Professional Documents

Culture Documents

JSA-Emerg Act-Oct 18, 07

JSA-Emerg Act-Oct 18, 07

Uploaded by

Ihwan AsrulCopyright:

Available Formats

You might also like

- JSA Erection of Steel StructureDocument9 pagesJSA Erection of Steel StructureLuqman Osman77% (13)

- Standard Deliverable List For Feasibility Conceptual FEED Detailed DesignDocument22 pagesStandard Deliverable List For Feasibility Conceptual FEED Detailed DesignRamamurthy Narshya92% (53)

- JHA For Blasting Painting Works FinalDocument7 pagesJHA For Blasting Painting Works Finalrosevelvet50% (10)

- Plasma Cutter Work Method Statement (SWMS) V8Document4 pagesPlasma Cutter Work Method Statement (SWMS) V8afonsobuenoNo ratings yet

- JHA - General Electrical WorkDocument7 pagesJHA - General Electrical WorkEL Mer96% (49)

- Jsa - Gas MonitoringDocument2 pagesJsa - Gas MonitoringaneshseNo ratings yet

- Job Safety AnalysisDocument1 pageJob Safety AnalysisChowKC03100% (5)

- SP0757A1-2 Permit To Work AloftDocument1 pageSP0757A1-2 Permit To Work AloftPolaris Bridgeman50% (2)

- Risk Assessment For Cable LayingDocument5 pagesRisk Assessment For Cable Layingpopamino50% (2)

- Chilled Water Pipe Installation - ACMVDocument4 pagesChilled Water Pipe Installation - ACMVbinhjuki100% (2)

- RA 002 - Engine Casing Exhaust Funnel - Hot WorkDocument6 pagesRA 002 - Engine Casing Exhaust Funnel - Hot Workdassi99No ratings yet

- JHA Civil WorksDocument2 pagesJHA Civil Worksethelchudi100% (11)

- Risk Assessment - Drain Pipe Connection at MLSDocument8 pagesRisk Assessment - Drain Pipe Connection at MLS逍逾No ratings yet

- Jha Hot Tapping WorkDocument6 pagesJha Hot Tapping Workrosevelvet100% (1)

- JSA-Steel Structure Erection-NDocument4 pagesJSA-Steel Structure Erection-NVivek Naik100% (2)

- Mie Hse Jha 002 - Welding, Cutting, Fabrication WorkDocument4 pagesMie Hse Jha 002 - Welding, Cutting, Fabrication WorkLuqman Osman100% (1)

- Grounding System Jsa 2008Document4 pagesGrounding System Jsa 2008Aldrin100% (5)

- HIRA No. 22-Installation & Use of Temp Electrical Supplies SBDDocument2 pagesHIRA No. 22-Installation & Use of Temp Electrical Supplies SBDVenkadesh Periathambi75% (4)

- Safe Work Method Statement - Part 1: Company DetailsDocument14 pagesSafe Work Method Statement - Part 1: Company DetailsNithun DeenadayalanNo ratings yet

- Risk RegisterDocument41 pagesRisk RegisterCaroline D'Souza100% (1)

- Assignment 1 Front Sheet: Qualification BTEC Level 5 HND Diploma in ComputingDocument33 pagesAssignment 1 Front Sheet: Qualification BTEC Level 5 HND Diploma in Computing(FG ĐN) Hoàng Minh HoànNo ratings yet

- Job Hazard Analysis (Jha) Worksheet: Installation/Facility Job Activity Location Description of Activity NoteDocument3 pagesJob Hazard Analysis (Jha) Worksheet: Installation/Facility Job Activity Location Description of Activity NoteganeshkanthNo ratings yet

- JSA Pipe HDPE & Install Pump Sentrifugal From River To Main RoadDocument13 pagesJSA Pipe HDPE & Install Pump Sentrifugal From River To Main RoadBrings MotoVlogNo ratings yet

- JSA-Removing Anchor Chain No 4.Document2 pagesJSA-Removing Anchor Chain No 4.Ihwan AsrulNo ratings yet

- Job Safety Analysis: Job Title: Installing Pneumatic Rubber FenderDocument3 pagesJob Safety Analysis: Job Title: Installing Pneumatic Rubber FenderIhwan AsrulNo ratings yet

- Air Compressor JHADocument4 pagesAir Compressor JHAMpire WansNo ratings yet

- Abrasive Blasting Works at WTF - 3 Construction Site 2018Document3 pagesAbrasive Blasting Works at WTF - 3 Construction Site 2018AldrinNo ratings yet

- RA Templates PipingDocument28 pagesRA Templates Pipingkla_alkNo ratings yet

- Contoh Manajemen ResikoDocument12 pagesContoh Manajemen Resikohibonardo100% (2)

- Crane Mobile SpecificationDocument13 pagesCrane Mobile Specificationsancakemre100% (2)

- Risk Assessment FormDocument9 pagesRisk Assessment FormAbu ZahidNo ratings yet

- JSA CT Drill CementDocument2 pagesJSA CT Drill Cementaneshse100% (1)

- Risk AssessmentDocument10 pagesRisk Assessmentalamdar321100% (2)

- Risk Assessment - Construction of Manholes at Landscape Node P1Document4 pagesRisk Assessment - Construction of Manholes at Landscape Node P1逍逾No ratings yet

- Job Hazard Analysis (Jha) Worksheet: Installation/Facility Job Activity Location Description of Activity NoteDocument2 pagesJob Hazard Analysis (Jha) Worksheet: Installation/Facility Job Activity Location Description of Activity Noteganeshkanth100% (1)

- RA 002 - LPSG Steam Pipe Hot Work in ERDocument6 pagesRA 002 - LPSG Steam Pipe Hot Work in ERdassi99No ratings yet

- 3.jsa - Arc Welding-NDocument5 pages3.jsa - Arc Welding-NVivek NaikNo ratings yet

- Jsa Installation of HV ApparatusDocument6 pagesJsa Installation of HV ApparatusLuqman OsmanNo ratings yet

- Risk AssessmentDocument3 pagesRisk AssessmentmiaicarbaNo ratings yet

- Job Safety Analysis For Internal Corrosion MonitoringDocument2 pagesJob Safety Analysis For Internal Corrosion MonitoringD_D121667% (3)

- Risk Assessment Non Routine - General JobDocument42 pagesRisk Assessment Non Routine - General JobGanesh Murugesan0% (1)

- L2RA-Personnel TransferDocument10 pagesL2RA-Personnel TransferSam Delo-deloNo ratings yet

- Specific Risk Assessment For Civil Work - Kijitonyama Shule SiteDocument5 pagesSpecific Risk Assessment For Civil Work - Kijitonyama Shule SiteemnelNo ratings yet

- Ra02 - Container OffloadingDocument3 pagesRa02 - Container OffloadingSamNo ratings yet

- TB StringingDocument1 pageTB StringingShafie ZubierNo ratings yet

- 6.2 - Hsse Risk ManagementDocument27 pages6.2 - Hsse Risk ManagementNwekeNwokomaAugustineNo ratings yet

- CVVVVDocument7 pagesCVVVVRajaNo ratings yet

- Jsa CMT BLCDocument2 pagesJsa CMT BLCaneshseNo ratings yet

- Mie-Hse-Jha-007 - Cable Pulling, Laying, Dressing Work, TerminationDocument6 pagesMie-Hse-Jha-007 - Cable Pulling, Laying, Dressing Work, TerminationLuqman Osman100% (3)

- Hazard Control GuideDocument6 pagesHazard Control GuideImran KhanNo ratings yet

- Kimanis Power Project: Job Safety AnalysisDocument6 pagesKimanis Power Project: Job Safety AnalysisLuqman OsmanNo ratings yet

- Safety Method StatementDocument14 pagesSafety Method StatementnayakyaNo ratings yet

- Job Safety Analysis (Rolling For MS Plates)Document1 pageJob Safety Analysis (Rolling For MS Plates)Muhammad Ali100% (2)

- Risk Assessment FormDocument5 pagesRisk Assessment FormRaghu KumarNo ratings yet

- COSH Training-Day 1Document4 pagesCOSH Training-Day 1Mikka Eve FabroquezNo ratings yet

- Conocophillips Indonesia - Ramba: Job Description: Area/Unit: Tag No/Equipment Description: ReferencesDocument3 pagesConocophillips Indonesia - Ramba: Job Description: Area/Unit: Tag No/Equipment Description: Referencesaneshse100% (9)

- Hse-Swms-013-A - Streetlighting Maintenance and Installation DM LightingDocument12 pagesHse-Swms-013-A - Streetlighting Maintenance and Installation DM Lightingapi-326016071100% (1)

- Risk Assessment - Erection of Temporary Shoring System at Valve Chamber No. 1 & No. 2rev1.1Document14 pagesRisk Assessment - Erection of Temporary Shoring System at Valve Chamber No. 1 & No. 2rev1.1Pang Lee Ching100% (1)

- Offshore Risk Assessment vol 1.: Principles, Modelling and Applications of QRA StudiesFrom EverandOffshore Risk Assessment vol 1.: Principles, Modelling and Applications of QRA StudiesNo ratings yet

- Occupational Radiation Protection in the Uranium Mining and Processing IndustryFrom EverandOccupational Radiation Protection in the Uranium Mining and Processing IndustryNo ratings yet

- Workplace Vocabulary for Esl Students: With Exercises and TestsFrom EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsNo ratings yet

- Reporting Format: Format of Ship ReportDocument4 pagesReporting Format: Format of Ship ReportIhwan AsrulNo ratings yet

- Forecast 1Document1 pageForecast 1Ihwan AsrulNo ratings yet

- Gangway Air Hose BurstDocument3 pagesGangway Air Hose BurstIhwan AsrulNo ratings yet

- Singapore VHF ReportingDocument1 pageSingapore VHF ReportingIhwan AsrulNo ratings yet

- Daftar Pengiriman DokumenDocument1 pageDaftar Pengiriman DokumenIhwan AsrulNo ratings yet

- Iv. Daily Forecast (06 May - 12 May 2017) For Oyong Terminal Madura ( (07 17' 20.00" S / 113 21' 22" E)Document2 pagesIv. Daily Forecast (06 May - 12 May 2017) For Oyong Terminal Madura ( (07 17' 20.00" S / 113 21' 22" E)Ihwan AsrulNo ratings yet

- Daftar Pengiriman Dokumen - October 14Document2 pagesDaftar Pengiriman Dokumen - October 14Ihwan AsrulNo ratings yet

- Pt. Cakra Bahana Fso. Surya Putra Jaya: A. Deck DepartementDocument3 pagesPt. Cakra Bahana Fso. Surya Putra Jaya: A. Deck DepartementIhwan AsrulNo ratings yet

- Daftar Pengiriman Dokumen - January 2017Document2 pagesDaftar Pengiriman Dokumen - January 2017Ihwan AsrulNo ratings yet

- Incident Investigation Report: Team Leader: Master Team Member: C/E, C/O, 2/E, 2/O, 3/O, A 3/O Detail EventsDocument1 pageIncident Investigation Report: Team Leader: Master Team Member: C/E, C/O, 2/E, 2/O, 3/O, A 3/O Detail EventsIhwan AsrulNo ratings yet

- Job Risk Assesment OfftakeDocument7 pagesJob Risk Assesment OfftakeIhwan Asrul100% (1)

- Submitted To QSE: Edition 2009 Revision 1 Date: 15 Jul 2009Document2 pagesSubmitted To QSE: Edition 2009 Revision 1 Date: 15 Jul 2009Ihwan AsrulNo ratings yet

- ECDIS Mandatory ECDIS Marine Equipment For Merchant Marine FURUNODocument11 pagesECDIS Mandatory ECDIS Marine Equipment For Merchant Marine FURUNOIhwan AsrulNo ratings yet

- 9812 090 Isd 0705 2 BDocument1 page9812 090 Isd 0705 2 BIhwan AsrulNo ratings yet

- 9812 090 Isd 0705 3 BDocument1 page9812 090 Isd 0705 3 BIhwan AsrulNo ratings yet

- Aco Akbar Masud Mcu 3Document1 pageAco Akbar Masud Mcu 3Ihwan AsrulNo ratings yet

- 9812 090 Isd 0705 1 BDocument1 page9812 090 Isd 0705 1 BIhwan AsrulNo ratings yet

- Pts - New Passenger Data Entry Form: Lifting - Balikpapan@bpmigas - Go.idDocument1 pagePts - New Passenger Data Entry Form: Lifting - Balikpapan@bpmigas - Go.idIhwan AsrulNo ratings yet

- Bon TangDocument8 pagesBon TangIhwan AsrulNo ratings yet

- Review Questions QuestionsDocument5 pagesReview Questions QuestionsJustine JaymaNo ratings yet

- Financial Management - MGT201: 7 Week of LecturesDocument10 pagesFinancial Management - MGT201: 7 Week of LecturesSyed Abdul Mussaver ShahNo ratings yet

- Out 3Document6 pagesOut 3Ilvita MayasariNo ratings yet

- Monthly Bulletin ECB - Okt 2011Document234 pagesMonthly Bulletin ECB - Okt 2011remcoxyiiNo ratings yet

- New Wordpad DocumentDocument4 pagesNew Wordpad DocumentAbdul Haseeb AmjadNo ratings yet

- STHDocument4 pagesSTHIvan MedićNo ratings yet

- Financial Technologies and DeFi A Revisit To The Digital Finance RevolutionDocument3 pagesFinancial Technologies and DeFi A Revisit To The Digital Finance RevolutionAista Putra WisenewNo ratings yet

- Lange J. Value-Oriented Leadership in Theory and Practice... 2023Document181 pagesLange J. Value-Oriented Leadership in Theory and Practice... 2023Nikolai LazarovNo ratings yet

- Climate Change and Its Interaction With Natural, Economic and Social ProcessesDocument8 pagesClimate Change and Its Interaction With Natural, Economic and Social ProcessesGammaz1973No ratings yet

- Classification: Strategic Capital InvestmentDocument14 pagesClassification: Strategic Capital InvestmentOliver LeeNo ratings yet

- Gbemich Services: Health, Safety and Environmental Management Systems Plan For Construction of SNEPCO FACILITYDocument20 pagesGbemich Services: Health, Safety and Environmental Management Systems Plan For Construction of SNEPCO FACILITYJames Adekunle OgunsolaNo ratings yet

- Topics - Caries - Under6 Yo PDFDocument2 pagesTopics - Caries - Under6 Yo PDFRizal ArdiNo ratings yet

- Effect of Flooding On Property Value A Case Study of Isheri North, Isheri, Lagos StateDocument7 pagesEffect of Flooding On Property Value A Case Study of Isheri North, Isheri, Lagos Statefagbemi KayodeNo ratings yet

- Generic Project Success and Project Management Success Criteria and Factors: Literature Review and SurveyDocument13 pagesGeneric Project Success and Project Management Success Criteria and Factors: Literature Review and Surveyjaveria khanNo ratings yet

- AL-LIN-50002 - 2009-Oct-27 - Rev3Document25 pagesAL-LIN-50002 - 2009-Oct-27 - Rev3Prashant TrivediNo ratings yet

- IATG 02 10 Introduction To Risk Management Principles v.2Document44 pagesIATG 02 10 Introduction To Risk Management Principles v.2DOC LABNo ratings yet

- Human Factors: Canadian Coast Guard Auxiliary - Pacific Canadian Coast Guard Auxiliary - PacificDocument117 pagesHuman Factors: Canadian Coast Guard Auxiliary - Pacific Canadian Coast Guard Auxiliary - PacificMaureen Janelle RemaneaNo ratings yet

- SPE 69594 Significance of Project Risking Methods On Portfolio Optimization ModelsDocument6 pagesSPE 69594 Significance of Project Risking Methods On Portfolio Optimization ModelsLINETTE ALBORNOZNo ratings yet

- Bakht 30 BBA 5tha Final Paper ImstudiesDocument5 pagesBakht 30 BBA 5tha Final Paper ImstudiesMuqaddar KhanNo ratings yet

- 21 Secrets I Wish I Knew at The Start of My Investing CareerDocument5 pages21 Secrets I Wish I Knew at The Start of My Investing Careerjohnsmith1806No ratings yet

- Financial Planning Education FrameworkDocument46 pagesFinancial Planning Education FrameworkdizhangNo ratings yet

- TP109 Dam Safety Guidelines Part 3 (1auckland City Council)Document22 pagesTP109 Dam Safety Guidelines Part 3 (1auckland City Council)drjaved12000No ratings yet

- Andhra Pradesh Municipal Audit ManualDocument146 pagesAndhra Pradesh Municipal Audit ManualChristie JonesNo ratings yet

- Chapter 4 Software Poroject PlanningDocument52 pagesChapter 4 Software Poroject Planningਅਮਰ ਪਾਲ ਸਿੰਘNo ratings yet

- 2021 Yds-1Document24 pages2021 Yds-1musa dafNo ratings yet

- AMIDA Walven SilalahiDocument7 pagesAMIDA Walven Silalahihz135874No ratings yet

- Akzo Nobel Risk ManagementDocument53 pagesAkzo Nobel Risk ManagementdhanuNo ratings yet

JSA-Emerg Act-Oct 18, 07

JSA-Emerg Act-Oct 18, 07

Uploaded by

Ihwan AsrulOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA-Emerg Act-Oct 18, 07

JSA-Emerg Act-Oct 18, 07

Uploaded by

Ihwan AsrulCopyright:

Available Formats

JOB SAFETY ANALYSIS

Project

Job Title

Leader

Contractor

No.

:

:

:

:

Sepanjang Early Oil Production

Pipe Sleeper & Pipe Support Installation

Sukardi ( Const Supt )

PT. Dwi Prima Sembada

WORK STEPS

-Detail working procedures

EQUIPMENT

TOOLS

MACHINES

3.1 SURVEY WORKS

- Leveling & Marking

3.2 EXCAVATION &

COMPACTION

3.3 INSTALL PRECAST

Theodolite

Incured by sharp object

Mattock

FACTOR

P

HE RF

- Personnel Injury

VL

Specific measures & prevention for each hazard

Assign someone responsible for each action

RESIDUAL

RISK

FACTORS

HE RF

L1 - Use the right tools & good

VL

L1

L2

L2

L2

M5

-Have to wear PPE standard

- Hit by Mattock

- Personnel Injury

L2 - Conduct pre use inspection / checklist

- Conduct supervision

Hit by Falling Object

- Personnel Injury

Crane & Rigging Failure

Crane &

SAFETY MEASURES & PREVENTION

- Conduct Tool Box Meeting

before Executing work

- Follow all Procedures involved

- Prepare First Aid Kit

Hand Compactor

Crane & Forklif

: April, 2006

: Sepanjang Island

RISK

Handtools

CONCRETE

3.4 INSTALL PIPE SUPPORT

- Personnel action

- Tool / Material/Object

Hazards

Effect

- Working Environment

Install

Pipe Sleeper

and

Pipe Support

HAZARDS

Date

Location

Incured by sharp object

M8 - Use the right tools & good

- Have to wear Hand gloves

- Personnel Injury

Welding Machine

M8 - Use the right tools & good

- Have to wear Hand gloves, safety shoes,

safety glass, Helmet

3.5 WELDING

Welding Machine

Fire or Explosion

- Injury/ Fatality

Electric Shock

M8 - Apply Hot Work Permit Prior Doing Hot Work

- Use the right tools & good

-Have to wear PPE standard

NOTE

P

HE

: Probability

: Hazard Effect

Page 1 of 13

RF

: Risk Factor

Page 2 of 13

JOB SAFETY ANALYSIS

Project

Job Title

Leader

: Sepanjang Early Oil Production

: Piping Installation

: Sukardi ( Const Supt )

Contractor

: PT. Dwi Prima Sembada

No.

WORK STEPS

-Detail working procedures

HOT WORKS

FABRICATE AND

4 INSTALL FOR

PIPING

4.1 WELDING

EQUIPMENT

TOOLS

MACHINES

Welding Machine

Date

Location

RISK

HAZARDS

Hazards

Effect

- Personnel action

- Tool / Material/Object

- Working Environment

- Fire /electricity

: April, 2006

: Sepanjang Island

FACTOR

P

HE RF

SAFETY MEASURES & PREVENTION

Specific measures & prevention for each hazard

Assign someone responsible for each action

RESIDUAL

RISK

FACTORS

HE

RF

M5

- Conduct Tool Box Meeting

before Executing work

- Follow all Procedures involved

- Prepare First Aid Kit

- ES-Injury/fatality H

H15 - Conduct Checklist for Welding Machine

- Grounding

- No Flammable liquid near of welding work

- Prepare Portable Fire Extinguisher/blanket

- Conduct close Supervision

- Complete PPE for Welding work

- Assure ace & oxy bottles save & good

- Smoke Radiation

- Insensible,

M M8 - Use masker / respirator

L2

M M8 - Use Welding Mask/ safety goggles

M M8 - Use ear plug/ earmuf

L2

L2

asphyxia

-

4.2 GRINDING

Grinding Machine

- Ultra Violet

- eye

- Noise

- Hearing annoyed M

- Extreme heat contac- Injury

M M8 - Use proper PPE

- New jointed & still hot marked

L2

- Electricity

M5

El.Shock - Fatality

H15 - Conduct Checklist for Grinding Machine

- No Flammable liquid near of welding work

Page 3 of 13

JOB SAFETY ANALYSIS

Project

Job Title

Leader

: Sepanjang Early Oil Production

: Piping Installation

: Sukardi ( Const Supt )

Contractor

: PT. Dwi Prima Sembada

No.

WORK STEPS

EQUIPMENT

TOOLS

MACHINES

-Detail working procedures

HAZARDS

- Personnel action

- Tool / Material/Object

- Working Environment

Date

Location

: April, 2006

: Sepanjang Island

RISK

Hazards

Effect

FACTOR

P

HE RF

SAFETY MEASURES & PREVENTION

Specific measures & prevention for each hazard

Assign someone responsible for each action

RESIDUAL

RISK

FACTORS

HE

RF

- Prepare Portable Fire Extinguisher/blanket

- Conduct close Supervision

- Incur.by a reef fract - Personnel Injury M

M M8 - Use Safety glass/ Face shield

L2

- Grinding Disc esca - Personnel Injury M

M M8 - Assure Safety Guard properly placed

L2

M5

- Disc recommended for Grinding Mach.

4.3 CUTTING

Cutting Torch

Fire / Explosive

Burnt / fatality

H15 - Conduct Checklist for Cutting Torch

- Cutting must have Flash Back Arrestor

- Assure ace & oxy bottles save & good

- No Flammable liquid near of welding work

- Prepare Portable Fire Extinguisher/blanket

- Conduct close Supervision

NOTE

P

HE

RF

: Probability

: Hazard Effect

: Risk Factor

Page 4 of 13

JOB SAFETY ANALYSIS

Project

Job Title

Leader

Contractor

No.

:

:

:

:

Sepanjang Early Oil Production

Mobilization

Sukardi ( Const Supt )

PT. Dwi Prima Sembada

WORK STEPS

EQUIPMENT

TOOLS

-Detail working procedures

MACHINES

HAZARDS

- Personnel action

Date

Location

RISK

Hazards

Effect

- Tool / Material/Object

HE RF

MOBILIZATION MATERIAL PIPE,

SAFETY MEASURES & PREVENTION

RISK

FACTORS

Specific measures & prevention for each hazard

Assign someone responsible for each action

HE RF

- Conduct Tool Box Meeting

VALVE, FITTING, STRUCTURE

before Executing work

& EQPT FROM PORT SURABAYA

- Follow all Procedures involved

TO SEPANJANG ISLAND

- Prepare First Aid Kit

Crane 45 Ton

Broken sling, fall object

FITTING, STRUCTURE & EQUIPMENT

Lifting gear

tying escaped.

TO LCT

LCT

1.1 LOADING MATERIAL PIPES, VALVE,

RESIDUAL

FACTOR

P

- Working Environment

: April, 2006

: Sepanjang Island

- Equipm.damage

M6 - All Operators must be experiences, certified

L2

L2

- Pre use Inspection Checklist must be done

before operating

- Assure all lifting gear on good condition

- Personal Injury

M6 - Don't stay under lifted object

- Have to wear Helmet

- Don't lift to exceed objects

Over draft

- Fatalilty

H15 - Available supervision

M5

- ship sink

M8 - Final loaded ( total cargo ) according to

L2

L2

document ship and signed by Harbour master

1.2 TRANSPORTATION FROM SBY

TO SEPANJANG BY LCT

LCT

Moderate sea , leaking,

LCT sink

Equip/Matl lost

M8 - Pre use inspection to LCT / SHIP

- Ship Particular must be appr.d by Syahbandar

- Port Clearance must be valid & on ship

- Captaint must be experience & certified/ skill

- Course condition control navigation

- If bad weather, ship not continue sea transport

Page 5 of 13

JOB SAFETY ANALYSIS

Project

Job Title

Leader

Contractor

No.

:

:

:

:

Sepanjang Early Oil Production

Mobilization

Sukardi ( Const Supt )

PT. Dwi Prima Sembada

WORK STEPS

EQUIPMENT

TOOLS

-Detail working procedures

MACHINES

HAZARDS

- Personnel action

Date

Location

: April, 2006

: Sepanjang Island

RISK

Hazards

FACTOR

Effect

- Tool / Material/Object

- Working Environment

RESIDUAL

HE RF

SAFETY MEASURES & PREVENTION

RISK

FACTORS

Specific measures & prevention for each hazard

Assign someone responsible for each action

HE RF

immed. look for peaceful protection closest.

- Fatality

H13 - Prepare crew list and must be acknowledged

M5

L2

L2

L2

L2

M5

by Harbour master

- Wear life jacket + ringbouy

- Prepare life craft/ resque boat

- Lasing cargo escaped

- stability change.

M8 - Assure all wires , span screw, staple remover

on good condition

- Lasing have to approved by Surveyor

- Smash-up usher ship.

- ship broken/sink

H10 - Navigation light must be on at the night

- Asuure Navigation Electro is good

- Navigator must be competence

- P2TL ( Solas 1972 ) must be followed by Nav.

1.3 DISCHARGING PIPES, VALVE,

FITTING STRUCTURE, EQUIPT

FROM LCT

Crane 25 Ton

Broken sling, fall object

Lifting gear

tying escaped.

- Equipm.damage

M6 - All Operators must be experiences, certified

- Conduct Pre use Inspection Checklist

LCT

- Assure all lifting gear on good condition

- Personal Injury

M6 - Don't stay under lifted object

- Have to wear Helmet

- Don't lift to exceed objects

- Fatalilty

Page 6 of 13

H15 - Available supervision

JOB SAFETY ANALYSIS

Project

Job Title

Leader

Contractor

No.

:

:

:

:

Sepanjang Early Oil Production

Mobilization

Sukardi ( Const Supt )

PT. Dwi Prima Sembada

WORK STEPS

-Detail working procedures

HAZARDS

EQUIPMENT

TOOLS

MACHINES

- Personnel action

Date

Location

RISK

Hazards

Effect

- Tool / Material/Object

Plate Bed Trailer - Bump to other equip

RESIDUAL

SAFETY MEASURES & PREVENTION

FACTOR

P

- Working Environment

1.4 TRANSPORT.PIPES, VALVE,

: April, 2006

: Sepanjang Island

HE RF

RISK

FACTORS

Specific measures & prevention for each hazard

Assign someone responsible for each action

HE RF

- Equip. Damage

M8 - All Operators must be experiences, certified

L2

- Injury/ Fatality

H15 - Max. speed 50km/ hr only

M5

L2

FITTING, STRUCTURE, EQUIPT

TO SITE LOCATION

- Bump to people

- Max speed 20km/hr passing solid area

resident / traffic busy

- Pipes & Fitting falling

- Traffic annoyed

M6 - assure good tying / not difuse.

down

NOTE

P

HE

RF

: Probability

: Hazard Effect

: Risk Factor

Prepared by :

Acknowledged by :

JONNI SIREGAR

Y. SUPRATIKNO

PT. DWI PRIMA SEMBADA

Approved by :

PT. DWI PRIMA SEMBADA

)

EMP - KANGEAN LTD.

Page 7 of 13

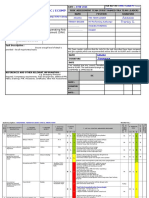

JOB SAFETY ANALYSIS

Project

Job Title

Leader

Contractor

:

:

:

:

Sepanjang Early Oil Production

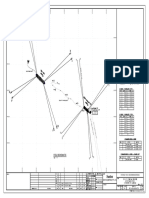

Emergency Action MT. Concord (FSO) Re Position.

Bambang PH ( Project Manager )

PT. Arah Prana

No.

WORK STEPS

EQUIPMENT

-Detail working procedures

TOOLS

MACHINES

Date

Location

HAZARDS

Hazards

Effect

- Personnel action

- Tool / Material/Object

18-Oct-07

Sepanjang Island

RISK

FACTOR

P HE RF

- Working Environment

:

:

SAFETY MEASURES & PREVENTION

Specific measures & prevention for each hazard

Assign someone responsible for each action

RESIDUAL

RISK

FACTORS

P HE RF

2 Construction Works

- Conduct Tool Box Meeting

before Executing work

- Follow all Procedures involved

- Prepare First Aid Kit

- Prepare Safety Reports

- Install Marker Buoy &

- DepthReading

- Tensioning of chain

2.1 Visual Inspection of all

Zodiac

Man over board

Mooring chain position.

Serious Injure or

H10

Fatality.

- Wear life jacket + ringbouy

M4

- Prepare life craft/resque boat/Zodiac

- Wearing PPE

2.2 Marker Buoy & Depth Reading

Zodiac

H10

Man Over Board

Damage,

Boat Leak

Serious Injure or

- Prepare life craft/resque boat/Zodiac

Danger from

Fatality

- Communication

Marine Life

2.3 - Tentioning Chain no.8

- Wear life jacket + ringbouy

- Wearing PPE & Life line.

H15

AHTS Garuda

Man Over Board

Damage,

Zodiac

Boat leak

Serious Injure or

- Prepare life craft/resque boat/Zodiac

Rigging Tools

Danger from

Fatality

- Communication

Marine Life

House Keeping

- Wearing PPE

Hit by/Struck by

Slip

- Wear life jacket + ringbouy

-House Keeping

Winch wire broken

- Riggers Skill & Close Supervising

Slipery

- Proper Tool & Equipment.

Weather

M4

Wind speed = max 15

Wave = 1.5 meters

Page 8 of 13

- Weather forecast

- Quick release on Garuda should be ready.

H11

JOB SAFETY ANALYSIS

Project

Job Title

Leader

Contractor

:

:

:

:

Sepanjang Early Oil Production

Emergency Action MT. Concord (FSO) Re Position.

Bambang PH ( Project Manager )

PT. Arah Prana

No.

WORK STEPS

EQUIPMENT

-Detail working procedures

TOOLS

MACHINES

2.4 - Securing the anchor chain

P

HE

RF

HAZARDS

Hazards

Effect

- Personnel action

- Tool / Material/Object

Rigging Tools

Struck by/Hit by

Bruised, Injury

Winch wire, slipery

Slip

:

:

18-Oct-07

Sepanjang Island

RISK

FACTOR

P HE RF

- Working Environment

after tensioning

NOTE

Date

Location

L2

SAFETY MEASURES & PREVENTION

Specific measures & prevention for each hazard

Assign someone responsible for each action

RESIDUAL

RISK

FACTORS

P HE RF

L1

- Wearing PPE

-House Keeping

Sugestion: - After Tensioning suceed, we have to follow up with Survey position of Anchors and Sinkers

to make sure that all of the Anchors and Sinkers not dragging and need BKI Inspector to

: Probability

ferform tension test.

: Hazard Effect

- Temporary Smit Breaker wire stopper need to be replace with the proper chain stopper ASAP.

: Risk Factor

- Additional anchor wire need to change with proper chain ASAP.

- Need extending chain No. 4 & no. 5 then tension no. 8 & no. 1. (Need torelease cantler shackle)

Prepared by :

BAMBANG PURNOMO HARRI

PT. ARAH PRANA

Acknowledged by :

MAX POLLA

PT. ARAH PRANA

Page 9 of 13

Approved by :

ROBERT PORSIANA

KANGEAN ENERGY INDONESIA

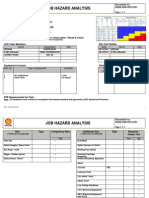

Risk Factor Matrix

HIGH

MEDIUM

LOW

> 1 in 10 highly likely

1 in 10 - 1 in 1000 sometime

< 1 in 1000 extremely unlikely

H15

H14

H11

H13

H12

H10

Permanent disability / DAWC

Moderate Damage

$ 100,000 - $ 500,000

Environmental Reportable

15 - 100 bbls

H9

M8

M4

Single or multiple minor injuries

Minor Facility Damage $ 100,000

Environment Minor Loss 1 - 15 bbls

M7

M6

L2

Single First Aid

Minor Facility Damage < $ 10,000

Environment Slight Loss < 1 bbls

M5

L3

L1

Probability

Hazard Effect

Very High (VH)

- Multiple Fatality

- Major Facility Damage > $ 5,000,000

- Environment Major Spill

1,000 - 10,000 bbls

High (H)

-

Single Fatality

Significant Facility Damage

$ 5,000,000 - $ 5,000,000

Environment Significant

Spill > 100 bbls

Medium (M)

-

Low (L)

Very Low (VL)

-

HAZARD CHECK LIST

Energy Source

Electricity

Gas or Oil

Radiation

Falling objects

Temperature extremes

Noise

Steam

Compressed Air

Explosive

Fire

Wave / Storm

Wind

Sea Current

Product Escape

Leak

Spill

Overflow

Wrong mix

Mechanical

Crushing

Shearing

Cutting

Caught in machinery

Impact

Stabbing

Friction

Vibration

Flying object

Moving object

Unpredicted ship movement

Material / Chemical

Exposure

Inhalation

Absorption

Swallow

Eye contact

Skin contact

The Work Site

Trip hazards

Fall from height

Confined space

Lighting & Rain

Other people, above, below,

adjacent behind

Blind corners

Waste material generated

Escape routes blocked

Wild Animal ( Shark, Snake etc )

Manual Handling

Pushing

Pulling

Lifting

Repetitive movements

Over exertion

Communication

Communication

Evaluation and Prioritization of Risk

Risk

Factor

15

14

13

12

11

10

Control Action

Immediate action, task must not proceed, serious loss potential. The task

should be re-defined or, further control measures put in place to reduce risk,

these controls again must be subject to a full assessment and accepted before

the task may commence.

Task may only proceed following direct authorization from OIM/Site Manager

following consultation with any specialist personnel and full assessment team.

Wherever possible the task should be re-defined to take account of the hazards

involved or the risk s

9

8

7

The task may proceed, however only under strict supervision and monitoring.

The team must revisit all areas of the assessment to see if risks may be reduced

further before the task is allowed to proceed.

6

5

4

3

Acceptable measures, however review to see if risk can be reduced still

further

2

1

Acceptable levels of risk no need to consider further measures.

You might also like

- JSA Erection of Steel StructureDocument9 pagesJSA Erection of Steel StructureLuqman Osman77% (13)

- Standard Deliverable List For Feasibility Conceptual FEED Detailed DesignDocument22 pagesStandard Deliverable List For Feasibility Conceptual FEED Detailed DesignRamamurthy Narshya92% (53)

- JHA For Blasting Painting Works FinalDocument7 pagesJHA For Blasting Painting Works Finalrosevelvet50% (10)

- Plasma Cutter Work Method Statement (SWMS) V8Document4 pagesPlasma Cutter Work Method Statement (SWMS) V8afonsobuenoNo ratings yet

- JHA - General Electrical WorkDocument7 pagesJHA - General Electrical WorkEL Mer96% (49)

- Jsa - Gas MonitoringDocument2 pagesJsa - Gas MonitoringaneshseNo ratings yet

- Job Safety AnalysisDocument1 pageJob Safety AnalysisChowKC03100% (5)

- SP0757A1-2 Permit To Work AloftDocument1 pageSP0757A1-2 Permit To Work AloftPolaris Bridgeman50% (2)

- Risk Assessment For Cable LayingDocument5 pagesRisk Assessment For Cable Layingpopamino50% (2)

- Chilled Water Pipe Installation - ACMVDocument4 pagesChilled Water Pipe Installation - ACMVbinhjuki100% (2)

- RA 002 - Engine Casing Exhaust Funnel - Hot WorkDocument6 pagesRA 002 - Engine Casing Exhaust Funnel - Hot Workdassi99No ratings yet

- JHA Civil WorksDocument2 pagesJHA Civil Worksethelchudi100% (11)

- Risk Assessment - Drain Pipe Connection at MLSDocument8 pagesRisk Assessment - Drain Pipe Connection at MLS逍逾No ratings yet

- Jha Hot Tapping WorkDocument6 pagesJha Hot Tapping Workrosevelvet100% (1)

- JSA-Steel Structure Erection-NDocument4 pagesJSA-Steel Structure Erection-NVivek Naik100% (2)

- Mie Hse Jha 002 - Welding, Cutting, Fabrication WorkDocument4 pagesMie Hse Jha 002 - Welding, Cutting, Fabrication WorkLuqman Osman100% (1)

- Grounding System Jsa 2008Document4 pagesGrounding System Jsa 2008Aldrin100% (5)

- HIRA No. 22-Installation & Use of Temp Electrical Supplies SBDDocument2 pagesHIRA No. 22-Installation & Use of Temp Electrical Supplies SBDVenkadesh Periathambi75% (4)

- Safe Work Method Statement - Part 1: Company DetailsDocument14 pagesSafe Work Method Statement - Part 1: Company DetailsNithun DeenadayalanNo ratings yet

- Risk RegisterDocument41 pagesRisk RegisterCaroline D'Souza100% (1)

- Assignment 1 Front Sheet: Qualification BTEC Level 5 HND Diploma in ComputingDocument33 pagesAssignment 1 Front Sheet: Qualification BTEC Level 5 HND Diploma in Computing(FG ĐN) Hoàng Minh HoànNo ratings yet

- Job Hazard Analysis (Jha) Worksheet: Installation/Facility Job Activity Location Description of Activity NoteDocument3 pagesJob Hazard Analysis (Jha) Worksheet: Installation/Facility Job Activity Location Description of Activity NoteganeshkanthNo ratings yet

- JSA Pipe HDPE & Install Pump Sentrifugal From River To Main RoadDocument13 pagesJSA Pipe HDPE & Install Pump Sentrifugal From River To Main RoadBrings MotoVlogNo ratings yet

- JSA-Removing Anchor Chain No 4.Document2 pagesJSA-Removing Anchor Chain No 4.Ihwan AsrulNo ratings yet

- Job Safety Analysis: Job Title: Installing Pneumatic Rubber FenderDocument3 pagesJob Safety Analysis: Job Title: Installing Pneumatic Rubber FenderIhwan AsrulNo ratings yet

- Air Compressor JHADocument4 pagesAir Compressor JHAMpire WansNo ratings yet

- Abrasive Blasting Works at WTF - 3 Construction Site 2018Document3 pagesAbrasive Blasting Works at WTF - 3 Construction Site 2018AldrinNo ratings yet

- RA Templates PipingDocument28 pagesRA Templates Pipingkla_alkNo ratings yet

- Contoh Manajemen ResikoDocument12 pagesContoh Manajemen Resikohibonardo100% (2)

- Crane Mobile SpecificationDocument13 pagesCrane Mobile Specificationsancakemre100% (2)

- Risk Assessment FormDocument9 pagesRisk Assessment FormAbu ZahidNo ratings yet

- JSA CT Drill CementDocument2 pagesJSA CT Drill Cementaneshse100% (1)

- Risk AssessmentDocument10 pagesRisk Assessmentalamdar321100% (2)

- Risk Assessment - Construction of Manholes at Landscape Node P1Document4 pagesRisk Assessment - Construction of Manholes at Landscape Node P1逍逾No ratings yet

- Job Hazard Analysis (Jha) Worksheet: Installation/Facility Job Activity Location Description of Activity NoteDocument2 pagesJob Hazard Analysis (Jha) Worksheet: Installation/Facility Job Activity Location Description of Activity Noteganeshkanth100% (1)

- RA 002 - LPSG Steam Pipe Hot Work in ERDocument6 pagesRA 002 - LPSG Steam Pipe Hot Work in ERdassi99No ratings yet

- 3.jsa - Arc Welding-NDocument5 pages3.jsa - Arc Welding-NVivek NaikNo ratings yet

- Jsa Installation of HV ApparatusDocument6 pagesJsa Installation of HV ApparatusLuqman OsmanNo ratings yet

- Risk AssessmentDocument3 pagesRisk AssessmentmiaicarbaNo ratings yet

- Job Safety Analysis For Internal Corrosion MonitoringDocument2 pagesJob Safety Analysis For Internal Corrosion MonitoringD_D121667% (3)

- Risk Assessment Non Routine - General JobDocument42 pagesRisk Assessment Non Routine - General JobGanesh Murugesan0% (1)

- L2RA-Personnel TransferDocument10 pagesL2RA-Personnel TransferSam Delo-deloNo ratings yet

- Specific Risk Assessment For Civil Work - Kijitonyama Shule SiteDocument5 pagesSpecific Risk Assessment For Civil Work - Kijitonyama Shule SiteemnelNo ratings yet

- Ra02 - Container OffloadingDocument3 pagesRa02 - Container OffloadingSamNo ratings yet

- TB StringingDocument1 pageTB StringingShafie ZubierNo ratings yet

- 6.2 - Hsse Risk ManagementDocument27 pages6.2 - Hsse Risk ManagementNwekeNwokomaAugustineNo ratings yet

- CVVVVDocument7 pagesCVVVVRajaNo ratings yet

- Jsa CMT BLCDocument2 pagesJsa CMT BLCaneshseNo ratings yet

- Mie-Hse-Jha-007 - Cable Pulling, Laying, Dressing Work, TerminationDocument6 pagesMie-Hse-Jha-007 - Cable Pulling, Laying, Dressing Work, TerminationLuqman Osman100% (3)

- Hazard Control GuideDocument6 pagesHazard Control GuideImran KhanNo ratings yet

- Kimanis Power Project: Job Safety AnalysisDocument6 pagesKimanis Power Project: Job Safety AnalysisLuqman OsmanNo ratings yet

- Safety Method StatementDocument14 pagesSafety Method StatementnayakyaNo ratings yet

- Job Safety Analysis (Rolling For MS Plates)Document1 pageJob Safety Analysis (Rolling For MS Plates)Muhammad Ali100% (2)

- Risk Assessment FormDocument5 pagesRisk Assessment FormRaghu KumarNo ratings yet

- COSH Training-Day 1Document4 pagesCOSH Training-Day 1Mikka Eve FabroquezNo ratings yet

- Conocophillips Indonesia - Ramba: Job Description: Area/Unit: Tag No/Equipment Description: ReferencesDocument3 pagesConocophillips Indonesia - Ramba: Job Description: Area/Unit: Tag No/Equipment Description: Referencesaneshse100% (9)

- Hse-Swms-013-A - Streetlighting Maintenance and Installation DM LightingDocument12 pagesHse-Swms-013-A - Streetlighting Maintenance and Installation DM Lightingapi-326016071100% (1)

- Risk Assessment - Erection of Temporary Shoring System at Valve Chamber No. 1 & No. 2rev1.1Document14 pagesRisk Assessment - Erection of Temporary Shoring System at Valve Chamber No. 1 & No. 2rev1.1Pang Lee Ching100% (1)

- Offshore Risk Assessment vol 1.: Principles, Modelling and Applications of QRA StudiesFrom EverandOffshore Risk Assessment vol 1.: Principles, Modelling and Applications of QRA StudiesNo ratings yet

- Occupational Radiation Protection in the Uranium Mining and Processing IndustryFrom EverandOccupational Radiation Protection in the Uranium Mining and Processing IndustryNo ratings yet

- Workplace Vocabulary for Esl Students: With Exercises and TestsFrom EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsNo ratings yet

- Reporting Format: Format of Ship ReportDocument4 pagesReporting Format: Format of Ship ReportIhwan AsrulNo ratings yet

- Forecast 1Document1 pageForecast 1Ihwan AsrulNo ratings yet

- Gangway Air Hose BurstDocument3 pagesGangway Air Hose BurstIhwan AsrulNo ratings yet

- Singapore VHF ReportingDocument1 pageSingapore VHF ReportingIhwan AsrulNo ratings yet

- Daftar Pengiriman DokumenDocument1 pageDaftar Pengiriman DokumenIhwan AsrulNo ratings yet

- Iv. Daily Forecast (06 May - 12 May 2017) For Oyong Terminal Madura ( (07 17' 20.00" S / 113 21' 22" E)Document2 pagesIv. Daily Forecast (06 May - 12 May 2017) For Oyong Terminal Madura ( (07 17' 20.00" S / 113 21' 22" E)Ihwan AsrulNo ratings yet

- Daftar Pengiriman Dokumen - October 14Document2 pagesDaftar Pengiriman Dokumen - October 14Ihwan AsrulNo ratings yet

- Pt. Cakra Bahana Fso. Surya Putra Jaya: A. Deck DepartementDocument3 pagesPt. Cakra Bahana Fso. Surya Putra Jaya: A. Deck DepartementIhwan AsrulNo ratings yet

- Daftar Pengiriman Dokumen - January 2017Document2 pagesDaftar Pengiriman Dokumen - January 2017Ihwan AsrulNo ratings yet

- Incident Investigation Report: Team Leader: Master Team Member: C/E, C/O, 2/E, 2/O, 3/O, A 3/O Detail EventsDocument1 pageIncident Investigation Report: Team Leader: Master Team Member: C/E, C/O, 2/E, 2/O, 3/O, A 3/O Detail EventsIhwan AsrulNo ratings yet

- Job Risk Assesment OfftakeDocument7 pagesJob Risk Assesment OfftakeIhwan Asrul100% (1)

- Submitted To QSE: Edition 2009 Revision 1 Date: 15 Jul 2009Document2 pagesSubmitted To QSE: Edition 2009 Revision 1 Date: 15 Jul 2009Ihwan AsrulNo ratings yet

- ECDIS Mandatory ECDIS Marine Equipment For Merchant Marine FURUNODocument11 pagesECDIS Mandatory ECDIS Marine Equipment For Merchant Marine FURUNOIhwan AsrulNo ratings yet

- 9812 090 Isd 0705 2 BDocument1 page9812 090 Isd 0705 2 BIhwan AsrulNo ratings yet

- 9812 090 Isd 0705 3 BDocument1 page9812 090 Isd 0705 3 BIhwan AsrulNo ratings yet

- Aco Akbar Masud Mcu 3Document1 pageAco Akbar Masud Mcu 3Ihwan AsrulNo ratings yet

- 9812 090 Isd 0705 1 BDocument1 page9812 090 Isd 0705 1 BIhwan AsrulNo ratings yet

- Pts - New Passenger Data Entry Form: Lifting - Balikpapan@bpmigas - Go.idDocument1 pagePts - New Passenger Data Entry Form: Lifting - Balikpapan@bpmigas - Go.idIhwan AsrulNo ratings yet

- Bon TangDocument8 pagesBon TangIhwan AsrulNo ratings yet

- Review Questions QuestionsDocument5 pagesReview Questions QuestionsJustine JaymaNo ratings yet

- Financial Management - MGT201: 7 Week of LecturesDocument10 pagesFinancial Management - MGT201: 7 Week of LecturesSyed Abdul Mussaver ShahNo ratings yet

- Out 3Document6 pagesOut 3Ilvita MayasariNo ratings yet

- Monthly Bulletin ECB - Okt 2011Document234 pagesMonthly Bulletin ECB - Okt 2011remcoxyiiNo ratings yet

- New Wordpad DocumentDocument4 pagesNew Wordpad DocumentAbdul Haseeb AmjadNo ratings yet

- STHDocument4 pagesSTHIvan MedićNo ratings yet

- Financial Technologies and DeFi A Revisit To The Digital Finance RevolutionDocument3 pagesFinancial Technologies and DeFi A Revisit To The Digital Finance RevolutionAista Putra WisenewNo ratings yet

- Lange J. Value-Oriented Leadership in Theory and Practice... 2023Document181 pagesLange J. Value-Oriented Leadership in Theory and Practice... 2023Nikolai LazarovNo ratings yet

- Climate Change and Its Interaction With Natural, Economic and Social ProcessesDocument8 pagesClimate Change and Its Interaction With Natural, Economic and Social ProcessesGammaz1973No ratings yet

- Classification: Strategic Capital InvestmentDocument14 pagesClassification: Strategic Capital InvestmentOliver LeeNo ratings yet

- Gbemich Services: Health, Safety and Environmental Management Systems Plan For Construction of SNEPCO FACILITYDocument20 pagesGbemich Services: Health, Safety and Environmental Management Systems Plan For Construction of SNEPCO FACILITYJames Adekunle OgunsolaNo ratings yet

- Topics - Caries - Under6 Yo PDFDocument2 pagesTopics - Caries - Under6 Yo PDFRizal ArdiNo ratings yet

- Effect of Flooding On Property Value A Case Study of Isheri North, Isheri, Lagos StateDocument7 pagesEffect of Flooding On Property Value A Case Study of Isheri North, Isheri, Lagos Statefagbemi KayodeNo ratings yet

- Generic Project Success and Project Management Success Criteria and Factors: Literature Review and SurveyDocument13 pagesGeneric Project Success and Project Management Success Criteria and Factors: Literature Review and Surveyjaveria khanNo ratings yet

- AL-LIN-50002 - 2009-Oct-27 - Rev3Document25 pagesAL-LIN-50002 - 2009-Oct-27 - Rev3Prashant TrivediNo ratings yet

- IATG 02 10 Introduction To Risk Management Principles v.2Document44 pagesIATG 02 10 Introduction To Risk Management Principles v.2DOC LABNo ratings yet

- Human Factors: Canadian Coast Guard Auxiliary - Pacific Canadian Coast Guard Auxiliary - PacificDocument117 pagesHuman Factors: Canadian Coast Guard Auxiliary - Pacific Canadian Coast Guard Auxiliary - PacificMaureen Janelle RemaneaNo ratings yet

- SPE 69594 Significance of Project Risking Methods On Portfolio Optimization ModelsDocument6 pagesSPE 69594 Significance of Project Risking Methods On Portfolio Optimization ModelsLINETTE ALBORNOZNo ratings yet

- Bakht 30 BBA 5tha Final Paper ImstudiesDocument5 pagesBakht 30 BBA 5tha Final Paper ImstudiesMuqaddar KhanNo ratings yet

- 21 Secrets I Wish I Knew at The Start of My Investing CareerDocument5 pages21 Secrets I Wish I Knew at The Start of My Investing Careerjohnsmith1806No ratings yet

- Financial Planning Education FrameworkDocument46 pagesFinancial Planning Education FrameworkdizhangNo ratings yet

- TP109 Dam Safety Guidelines Part 3 (1auckland City Council)Document22 pagesTP109 Dam Safety Guidelines Part 3 (1auckland City Council)drjaved12000No ratings yet

- Andhra Pradesh Municipal Audit ManualDocument146 pagesAndhra Pradesh Municipal Audit ManualChristie JonesNo ratings yet

- Chapter 4 Software Poroject PlanningDocument52 pagesChapter 4 Software Poroject Planningਅਮਰ ਪਾਲ ਸਿੰਘNo ratings yet

- 2021 Yds-1Document24 pages2021 Yds-1musa dafNo ratings yet

- AMIDA Walven SilalahiDocument7 pagesAMIDA Walven Silalahihz135874No ratings yet

- Akzo Nobel Risk ManagementDocument53 pagesAkzo Nobel Risk ManagementdhanuNo ratings yet