channels together .

Waler Web Crippling

Using AISC Steel Manual Section 5

0.75

Length Of Bearing Plate ,N =

Channel Fillet Dimension,K=

Web Thickness , t =

Yield stress ,Fy=

Clear distance b.t.w Channels, l =

(

7.5

2

0.379

36

3

in.

in.

in.

ksi

in.

1.09888335 ksi

<

27 ksi.= 0.75fy

O.k

Bearing Plate

Bearing Plate

1.5in.

3in.

2 -C10X20

Page 6 of 6

REFERENCE

DESIGN CALCULATIONS & FORMULAS

Mmax=

Sreq'd =

()

Output

8.62106954 k-in

0.39912359 in3

The section modulus of the plate is =

tp =

Sreqd=

Use

0.56506537 in.

3/4

in. plate

>

0.57 in. plate

O.k

You might also like

- Sheet Pile DesignDocument5 pagesSheet Pile DesignnileshbhusariNo ratings yet

- Shore Pile DesignDocument30 pagesShore Pile DesignMuhammad Mynul Hossain100% (13)

- Cantilever Sheet Pile DesignDocument14 pagesCantilever Sheet Pile DesignMaltesh H100% (3)

- Settlement (N Values)Document6 pagesSettlement (N Values)Hiranya VarmaNo ratings yet

- Fe Sheet Pile WallDocument22 pagesFe Sheet Pile WallBogie Prastowo MahardhikaNo ratings yet

- Sheet Pile Wall DesignDocument7 pagesSheet Pile Wall DesignSavy VannNo ratings yet

- Example Cantilever Soldier Piles: Ca, Active CP, Passive Coefficient CoefficientDocument2 pagesExample Cantilever Soldier Piles: Ca, Active CP, Passive Coefficient CoefficientVinh DuongNo ratings yet

- Pile DesignDocument56 pagesPile Designsamwong87100% (3)

- H4135A eDocument6 pagesH4135A earunkuriankNo ratings yet

- Pile SpringDocument6 pagesPile Springkaleswara_tellakula100% (2)

- CV6313 - AY2019-20 L4 - Lateral Response of A Single PileDocument53 pagesCV6313 - AY2019-20 L4 - Lateral Response of A Single PileLordM00nNo ratings yet

- Design of Sheet PileDocument14 pagesDesign of Sheet PileRifka AmaliaNo ratings yet

- Sheet Pile 1Document13 pagesSheet Pile 1belacewNo ratings yet

- Properties of Pile: 4.0 Design Calculation of Pile Foundations Calculation of Pile InputDocument15 pagesProperties of Pile: 4.0 Design Calculation of Pile Foundations Calculation of Pile InputARUN RAWATNo ratings yet

- Pile Design CalculationDocument69 pagesPile Design Calculationhessian123No ratings yet

- Desing Report - Temporary Sheet PileDocument6 pagesDesing Report - Temporary Sheet PileHafiz KamarudinNo ratings yet

- Wallap Input Data Bada Chauraha Station Top Down Grid 08-11-750mm CS at 8.15mDocument18 pagesWallap Input Data Bada Chauraha Station Top Down Grid 08-11-750mm CS at 8.15msumit rawatNo ratings yet

- BH 1 UploadDocument8 pagesBH 1 UploadTee Bun PinNo ratings yet

- Sachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997Document14 pagesSachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997sitheeqNo ratings yet

- Pile DesignDocument12 pagesPile DesignRaxKitNo ratings yet

- 9.3 Strut Design ISMB (Hor)Document7 pages9.3 Strut Design ISMB (Hor)24x7civilconsultantNo ratings yet

- Bearing Capacity of SoilDocument7 pagesBearing Capacity of SoilAsad Hayat WarraichNo ratings yet

- Dynamic Calculation For Retaining WallDocument6 pagesDynamic Calculation For Retaining WallSabrina ImloulNo ratings yet

- Design - BorepileDocument10 pagesDesign - BorepileSumedha MayadunnaNo ratings yet

- Analysis and Design of Cantilever Retaining Walls On Staad ProDocument12 pagesAnalysis and Design of Cantilever Retaining Walls On Staad ProCamilo TercerosNo ratings yet

- Cantilever Soldier Pile DesignDocument1 pageCantilever Soldier Pile DesignSAEED NegarNo ratings yet

- Design Retaining WallDocument98 pagesDesign Retaining WallAnkush SharmaNo ratings yet

- Design of Pile FoundationDocument16 pagesDesign of Pile FoundationD SRINIVASNo ratings yet

- Calculation Manhole Type - 02Document25 pagesCalculation Manhole Type - 02ameena ahamedNo ratings yet

- Retaining Wall DesignDocument5 pagesRetaining Wall DesignbharatNo ratings yet

- SQ RC Driven Pile Capacity CalculationDocument251 pagesSQ RC Driven Pile Capacity Calculationsaravanan100% (1)

- Winkler Spring Calculation ForAbutment BoredPileDocument1 pageWinkler Spring Calculation ForAbutment BoredPileVal Beltran100% (2)

- Drain Cum Retaining WallDocument12 pagesDrain Cum Retaining WallvivekNo ratings yet

- Lateral Geotechnical Capacity of Pile 350x350mm Free HeadDocument12 pagesLateral Geotechnical Capacity of Pile 350x350mm Free HeadPriodeep ChowdhuryNo ratings yet

- Ceng3143 Fge-III Ext Chapter5Document122 pagesCeng3143 Fge-III Ext Chapter5ABAMELANo ratings yet

- Sheet Pile Design SampleDocument4 pagesSheet Pile Design SampleMarvin SabadoNo ratings yet

- Bearing Capacity VesicDocument13 pagesBearing Capacity VesicZhenhe SongNo ratings yet

- Pile Conditions: Input Quantities Value Units CommentDocument16 pagesPile Conditions: Input Quantities Value Units CommentMarcos MaNo ratings yet

- Shoring Design - Contiguous Pile, Soldier Piles System, Secant Piles SystemDocument53 pagesShoring Design - Contiguous Pile, Soldier Piles System, Secant Piles Systemျမတ္ သူ ေအာင္No ratings yet

- Lateral Pile Capacity - BromsDocument2 pagesLateral Pile Capacity - Bromscalky117100% (1)

- Chapter - 2 - Sheet PileDocument28 pagesChapter - 2 - Sheet PilebeleteNo ratings yet

- Project: Pilipinas Kao Inc.: Slope StabilityDocument5 pagesProject: Pilipinas Kao Inc.: Slope StabilityclarkgaguiNo ratings yet

- Sheet Pile Calculation REF Calculations OutputDocument7 pagesSheet Pile Calculation REF Calculations OutputAgboola OluwasolaNo ratings yet

- Design of Retaining Wall..Document9 pagesDesign of Retaining Wall..Sovan PramanickNo ratings yet

- B1-2A Pile ShearDocument8 pagesB1-2A Pile ShearFranklyn P. GenoveNo ratings yet

- Pile Capacity Calculation With Bore-Logs Method (Meyerhof Equation)Document82 pagesPile Capacity Calculation With Bore-Logs Method (Meyerhof Equation)mathuNo ratings yet

- Lateral Force For One-Story Wall Based On IBC 2006: G G I G G Q W C C V C C KKKDocument3 pagesLateral Force For One-Story Wall Based On IBC 2006: G G I G G Q W C C V C C KKKLivian TeddyNo ratings yet

- Rock Socket EC 7 Template Rev 00Document42 pagesRock Socket EC 7 Template Rev 00Vistash BuharyNo ratings yet

- King PostDocument9 pagesKing PostNyan OoNo ratings yet

- Deep Beam CheckDocument10 pagesDeep Beam CheckNikhil AgrawalNo ratings yet

- PPTDocument21 pagesPPTKunwarKhaliqeAhmadNo ratings yet

- Pile CapacityDocument6 pagesPile Capacityhemantkle2u100% (2)

- Pile FundationDocument49 pagesPile FundationFranklyn GenoveNo ratings yet

- Rectangular DuctDocument67 pagesRectangular DuctAUCE9802100% (3)

- Sheet Stair Design UOL Class Lectrure Project SubjectDocument3 pagesSheet Stair Design UOL Class Lectrure Project Subjecthafiz zain saeedNo ratings yet

- Structural ReviewDocument46 pagesStructural ReviewNicholas Thompson100% (1)

- Footing Design Calculations TowerDocument37 pagesFooting Design Calculations TowersetuinfNo ratings yet

- Static Model BraDocument27 pagesStatic Model BraPatranNo ratings yet

- Tributary Load and Load PathDocument14 pagesTributary Load and Load PathPandal RajNo ratings yet

- Erc - Valve Pit CalculationDocument30 pagesErc - Valve Pit Calculationisaacjoe77No ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Calculation & Formuals: ReferenceDocument3 pagesCalculation & Formuals: ReferenceAddrien DanielNo ratings yet

- Reference Output Calculations & FormulasDocument4 pagesReference Output Calculations & FormulasAddrien DanielNo ratings yet

- Solutions To Assignment 4 MATH110BDocument8 pagesSolutions To Assignment 4 MATH110BAddrien DanielNo ratings yet

- Blockwork PDFDocument11 pagesBlockwork PDFAddrien DanielNo ratings yet

- Done By: CHK By: Revision: Output Title: Calculations & Formulas X-DirectionDocument5 pagesDone By: CHK By: Revision: Output Title: Calculations & Formulas X-DirectionAddrien DanielNo ratings yet

- Z PurlinDocument2 pagesZ PurlinAddrien DanielNo ratings yet

- Cold-Formed Steel Structures To The AISI Specification - 0824792947Document405 pagesCold-Formed Steel Structures To The AISI Specification - 0824792947irdl92% (12)

- Gec8 PDFDocument293 pagesGec8 PDFAddrien DanielNo ratings yet

- Structural SlabDocument3 pagesStructural SlabAddrien DanielNo ratings yet

- SI UnitsDocument4 pagesSI UnitsAddrien DanielNo ratings yet

- Formula Sheet 4-Concrete DesignDocument7 pagesFormula Sheet 4-Concrete DesignAddrien DanielNo ratings yet

- Columb Soil CoefficientDocument2 pagesColumb Soil CoefficientAddrien DanielNo ratings yet

- Formula Sheet 5-Slabs, Compositie Beams, Prestress Concrete Design, Steel ConnectionDocument14 pagesFormula Sheet 5-Slabs, Compositie Beams, Prestress Concrete Design, Steel ConnectionAddrien DanielNo ratings yet

- ASTM A992: Output Calculations & FormulasDocument1 pageASTM A992: Output Calculations & FormulasAddrien DanielNo ratings yet

- Combined FootingDocument4 pagesCombined FootingAddrien DanielNo ratings yet

- Overall Equipment Effectiveness in Coal Mining Company: A Case StudyDocument6 pagesOverall Equipment Effectiveness in Coal Mining Company: A Case StudyRohis Al - MijanNo ratings yet

- Conference Program USFQ SISE IIN2019Document10 pagesConference Program USFQ SISE IIN2019Andres SanchezNo ratings yet

- LMN20040R-RC12000W Ultra Large Laser Cutting Machine Technical ParametersDocument20 pagesLMN20040R-RC12000W Ultra Large Laser Cutting Machine Technical ParametersTaha TitoNo ratings yet

- Flyer Culticam - 2023 en DataDocument5 pagesFlyer Culticam - 2023 en DataEvgen WoofNo ratings yet

- Pretest, RC Part 2 PDFDocument1 pagePretest, RC Part 2 PDFleanne DespaNo ratings yet

- The Kenya Universities and Colleges Central Placement Service (Kuccps) InstituDocument3 pagesThe Kenya Universities and Colleges Central Placement Service (Kuccps) InstituJacksonNo ratings yet

- 07-Relay TechnologyDocument13 pages07-Relay Technologyapi-3769988No ratings yet

- Engineering Design ShowcaseDocument36 pagesEngineering Design ShowcaseHarisSafiNo ratings yet

- JFZ-22F Split-Phase Auxiliary Relay Equipment - MANUAL (0SF.459.017E) - V2.2Document44 pagesJFZ-22F Split-Phase Auxiliary Relay Equipment - MANUAL (0SF.459.017E) - V2.2duonzaNo ratings yet

- SNR - Engineering - 19 - Unit3 - Ia1 - Ass - Inst - Project PDFDocument9 pagesSNR - Engineering - 19 - Unit3 - Ia1 - Ass - Inst - Project PDFPaul TatelNo ratings yet

- 2021 LWRC W40 007Document1 page2021 LWRC W40 007Jay ar TenorioNo ratings yet

- Metrology Chapter 9Document83 pagesMetrology Chapter 9Sweekar KhadkaNo ratings yet

- 2post Car Lifter - Sheet2Document2 pages2post Car Lifter - Sheet2pavansvgp2003No ratings yet

- Distributed Control SystemDocument8 pagesDistributed Control SystemParth ShethNo ratings yet

- CAIP Part IDocument914 pagesCAIP Part ILeoLaureatte100% (5)

- Pile Foundation#2 PDFDocument79 pagesPile Foundation#2 PDFErwin Nur WicaksonoNo ratings yet

- Recommended OilsDocument8 pagesRecommended OilsAhmad Faishal LuthfiNo ratings yet

- By Awad S. Hanna, Ph. D., P. E. The University of Wisconsin, MadisonDocument28 pagesBy Awad S. Hanna, Ph. D., P. E. The University of Wisconsin, MadisontechethiocomNo ratings yet

- Piling Practices Under Eurocode 7 (Contractor Point of View) PDFDocument42 pagesPiling Practices Under Eurocode 7 (Contractor Point of View) PDFBatu GajahNo ratings yet

- Some Critical Issues 4 Injection MoldingDocument280 pagesSome Critical Issues 4 Injection MoldingMiralles Martínez JordiNo ratings yet

- B.Tech in AI and Data ScienceDocument23 pagesB.Tech in AI and Data ScienceMan mNo ratings yet

- The Benefits of The Incremental LaunchingDocument24 pagesThe Benefits of The Incremental LaunchingmrlobboNo ratings yet

- E.naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - V2.0.2Document2 pagesE.naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - V2.0.2Max100% (1)

- Project of Design by Group 3Document54 pagesProject of Design by Group 3etayhailu100% (4)

- ELF GLOBAL Solutions ProfileDocument6 pagesELF GLOBAL Solutions Profile987_bbbNo ratings yet

- 6ELTswagelok+Tube Weld Fittings For High Temp UseDocument2 pages6ELTswagelok+Tube Weld Fittings For High Temp UseRifai Idris50% (2)

- Building - Codes and HousingDocument53 pagesBuilding - Codes and HousingVeronica HernandezNo ratings yet

- Study On The Strength of EarthbagsDocument28 pagesStudy On The Strength of EarthbagsZherrinore Rasay100% (1)

- Seminar Report State Load Despatch Centre (RRVPNL) : Mr. Subhash Swami Hemraj Gurjar (15EAOEE013)Document40 pagesSeminar Report State Load Despatch Centre (RRVPNL) : Mr. Subhash Swami Hemraj Gurjar (15EAOEE013)HEMRAJ KHATANANo ratings yet