Professional Documents

Culture Documents

JSA-Test Pressure Hose - Feb, 08

JSA-Test Pressure Hose - Feb, 08

Uploaded by

Ihwan AsrulOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA-Test Pressure Hose - Feb, 08

JSA-Test Pressure Hose - Feb, 08

Uploaded by

Ihwan AsrulCopyright:

Available Formats

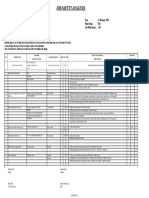

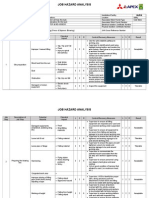

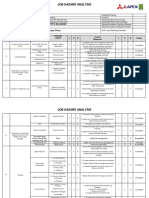

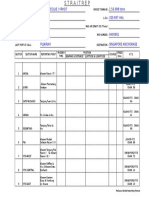

JOB SAFETY ANALYSIS

Job Title :Pressure Leak Test Discharge Hose

Location

Leader

Crew List

: Sesiil Shelter Area - FSO Concord.

: Max Polla / Bambang Eko

: See attachement

Date

: 16 February 2008

Work Permit

: YES

Hot Work Permit : NO

HSE Notes :

PPE Standard : Coverall; Safety Shoes; Safety Hat; Safety Glass; Hand Gloves.

Issue Work Permit and conduct tool box meeting before commencement the job.

Working above or on the water and personal transfer by boat, personnel should wear work vest or life jacket if needed.

Communication among personnel in charge should be well maintained.

Diver crew should be standby just in case any leak from floating hose flange.

NO

WORK STEPS

Basic step & tool used

Work Site Preparation

HAZARDS

IDENTIFICATION

How can people get

injured use checklist on

form 2

HAZARDS EFFECT

RISK FACTOR

Type of injury worst case

HE

RF

SAFETY MEASURES &

RESIDUAL

PREVENTION

RISK FACTOR

Assign Responsible Person for each action

HE

RF

Slip

Squeeze

Bad weather

Twisted/Keseleo

Injured

Bruised

L

L

L

L

L

L

L2 1. Make sure that working area is not slippery and free from obstructions

that may obstruct work activity and make activity unsafe.

L2

L2 2. Install barricade as needed.

3. Do not hurry.

4. Double check equipment / Tools / Materials needed.

5. Wind speed 20 kts and wave 1.5 m

NS

L1

NS

L1

NS

L1

Line up Air supply from Concord

facility

Carry/pull air hose then slip

and connected to the inlet

manifold.

Back injured

L

L

M

M

M4 1. Maintain good and clear communication between Concord crew and KEI or Rigger crew.

M4 2. Make sure that from discharge compressor is open and no leak till to the manifold.

3. Provide Pressure gauge for monitoring pressure in the hose.

L2

Broken hand

L2

Start pressurize the line

Pressure spread out from

flange

Hose disconnected from

quick release nipple and hit by.

Eye injured

body injured or leg

injured.

M4 1. Make sure pressure is increase slowly.

2. When pressure out from vent line, close the vent valve immeadiately.

M4 3. Maintain good and clear communication among Concord crew, and man who watch the

pressure on the manifold.

4. Pressurize the line up to 50 psi slowly, make sure the pressure up to 70 psig as necessary

and hold for about half an hour.

L2

L1

L2

Check the leak on each join

Doing by Diver.

Air spread out.

Eye injured

M4 1. Wear safety glass.

NS

L1

Depressurize the line.

Air /any material spread out

Eye injured

M4 1. Wear safety glass.

2. Bleed the pressure slowly.

L2

L2

L2

VL

L1

Disconnect the air supply inlet

House Keeping

Carry air hose in place.

Slippery floor.

Hand injured

bruised

Back Injured

Bruised

L

L

M

L

L2 1. Make sure the valve close and Air Compressor shut off.

2. Keep people away and disconnect the line from 1/2" quick connection coupling.

M4 1. Tidy up work place and put back all tools to their place.

L2 2. Separate all used materials/trash by following the hazardous materials types.

3. Before leaving the work place, make sure that work place is safe and clean.

Prepared by

Approved by

signed

signed

Max Polla / Bambang Eko

PT. Arah Prana

Robert Porsiana.

KEI

343333313.xls

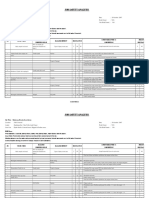

JOB SAFETY ANALYSIS

Job Title :Pressure Leak Test Discharge Hose

Location

Leader

Crew List

: Sesiil Shelter Area - FSO Concord.

: Max Polla / Bambang Eko

: See attachement

Date

: 16 February 2008

Work Permit

: YES

Hot Work Permit : NO

HSE Notes :

PPE Standard : Coverall; Safety Shoes; Safety Hat; Safety Glass; Hand Gloves.

Issue Work Permit and conduct tool box meeting before commencement the job.

Working above or on the water and personal transfer by boat, personnel should wear work vest or life jacket if needed.

Communication among personnel in charge should be well maintained.

Diver crew should be standby just in case any leak from floating hose flange.

NO

WORK STEPS

Basic step & tool used

HAZARDS

IDENTIFICATION

How can people get

injured use checklist on

form 2

HAZARDS EFFECT

Type of injury worst case

RISK FACTOR

HE

SAFETY MEASURES &

RESIDUAL

PREVENTION

RISK FACTOR

Assign Responsible Person for each action

RF

343333313.xls

HE

RF

You might also like

- Risk Assessment No 01 ANCHOR HANDLING IN GENERAL Rev 03Document5 pagesRisk Assessment No 01 ANCHOR HANDLING IN GENERAL Rev 03Devi Ratna Pratiwi78% (9)

- Risk Assessment For CanopyDocument5 pagesRisk Assessment For CanopyJSN179100% (7)

- Jsa For Lifting (Crane) 016Document6 pagesJsa For Lifting (Crane) 016aliraza572271% (28)

- Risk Assessment No. 24 MOORING TO WHARF - VESSELS Rev. 02 28.1Document3 pagesRisk Assessment No. 24 MOORING TO WHARF - VESSELS Rev. 02 28.1Devi Ratna Pratiwi100% (5)

- Plumbing N2 Hands-On!Document13 pagesPlumbing N2 Hands-On!Future Managers Pty Ltd80% (5)

- Risk Assessment No. 42 WORKING OVER-SIDE Rev. 02 28.12.09Document2 pagesRisk Assessment No. 42 WORKING OVER-SIDE Rev. 02 28.12.09Devi Ratna Pratiwi80% (5)

- Job Safety Analysis: Pipe Cutting Cleaning and Flushing GeneralDocument2 pagesJob Safety Analysis: Pipe Cutting Cleaning and Flushing GeneralNico Raharjo60% (5)

- Risk Assessment No. 07 BUNKER SHIP TO SHIP Rev. 02 20.03.09Document3 pagesRisk Assessment No. 07 BUNKER SHIP TO SHIP Rev. 02 20.03.09Devi Ratna Pratiwi83% (6)

- SP0757A1-2 Permit To Work AloftDocument1 pageSP0757A1-2 Permit To Work AloftPolaris Bridgeman50% (2)

- JSA-012 Low-Flow Groundwater SamplingDocument3 pagesJSA-012 Low-Flow Groundwater SamplingfrancisseeNo ratings yet

- Risk Assessment No. 26 PASSENGER TRANSFER Rev. 02 20.03.09Document2 pagesRisk Assessment No. 26 PASSENGER TRANSFER Rev. 02 20.03.09Devi Ratna Pratiwi100% (2)

- Risk Assessment No. 04 ANCHOR HANDLING, RUNNING, SUIT CASE BUDocument3 pagesRisk Assessment No. 04 ANCHOR HANDLING, RUNNING, SUIT CASE BUDevi Ratna PratiwiNo ratings yet

- Job Hazard Analysis For Desalination of First Effect RetubingDocument7 pagesJob Hazard Analysis For Desalination of First Effect Retubingmc chesterNo ratings yet

- Chilled Water Pipe Installation - ACMVDocument4 pagesChilled Water Pipe Installation - ACMVbinhjuki100% (2)

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisJeojie JieNo ratings yet

- Ultimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsFrom EverandUltimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsRating: 3 out of 5 stars3/5 (8)

- Job Title: Pressure Leak Test Discharge Hose: HSE NotesDocument1 pageJob Title: Pressure Leak Test Discharge Hose: HSE NotesIhwan AsrulNo ratings yet

- Job Safety Analysis: Job Title: Installing Pneumatic Rubber FenderDocument3 pagesJob Safety Analysis: Job Title: Installing Pneumatic Rubber FenderIhwan AsrulNo ratings yet

- JSA-Discharging & Flushing CoargoDocument2 pagesJSA-Discharging & Flushing CoargoIhwan AsrulNo ratings yet

- Job Safety Analysis: Job Title: Membongkar Hose Strings Dari Mini PlatformDocument2 pagesJob Safety Analysis: Job Title: Membongkar Hose Strings Dari Mini PlatformIhwan AsrulNo ratings yet

- Job Safety Analysis: Job Title: Yokohama Fender InstallationDocument8 pagesJob Safety Analysis: Job Title: Yokohama Fender InstallationIhwan AsrulNo ratings yet

- JSA-Removing Anchor Chain No 4.Document2 pagesJSA-Removing Anchor Chain No 4.Ihwan AsrulNo ratings yet

- Takudzwa M. Mteliso Support Rig Drilling and InstallationDocument14 pagesTakudzwa M. Mteliso Support Rig Drilling and InstallationTakudzwa MtelisoNo ratings yet

- Safety Training Hydrojetting of Exchangers GeneralDocument15 pagesSafety Training Hydrojetting of Exchangers GeneralandinumailNo ratings yet

- RA For High Pressure Cleaning Using HPCE 520-330Document3 pagesRA For High Pressure Cleaning Using HPCE 520-330George CristianNo ratings yet

- Hydro Testing On Piping System Utility and Plant Piping Jsa 2012Document4 pagesHydro Testing On Piping System Utility and Plant Piping Jsa 2012AldrinNo ratings yet

- CTU UnloadDocument2 pagesCTU UnloadaneshseNo ratings yet

- JHA Blowing PressDocument5 pagesJHA Blowing PressLuqman OsmanNo ratings yet

- SMP For Pullcord and BeltswayDocument2 pagesSMP For Pullcord and BeltswayROHIT SINGHNo ratings yet

- Tennin HAZOPDocument4 pagesTennin HAZOPMohamed SamirNo ratings yet

- Near Miss - OCIMF Definition: Working AloftDocument10 pagesNear Miss - OCIMF Definition: Working AloftНина РыбкинаNo ratings yet

- How Chin Engineering: Job Safety AnalysisDocument6 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- Job Safety Analysis: Job Title: Survey Equipment InstallationDocument1 pageJob Safety Analysis: Job Title: Survey Equipment InstallationIhwan AsrulNo ratings yet

- Job Safety Analysis Work Sheet Electrician: Activity Hazards Risk Control Measures ResponsibleDocument2 pagesJob Safety Analysis Work Sheet Electrician: Activity Hazards Risk Control Measures ResponsibleDeny SafariNo ratings yet

- Jha Lin FillingDocument6 pagesJha Lin FillingLuqman OsmanNo ratings yet

- Risk Assessment For Shore ProtectionDocument4 pagesRisk Assessment For Shore ProtectionIndira SriramNo ratings yet

- Abrasive Blasting Works at WTF - 3 Construction Site 2018Document3 pagesAbrasive Blasting Works at WTF - 3 Construction Site 2018AldrinNo ratings yet

- JHA For Crates-Boxes With Potential Hazardous SubstancesDocument4 pagesJHA For Crates-Boxes With Potential Hazardous SubstancesTnarg Ragaw100% (1)

- Enclosed Space EntryDocument5 pagesEnclosed Space EntryAshok Kumar100% (1)

- Encl SPC + RescueDocument3 pagesEncl SPC + Rescuesaurav naskarNo ratings yet

- Enclosed SpacesDocument5 pagesEnclosed Spacesمرتضى جبار السودانيNo ratings yet

- HSE Tool Box TalkDocument47 pagesHSE Tool Box TalkAbdulKather100% (11)

- TM 55 1905 242 14Document1,001 pagesTM 55 1905 242 14mercury7k29750No ratings yet

- JSA Chemicals CleaningDocument2 pagesJSA Chemicals CleaningVijay RajaindranNo ratings yet

- Airboat Safety ManualDocument22 pagesAirboat Safety ManualArabyAbdel Hamed SadekNo ratings yet

- IDC SOP # 16 Check or Replace Valves, Springs or Seat On Mud PumpDocument3 pagesIDC SOP # 16 Check or Replace Valves, Springs or Seat On Mud PumpkareemNo ratings yet

- Job Safety AnalysisDocument22 pagesJob Safety AnalysisAariz ZaidNo ratings yet

- Job Safety Analysis Work Sheet: Arabian Pipeline & Services Company WR # K002849Document20 pagesJob Safety Analysis Work Sheet: Arabian Pipeline & Services Company WR # K002849Barkat Ullah50% (2)

- BOP-08 - (Koomey Unit, Bleed Off Pressure) - RV (1) Jan. '05Document1 pageBOP-08 - (Koomey Unit, Bleed Off Pressure) - RV (1) Jan. '05Abdul Hameed OmarNo ratings yet

- Kimanis Power Project: Job Safety AnalysisDocument6 pagesKimanis Power Project: Job Safety AnalysisLuqman OsmanNo ratings yet

- MARS 227 September 2011Document4 pagesMARS 227 September 2011captkcNo ratings yet

- JSA FormDocument6 pagesJSA FormAjeesh CochinNo ratings yet

- Job Safety AnalysisDocument4 pagesJob Safety AnalysisDedi Apriadi71% (7)

- SOP Plant LPKF Protoflow Reflow Oven EM315 31aug2016Document2 pagesSOP Plant LPKF Protoflow Reflow Oven EM315 31aug2016esfhNo ratings yet

- RA 002 - HFO Line Pressure TestDocument4 pagesRA 002 - HFO Line Pressure Testdassi99100% (1)

- Air Crash Investigations - Loss of Cargo Door - The Near Crash of United Airlines Flight 811From EverandAir Crash Investigations - Loss of Cargo Door - The Near Crash of United Airlines Flight 811No ratings yet

- The Skipper's Pocketbook: A Pocket Database For The Busy SkipperFrom EverandThe Skipper's Pocketbook: A Pocket Database For The Busy SkipperNo ratings yet

- Reporting Format: Format of Ship ReportDocument4 pagesReporting Format: Format of Ship ReportIhwan AsrulNo ratings yet

- Daftar Pengiriman Dokumen - October 14Document2 pagesDaftar Pengiriman Dokumen - October 14Ihwan AsrulNo ratings yet

- Singapore VHF ReportingDocument1 pageSingapore VHF ReportingIhwan AsrulNo ratings yet

- Forecast 1Document1 pageForecast 1Ihwan AsrulNo ratings yet

- Iv. Daily Forecast (06 May - 12 May 2017) For Oyong Terminal Madura ( (07 17' 20.00" S / 113 21' 22" E)Document2 pagesIv. Daily Forecast (06 May - 12 May 2017) For Oyong Terminal Madura ( (07 17' 20.00" S / 113 21' 22" E)Ihwan AsrulNo ratings yet

- Daftar Pengiriman DokumenDocument1 pageDaftar Pengiriman DokumenIhwan AsrulNo ratings yet

- Gangway Air Hose BurstDocument3 pagesGangway Air Hose BurstIhwan AsrulNo ratings yet

- Pt. Cakra Bahana Fso. Surya Putra Jaya: A. Deck DepartementDocument3 pagesPt. Cakra Bahana Fso. Surya Putra Jaya: A. Deck DepartementIhwan AsrulNo ratings yet

- Daftar Pengiriman Dokumen - January 2017Document2 pagesDaftar Pengiriman Dokumen - January 2017Ihwan AsrulNo ratings yet

- Incident Investigation Report: Team Leader: Master Team Member: C/E, C/O, 2/E, 2/O, 3/O, A 3/O Detail EventsDocument1 pageIncident Investigation Report: Team Leader: Master Team Member: C/E, C/O, 2/E, 2/O, 3/O, A 3/O Detail EventsIhwan AsrulNo ratings yet

- Submitted To QSE: Edition 2009 Revision 1 Date: 15 Jul 2009Document2 pagesSubmitted To QSE: Edition 2009 Revision 1 Date: 15 Jul 2009Ihwan AsrulNo ratings yet

- Job Risk Assesment OfftakeDocument7 pagesJob Risk Assesment OfftakeIhwan Asrul100% (1)

- 9812 090 Isd 0705 1 BDocument1 page9812 090 Isd 0705 1 BIhwan AsrulNo ratings yet

- ECDIS Mandatory ECDIS Marine Equipment For Merchant Marine FURUNODocument11 pagesECDIS Mandatory ECDIS Marine Equipment For Merchant Marine FURUNOIhwan AsrulNo ratings yet

- 9812 090 Isd 0705 2 BDocument1 page9812 090 Isd 0705 2 BIhwan AsrulNo ratings yet

- Pts - New Passenger Data Entry Form: Lifting - Balikpapan@bpmigas - Go.idDocument1 pagePts - New Passenger Data Entry Form: Lifting - Balikpapan@bpmigas - Go.idIhwan AsrulNo ratings yet

- 9812 090 Isd 0705 3 BDocument1 page9812 090 Isd 0705 3 BIhwan AsrulNo ratings yet

- Bon TangDocument8 pagesBon TangIhwan AsrulNo ratings yet

- Aco Akbar Masud Mcu 3Document1 pageAco Akbar Masud Mcu 3Ihwan AsrulNo ratings yet

- Seaflex 55 BrochureDocument6 pagesSeaflex 55 BrochurejohnnylakeNo ratings yet

- Sans1507 4Document21 pagesSans1507 4tutsiegpNo ratings yet

- ChromatographyDocument453 pagesChromatographyAlejandroMendozaNo ratings yet

- Competency Exam in Organic ChemistryDocument4 pagesCompetency Exam in Organic ChemistryRaymond Yabut100% (1)

- Comprehensive Coordination ChemistryDocument818 pagesComprehensive Coordination Chemistryrace egrNo ratings yet

- Cyanide Recovery and Detoxification Study On Seabridge Gold's KSM ProjectDocument15 pagesCyanide Recovery and Detoxification Study On Seabridge Gold's KSM ProjectlauramanjarresNo ratings yet

- Local Media2583321454234322918Document26 pagesLocal Media2583321454234322918Blanch Korver SottoNo ratings yet

- Astm A27-03Document4 pagesAstm A27-03Mario RodríguezNo ratings yet

- Total Carbon and Nitrogen Determination in Soil: Application NoteDocument3 pagesTotal Carbon and Nitrogen Determination in Soil: Application Notelaoying qdNo ratings yet

- Astm D7678-17 (2022) - Astm D7678-17 (2022)Document7 pagesAstm D7678-17 (2022) - Astm D7678-17 (2022)Risti Kurnia FajrinNo ratings yet

- Produts and List Prices 2002Document16 pagesProduts and List Prices 2002jonNo ratings yet

- ME 207 - Chapter 5 - P2Document9 pagesME 207 - Chapter 5 - P2rathanNo ratings yet

- Id DrilzoneDocument1 pageId DrilzoneWael El EssawyNo ratings yet

- Lab - PH - VirtualDocument4 pagesLab - PH - VirtualShiyamala SubramaniamNo ratings yet

- ACFrOgDbpWU - FRbZFyZfHiFPC5Ay - LCl1OV1zh5IcvlG4vxJm0MRJZF 11O1Z4DUgJLLByFOpvtEWF9GUpwcOXdufDkkxyCwzWkzT7QuLF8ngyPe R Zy8roOBxxlQ PDFDocument24 pagesACFrOgDbpWU - FRbZFyZfHiFPC5Ay - LCl1OV1zh5IcvlG4vxJm0MRJZF 11O1Z4DUgJLLByFOpvtEWF9GUpwcOXdufDkkxyCwzWkzT7QuLF8ngyPe R Zy8roOBxxlQ PDFgamal90No ratings yet

- DAPUSDocument3 pagesDAPUSLidya AmelianaNo ratings yet

- Validation Part2Document48 pagesValidation Part2gvasNo ratings yet

- Vital Pulp Therapy FinalDocument142 pagesVital Pulp Therapy FinalParamesh NdcNo ratings yet

- Aviation Gasolines: Standard Specification ForDocument8 pagesAviation Gasolines: Standard Specification ForDennise ChicaizaNo ratings yet

- Synthroid Vs Desiccated (Armour) ThyroidDocument3 pagesSynthroid Vs Desiccated (Armour) Thyroidsamyali100_850120056No ratings yet

- PH System Overview2Document13 pagesPH System Overview2Rahmat Habib PohanNo ratings yet

- Week 4 N 5 - Design of Rectangular Beam SectionDocument77 pagesWeek 4 N 5 - Design of Rectangular Beam SectionTeaMeeNo ratings yet

- Secureloc PortalocDocument6 pagesSecureloc PortalocMSMCCANo ratings yet

- Policy Statement: Subject: Flammability Testing of Interior Date: 7-3-13 Initiated By: Policy NoDocument28 pagesPolicy Statement: Subject: Flammability Testing of Interior Date: 7-3-13 Initiated By: Policy NoMichaelNo ratings yet

- 2-D Modeling of Underground Coal Gasification (UCG) : S. Srikantiah, G. Samdani, S. Mahajani, A. Ganesh, P. AghalayamDocument26 pages2-D Modeling of Underground Coal Gasification (UCG) : S. Srikantiah, G. Samdani, S. Mahajani, A. Ganesh, P. AghalayamVishnu UppalakkalNo ratings yet

- ETME205TS2Document1 pageETME205TS2Dishant KumarNo ratings yet

- Cut and Assemble Mineral Crystal Shapes 2Document9 pagesCut and Assemble Mineral Crystal Shapes 2haera haeraNo ratings yet

- Resource Recovery Assessment at A Pulp Mill Wastewater Treatment Plant in UruguayDocument9 pagesResource Recovery Assessment at A Pulp Mill Wastewater Treatment Plant in UruguayElSujeto 999 :3No ratings yet

- PRESCRIBER RxChange v10.6 20130501 Certification Test Scenarios 2013 V 1.0Document9 pagesPRESCRIBER RxChange v10.6 20130501 Certification Test Scenarios 2013 V 1.0Rabindra P.SinghNo ratings yet