Professional Documents

Culture Documents

TPS QA KA AA 001 (C01) Welding Tank Procedure

TPS QA KA AA 001 (C01) Welding Tank Procedure

Uploaded by

Touil HoussemOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TPS QA KA AA 001 (C01) Welding Tank Procedure

TPS QA KA AA 001 (C01) Welding Tank Procedure

Uploaded by

Touil HoussemCopyright:

Available Formats

CONSTRUCTION OF NEW WATER

STORAGE TANK T3

WELDING STORAGE TANK PROCEDURE

CONTRACTOR Document N:

55302-TPS-QA-KA-AA-001

Rev: C01

Page : 1 of 10

CONSTRUCTION OF NEW WATER STORAGE

TANK T3

WELDING STORAGE TANK PROCEDURE

06/01/2017

C01

Issued For Approval

AEC: H.R

PIC: M.H

AEC: T.KH

26/11/2016

B01

Issued For Review

H.R

H.R

T.KH

Date

Rev.

Description of Revision

Prepared by Verified by Approved by

Document Elaborated by : AEC

Company

Approval

CONSTRUCTION OF NEW WATER

STORAGE TANK T3

WELDING STORAGE TANK PROCEDURE

CONTRACTOR Document N:

55302-TPS-QA-KA-AA-001

Rev: C01

Page : 2 of 10

TABLE OF CONTENTS

ABBREVIATIONS.......................................................................................................................................... 3

DEFINITIONS................................................................................................................................................ 4

REFERENCES & STANDARDS.................................................................................................................... 4

TABLE OF HOLDS........................................................................................................................................ 5

1.

INTRODUCTION................................................................................................................................... 6

2.

MATERIAL............................................................................................................................................ 6

2.1

GENERAL............................................................................................................................................. 6

2.2

PLATES................................................................................................................................................ 6

2.3

SHEETS................................................................................................................................................ 6

2.4

WELDING ELECTRODES.................................................................................................................... 6

2.5

PIPING.................................................................................................................................................. 7

2.6

FLANGES............................................................................................................................................. 7

3.

DESIGN................................................................................................................................................. 7

3.1

SIZE OF WELD..................................................................................................................................... 7

3.2 TYPE OF WELD.................................................................................................................................... 7

4.

WELDING SEQUENCE........................................................................................................................ 8

5.

APPENDIX............................................................................................................................................ 9

CONSTRUCTION OF NEW WATER

STORAGE TANK T3

WELDING STORAGE TANK PROCEDURE

CONTRACTOR Document N:

55302-TPS-QA-KA-AA-001

ABBREVIATIONS

- TPS

: Thyna Petroleum Services

- CFTP

: Compagnie Franco-Tunisienne des Ptrole

- ASME

: American Society of Mechanical Engineers

- PQR

: Procedure Qualification Record

- WPS

: Welder Performance Specification

- PIC

: Process Inspection & control

Rev: C01

Page : 3 of 10

CONSTRUCTION OF NEW WATER

STORAGE TANK T3

WELDING STORAGE TANK PROCEDURE

CONTRACTOR Document N:

55302-TPS-QA-KA-AA-001

Rev: C01

Page : 4 of 10

DEFINITIONS

- Company

Thyna Petroleum Servises (TPS).

- Project

Construction of new water storage tank T3

- Contractors

AEC.

- Shall

Is to be understood mandatory

- Should

Is to be understood as strongly recommended

- May be

Is to be understood as giving freedom of choice

- The work

All activities for the construction of the defined elements as

detailed in the scope of work.

- Approved

Agreed and approved by Company.

REFERENCES & STANDARDS

-

Company specification.

API 650 : Welded Tanks for oil storage

API SPEC 12C : Specification for Field Welded Tanks for Storage of Production Liquids

PQR: AEC-S235 JR-SMAW

CONSTRUCTION OF NEW WATER

STORAGE TANK T3

WELDING STORAGE TANK PROCEDURE

CONTRACTOR Document N:

55302-TPS-QA-KA-AA-001

Rev: C01

Page : 5 of 10

TABLE OF HOLDS

Hold

Section

Comment

CONSTRUCTION OF NEW WATER

STORAGE TANK T3

WELDING STORAGE TANK PROCEDURE

CONTRACTOR Document N:

55302-TPS-QA-KA-AA-001

Rev: C01

Page : 6 of 10

1. INTRODUCTION

This procedure establishes minimum requirements for material, design, fabrication, erection,

welding and testing for vertical, cylindrical, aboveground, closed- and open-top, welded storage

tanks in various sizes and capacities for internal pressures approximating atmospheric pressure.

The Contractor is responsible for complying with all provisions of this Standard. Inspection by

third party does not negate the Manufacturers obligation to provide quality control and inspection

necessary to ensure such compliance.

2. MATERIAL

2.1

GENERAL

Materials listed in this section have been selected to provide adequate strength and reasonable

service life. Other materials having mechanical properties equal to or greater than those listed

may be used by agreement between the purchaser and the manufacturer. Where higher strength

materials are used, the minimum thickness called for in this specification shall not be reduced..

2.2

PLATES

Plates shall conform to the latest edition of one of the following ASTM standards: ASTM A283

(S235 JR). Shell plates for which minimum thicknesses have been fixed for practical reasons

(greater than required by computation) and which will not under run the required computed

thickness by more than 0.01 in., as well as all roof and bottom plates, may be purchased on a

weight basis. The plate thicknesses or weights, as stipulated herein, are minimums: thicker or

heavier material may be required on the order at the option of the purchaser.

2.3

SHEETS

Sheets shall conform to the latest revision of ASTM A283, Grade C (S235 JR), open-hearth

process and basic oxygen process. Sheets shall be ordered on a weight and thickness basis, at

the option of the tank Company.

2.4

WELDING ELECTRODES

Manual arc-welding electrodes shall conform to the E70 Series of Classification (suitable for the

electric current characteristics, the position of welding, and other conditions of intended use) in

the latest edition of AWS A5.1, as per our PQR BCAT/AEC/02/2010,

Filler Metals: AWS A 5.lE 7018

Brand: ESAB

Type OK 48.00

Thikness : 2.5 ; 3.2 ; 4 & 5 mm

Preheat: Yes

CONSTRUCTION OF NEW WATER

STORAGE TANK T3

WELDING STORAGE TANK PROCEDURE

CONTRACTOR Document N:

55302-TPS-QA-KA-AA-001

2.5

Rev: C01

Page : 7 of 10

PIPING

Pipe shall conform to Grade A or B of the latest edition of API 5L, ASTM A53, or ASTM A106.

2.6

FLANGES

Hub slip-on welding or welding-neck flanges shall conform to the material requirements for forged

carbon steel flanges as specified in ASME B16.5.

3. DESIGN

3.1

SIZE OF WELD

The size of a weld shall be based on the following dimensions:

a) groove weld: the joint penetration (depth of chamfering plus the root penetration when

specified);

b) fillet weld: for equal leg fillet welds, the leg length of the largest isosceles right-triangle which

can be inscribed within the fillet-weld cross-section; while for unequal leg fillet welds, the leg

lengths of the largest right-triangle which can be inscribed within the fillet-weld cross-section.

3.2 TYPE OF WELD

3.2.1 Bottom Joints (thickness 10 mm)

Bottom joints, sheet metal cover with fillet weld.

Root: Filler metal OK 7018 3.2 mm

Hot: Filler metal OK 7018 4 mm

Cap: Filler metal OK 7018 4 mm

3.2.2 Shell 01 & annular bottom plate (08 mm) joints

The tank bottom shall be attached to the tank shell by full-fillet welds, both inside and outside.

Root: Filler metal OK 7018 3.2 mm

Hot: Filler metal OK 7018 3.2 mm

Cap: Filler metal OK 7018 3.2 mm

CONSTRUCTION OF NEW WATER

STORAGE TANK T3

WELDING STORAGE TANK PROCEDURE

CONTRACTOR Document N:

55302-TPS-QA-KA-AA-001

Rev: C01

Page : 8 of 10

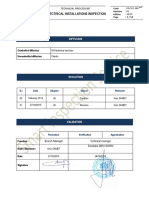

3.2.3 Shell 01 (8 mm) and shell 02 (8 mm) joints

Shell-plate joints shall be double-welded butt joints with complete penetration.

Horizontal and vertical welding (see picture A)

Picture A

Picture B

Vertical Shell joint butt weld (Root, hoot and cap in outside & Root inside)

3.2.4 Shell 02 (8 mm) and shell 03 (6 mm) joints

Shell-plate joints shall be double-welded butt joints with complete penetration.

Horizontal and vertical welding (see picture A & B)

CONSTRUCTION OF NEW WATER

STORAGE TANK T3

WELDING STORAGE TANK PROCEDURE

CONTRACTOR Document N:

55302-TPS-QA-KA-AA-001

Rev: C01

Page : 9 of 10

3.2.5 Shell 03 (6 mm) and shell 04 (6 mm) joints

Shell-plate joints shall be double-welded butt joints with complete penetration.

Horizontal and vertical welding (see picture A& B)

3.2.6 Shell 04 (8 mm) and compression ring (10 mm) joints

Shell plate shall be attached to the compression ring by full-fillet welds, both inside and outside.

Root: Filler metal OK 7018 3.2 mm

Hot: Filler metal OK 7018 3.2 mm

Cap: Filler metal OK 7018 3.2 mm

3.2.7 Compression ring (10 mm)) and roof plate (6 mm) joints

Roof plate shall be attached to the compression ring by full-fillet welds, in outside.

Root: Filler metal OK 7018 3.2 mm

Hot: Filler metal OK 7018 3.2 mm

Cap: Filler metal OK 7018 3.2 mm

3.2.8 Plate Roof (thickness 6 mm)

Roof joints, sheet metal cover with fillet weld.

Root: Filler metal OK 7018 3.2 mm

Hot: Filler metal OK 7018 3.2 mm

Cap: Filler metal OK 7018 3.2 mm

CONSTRUCTION OF NEW WATER

STORAGE TANK T3

WELDING STORAGE TANK PROCEDURE

CONTRACTOR Document N:

55302-TPS-QA-KA-AA-001

Rev: C01

Page : 10 of 10

3.2.9 Nozzle

Nozzle reinforcement with tank and reinforcement with nozzle shall be welded with fillet weld.

Root: Filler metal OK 7018 3.2 mm

Hot: Filler metal OK 7018 3.2 mm

Cap: Filler metal OK 7018 3.2 mm

4. APPENDIX

You might also like

- Visual Inspection ProcedureDocument8 pagesVisual Inspection ProcedureTouil Houssem100% (3)

- MT ProcedureDocument9 pagesMT ProcedureTouil Houssem100% (1)

- Die and Punch - Project ReportDocument29 pagesDie and Punch - Project ReportPawan mehta100% (1)

- Checklist For Separator Cum Storage TankDocument5 pagesChecklist For Separator Cum Storage TankRamalingam PrabhakaranNo ratings yet

- EIL Shedule of Rates ENQ - REV0Document20 pagesEIL Shedule of Rates ENQ - REV0kotiNo ratings yet

- VaconoDocument16 pagesVaconoLassadNo ratings yet

- Kirshant Roll 11 Industrial ReportDocument50 pagesKirshant Roll 11 Industrial ReportKIRSHANT TomerNo ratings yet

- Concepto ALARP PDFDocument22 pagesConcepto ALARP PDFLuis Olle ArrolaNo ratings yet

- Isa 540Document100 pagesIsa 540Maxim50% (2)

- Foam Chamber Data SheetDocument6 pagesFoam Chamber Data Sheetadilmomin45No ratings yet

- Class P15A6Document7 pagesClass P15A6SalimNo ratings yet

- BTP2B-EPCIC-BTJTB-M-TDS-0003 Rev.X PDFDocument7 pagesBTP2B-EPCIC-BTJTB-M-TDS-0003 Rev.X PDFandrianoNo ratings yet

- TRHT SP Te 86 Oo 203 - 0Document28 pagesTRHT SP Te 86 Oo 203 - 0belhaska100% (1)

- Shop Inspection Requirements and Inspection and Testing Sequence For Tank ComponentsDocument4 pagesShop Inspection Requirements and Inspection and Testing Sequence For Tank ComponentsdurraaiNo ratings yet

- Above Ground TanksDocument6 pagesAbove Ground TanksGyanendra Narayan NayakNo ratings yet

- Saes B 001Document2 pagesSaes B 001Ahmed Nasralla HefnawyNo ratings yet

- TanneryDocument64 pagesTanneryDivya NaradasuNo ratings yet

- Fisher Cryogenic ValveDocument12 pagesFisher Cryogenic ValvePratik PatelNo ratings yet

- G-05 NocDocument17 pagesG-05 NocRochdi SahliNo ratings yet

- GS Saf 321aDocument20 pagesGS Saf 321aAhmad SaeedNo ratings yet

- P RefStd - 4043 - 002 - v091130 - EN - LOPADocument2 pagesP RefStd - 4043 - 002 - v091130 - EN - LOPAMeoNo ratings yet

- PROJECT STANDARDS AND SPECIFICATIONS Fla PDFDocument12 pagesPROJECT STANDARDS AND SPECIFICATIONS Fla PDFAsif Haq100% (1)

- Heater Nomenclature1 PDFDocument42 pagesHeater Nomenclature1 PDFmujeebmeharNo ratings yet

- Abschn 14Document3 pagesAbschn 14Vikas NaikNo ratings yet

- 100 Yer Pe Yss 0438Document36 pages100 Yer Pe Yss 0438Mohammad Aamir PerwaizNo ratings yet

- 230Materials&EnergyModule (1) PS CAPECODocument5 pages230Materials&EnergyModule (1) PS CAPECOPradeep SutharNo ratings yet

- Info Dec 13Document13 pagesInfo Dec 13Malik Uzair ZafarNo ratings yet

- Major Accident PreventionDocument28 pagesMajor Accident PreventionRoger MooncasterNo ratings yet

- Pressure Vessel PlateDocument4 pagesPressure Vessel PlateYetkin ErdoğanNo ratings yet

- VMH - Mounded Bullet Foundation Guidance PDFDocument5 pagesVMH - Mounded Bullet Foundation Guidance PDFMauricio R MoralesNo ratings yet

- Engineering Group: Kuwait Oil Company (K.S.C.)Document14 pagesEngineering Group: Kuwait Oil Company (K.S.C.)Aravindan Ganesh KumarNo ratings yet

- LNG Gas Dispersion PaperDocument7 pagesLNG Gas Dispersion Paperbaaziz2015No ratings yet

- Dry Bulk Storage Tank SpecificationDocument7 pagesDry Bulk Storage Tank SpecificationMohamed Mostafa IbrahimNo ratings yet

- Saep 303Document59 pagesSaep 303Demac SaudNo ratings yet

- Sample Dropped Object ReportDocument36 pagesSample Dropped Object ReportRiyaz ahamedNo ratings yet

- Gunnebo Masterlink PDFDocument3 pagesGunnebo Masterlink PDFJason RobertsNo ratings yet

- JMS For Erection of Stiffener Angle With Existing Curb Channel With Erection of Deflector Plate Arrangement For Tank006Document9 pagesJMS For Erection of Stiffener Angle With Existing Curb Channel With Erection of Deflector Plate Arrangement For Tank006AshutoshNo ratings yet

- Pdvsa: Manual de Ingenieria de DiseñoDocument2 pagesPdvsa: Manual de Ingenieria de DiseñokordaasNo ratings yet

- A8ij 300 25 BD 0006 - 1Document34 pagesA8ij 300 25 BD 0006 - 1becpavanNo ratings yet

- 123Document8 pages123josethompsonNo ratings yet

- New SSIV InstallationDocument12 pagesNew SSIV InstallationDidiNo ratings yet

- 1113 Maintenance of PRVDocument63 pages1113 Maintenance of PRVhardito sussatrioNo ratings yet

- 2018 - Dlsud - Esd Diagram - Logic Diagram - GRP 5Document1 page2018 - Dlsud - Esd Diagram - Logic Diagram - GRP 5Jake Polo SantiagoNo ratings yet

- Storage Tanks Calculation Template: Oil & Gas Production: Company Name: Site Name: RN: Fin: Epn: Cin: Data InputsDocument1 pageStorage Tanks Calculation Template: Oil & Gas Production: Company Name: Site Name: RN: Fin: Epn: Cin: Data InputsihllhmNo ratings yet

- All To Know About IFR & EFRDocument30 pagesAll To Know About IFR & EFRyazNo ratings yet

- Asme B31 - Pressure PipingDocument3 pagesAsme B31 - Pressure PipingAndhyka Cakrabuana AdhitamaNo ratings yet

- WPE1 Course NotesDocument288 pagesWPE1 Course NotesLukasz TerlikowskiNo ratings yet

- Vacono Erection ManualDocument60 pagesVacono Erection Manualjfilipovic67% (3)

- WTIA TN 11 Commentary On The Standard ASNZS 1554 Structural Steel WeldingDocument99 pagesWTIA TN 11 Commentary On The Standard ASNZS 1554 Structural Steel WeldingZac NastNo ratings yet

- UL-142 R912 Installation InstructionsDocument4 pagesUL-142 R912 Installation InstructionsRodrigoNo ratings yet

- Tubular and Process Assemblies: W A T L O WDocument34 pagesTubular and Process Assemblies: W A T L O WEliasNo ratings yet

- La WbsebDocument11 pagesLa WbsebPritamNo ratings yet

- Revise Storage Tank InspectionsDocument17 pagesRevise Storage Tank InspectionsJacek100% (1)

- Ed Temporary Refuge IntegrityDocument27 pagesEd Temporary Refuge Integrityliamo88880No ratings yet

- 32 Samss 005Document33 pages32 Samss 005naruto256100% (1)

- Gas Dispersion Modeling For Flare Stacks Using FlaresimDocument68 pagesGas Dispersion Modeling For Flare Stacks Using Flaresimchemengr.samadjanNo ratings yet

- Ana Bmu: Company ProfileDocument27 pagesAna Bmu: Company ProfileAvishay TufikianNo ratings yet

- UMS-IMC-F07-0011 - Terms of Reference (ToR) For SIL ClassificationDocument20 pagesUMS-IMC-F07-0011 - Terms of Reference (ToR) For SIL ClassificationRichard Ikwubute100% (1)

- IEC TS 62600-4 TechnologyDocument28 pagesIEC TS 62600-4 TechnologysainivijayNo ratings yet

- 2015 References Terminals EDocument59 pages2015 References Terminals EAllyson JohnsonNo ratings yet

- Saes B 069Document9 pagesSaes B 069Cane CirpoNo ratings yet

- Jacobs (HPCL) Standard On Pressure Vessel & He PDFDocument52 pagesJacobs (HPCL) Standard On Pressure Vessel & He PDFAnit100% (2)

- Sample UDS DocumentDocument14 pagesSample UDS Documentnilesh_raykarNo ratings yet

- GS Moo PVV 612 00 enDocument34 pagesGS Moo PVV 612 00 enTouil HoussemNo ratings yet

- TR015-P LR - Mazarine Update 29-08-17Document10 pagesTR015-P LR - Mazarine Update 29-08-17Touil HoussemNo ratings yet

- TR015-P LR - MazarineDocument10 pagesTR015-P LR - MazarineTouil HoussemNo ratings yet

- WR026-G SC - MazarineDocument4 pagesWR026-G SC - MazarineTouil HoussemNo ratings yet

- Application Guidelines Kinross Tasiast Graduate Program July 2017Document6 pagesApplication Guidelines Kinross Tasiast Graduate Program July 2017Touil HoussemNo ratings yet

- DESIGNCALCULATION (Enregistré Automatiquement)Document6 pagesDESIGNCALCULATION (Enregistré Automatiquement)Touil HoussemNo ratings yet

- Fence: Steel Cover 1.5mm With Lead Layer 3mm With Security LockDocument1 pageFence: Steel Cover 1.5mm With Lead Layer 3mm With Security LockTouil HoussemNo ratings yet

- Rig 814 Componnents: Items Material DescriptionDocument2 pagesRig 814 Componnents: Items Material DescriptionTouil HoussemNo ratings yet

- Calculation Radiation: Design FOR Storage DepotDocument5 pagesCalculation Radiation: Design FOR Storage DepotTouil HoussemNo ratings yet

- Air Pig Baker Model Rev 01Document1 pageAir Pig Baker Model Rev 01Touil HoussemNo ratings yet

- Ismail Marweni - Qa&Hseq Manager - 03!05!2017Document5 pagesIsmail Marweni - Qa&Hseq Manager - 03!05!2017Touil HoussemNo ratings yet

- Welding RegisterDocument1 pageWelding RegisterTouil HoussemNo ratings yet

- PQ-TEC-300 - Inspection Procedure of Electrical InspectionDocument13 pagesPQ-TEC-300 - Inspection Procedure of Electrical InspectionTouil Houssem100% (1)

- Welding RegisterDocument1 pageWelding RegisterTouil HoussemNo ratings yet

- Inspection of Life-Saving Equipment: Client: Object Equipement Date of InspDocument1 pageInspection of Life-Saving Equipment: Client: Object Equipement Date of InspTouil HoussemNo ratings yet

- Certificat SoudeurDocument2 pagesCertificat SoudeurTouil Houssem100% (1)

- RE: Quality Control InspectorDocument1 pageRE: Quality Control InspectorTouil HoussemNo ratings yet

- NR216 2016-01Document254 pagesNR216 2016-01Touil HoussemNo ratings yet

- WPQ Ejcom Nr476Document13 pagesWPQ Ejcom Nr476Touil HoussemNo ratings yet

- Guidelines For Gas Tungsten Arc Welding (GTAW)Document24 pagesGuidelines For Gas Tungsten Arc Welding (GTAW)Touil HoussemNo ratings yet

- Workshop PolytechnicDocument5 pagesWorkshop PolytechnicAneesh Kumar0% (1)

- Importance of Mineral Based IndustriesDocument2 pagesImportance of Mineral Based Industriesshadow146No ratings yet

- Thermal Aspects of Metal Cutting ProcessDocument14 pagesThermal Aspects of Metal Cutting ProcessCORONA EVENTNo ratings yet

- Painting Standard ListDocument15 pagesPainting Standard Listvikas dahiyaNo ratings yet

- Sublimation Heat Press Quick Guide 1Document2 pagesSublimation Heat Press Quick Guide 1renato jr baylasNo ratings yet

- ASME B16.21 Ring and Full Face Dimensions 150 2500# B16.5 & 16.47 Series A&bDocument13 pagesASME B16.21 Ring and Full Face Dimensions 150 2500# B16.5 & 16.47 Series A&bMONo ratings yet

- HRN ISO en 12944-1 - Korozivna Zastita Celicnih Konstrukcija Premazima - Dio 1. Osnovne InformacijeDocument32 pagesHRN ISO en 12944-1 - Korozivna Zastita Celicnih Konstrukcija Premazima - Dio 1. Osnovne InformacijeMarko VrcaNo ratings yet

- Practical Guidelines For The Fabrication of Duplex Stainless Steels (2nd Edition)Document64 pagesPractical Guidelines For The Fabrication of Duplex Stainless Steels (2nd Edition)sanketNo ratings yet

- Technical Handbook Stainless Steel WeldingDocument92 pagesTechnical Handbook Stainless Steel WeldingRamesh sivanNo ratings yet

- RA9260Document1 pageRA9260Vivek PatilNo ratings yet

- Novares Marocco: FrigelDocument15 pagesNovares Marocco: FrigelHarmouche MedNo ratings yet

- Life Is Movement, Movement Is LifeDocument37 pagesLife Is Movement, Movement Is LifeUmair SaleemNo ratings yet

- FBC BoilersDocument8 pagesFBC Boilerssk3146No ratings yet

- 20me53i Week6 Day3 Session1Document6 pages20me53i Week6 Day3 Session1rajuNo ratings yet

- SMAWDocument8 pagesSMAWmostafaNo ratings yet

- NWS Residual Stress Measurement in Dissimilar Welding JointDocument30 pagesNWS Residual Stress Measurement in Dissimilar Welding JointHarshitkumarNo ratings yet

- Rogers Si3n4 DCB Amb 20130117Document17 pagesRogers Si3n4 DCB Amb 20130117anon_901131682No ratings yet

- 2 Introduction-Refractories ApresentaçãoDocument11 pages2 Introduction-Refractories ApresentaçãoBrunoNo ratings yet

- Product Information: High-Temperature Oil, Light-Coloured, SyntheticDocument2 pagesProduct Information: High-Temperature Oil, Light-Coloured, SyntheticIván ChávezNo ratings yet

- Piton T. Pistola - New AgeDocument1 pagePiton T. Pistola - New AgeDiana V. RosalesNo ratings yet

- CE Mark and DoP - QHPSDocument2 pagesCE Mark and DoP - QHPSHoangNo ratings yet

- PP 11.01 TapTee Items 06-2008 IVDocument1 pagePP 11.01 TapTee Items 06-2008 IVHumberto MárquezNo ratings yet

- ASTM A866-14 Standard Specification For Medium Carbon Anti-Friction Bearing SteelDocument4 pagesASTM A866-14 Standard Specification For Medium Carbon Anti-Friction Bearing SteelserkandmNo ratings yet

- Nitoseal RTVDocument2 pagesNitoseal RTVtalatzahoorNo ratings yet

- Mohit Khatri Final Internship ReportDocument41 pagesMohit Khatri Final Internship ReportShubham ThawariNo ratings yet

- Turning Grades GC3225 and GC3210: Two Grades Covering All Cast Iron Turning OperationsDocument4 pagesTurning Grades GC3225 and GC3210: Two Grades Covering All Cast Iron Turning OperationsBilal AhmedNo ratings yet

- Special Steels SB4: For Cold Deformation and BearingsDocument1 pageSpecial Steels SB4: For Cold Deformation and BearingsRollpass DesignNo ratings yet

- F-720-155 Rev. D Piston & Piston KitsDocument3 pagesF-720-155 Rev. D Piston & Piston KitsСергейИгнатовNo ratings yet

- Knife Sharpening Guide by MikartoDocument10 pagesKnife Sharpening Guide by MikartoJesse KrebsNo ratings yet