Professional Documents

Culture Documents

Design of RCC Slab

Design of RCC Slab

Uploaded by

ZevanyaRolandTualakaCopyright:

Available Formats

You might also like

- Design of WingwallDocument29 pagesDesign of WingwallMar MartillanoNo ratings yet

- Slab Design ExcelDocument6 pagesSlab Design ExcelsahmeduNo ratings yet

- Beam Design by SP 16Document1 pageBeam Design by SP 16Arnab Deb67% (3)

- Continuous Slab Design ProgrammeDocument31 pagesContinuous Slab Design ProgrammeNikhilNo ratings yet

- Slab Design ExcelDocument30 pagesSlab Design Excelwajid ahmadNo ratings yet

- FOOTING DESIGN Excel SheetDocument2 pagesFOOTING DESIGN Excel SheetHarish Ram100% (1)

- Water Tank Base Slab DesignDocument6 pagesWater Tank Base Slab DesignSadeesh Kumar100% (1)

- Base Plate DesignDocument21 pagesBase Plate Designtitir bagchi100% (1)

- Canal Trough Slab Trough Side Wall Road Slab Concrete Steel: Design of Pier With Pier Footing For Canal TroughDocument15 pagesCanal Trough Slab Trough Side Wall Road Slab Concrete Steel: Design of Pier With Pier Footing For Canal TroughSandip UpNo ratings yet

- Brayton Cycle Experiment - Jet EngineDocument10 pagesBrayton Cycle Experiment - Jet EngineAsif MohammedNo ratings yet

- Identification System Kks Chapter I KksDocument280 pagesIdentification System Kks Chapter I KksSupratim PalNo ratings yet

- RCC Doubly Reinforced Beam by Is 456: 2000 (LSM)Document26 pagesRCC Doubly Reinforced Beam by Is 456: 2000 (LSM)mafiapumba67% (3)

- Design of Rectangular RCC Column Using SP 16 SpreadsheetDocument34 pagesDesign of Rectangular RCC Column Using SP 16 SpreadsheetRishika DixitNo ratings yet

- Column Design Calculation PDFDocument2 pagesColumn Design Calculation PDFSamantha0% (1)

- Column Design LSMDocument7 pagesColumn Design LSMnishusaini100% (1)

- Eccentric-Footing 2Document5 pagesEccentric-Footing 2Yash GoyalNo ratings yet

- Design of Short Column (Biaxial Bending)Document3 pagesDesign of Short Column (Biaxial Bending)meenu100% (2)

- Design BookDocument53 pagesDesign BookmollikaminNo ratings yet

- Flat Slab 6 X 6 Ext PNLDocument5 pagesFlat Slab 6 X 6 Ext PNLDarshan Shah100% (1)

- 408010745-Rigid-Pavement-xls CopiedDocument17 pages408010745-Rigid-Pavement-xls CopiedrajNo ratings yet

- Design of Slab (One Way)Document9 pagesDesign of Slab (One Way)anumned100% (1)

- Curved+Beam+by+B C +punmiaDocument34 pagesCurved+Beam+by+B C +punmiaHasanuzzaman PalashNo ratings yet

- One Way Slab DesignDocument10 pagesOne Way Slab DesignBijendra PradhanNo ratings yet

- RCC Design SheetsDocument79 pagesRCC Design Sheetssurendra_panga100% (2)

- 2018 May 29 Circular Tank With WaterDocument4 pages2018 May 29 Circular Tank With WaterPRAKASHNo ratings yet

- Design of Two Way SlabDocument64 pagesDesign of Two Way SlabVINOTHINI100% (1)

- Wind Load Calculation of Gable As Per Is 875Document1 pageWind Load Calculation of Gable As Per Is 875kapil075No ratings yet

- 11.staircase Design Spreadsheet As Per IS 800Document4 pages11.staircase Design Spreadsheet As Per IS 800Mahadev D. Bhandare50% (2)

- Staircase Design IS456-2000Document2 pagesStaircase Design IS456-2000Nitesh Singh100% (1)

- Raft Footing DesignDocument7 pagesRaft Footing DesignPrakash ShresthaNo ratings yet

- Slab DesignDocument28 pagesSlab DesignUlasi IfeanyiNo ratings yet

- Design of RCC Retaining Wall at RelangiDocument18 pagesDesign of RCC Retaining Wall at RelangiD.V.Srinivasa RaoNo ratings yet

- RCC Design SheetsDocument69 pagesRCC Design SheetsFahim H bepari100% (1)

- RCC - Design Excel SheetDocument10 pagesRCC - Design Excel SheetYashas KatugamNo ratings yet

- Design of PurlinsDocument8 pagesDesign of PurlinsLa BeamNo ratings yet

- Beam-Design-R CDocument123 pagesBeam-Design-R CMarkNo ratings yet

- Column Design LSMDocument5 pagesColumn Design LSMjohn cena09No ratings yet

- RCC Column Effective Length As Per Is 456 - 2000Document4 pagesRCC Column Effective Length As Per Is 456 - 2000G.RameshNo ratings yet

- RCC Beam Design Task-01Document29 pagesRCC Beam Design Task-01Mohamed SaheelNo ratings yet

- R.C.C Beam DesignDocument2 pagesR.C.C Beam DesignPankaj Chopra67% (15)

- Isolated Footing DesignDocument5 pagesIsolated Footing DesignMJ AbunagaNo ratings yet

- One Way SlabDocument10 pagesOne Way SlabGayan Indunil100% (1)

- Design ProjectDocument36 pagesDesign Projectveenabalu20No ratings yet

- One Way Slab DesignDocument4 pagesOne Way Slab DesignMario FeghaliNo ratings yet

- Boundary Wall Design VAX LCDocument3 pagesBoundary Wall Design VAX LCShubham KhareNo ratings yet

- RCDC Plinth BeamsDocument25 pagesRCDC Plinth BeamsEr Suresh Kumar50% (2)

- Cantilever Footing 1Document8 pagesCantilever Footing 1Hafiz Kamarudin100% (2)

- L Shaped Reatining WAll With HORZONTAL Bach FillDocument29 pagesL Shaped Reatining WAll With HORZONTAL Bach Fillsarveshfdk48100% (2)

- Strap Footing Design As Per Is 456Document4 pagesStrap Footing Design As Per Is 456Sanjay Rokka75% (4)

- Design of RCC BuildingDocument5 pagesDesign of RCC Buildingshreejay maneNo ratings yet

- Strap Footing Sample PDFDocument6 pagesStrap Footing Sample PDFRegan Tandukar44% (9)

- Design of Isolated FootingDocument10 pagesDesign of Isolated Footingramdev panditNo ratings yet

- Pure Water SumpDocument8 pagesPure Water SumpVarad Sonawadekar100% (1)

- Design of BeamDocument17 pagesDesign of BeamAbhinav Chowdary100% (2)

- Design of Eccentric Loaded Footing Using TeddsDocument7 pagesDesign of Eccentric Loaded Footing Using TeddsRoberto Catalani100% (1)

- Slab Design Calculation: f (5* f A /8 A βDocument1 pageSlab Design Calculation: f (5* f A /8 A βchannajayamangala100% (1)

- Design of Continuos Beam As Per IS 456-2000 1) Design Data: Eff CK 2 2Document5 pagesDesign of Continuos Beam As Per IS 456-2000 1) Design Data: Eff CK 2 2khaniskhan03No ratings yet

- StariDocument28 pagesStariBikal BastakotiNo ratings yet

- S4 - Roof DeckDocument2 pagesS4 - Roof DeckJoemarie MartinezNo ratings yet

- SRB DesignDocument3 pagesSRB DesignRam LangheNo ratings yet

- Escaltor Cantilever Beam: Load CalculationDocument6 pagesEscaltor Cantilever Beam: Load CalculationJAYASHREEBHUVANANo ratings yet

- 2F Floor (S4)Document6 pages2F Floor (S4)Zulkiflee TaugNo ratings yet

- Hetauda Raft DesignDocument92 pagesHetauda Raft DesignSurendra MaharjanNo ratings yet

- Energy PlusDocument29 pagesEnergy Plusbloodpaint87No ratings yet

- PCAB List of Licensed Contractors For CFY 2017-2018 As of 04 Dec 2017 - WebDocument734 pagesPCAB List of Licensed Contractors For CFY 2017-2018 As of 04 Dec 2017 - WebGenesis Castro (Engr. Pianista)No ratings yet

- Classicalgases PDFDocument30 pagesClassicalgases PDFingarionNo ratings yet

- Lever Launchers - Art InstructableDocument29 pagesLever Launchers - Art Instructableapi-519936814No ratings yet

- Theory of Machines Interview Questions and AnswersDocument11 pagesTheory of Machines Interview Questions and Answerskumarmohit0203No ratings yet

- 4-Oil Based Muds 1Document15 pages4-Oil Based Muds 1Vamsee KrishnaNo ratings yet

- Lecture 7: Lti Odes & The Matrix ExponentialDocument5 pagesLecture 7: Lti Odes & The Matrix ExponentialBabiiMuffinkNo ratings yet

- Gregory Hodowanec Rhysmonic Cosmology Treatise)Document27 pagesGregory Hodowanec Rhysmonic Cosmology Treatise)wayne thompsonNo ratings yet

- Properly Calculate Vessel and Piping Wall Temperatures During Depressuring and Relief - G.A. MelhemDocument20 pagesProperly Calculate Vessel and Piping Wall Temperatures During Depressuring and Relief - G.A. MelhemDavid Smith50% (2)

- Sinker EdmDocument23 pagesSinker Edmdario larrosaNo ratings yet

- Line Joining S (Yield Strength of The Material) On Mean Stress Axis andDocument19 pagesLine Joining S (Yield Strength of The Material) On Mean Stress Axis andgauravkumar bhandariNo ratings yet

- Control System Lab: Practical ManualDocument9 pagesControl System Lab: Practical ManualVats AlokNo ratings yet

- Chemistry - Ch3 - Part - I-UNIVERSITY HUB PAKISTANDocument6 pagesChemistry - Ch3 - Part - I-UNIVERSITY HUB PAKISTANMuawwiz Ali YousufNo ratings yet

- Using Emrax Motors For EvDocument4 pagesUsing Emrax Motors For Evgn_ro100% (1)

- R09-Fatigue, Creep and Fracture MechanicsDocument2 pagesR09-Fatigue, Creep and Fracture MechanicsKiran KumarNo ratings yet

- Wind PowerDocument77 pagesWind PowersreeramNo ratings yet

- Dme Unit-1Document34 pagesDme Unit-1Sathis KumarNo ratings yet

- Past Paper Questions ElectromagnetismDocument11 pagesPast Paper Questions ElectromagnetismruukiNo ratings yet

- CE00036-3-Data Communication Systems Individual Assignment Page 1 of 34Document34 pagesCE00036-3-Data Communication Systems Individual Assignment Page 1 of 34Prem PandeyNo ratings yet

- Pour CupsDocument2 pagesPour CupsskluxNo ratings yet

- Mechanical Behaviour of MaterialsDocument2 pagesMechanical Behaviour of MaterialsMyameSirameNo ratings yet

- Quantel Optimis II Service Manual 61-67Document7 pagesQuantel Optimis II Service Manual 61-67Vladimir LevchenkoNo ratings yet

- Experiment 1: Thin Layer Chromatography Femi Ajayi 8266716 CHM1321 Lab 4 January 26 2016 Lab Instructor: Indee Ranasinghe Professor: William OgilvieDocument12 pagesExperiment 1: Thin Layer Chromatography Femi Ajayi 8266716 CHM1321 Lab 4 January 26 2016 Lab Instructor: Indee Ranasinghe Professor: William OgilvieDanielle SarpongNo ratings yet

- Geiger Muller Counter To Detect X-RaysDocument7 pagesGeiger Muller Counter To Detect X-RaysSuraj M NadarNo ratings yet

- Effect On Concrete Properties After Substituting Fine Aggregate by Crushed Groundnut Shells and Addition of Sugarcane Bagasse AshDocument5 pagesEffect On Concrete Properties After Substituting Fine Aggregate by Crushed Groundnut Shells and Addition of Sugarcane Bagasse AshEditor IJTSRDNo ratings yet

- Semiconductor Defect ClassificationDocument6 pagesSemiconductor Defect ClassificationChang Jae LeeNo ratings yet

- How Magnetic Induction Lamps WorkDocument4 pagesHow Magnetic Induction Lamps WorkMarlon BoucaudNo ratings yet

Design of RCC Slab

Design of RCC Slab

Uploaded by

ZevanyaRolandTualakaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of RCC Slab

Design of RCC Slab

Uploaded by

ZevanyaRolandTualakaCopyright:

Available Formats

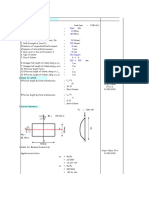

SECTION (MM)

PI (constant)

LONG SPAN

SHORT SPAN

COVER

MATERIAL:

GRADE OF CONCRETE

GRADE OF STEEL - MAIN

GRADE OF STEEL - SECONDARY

LOADS (Kn/m2) :

LIVE LOAD

FF LOAD

PARTITION LOAD

MISCELLANEOUS LOAD

SAFETY FACTOR:

FORCES

CONDITION:

R

3.14159265

6700

4300

15

M15

Fe 415

Fe 415

3.00

0.60

0

0

1.50

3

ASSUME OVERALL THICKNESS OF SLAB

EFFECTIVE DEPTH AS PER DESIGN

ADOPT EFFECTIVE DEPTH AS

OVERALL DEPTH

125 mm

79.72 mm

105 mm

125 mm

REINFORCEMENT:

DIA OF MAIN REINFORCEMENT IN MM

DIA OF DISTRIBUTION REINFORCEMENT IN MM

DIA OF TORSION REINFORCEMENT IN MM

10

8

8

Reinforcement in middle strip:

Steel along short span:

Dia of reinforcement

Spacing of bars c/c

PROVIDE SPACING OF BARS c/c

Total area provided

754

10

104.16

100

mm2

mm

mm

mm

O.K.

785.4 mm2

Area of tension steel Aty along long

span:

226.08 mm2

since required area is greater than

minimum required area, hence o.k.,

provide area

Dia of reinforcement

Spacing of bars c/c

PROVIDE SPACING OF BARS c/c

226.08

8

222.35

150

Total area provided

335.13 mm2

mm2

mm

mm

mm

O.K.

Reinforcement in edge strip:

Minimum reinforcement

Dia of reinforcement

Along short span :

Spacing of bars c/c

PROVIDE SPACING OF BARS c/c

150.00 mm2

8 mm

335.13 mm

200 mm

Revise

O.K.

Total area provided

Along short span :

Spacing of bars c/c

PROVIDE SPACING OF BARS c/c

251.35 mm2

O.K.

335.13 mm

300 mm

O.K.

O.K.

Total area provided

167.57 mm2

O.K.

Corner Reinforcement:

Length of corner reinforcement

Area of each layer of reinforcement

Dia of reinforcement

Spacing of bars c/c

876

566

8

83

mm

mm2

mm

mm

Check for shear at short edge:

Nominal shear stress,v

In slabs c'

0.21 N/mm2

0.321 N/mm2

The Slab panel is SAFE in shear.

Check for development length at short edge:

Dia of bar used

8 mm

8.13 mm

Dia of bar used is less than required one , hence o.k.

Check for deflection:

Allowable L/d =

Actual L/d

Deflection requirements are O.K.

44.8

41.95

DESIGN OF R.C.C. SLAB (IS456-1978)

DESIGN DATA :

SECTION (MM):

LONG SPAN, Ly

SHORT SPAN, Lx

COVER

MATERIAL:

GRADE OF CONCRETE

GRADE OF STEEL - MAIN

GRADE OF STEEL - SECONDARY

LOADS (Kn/m2) :

LIVE LOAD

FF LOAD

PARTITION LOAD

MISCELLANEOUS LOAD

SAFETY FACTOR:

FORCES

6700

4300

15

M15

Fe 415

Fe 415

3.00

0.60

0

0

1.50

CONDITION:

RESTRAINED SLAB

ONE LONG EDGE DISCONTINUOUS

DESIGN:

ck =

15 N/mm2

y(main) =

415 N/mm2

y (secondary) =

N.A. factor =

415 N/mm2

0.48

1.56

Ly / Lx =

This is two-way slab.

Assume overall thicness of slab, D

Effective depth, d

Effective spans will be

lx = Lx + d

ly = Ly + d

ly / lx =

Moments along short span Mx and along

long span My are given by :

Mx = x w lx

My = y w lx

Corresponding ly /lx,

For positive moment at mid span

x =

y =

For negative moment at continuous edge

x =

y =

125 mm

105 mm

4.405 m

6.805 m

1.5

0.0512

0.028

0.0672

0.037

DESIGNED & DEVELOPED BY IDCS BASTI, INDIA

contd. On next page

DESIGN OF R.C.C. SLAB (IS456-1978)

Dead load of slab, wd = D x 25

3.13 kN/m2

Live load, wl

3.00 kN/m2

Finish load, wf

0.60 kN/m2

Partition Load, wp

0.00 kN/m2

Miscellaneous load, w'

0.00 kN/m2

Total load, w = wd+wl+wf+wp+w'

6.73 kN/m2

Factored load, wu = safety factor x w

Positive moment at mid span

Mx = x w lx

My = y w lx

For negative moment at continuous edge

Mx = x w lx

My = y w lx

10.09 kN/m2

10.024 kNm/m

5.482 kNm/m

13.157 kNm/m

7.244 kNm/m

The effective depth shall be designed for

maximum of moment,i.e.

13.157

The effective depth d of the slab is given by

0.138ckbd2

d =

79.72

Adopt effective depth,d

105

Adopt overall depth,D

125

Along the long edge:

Length 0f the middle strip

5.10

Length 0f the edge strip

0.851

Along the short edge:

Length 0f the middle strip

3.304

Length 0f the edge strip

0.551

Minimum area of steel

0.12%

Hence, Minimum area of steel

Reinforcement in middle strip:

Steel along short span:

Atx = 0.36 ck b Xm / 0.87y

Dia of reinforcement

Area of bar

Spacing of bars c/c

Providing spacing of bars c/c

Total area provided, Atxp

Area of tension steel Aty along long

span:

d' = d - dia of bar

a = 0.87 x y2 / ck x 1000

b = 0.87 x y x d'

c = Mx

Aty =( bb-4ac) / 2a

kNm/m

mm

mm

mm

m

m

m

m

150.00 mm2

754 mm2

10 mm

78.54 mm2

104.16 mm

100 mm

O.K.

785.4 mm2

O.K.

95 mm

9.989

34299.750

7244000

226.08 mm2

DESIGNED & DEVELOPED BY IDCS BASTI, INDIA

contd. On next page

DESIGN OF R.C.C. SLAB (IS456-1978)

since required area is greater than

minimum required area, hence o.k.,

provide area

Dia of reinforcement

226.08

mm2

8 mm

Area of bar

Spacing of bars c/c

Providing spacing of bars c/c

50.27 mm2

222.35 mm

150 mm

O.K.

Total area provided, Atyp

335.13 mm2

O.K.

Curtail alternate bars at 1/10 th of effective span in each

direction in accordance with clause C-2.1.1 of the Code.

Provide 50% of the maximum positive steel at top near the

supports to resist bending moment due to partial fixity. This

steel is provided in length 0.1l from the face of supports.

Reinforcement in edge strip:

Minimum reinforcement =

Dia of reinforcement

Area of bar

Along short span :

Spacing of bars c/c

Providing spacing of bars c/c

150.00 mm2

8

50.27 mm2

335.13 mm

200 mm

Revise

O.K.

Total area provided, Atyp

Along long span :

Spacing of bars c/c

Providing spacing of bars c/c

251.35 mm2

O.K.

335.13 mm

300 mm

O.K.

O.K.

Total area provided, Atyp

Corner reinforcement:

Length of corner reinforcement=0.2 lx

167.57 mm2

O.K.

876 mm

Area of each layer of reinforcement= 75%

0f area required for maximum midspan

moment

Dia of reinforcement

Area of bar

no. of bars per rm

Spacing of bars c/c

566

8

50.27

12

83

Check for shear at short edge:

Maximum SF, Vu = 0.5wLx

21.69 kN/m

Nominal shear stress,v= Vu/bd

Percent tension steel = 100As / bd

Shear strength of concrete,c =

mm2

mm

mm2

mm

0.21 N/mm2

0.11 %

DESIGNED & DEVELOPED BY IDCS BASTI, INDIA

contd. On next page

DESIGN OF R.C.C. SLAB (IS456-1978)

= 0.8 ck / 6.89 Pt > 1.0

c = 0.85/6 0.80ck ((1+5) -1)

In slabs c' = k c

The Slab panel is SAFE in shear.

Check for development length at short edge:

d' =

Moment of resistance,

M1 = 0.87y At(d'-(y At / ck b))

Vu =

Anchorage value of bars,Lo =60+ 8

Development length, Ld = 56

Ld 1.3 M1/Vu + Lo

56 1.3 M1/Vu + Lo

15.833

0.247 N/mm2

0.321 O.K.

96 mm

5527464.11 Nmm

21.69 kN

124 mm

455.29 mm

8.13 mm

Dia of bar used is less than required one

, hence o.k.

Check for deflection:

Percent tension steel at midspan =

100As / bd

=

=

=

=

Allowable L/d =

Actual L/d =

Deflection requirements are O.K.

0.32

1.4

1

1

32

44.8

41.95

You might also like

- Design of WingwallDocument29 pagesDesign of WingwallMar MartillanoNo ratings yet

- Slab Design ExcelDocument6 pagesSlab Design ExcelsahmeduNo ratings yet

- Beam Design by SP 16Document1 pageBeam Design by SP 16Arnab Deb67% (3)

- Continuous Slab Design ProgrammeDocument31 pagesContinuous Slab Design ProgrammeNikhilNo ratings yet

- Slab Design ExcelDocument30 pagesSlab Design Excelwajid ahmadNo ratings yet

- FOOTING DESIGN Excel SheetDocument2 pagesFOOTING DESIGN Excel SheetHarish Ram100% (1)

- Water Tank Base Slab DesignDocument6 pagesWater Tank Base Slab DesignSadeesh Kumar100% (1)

- Base Plate DesignDocument21 pagesBase Plate Designtitir bagchi100% (1)

- Canal Trough Slab Trough Side Wall Road Slab Concrete Steel: Design of Pier With Pier Footing For Canal TroughDocument15 pagesCanal Trough Slab Trough Side Wall Road Slab Concrete Steel: Design of Pier With Pier Footing For Canal TroughSandip UpNo ratings yet

- Brayton Cycle Experiment - Jet EngineDocument10 pagesBrayton Cycle Experiment - Jet EngineAsif MohammedNo ratings yet

- Identification System Kks Chapter I KksDocument280 pagesIdentification System Kks Chapter I KksSupratim PalNo ratings yet

- RCC Doubly Reinforced Beam by Is 456: 2000 (LSM)Document26 pagesRCC Doubly Reinforced Beam by Is 456: 2000 (LSM)mafiapumba67% (3)

- Design of Rectangular RCC Column Using SP 16 SpreadsheetDocument34 pagesDesign of Rectangular RCC Column Using SP 16 SpreadsheetRishika DixitNo ratings yet

- Column Design Calculation PDFDocument2 pagesColumn Design Calculation PDFSamantha0% (1)

- Column Design LSMDocument7 pagesColumn Design LSMnishusaini100% (1)

- Eccentric-Footing 2Document5 pagesEccentric-Footing 2Yash GoyalNo ratings yet

- Design of Short Column (Biaxial Bending)Document3 pagesDesign of Short Column (Biaxial Bending)meenu100% (2)

- Design BookDocument53 pagesDesign BookmollikaminNo ratings yet

- Flat Slab 6 X 6 Ext PNLDocument5 pagesFlat Slab 6 X 6 Ext PNLDarshan Shah100% (1)

- 408010745-Rigid-Pavement-xls CopiedDocument17 pages408010745-Rigid-Pavement-xls CopiedrajNo ratings yet

- Design of Slab (One Way)Document9 pagesDesign of Slab (One Way)anumned100% (1)

- Curved+Beam+by+B C +punmiaDocument34 pagesCurved+Beam+by+B C +punmiaHasanuzzaman PalashNo ratings yet

- One Way Slab DesignDocument10 pagesOne Way Slab DesignBijendra PradhanNo ratings yet

- RCC Design SheetsDocument79 pagesRCC Design Sheetssurendra_panga100% (2)

- 2018 May 29 Circular Tank With WaterDocument4 pages2018 May 29 Circular Tank With WaterPRAKASHNo ratings yet

- Design of Two Way SlabDocument64 pagesDesign of Two Way SlabVINOTHINI100% (1)

- Wind Load Calculation of Gable As Per Is 875Document1 pageWind Load Calculation of Gable As Per Is 875kapil075No ratings yet

- 11.staircase Design Spreadsheet As Per IS 800Document4 pages11.staircase Design Spreadsheet As Per IS 800Mahadev D. Bhandare50% (2)

- Staircase Design IS456-2000Document2 pagesStaircase Design IS456-2000Nitesh Singh100% (1)

- Raft Footing DesignDocument7 pagesRaft Footing DesignPrakash ShresthaNo ratings yet

- Slab DesignDocument28 pagesSlab DesignUlasi IfeanyiNo ratings yet

- Design of RCC Retaining Wall at RelangiDocument18 pagesDesign of RCC Retaining Wall at RelangiD.V.Srinivasa RaoNo ratings yet

- RCC Design SheetsDocument69 pagesRCC Design SheetsFahim H bepari100% (1)

- RCC - Design Excel SheetDocument10 pagesRCC - Design Excel SheetYashas KatugamNo ratings yet

- Design of PurlinsDocument8 pagesDesign of PurlinsLa BeamNo ratings yet

- Beam-Design-R CDocument123 pagesBeam-Design-R CMarkNo ratings yet

- Column Design LSMDocument5 pagesColumn Design LSMjohn cena09No ratings yet

- RCC Column Effective Length As Per Is 456 - 2000Document4 pagesRCC Column Effective Length As Per Is 456 - 2000G.RameshNo ratings yet

- RCC Beam Design Task-01Document29 pagesRCC Beam Design Task-01Mohamed SaheelNo ratings yet

- R.C.C Beam DesignDocument2 pagesR.C.C Beam DesignPankaj Chopra67% (15)

- Isolated Footing DesignDocument5 pagesIsolated Footing DesignMJ AbunagaNo ratings yet

- One Way SlabDocument10 pagesOne Way SlabGayan Indunil100% (1)

- Design ProjectDocument36 pagesDesign Projectveenabalu20No ratings yet

- One Way Slab DesignDocument4 pagesOne Way Slab DesignMario FeghaliNo ratings yet

- Boundary Wall Design VAX LCDocument3 pagesBoundary Wall Design VAX LCShubham KhareNo ratings yet

- RCDC Plinth BeamsDocument25 pagesRCDC Plinth BeamsEr Suresh Kumar50% (2)

- Cantilever Footing 1Document8 pagesCantilever Footing 1Hafiz Kamarudin100% (2)

- L Shaped Reatining WAll With HORZONTAL Bach FillDocument29 pagesL Shaped Reatining WAll With HORZONTAL Bach Fillsarveshfdk48100% (2)

- Strap Footing Design As Per Is 456Document4 pagesStrap Footing Design As Per Is 456Sanjay Rokka75% (4)

- Design of RCC BuildingDocument5 pagesDesign of RCC Buildingshreejay maneNo ratings yet

- Strap Footing Sample PDFDocument6 pagesStrap Footing Sample PDFRegan Tandukar44% (9)

- Design of Isolated FootingDocument10 pagesDesign of Isolated Footingramdev panditNo ratings yet

- Pure Water SumpDocument8 pagesPure Water SumpVarad Sonawadekar100% (1)

- Design of BeamDocument17 pagesDesign of BeamAbhinav Chowdary100% (2)

- Design of Eccentric Loaded Footing Using TeddsDocument7 pagesDesign of Eccentric Loaded Footing Using TeddsRoberto Catalani100% (1)

- Slab Design Calculation: f (5* f A /8 A βDocument1 pageSlab Design Calculation: f (5* f A /8 A βchannajayamangala100% (1)

- Design of Continuos Beam As Per IS 456-2000 1) Design Data: Eff CK 2 2Document5 pagesDesign of Continuos Beam As Per IS 456-2000 1) Design Data: Eff CK 2 2khaniskhan03No ratings yet

- StariDocument28 pagesStariBikal BastakotiNo ratings yet

- S4 - Roof DeckDocument2 pagesS4 - Roof DeckJoemarie MartinezNo ratings yet

- SRB DesignDocument3 pagesSRB DesignRam LangheNo ratings yet

- Escaltor Cantilever Beam: Load CalculationDocument6 pagesEscaltor Cantilever Beam: Load CalculationJAYASHREEBHUVANANo ratings yet

- 2F Floor (S4)Document6 pages2F Floor (S4)Zulkiflee TaugNo ratings yet

- Hetauda Raft DesignDocument92 pagesHetauda Raft DesignSurendra MaharjanNo ratings yet

- Energy PlusDocument29 pagesEnergy Plusbloodpaint87No ratings yet

- PCAB List of Licensed Contractors For CFY 2017-2018 As of 04 Dec 2017 - WebDocument734 pagesPCAB List of Licensed Contractors For CFY 2017-2018 As of 04 Dec 2017 - WebGenesis Castro (Engr. Pianista)No ratings yet

- Classicalgases PDFDocument30 pagesClassicalgases PDFingarionNo ratings yet

- Lever Launchers - Art InstructableDocument29 pagesLever Launchers - Art Instructableapi-519936814No ratings yet

- Theory of Machines Interview Questions and AnswersDocument11 pagesTheory of Machines Interview Questions and Answerskumarmohit0203No ratings yet

- 4-Oil Based Muds 1Document15 pages4-Oil Based Muds 1Vamsee KrishnaNo ratings yet

- Lecture 7: Lti Odes & The Matrix ExponentialDocument5 pagesLecture 7: Lti Odes & The Matrix ExponentialBabiiMuffinkNo ratings yet

- Gregory Hodowanec Rhysmonic Cosmology Treatise)Document27 pagesGregory Hodowanec Rhysmonic Cosmology Treatise)wayne thompsonNo ratings yet

- Properly Calculate Vessel and Piping Wall Temperatures During Depressuring and Relief - G.A. MelhemDocument20 pagesProperly Calculate Vessel and Piping Wall Temperatures During Depressuring and Relief - G.A. MelhemDavid Smith50% (2)

- Sinker EdmDocument23 pagesSinker Edmdario larrosaNo ratings yet

- Line Joining S (Yield Strength of The Material) On Mean Stress Axis andDocument19 pagesLine Joining S (Yield Strength of The Material) On Mean Stress Axis andgauravkumar bhandariNo ratings yet

- Control System Lab: Practical ManualDocument9 pagesControl System Lab: Practical ManualVats AlokNo ratings yet

- Chemistry - Ch3 - Part - I-UNIVERSITY HUB PAKISTANDocument6 pagesChemistry - Ch3 - Part - I-UNIVERSITY HUB PAKISTANMuawwiz Ali YousufNo ratings yet

- Using Emrax Motors For EvDocument4 pagesUsing Emrax Motors For Evgn_ro100% (1)

- R09-Fatigue, Creep and Fracture MechanicsDocument2 pagesR09-Fatigue, Creep and Fracture MechanicsKiran KumarNo ratings yet

- Wind PowerDocument77 pagesWind PowersreeramNo ratings yet

- Dme Unit-1Document34 pagesDme Unit-1Sathis KumarNo ratings yet

- Past Paper Questions ElectromagnetismDocument11 pagesPast Paper Questions ElectromagnetismruukiNo ratings yet

- CE00036-3-Data Communication Systems Individual Assignment Page 1 of 34Document34 pagesCE00036-3-Data Communication Systems Individual Assignment Page 1 of 34Prem PandeyNo ratings yet

- Pour CupsDocument2 pagesPour CupsskluxNo ratings yet

- Mechanical Behaviour of MaterialsDocument2 pagesMechanical Behaviour of MaterialsMyameSirameNo ratings yet

- Quantel Optimis II Service Manual 61-67Document7 pagesQuantel Optimis II Service Manual 61-67Vladimir LevchenkoNo ratings yet

- Experiment 1: Thin Layer Chromatography Femi Ajayi 8266716 CHM1321 Lab 4 January 26 2016 Lab Instructor: Indee Ranasinghe Professor: William OgilvieDocument12 pagesExperiment 1: Thin Layer Chromatography Femi Ajayi 8266716 CHM1321 Lab 4 January 26 2016 Lab Instructor: Indee Ranasinghe Professor: William OgilvieDanielle SarpongNo ratings yet

- Geiger Muller Counter To Detect X-RaysDocument7 pagesGeiger Muller Counter To Detect X-RaysSuraj M NadarNo ratings yet

- Effect On Concrete Properties After Substituting Fine Aggregate by Crushed Groundnut Shells and Addition of Sugarcane Bagasse AshDocument5 pagesEffect On Concrete Properties After Substituting Fine Aggregate by Crushed Groundnut Shells and Addition of Sugarcane Bagasse AshEditor IJTSRDNo ratings yet

- Semiconductor Defect ClassificationDocument6 pagesSemiconductor Defect ClassificationChang Jae LeeNo ratings yet

- How Magnetic Induction Lamps WorkDocument4 pagesHow Magnetic Induction Lamps WorkMarlon BoucaudNo ratings yet