Professional Documents

Culture Documents

User S Guide Title Pro Dialog Control 4 For Air Water Cooled Chillers Series 30 GX HXC Version 2 PDF

User S Guide Title Pro Dialog Control 4 For Air Water Cooled Chillers Series 30 GX HXC Version 2 PDF

Uploaded by

mquaiottiCopyright:

Available Formats

You might also like

- McQuay HallScrew HS-3100 Series Compressor Service ManualDocument82 pagesMcQuay HallScrew HS-3100 Series Compressor Service ManualMicha W.67% (12)

- 06na660027 99ta526307Document41 pages06na660027 99ta526307mkct100% (1)

- Service Bulletin: SUBJECT: 19XR Split Ring Diffuser Assembly and SetupDocument18 pagesService Bulletin: SUBJECT: 19XR Split Ring Diffuser Assembly and SetupANGEL MURILLO100% (1)

- Comp (1) RepaireDocument14 pagesComp (1) RepaireKalimulla Shaik100% (8)

- PFS Single Screw Water Cooled Chiller: Service ManualDocument142 pagesPFS Single Screw Water Cooled Chiller: Service Manualmk saravanan0% (1)

- Manual of 06naDocument35 pagesManual of 06naKannan Krishnamoorthy100% (8)

- RLC-SVD02B-EN New Liquid Level SensorDocument4 pagesRLC-SVD02B-EN New Liquid Level Sensorluis100% (3)

- 30 Series IssuesDocument73 pages30 Series Issuesnansusan100% (6)

- PasswörterDocument3 pagesPasswörterAnonymous oGAS6Y100% (1)

- Rtaa Svd01a en - 01012004Document10 pagesRtaa Svd01a en - 01012004alcomech100% (3)

- Tabela Fator K - VAV Trox PDFDocument2 pagesTabela Fator K - VAV Trox PDFmquaiottiNo ratings yet

- Tabela Fator K - VAV TroxDocument2 pagesTabela Fator K - VAV TroxmquaiottiNo ratings yet

- C0319 Frame 3 Rolling Element Bearing Replacement-MARUMADocument8 pagesC0319 Frame 3 Rolling Element Bearing Replacement-MARUMAANGEL MURILLONo ratings yet

- 30ka Iom 6-2-19Document59 pages30ka Iom 6-2-19Athikom Ton Kongsup100% (1)

- Chiller Manual Pro DialogDocument36 pagesChiller Manual Pro DialogLuciano Lopes Simões100% (1)

- Chiller CodesDocument1 pageChiller CodesBaltik2672No ratings yet

- York Air Cooled Screw Liquid Chillers (Style G)Document120 pagesYork Air Cooled Screw Liquid Chillers (Style G)Braun-installations100% (1)

- Comp Internal PartsDocument2 pagesComp Internal PartsWidya Putra100% (4)

- RTHD and Rtac: Diagnostic Troubleshooting RepairDocument74 pagesRTHD and Rtac: Diagnostic Troubleshooting RepairMarko BukovčanNo ratings yet

- 06na NW Parts BreakdownDocument14 pages06na NW Parts BreakdownAmaurys Centeno100% (8)

- 160.00-m3 Vs Oil PumpDocument16 pages160.00-m3 Vs Oil PumpArshad Mahmood100% (2)

- Chha280 RTHB300Document7 pagesChha280 RTHB300air688No ratings yet

- Carrier S.A. Liste de Pieces Spare Parts List: REF: 30HXC175-A-901 - EE - Date: 03/10/00Document1 pageCarrier S.A. Liste de Pieces Spare Parts List: REF: 30HXC175-A-901 - EE - Date: 03/10/00vickers100% (2)

- Hss 3200 App Iss 2.3 07 11Document58 pagesHss 3200 App Iss 2.3 07 11Luis Carlos80% (5)

- Chiiler CodesDocument2 pagesChiiler Codesadylazar788% (8)

- Rt-Svb17a-E4 Rtac Heater ReplacementDocument4 pagesRt-Svb17a-E4 Rtac Heater ReplacementPatrick100% (1)

- Motors Test InBITZERDocument4 pagesMotors Test InBITZERAgus CahyonoNo ratings yet

- MAQUET CARDIOHELP Disposables HLS - Module - Advanced PDFDocument2 pagesMAQUET CARDIOHELP Disposables HLS - Module - Advanced PDFXavi AnpiNo ratings yet

- User's Guide Title Pro-Dialog Control 4 For Air & Water Cooled Chillers Series 30 GX & HXC Version 2Document100 pagesUser's Guide Title Pro-Dialog Control 4 For Air & Water Cooled Chillers Series 30 GX & HXC Version 2vitor4santos_6100% (3)

- Carlyle 104mm Screw-RefrigDocument37 pagesCarlyle 104mm Screw-RefrigMiguel Ángel Puche MoralesNo ratings yet

- RTAA 100tr-SB-18 Lip Seal FailuresDocument4 pagesRTAA 100tr-SB-18 Lip Seal FailuresWidya Putra100% (1)

- 19 XR Pic 2 e 19 XR Pic 3, Um e Dois Estágios.Document122 pages19 XR Pic 2 e 19 XR Pic 3, Um e Dois Estágios.Matheus Ribeiro Lemes100% (2)

- YORK YVAA Air Cooled VSD Chiller Presentation Part 1Document40 pagesYORK YVAA Air Cooled VSD Chiller Presentation Part 1iga9481100% (4)

- UCM-CLD Set Up L80 - SB - 050 - EDocument9 pagesUCM-CLD Set Up L80 - SB - 050 - EEvgeniy MaslovNo ratings yet

- YAEP Parts ListDocument40 pagesYAEP Parts ListRadwan AL TrougNo ratings yet

- J An e Hall Screw Compressor Model 4200 o and M Manual PDFDocument86 pagesJ An e Hall Screw Compressor Model 4200 o and M Manual PDFpraveen kumar vengadasamy100% (1)

- 30GX and 30HXC Series Controls - ManualDocument36 pages30GX and 30HXC Series Controls - ManualMahmoud Mohamed67% (3)

- Compressors Repair KitsDocument10 pagesCompressors Repair KitsfrigoremontNo ratings yet

- 160.00-M3 VS Oil Pump PDFDocument16 pages160.00-M3 VS Oil Pump PDFArshad Mahmood100% (1)

- 30XA WIRING 30xa-1w PDFDocument20 pages30XA WIRING 30xa-1w PDFKumar sssssNo ratings yet

- 160 78-O1Document28 pages160 78-O1George100% (1)

- Set-Up Guide and General Troubleshooting Information For The S811 Solid State StarterDocument16 pagesSet-Up Guide and General Troubleshooting Information For The S811 Solid State Starteralkmind100% (3)

- Trane Rtaa en Rtab r22 Eng2Document32 pagesTrane Rtaa en Rtab r22 Eng2jefhdez67% (3)

- 30XA Chiller CatalogDocument18 pages30XA Chiller CatalogKrishnan Govindaraj100% (1)

- 160 73-rp2Document64 pages160 73-rp2Ali Muzzafar100% (1)

- York Max-E Model YRDocument168 pagesYork Max-E Model YRmarco_christoforidis100% (6)

- New Orings and New Shaft Seal PNsDocument3 pagesNew Orings and New Shaft Seal PNsMahmoud Mohamed0% (1)

- Renewal Parts YK (Stype F)Document56 pagesRenewal Parts YK (Stype F)Thang TV100% (2)

- 160.76-O2 (1018) OperationDocument210 pages160.76-O2 (1018) Operationajcno100% (1)

- Mnual Compressor Parafuso 06NADocument33 pagesMnual Compressor Parafuso 06NADeco Dluxe100% (4)

- Dunham Bush DCLC R134ADocument6 pagesDunham Bush DCLC R134Agerald077No ratings yet

- Rtaa IomDocument140 pagesRtaa IomFabian Lopez100% (1)

- Comp Carly Scre Refrig 2004Document52 pagesComp Carly Scre Refrig 2004Deco DluxeNo ratings yet

- A11-019 Toshiba R410Document241 pagesA11-019 Toshiba R410list16947No ratings yet

- Manual Compressor Sigma Control, EnglishDocument151 pagesManual Compressor Sigma Control, EnglishАлександр ЩербаковNo ratings yet

- Model 1050 ManualDocument170 pagesModel 1050 ManualExatron Inc.No ratings yet

- Narkomed 6000 Anesthesia Machine Service ManualDocument518 pagesNarkomed 6000 Anesthesia Machine Service Manualjonathan morales labarca100% (5)

- Aib Ga11-30cDocument40 pagesAib Ga11-30ctheloniussherek100% (1)

- 20142400Document40 pages20142400Max BibikovNo ratings yet

- pd4 Ugx1Document21 pagespd4 Ugx1sarcitoNo ratings yet

- SHRMe Service Manual PDFDocument334 pagesSHRMe Service Manual PDFSohail Ahmed0% (1)

- Aib Ga30-55cDocument42 pagesAib Ga30-55cJose CoelhoNo ratings yet

- SM Printer Unit Ir6000Document369 pagesSM Printer Unit Ir6000ADVC TECHNo ratings yet

- Tecnico Mvd-V5x Cl23300-307 enDocument105 pagesTecnico Mvd-V5x Cl23300-307 enmquaiottiNo ratings yet

- WEG Cfw501 Manual Do Usuario 10001991016 Manual Portugues BRDocument149 pagesWEG Cfw501 Manual Do Usuario 10001991016 Manual Portugues BRmquaiottiNo ratings yet

- Operation Manual: SYSDRIVE Modbus Master SoftwareDocument52 pagesOperation Manual: SYSDRIVE Modbus Master SoftwaremquaiottiNo ratings yet

- Somove V2.0: Installation NotesDocument8 pagesSomove V2.0: Installation NotesmquaiottiNo ratings yet

- VLT Motion Control Tools: Making Modern Living PossibleDocument139 pagesVLT Motion Control Tools: Making Modern Living PossiblemquaiottiNo ratings yet

- Emo 85 FDocument1 pageEmo 85 FmquaiottiNo ratings yet

- User'S Manual: Sysdrive 3G3JvDocument235 pagesUser'S Manual: Sysdrive 3G3JvmquaiottiNo ratings yet

- Termostato Digital On-Off 24V ABACO Mod. ABC908PITDocument8 pagesTermostato Digital On-Off 24V ABACO Mod. ABC908PITmquaiottiNo ratings yet

- CCN - Lonworks LEI Installation InstructionsDocument3 pagesCCN - Lonworks LEI Installation InstructionsmquaiottiNo ratings yet

- DCS303A51Document51 pagesDCS303A51mquaiottiNo ratings yet

- Operation Manual DCS601C51 - tcm511-273523Document98 pagesOperation Manual DCS601C51 - tcm511-273523mquaiottiNo ratings yet

- Control SystemsDocument8 pagesControl SystemsmquaiottiNo ratings yet

- Installation Manual (DH84309201) - 07Document24 pagesInstallation Manual (DH84309201) - 07mquaiottiNo ratings yet

- Pressure Transmitter For General Purpose Type MBS 1700 and MBS 1750Document8 pagesPressure Transmitter For General Purpose Type MBS 1700 and MBS 1750mquaiottiNo ratings yet

- T6865 Series Large LCD Digital ThermostatDocument6 pagesT6865 Series Large LCD Digital ThermostatmquaiottiNo ratings yet

- 30ra 2TDocument100 pages30ra 2TmquaiottiNo ratings yet

- Mechanical Engineering - Yale UniversityDocument7 pagesMechanical Engineering - Yale UniversityMalletNjonkemNo ratings yet

- Chem. 21313 Advanced Analytical Chemistry - III 4 CreditsDocument14 pagesChem. 21313 Advanced Analytical Chemistry - III 4 CreditsCheska Mae E. Manuel100% (1)

- ChymosinDocument242 pagesChymosinvbortizlNo ratings yet

- MEK453-Assignment 1 - (Oct 23-Feb 24)Document2 pagesMEK453-Assignment 1 - (Oct 23-Feb 24)Espresso LatteNo ratings yet

- Class 10 Sa and VolumeDocument2 pagesClass 10 Sa and VolumeArubaNo ratings yet

- Shaojun Zhou - Gas Technology InstituteDocument29 pagesShaojun Zhou - Gas Technology InstituteShitalbioNo ratings yet

- Tutorial Eusipco Tonello PDFDocument150 pagesTutorial Eusipco Tonello PDFchandanjha2010No ratings yet

- Side Runner & Purlin DesignDocument5 pagesSide Runner & Purlin DesignArun KesbhatNo ratings yet

- Enescu M. (Balas)Document6 pagesEnescu M. (Balas)FarahatNo ratings yet

- The Boron Family & Its Physical and Chemical PropertiesDocument15 pagesThe Boron Family & Its Physical and Chemical PropertiesTr Mazhar PunjabiNo ratings yet

- Hitler Vs Frabato by Robert Bruce Baird PDFDocument158 pagesHitler Vs Frabato by Robert Bruce Baird PDFKernel Panic100% (2)

- Mechanization On Harvesting and Infied Collection of Oil PalmDocument21 pagesMechanization On Harvesting and Infied Collection of Oil PalmShamil Al Dafar100% (2)

- History of Rail TransportDocument4 pagesHistory of Rail TransportAsif MalikNo ratings yet

- Surveying Lab ManualDocument76 pagesSurveying Lab ManualIan Lawrence YupanoNo ratings yet

- Tugas 5 1 Purworejo 19.0.1C 31-08-2021: Reliability AnalysisDocument17 pagesTugas 5 1 Purworejo 19.0.1C 31-08-2021: Reliability AnalysisMuhammad DavidNo ratings yet

- NLMDocument16 pagesNLMBrahmananda ChakrabortyNo ratings yet

- Engineering Manual Viscous and High Density: General Industry SegmentDocument52 pagesEngineering Manual Viscous and High Density: General Industry SegmentingrbarrosNo ratings yet

- STEP File Analyzer PMI Representation STPDocument365 pagesSTEP File Analyzer PMI Representation STPwenNo ratings yet

- Lab Report FinalDocument7 pagesLab Report Finalfrancis mbuguaNo ratings yet

- 10 - GEST 73 25 Edition 13 - Transfer of Dry Chlorine by Piping SystemsDocument31 pages10 - GEST 73 25 Edition 13 - Transfer of Dry Chlorine by Piping SystemsAdemilson JuniorNo ratings yet

- Ijftr 34 (2) 137-143Document7 pagesIjftr 34 (2) 137-143Mohammad HussainNo ratings yet

- Nonconvex Proximal Splitting With Computational Errors: Suvrit SraDocument20 pagesNonconvex Proximal Splitting With Computational Errors: Suvrit SrafhhgfghtNo ratings yet

- MeifmasvassDocument2 pagesMeifmasvassbobNo ratings yet

- BioprintingDocument18 pagesBioprintingmukeshNo ratings yet

- Shrinkage Factors of Cohesive Soils by The Water Submersion MethodDocument7 pagesShrinkage Factors of Cohesive Soils by The Water Submersion MethodAna Isabel TadeoNo ratings yet

- Torque Calculation of Hysteresis Motor Using Fem With - 2Document26 pagesTorque Calculation of Hysteresis Motor Using Fem With - 2Saurabh KumarNo ratings yet

- Notes Vincent Bruneau SSFDocument26 pagesNotes Vincent Bruneau SSFAlba García RuizNo ratings yet

- 0 TN 503 RS MeasurementDocument15 pages0 TN 503 RS MeasurementAli JavedNo ratings yet

- BAS Flyer PDFDocument2 pagesBAS Flyer PDFFilip TeofilskiNo ratings yet

User S Guide Title Pro Dialog Control 4 For Air Water Cooled Chillers Series 30 GX HXC Version 2 PDF

User S Guide Title Pro Dialog Control 4 For Air Water Cooled Chillers Series 30 GX HXC Version 2 PDF

Uploaded by

mquaiottiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

User S Guide Title Pro Dialog Control 4 For Air Water Cooled Chillers Series 30 GX HXC Version 2 PDF

User S Guide Title Pro Dialog Control 4 For Air Water Cooled Chillers Series 30 GX HXC Version 2 PDF

Uploaded by

mquaiottiCopyright:

Available Formats

COPY N

SPECIFICATION

N

ECG-UG-00-001

DATE

06/12/00

ECG CARRIER S.A.

USER'S GUIDE

TITLE: PRO-DIALOG CONTROL 4 FOR AIR & WATER COOLED

CHILLERS SERIES 30 GX & HXC VERSION 2

SYNOPTIQUE CARRIER - AIR-COOLED BI CIRCUIT - ABC PARTNERS 08/06/98

REV: original

Property of CARRIER S.A. Montluel.

Not to be disclosed to persons outside the organization without Written authorization

USER'S GUIDE FOR

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

ORIGINATOR

COPY #

1

ECG-UG-02-002

Rev: original

Ba-Tung PHAM

NAME

Carrier Service

COMPANY

Carrier

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

Page: /98

USER'S GUIDE FOR

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

ECG-UG-02-002

Rev: original

Page:2 /98

CONTENTS

1 - INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 - About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 - Manual Structure and contents . . . . . . . . . . . . . . . . . . 4

2 - GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 - Generalities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 - Software Reference Number . . . . . . . . . . . . . . . . . . . .

2.3 - Abbreviations Used . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.4.7 - Service 4 configuration from Service

Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2.4.8 - Service 4 configuration from Main

Interface, runtime sub menu . . . . . . 31

4

4

7

7

4.2.5 - User Configuration . . . . . . . . . . . . . . . . . . . . . . 32

3 - HARDWARE DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 - Produc Component . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1.1 - Basic Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1.2 - CCN/Clock Option Board . . . . . . . . . . . . . . . . . 10

3.1.3 - Screw Compressor Protection Module . . . . . 11

3.1.3.1 - Screw Compressor Module Layout 11

3.1.3.2 - Compressor Part Number/MTA Header

Configuration . . . . . . . . . . . . . . . . . . . . 12

3.1.4 - 4 xDO Board . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4.1 - General . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4..2 - Terminal J4 Description . . . . . . . .

3.1.5 - AUX Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.5.1 - General . . . . . . . . . . . . . . . . . . . . . . . .

3.1.6 - EXV Driver Board . . . . . . . . . . . . . . . . . . . . . . . .

3.1.7 - 4 x AI - 2 x AO Board . . . . . . . . . . . . . . . . . . . .

3.1.8 - Aquasnap Basic Board . . . . . . . . . . . . . . . . . .

12

12

12

13

13

14

14

16

3.2 - Pressure Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.1 - High Pressure Side Sensors . . . . . . . . . . . . . 17

3.2.2 - Large Band Pressure Sensors . . . . . . . . . . . 17

3.2.3 - Suction and economizer Pressure Sensors 18

3.3 - Thermistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.3.1 - Discharge Gas temperature . . . . . . . . . . . . . . 18

3.3.2 - 5K Resistor : Resistance vs Temperature

4.2.6 - Network Configuration . . . . . . . . . . . . . . . . . .

4.2.6.1 - General . . . . . . . . . . . . . . . . . . . . . . .

4.2.6.2 - Configuring a Control as a

Broadcast Acknowledger . . . . . . . .

4.2.6.3 - Setting Time and Date . . . . . . . . . .

4.2.6.4 - Alarm Configuration Table . . . . . .

4.3 - Cooler Interlock Contact . . . . . . . . . . . . . . . . . . . . . . . . 36

4.4 - Cooler heater control . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.5 - Oil heater control . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.6 - Motor cooling control without plate exchanger

economizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.7 - Motor cooling control without sub cooling plate

exchanger economizer . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.7.1 - Motor cooling with TQ feedback Signal Control 37

4.8 - Capacity Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.8.1 - Logic Description . . . . . . . . . . . . . . . . . . . . . . . 38

4.8.1.1 - Basic Logic . . . . . . . . . . . . . . . . . . . 38

4.8.1.2 - Z Multiplier Calculation . . . . . . . . 38

4.8.1.3 - Overrides . . . . . . . . . . . . . . . . . . . . 39

4.9 - Compressors & loaders loading sequence . . . . . . . 40

4.9.1 - General Description . . . . . . . . . . . . . . . . . . . . . 40

4.9.2 - Compressor capacity determination . . . . . . 41

4.9.3 - Staged Loading Increasing Capacity Logic 41

4.9.4 - Equal Loading Increasing Capacity Logic

4 - CONTROL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.4 - Service Configuration . . . . . . . . . . . . . . . . . . . 25

4.2.4.1 - Service 1 configuration from Service

Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.4.2 - Service 1 configuration from Main

Interface . . . . . . . . . . . . . . . . . . . . . . . . 27

4.2.4.3 - Service 2 configuration from Service

Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.4.4 - Service 2 configuration from Main

Interface . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.4.5 - Service 3 configuration from Service

Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2.4.6 - Service 3 configuration from Main

Interface . . . . . . . . . . . . . . . . . . . . . . . . 31

32

32

33

4.2.6.5 - Master/Slave Configuration . . . . . 35

Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1 - General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2 - Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.1 - General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.2 - Main Interface Configuration sub menu

structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.3 - Factory Configuration . . . . . . . . . . . . . . . . . . . 21

4.2.3.1 - Factory configuration from Service

Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2.3.2 - Factory configuration from Main

Interface . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2.3.3 - Economizer TQ valve Feedback

Signal Wiring . . . . . . . . . . . . . . . . . . . . 24

32

32

with close control = NO . . . . . . . . . . . . . . . . . 41

4.9.5 - Equal Loading Increasing Capacity Logic

with close control = YES . . . . . . . . . . . . . . . . 42

4.9.6 - Equal Loading Decreasing Capacity Logic

with close control = YES . . . . . . . . . . . . . . . . 42

4.9.7 - Equal Loading Decreasing Capacity Logic

with close control = NO . . . . . . . . . . . . . . . . . 43

4.9.8 - Staged Loading Decreasing Capacity Logic

with close control = NO . . . . . . . . . . . . . . . . . 43

4.9.9 - Staged Loading Decreasing Capacity Logic

with close control = YES . . . . . . . . . . . . . . . . 44

4.10 - EXV Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.10.1 - General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.10.2 - Overrides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.11 - Air Cooled Condensing Pressure Control . . . . . . . 46

4.12.1 - Air Cooled Condensing Pressure Control Fan staging with AUX board . . . . . . . . . . . . . . . . . 46

4.12.2 - Air Cooled Condensing Pressure Control Fan staging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.13 - Water Cooled Condensing Pressure Control . . . . 47

4.14 - High Pressure Override . . . . . . . . . . . . . . . . . . . . . . . 48

4.15 - High Current Override . . . . . . . . . . . . . . . . . . . . . . . . . 48

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

USER'S GUIDE FOR

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

ECG-UG-02-002

Rev: original

CONTENTS

4.16 - Stopping Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.16.1 - Stopping a compressor by capacity

unloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.16.2 - Stopping the unit by manual command

(OFF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.16.3 - Stopping a circuit by failure . . . . . . . . . . . . . 48

4.17 - Oil pressure control . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.17.1 - Oil pressure setpoint determination . . . . . 49

4.17.2 - Oil pump control . . . . . . . . . . . . . . . . . . . . . . . 49

4.17.3 - Low oil pressure alarm determination . . . . 49

4.17.4 - Differential Oil Pressure Setpoint 1

alarm condition summary . . . . . . . . . . . . . . . 50

4.18 - Reclaim Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.18.1 - General Description . . . . . . . . . . . . . . . . . . . 51

4.18.2 - Reclaim to Air Cooled Changeover

Initiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.18.3 - Air Cooled To Reclaim Changeover

Initiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.18.4 - Reclaim Operation hr_status

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.18.5 - Reclaim Operation Using Air Cooled

Exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.18.6 - Reclaim Condenser Water Valve Control 52

4.18.7 - Reclaim Condenser Heater Control . . . . . 52

4.19 - Two Units Master/Slave Control . . . . . . . . . . . . . . . . 53

4.19.1 - General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.19.2 - Abnormal Conditions . . . . . . . . . . . . . . . . . . 55

5 - CCN ALARM MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6 - CCN COMPATIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

7 - PRO_DIALOG 4 DOWNLOADER ADDENDUM

INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Appendix A - CCN DIPSLAY, SETPOINT, MAINTENANCE,

CONFIGURATION TABLE SCREENS . . . . . . . 61

Appendix B - CCN Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Appendix C - Wiring Schemes . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Appendix D - JBUS memory with GX& HX

default configuration . . . . . . . . . . . . . . . . . . . . . . . . 96

Appendix E - SAM Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Appendix F - CCN Network Example . . . . . . . . . . . . . . . . . . . . . 98

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

Page:3 /98

USER'S GUIDE FOR

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

ECG-UG-02-002

Rev: original

Page: 4/98

1 - INTRODUCTION

1.1 - ABOUT THIS MANUAL

This manual is intended to be used as an additional guide for using and configuring the Pro-Dialog control for

the 30GX & HX chillers. The use of this document does not substitute the IOM.

This manual is intended for use by Service organizations inside the Carrier corporation. It is delivered on

the express condition that it is not to be disclosed, reproduced in whole or in part, or used for

manufacture by anyone other than Carrier Corporation.

1.2 - MANUAL STRUCTURE AND CONTENTS

This manual includes the following sections:

v Introduction

v Product general description

v Hardware description

v Control description

v Appendixes

The introduction and product general description sections contain information about this manual as an overview

of the 30GX&HX Pro-Dialog Plus controls.

The hardware section provides complete information on boards, devices and connections used by the product.

The control description section is divided in several subsections. First provides a main description of hardware

configuration. This subsection provides sufficient information to runs the control in the most operating cases. For

more complete information, use the remaining sections and also IOM. Second subsection describes all the unit

configuration and the methods to modify it. The last subsections describe the unit control logics.

2 - GENERAL DESCRIPTION

2.1 - GENERALITIES

PRO-DIALOG is a system for controlling units which use screw compressors:

w Dual circuits

w Air cooled and water cooled chillers

w Non reversible heat machines

PRO-DIALOG controls compressors and loaders needed to maintain the desired leaving or entering water

control point. It automatically sets the position of the electronic expansion valve to maintain a correct refrigerant

flow in the cooler. For air cooled units it controls the operation of the fans to maintain the correct condensing

pressure in each circuit.

Safety circuits in the unit are constantly monitored by PRO-DIALOG to ensure its safe operation. PRO-DIALOG

also gives access to a Quick Test program covering all inputs and outputs excepted compressors outputs.

The control features of the 30GX&HX Pro-Dialog Plus are divided into standard features and options

(additional board needed):

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

USER'S GUIDE FOR

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

ECG-UG-02-002

Rev: original

Standard features:

w

Local control

Remote control (external contacts)

CCN control

Compressor & loader sequence control (up to 4 compressors - two loaders per compressor)

Cooler leaving or entering fluid temperature control

Ramp loading

Delay at startup

Circuit & Compressors loading sequence optimization

Heat machine condenser entering or leaving fluid control

Head pressure control

Cooling dual setpoints control

Temperature reset

Outdoor temperature monitoring

Demand limit control

High pressure and high current override

Cooler and Condenser pump control

Oil temperature control

Motor temperature control

Safety lock control

Quick test function

Diagnostics function

Local Interface Display with Metric units

Digital pressure gauges through the main interface

Display of all I/O and other data

CCN Network compatibility

Occupancy and dual setpoint schedules

SAM (LID 1B) compatibility

Alarm POC

System Manager compatibility

Integrated two chillers master/slave control

Available options With optional board:

w

Varifan control

Condenser water valve control

Reclaim sensors

Cooler heater control

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

Page: 5/98

USER'S GUIDE FOR

ECG-UG-02-002

Rev: original

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

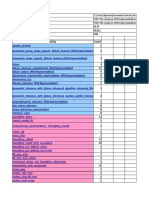

FUNCTIONS

HARDWARE

OPTION

FACTORY

CONFIG

Chiller Type

Air Cooled

Water Cooled

Heat Machine

SERVICE

CONFIG

Page: 6/98

USER

CONFIG

No configuration required

Refrigerant R134

Heat Reclaim Option

Cooler Fluid Type

Water

Medium Brine

Low Temperature Brine

x

x

Economizer Select

Large Band Oil Transducer Select

Compressor Number (1 to 4) & Capacity

x

No configuration required

Loader ( 2 per compressor)

EXV

1500 steps = Mueller, unipolar, 33 steps/s

Fans

2 Separate Circuits with 1 to 8 fans per circuit

Cooler Heater Select

Economizer Motor cooling TQ valve feedback

signal

Compressor Number (1 to 4) & Capacity

Unit on/off schedule control

x**

Night head pressure control mode

x**

Night capacity limitation mode

x**

Time and OAT broadcast capability

x**

Water pump periodical quick start sequence

x**

Cooler pump #1 and # 2 control sequence

Entering Fluid Control

Condenser Pump Control Select

Loading Sequence

Equal

Staged

Demand Limit Type Select

Reset Type Select (Heat & Cool)

Setpoint Control (single or dual)

No configuration required

Ramp Loading (Heat & Cool)

Cooling and heating Capacity Adjustment

(z multiplier)

Delay at startup

Condenser Sensors

Heat Reclaim Sensors

Reclaim Condenser Water Valve

Condenser Varifan or Water Valve

0-10 Vdc

10-0 Vdc

4-20 mA

20-4 mA

x

No configuration required

Oil Transducers On all compressors

x

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

USER'S GUIDE FOR

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

FUNCTIONS

HARDWARE

OPTION

FACTORY

CONFIG

ECG-UG-02-002

Rev: original

SERVICE

CONFIG

Maximum Condensing Temperature Override

Maximum Current Override

Close Control Select

FSM & CSM II Control

Two units Master/Slave Control

Page: 7/98

USER

CONFIG

** : require a CCN/Clock board

All Pro-Dialog controls can work either autonomously or they can be interfaced with the Carrier Comfort Network

(CCN). In the later case a communication data cable is used to connect the unit to the CCN communication bus.

When Pro-Dialog system operates autonomously it retains all of its own control capabilities but does not offer

the functionality of the CCN network.

2.2 - SOFTWARE REFERENCE NUMBER

This software is referenced under the 15 digits software reference number:

CSA-SR-208410XX

The two last digits (XX) provides the software version (e.g. 2.0).

15 digits reference number can be displayed in the CCN configuration Ctrl_ID table through the Building

Supervisor, the Network Service Tool or the 30GX&HX Downloader.

Unit Main Interface Configuration Menu allows to display the software version: item #13, user 1 menu.

2.2 - Abbreviations Used

In this manual, the refrigeration circuits are called circuit A and circuit B. The compressors in circuit A are

labeled A1, and A2. Those in circuit B are B1 and B2.

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

USER'S GUIDE FOR

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

ECG-UG-02-002

Rev: original

3 - HARDWARE DESCRIPTION

3.1 - PRODUCT COMPONENT

This control shall employ the following electronic modules:

Basic Board

NRCP Board

CCN and RTC Board

4 x DO Board (087)

4xAI - 2xAO Board

8 x DO Board (Auxiliary 2)

8xDO - 4xAI - 2xAO Board (Auxiliary 1)

EXV Board

Screw Compressor Protection Module

Local Interface Device 30GX dual circuits

Local Interface Device 30HX dual circuits

Local Interface Device 30GX single circuit

Local Interface Device 30HX single circuit

32 GB 500 182 EE

32 GB 500 052 EE

32 GB 500 062 EE

OP 12AS 004 EE

OP 12AS 005 EE

32 GB 500 312 EE

32 GB 500 322 EE

32 GB 500 192 EE

32 GB 500 232 EE

32 GB 500 092 EE

32 GB 500 112 EE

32 GB 500 082 EE

32 GB 500 102 EE

This control shall employ the following sensors modules:

Thermistors

Low Pressure Transducer

High Pressure Transducer

Large Band Oil transducer

HH79NZ047C (small size)

HH79NZ059C (large size)

OP12DA040 EE

OP12DA039 EE

OP12DA057 (for unit operating in low ambient)

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

Page: 8/98

USER'S GUIDE FOR

ECG-UG-02-002

Rev: original

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

Page: 9/98

COMPONENT USAGE

UNIT TYPE : WATER COOLED

NUMBER OF COMPRESSORS

COMPONENTS

PD4 - BASIC BOARD

PD4 - SCPM BOARD

PD4 - EXV BOARD

2[2]

2[2]

2[2]

4 x AI-2xAO BOARD

1[1]

1[1]

1[1]

1[1]

AUX 1 BOARD

1[1]

1[1]

1[1]

1[1]

UNIT TYPE : AIR COOLED - 2 FAN STAGES PER CIRCUIT MAX

NUMBER OF COMPRESSORS

COMPONENTS

PD4 - BASIC BOARD

PD4 - SCPM BOARD

2[2]

2[2]

2[2]

2[3]

1[3]

1[3]

1[3]

PD4 - EXV BOARD

4x DO BOARD

AUX 2 BOARD (8xDO)

1[3]

1[3]

1[3]

1[3]

NRCP BASIC BOARD

1[4]

1[4]

1[4]

1[4]

4 x AI-2xAO BOARD

1[1]

1[1]

1[1]

1[1]

AUX 1 BOARD

1[1]

2[1]

2[1]

2[1]

UNIT TYPE : AIR COOLED - MORE THAN 2 FAN STAGES (if no AUX board) or MORE

THAN 4 FAN STAGES (AUX BOARD) PER CIRCUIT

NUMBER OF COMPRESSORS

COMPONENTS

PD4 - BASIC BOARD

PD4 - SCPM BOARD

PD4 - EXV BOARD

2[2]

2[2]

2[2]

4x DO BOARD

2[3]

2[3]

2[3]

2[3]

AUX 2 BOARD (8xDO)

1[3]

1[3]

1[3]

1[3]

NRCP BASIC BOARD

1[4]

1[4]

1[4]

4 x AI-2xAO BOARD

1[1]

1[1]

1[1]

1[1]

AUX 1 BOARD

1[1]

1[1]

1[1]

1[1]

1 - additional 4 x AI - 2 x AO board or 8xD0-4xAI-2xAO board required for varifan or reclaim sensors or

water valve option

2 - Second EXV board is required for motor cooling using EXV valve on economizer units

3- 4xDO board or 8xDO board is required to control fans. 4xDO is also used to control hot gas bypass

valve on units with single compressor.

4-additional NRCP board is required for reclaim option or cooler heater option.

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

USER'S GUIDE FOR

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

ECG-UG-02-002

Rev: original

Page: 10/98

3.2 - Basic Board

The PD4 - Basic board is 24VAC power supplied. It contains 8 Discrete Inputs (Switch type), 8 Digital Outputs (5

triacs and 3 relays), 10 Analog Inputs (five thermistors and four pressure transducers) and 1 analog input (0-10

Vdc) . See the schemes in Appendix E. The software is contained in a Flash EPROM (downloadable only with

Downloader). All the setpoints, runtime and configuration parameters are contained in an EEPROM (data

storage at power down).

TERMINAL

CHANNEL

J6

Cooling leaving water temperature

All

J6

Cooling entering water temperature

All

J6

Master/Slave common piping fluid temperature

Master/Slave

J6

Outside Temperature

Air cooled

J6

Condenser leaving water temperature

Water cooled and heat pump

J6

Condenser entering water temperature

Water cooled and heat pump

J7A

Circuit A discharge pressure

All

J7B

Circuit A suction pressure

All

J7C

Circuit B discharge pressure

All

J7D

Circuit B suction pressure

All

J8

10

0-10 VDC setpoint reset signal or demand limit signal All

J4

11

Remote Control switch status

All

J4

12

Dual setpoint switch

All

J4

13

Heat Cool switch

Heat machine

J4

13

Heat Reclaim switch

All excepted heat machine

J4

14

Demand limit switch

All

J4 & J5

J5

FUNCTION

15 a & 15 b Cooler flow switch & customer interlock (lock_1)

UNIT TYPE

All

16 a & 16 b Electrical box thermostat & network power reverse All

phase detection

J5

17

Condenser flow switch

All excepted air cooled without

reclaim option

J5

18

Cooler pump default

All

J2

19

Cooler Pump #1

All

J2

20

Cooler Pump #2

All

J2

21

Condenser Pump

All excepted air cooled without

reclaim option

J2

22

Oil Heater Circuit A

Air cooled

J2

23

Oil Heater Circuit B

Air cooled

J3

24

Alarm Circuit A

All

J3

25

Alarm Circuit B

All

J3

26

Safety Critical Signal (for Contactor Failure)

All

3.2 - CCN/Clock Option Board (factory installed)

The PD4 - Global chiller controller has a small option board that can be connected to the Basic Board via a

single 10 pin header and 4 metal standoff. This option board contains one RS-485 driver for CCN

communication, a real time clock and super cap for two weeks backup. There are two connectors for CCN. One

is a 3 pin screw connector ( 1= + signal, 2 = ground signal, 3 = - signal) and the other is a 6 pins phone jack.

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

USER'S GUIDE FOR

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

ECG-UG-02-002

Rev: original

Page: 11/98

3.3 - Screw Compressor Protection Module

This board shall monitor compressor pressure transducer, temperature sensors, oil level, high pressure switch,

motor cooling solenoids, oil pumps, motor current, compressor wye-delta startup and compressor protection.

3.3.1 Screw Compressor Module Layout

N.B :Only Y dip switch of the 4 is used to configure start-delta startup procedure (when in ON

position), the 3 others shall remain OFF ! If not, MTA header configuration alarm will occur.

Connector AI #* Channel#

J9

1

1

J9

2

2

J10A

3

3

J10B

4

4

Type

5K thermistor

5K thermistor

0-5V pressure transducer

0-5V pressure transducer

Usual Functions

Compressor temperature

Discharge Gas Temperature

Economizer pressure

Oil pressure

Connector CT #* Channel#

J8

1

J8

2

J8

3

Connector DI #* Channel#

J7

1

5

J6

2

6

Type

Current sensor 1

Current sensor 2

Current sensor 3

Type

Dry contact

Dry contact

Usual Functions

Current Phase #1

Current Phase #2

Current Phase #3

Main Functions

High Pressure

Oil level

Connector DO #*

Channel#

J3

J3

J4

J2

J2

J2

1

2

3

4

5

6

7

8

9

12

13

14

J2

J2

7

8

10

11

Type

Load max

(Voltage,power)

Relay/Triac 115VAC, 250VA

Relay/TRiac 115VAC, 70VA,

115VAC,145VA,Triac

24VAC ,10VA

Triac

24VAC, 26 VA

Triac

24VAC, 10VA

Triac

Triac

Triac

24VAC, 10VA

24VAC, 10VA

Main Functions

Compressor output D

Compressor output Y

Oil pump

Oil solenoid

Motor cooling #1

Motor cooling #2 or economizer valve for

circuit which has 2 compressors

Loader #1

Loader #2

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

USER'S GUIDE FOR

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

ECG-UG-02-002

Rev: original

Page: 12/98

3.3.2- Compressor Part Number / MTA header configuration

Compressor phase 3 Part Number

Tons

MTA

(for 400V)

Compressor MTA Header Config

MSB(8 . . . . . . . 1) LSB

06NA2300S5E

80

298

01111100

06NA2300S5N

80

240

01011111

06NA2250S7N

66

204

01001101

06NW2300S5E

80

218

01010100

06NA2209S7N

56

170

00111100

06NA2174S7N

46

142

00101110

06NW2250S7N

66

164

00111001

06NA2146S7N

39

114

00100000

06NW2300S7N

80

198

01001010

06NW2209S7N

56

136

00101011

06NW2174S7N

46

112

00011111

06NW2146S7N

39

92

00010101

3.1.4 - 4xDO BOARD

The 4xDO board has 4 digital outputs capable of switching 24 VAC at 1 amp numbered from 1 to 4 on connector

J4. They have a common point numbered 12 on connector J4.

D0 #1 and Do # 2 shall support 1 fan

D0 #3 shall support 1 fan if circuit has less than 5 fans. It shall support 2 fans if circuit has more than 4 fans.

D0 #4 shall support 1 fan if circuit has less than 6 fans. It shall support

2 fans if circuit has 6 fans.

3 fans if circuit has 7 fans.

4 fans if circuit has 8 fans.

3.1.4.2 - Terminal J4 Description

TO CONTACTOR # 1

DO #1

TO CONTACTOR # 2

DO #2

TO CONTACTOR #3 (or and #4)

DO #3

TO OTHER CONTACTORS

DO #4

11 12 12

TERMINAL J4

24 VAC DO

POWER SUPPLY

TRIAC

pins 12 are connected together

TRIAC

TRIAC

TRIAC

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

USER'S GUIDE FOR

ECG-UG-02-002

Rev: original

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

Page: 13/98

3.1.5 - AUX Boards

3.1.5.1 - General

143 mm ( 5.60 in )

l

------

J9

PD4-AUX1 32GB 500 322 EE CEPL130487-01 STATUS SIO

R S V

CH14

75 mm

(2.95

in)

J7

J2

CH13

J5

CH13

J4

J3

J8

T

P

V

T

P

V

R S V

-- G +

3 2 1

SIO

-- G +

3 2 1

J1

24VAC

12 11

CH14

CH -- CH -- CH -- CH -1

2

3

4

CH -- CH -- CH -- CH -5

6

7

8

CH

9

--

CH

10

--

CH

11

--

CH

12

--

J6

------

The AUX1 board shall allow:

w the control of 1 to 8 fan stages;

w the monitoring of 4 temperatures or 2 temperatures and 2 pressures.

w the control of 2 Varifan or two water valves

The AUX2 board shall allow:

w the control of 1 to 8 fan stages.

Discrete outputs requirements: AUX1 and AUX2

Board

Connector

J2

AUX1

&

AUX2

DO #

Channel#

Main Functions

Fan 1 - circuit A or circuit B/ Pumpdown valve A

Fan 2 - circuit A or circuit B/ Reclaim valve A

Fan 3 - circuit A or circuit B

Fan 4 - circuit A or circuit B/ Pumpdown valve B

Fan 5 - circuit A, 1 or 5 circuit B/ Reclaim valve B

Fan 6 - circuit A , 2 or 6 circuit B

Fan 7 - circuit A , 3 or 7 circuit B/Reclaim option,

condenser heater

Fan 8 - circuit A , 4 or 8 circuit B

J3

All are standard 24 VAC/10%. All 24Vac common ground must be connected together on board and to 24Vac

ground pin of J1. All DOs total consomption = 115VA

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

USER'S GUIDE FOR

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

ECG-UG-02-002

Rev: original

Page: 14/98

3.1.6 - EXV BOARD

The EXV board shall be able to control 2 EXVs and 2 thermistors.

Analog inputs requirements

Connector

AI

#*

Type

Usual Functions

J3 (TH A)

5/10 K thermistor Economizer Motor Cooling TQ Valve Feedback Signal Circuit A

J3 (TH B)

5/10 K thermistor Economizer Motor Cooling TQ Valve Feedback Signal Circuit B

Discrete output requirements

The EXV board shall be able to drive both unipolar and bipolar stepper motors via a common connector. The

default configuration shall be unipolar, 30 steps/s step rates and 1500 steps range such as to allow easy retrofit

with Pro-Dialog phase 1, 2 and 3 units fitted with Mueller Brass EXVs. It shall be able to handle 12V @ 0.5 A per

coil and maintain a step rate of at least 200 steps per second (unipolar or bipolar).

Note: board shall be able to handle a total coil load of 1 Amp for unipolar and 2 Amps for bipolar.

Connection to the EXV shall be done through two Molex, 5 pin, 3.91 pitch (one per EXV) [J2A & J2B].

1

Coil 1

2

Coil 2

Connector J2A & J2B - Pins description

3

4

5

Coil 3

Coil 4

12VDC (for unipolar stepper motor)

3.1.7 - 4xAI-2xAO BOARD

This board provides 4 analog inputs (labeled AI #1, AI #2, AI #3, and AI #4 on the terminal J2) and 2 analog

outputs (labeled AO #1 and AO #2 on the terminal J1). It allows to use the following features:

w Optional reclaim thermistors when reclaim option is not used

w Remote discharge transducer on remote condenser on split units.

w Optional varifan on air cooled units or water valve on water cooled units

Each input can be independently configured with a bridge allowing to close 3 pair of pins named T,C or V.

J2

ANALOG

INPUT

BRIDGE

POSITION

FUNCTION

PINS

T,C

unused

1-R

Pressure transducer

(remote discharge

pressure circuit A)

V-1-R

T,C

unused

1-R

Pressure transducer

(remote discharge

pressure circuit B)

V-1-R

AI #1

AI #2

REMARKS

unused

V: Transducers 5 Volts power supply

1: Signal

R: -

Carrier thermistor: HH 79NZ 047, 5K@ 25C

V: Transducers 5 Volts power supply

1: Signal

R: -

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

USER'S GUIDE FOR

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

ECG-UG-02-002

Rev: original

J2

ANALOG

INPUT

AI #3

AI #4

BRIDGE

POSITION

FUNCTION

PINS

REMARKS

Reclaim leaving

thermistor

1-R

not used

V-1-R

unused

1-R

1: +

R: -

Reclaim entering

thermistor

1-R

Carrier thermistor: HH 79NZ 047, 5K@ 25C

not used

V-1-R

unused

1-R

Carrier thermistor: HH 79NZ 047, 5K@ 25C

V: Transducers 5 Volts power supply

1: Signal

R: -

V: Transducers 5 Volts power supply

1: Signal

R: 1: +

R: -

Each output can be independently configured with a bridge allowing to close 2 pair of pins named C or V.

J1

ANALOG

OUTPUT

BRIDGE

POSITION

FUNCTION

PINS

REMARKS

0- 10 Vdc Varifan circuit

A or water valve

5-R

5: +

R: -

4 - 20 mA Varifan

circuit A or water valve

5-R

5: +

R: -

0-10 Vdc Varifan circuit

B

6-R

6: +

R: -

4 - 20 mA Varifan

circuit B

6-R

6: +

R: -

AO #1

AO #2

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

Page: 15/98

USER'S GUIDE FOR

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

ECG-UG-02-002

Rev: original

Page: 16/98

3.1.8 - Aquasnap Basic Board

This board is used on global chiller as slave board for air cooled units with reclaim option or cooler heater option.

It contains 8 Discrete Inputs (switch type), 10 Digital Outputs (8 triacs and 2 relays), 6 Analog Inputs (four 5K or

10K thermistors and two active pressure transducer types) and 1 analog output (0-10 Vdc).

Channel Number

I/O

01

AI_1

Type

FUNCTION

Thermistor 5K or 10K

Reclaim option leaving temperature

02

AI 2

Thermistor 5K or 10K

Reclaim option entering temperature

03, 04

AI 3

Thermistor 5K or 10K

unused

05

AI_5

Pressure transducer 0 - 5 Vdc

Reclaim option pumpdown pressure circuit A

06

AI 6

Pressure transducer 0 - 5 Vdc

Reclaim option pumpdown pressure circuit B

07

AO_1

0 - 10 Vdc

Reclaim option, condenser water valve

08 to 15

DIs

Relay input

unused

DO_13

Triac

17

DO_24

Triac

reclaim option or cooler heater option, circuit A,

refrigerant condenser entering solenoid

reclaim option or cooler heater option, circuit B,

refrigerant condenser entering solenoid

18

DO 3

Triac

unused

19

DO 4

Triac

Reclaim option, condenser heater

20

DO_5

Triac

Reclaim option, pumpdown solenoids circuit A

21

DO 6

Triac

Reclaim option, pumpdown solenoids circuit B

22

DO_7

Triac

unused

23

DO 8

Triac

Cooler heater output

24

DO_9

Relay output

Cooler heater option, condenser and cooler

refrigerant isolation solenoid circuit A

25

DO_10

Relay output

Cooler heater option, condenser and cooler

refrigerant isolation solenoid circuit B

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

USER'S GUIDE FOR

ECG-UG-02-002

Rev: original

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

Page: 17/98

3.2 - Pressure sensors

They are used to measure in each circuit :

w

Discharge gas pressure

Suction pressure

Economizer pressure

and in each compressor :

w

Oil pressure

Economizer pressure on first compressor and also in the second compressor if unit is not equipped

with economizer

They are electronic sensors which linearise the output signal and deliver a 0 to 5 Vdc to either the basic board or

to an analog board. Three types of sensors are used.

3.2.1 - High pressure side sensors

They are used to measure discharge pressure and oil pressures when large band oil pressure transducer is not

selected. Carrier part: OP12DA039

5

Voltage (VDC)

50

345

100

689

150

1034

200

1379

300

250

2068

1724

Pressure

350

2414

400

2758

450

3103

500

3447

PSI

kPa

High pressure side transducer curve

3.2.2 - Large band pressure sensors

They are used to measure oil pressures for unit operating with low ambient (when large band oil pressure

transducer is selected). Carrier part: OP12DA057

5

Voltage (VDC)

-6.6

-45

50

345

100

689

155

1068

215

276

1904

1484

Pressure

327

2252

387

2670

420

2895

500

3447

PSI

kPa

Large band oil pressure transducer curve

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

USER'S GUIDE FOR

ECG-UG-02-002

Rev: original

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

Page: 18/98

3.2.3 - Suction Pressure and Economizer Pressure sensors

These are in the low pressure side. Suction pressure transducer takes the place of the low pressure switches,

low pressure gauges and the low pressure safety switch (where these are usually fitted). Economizer pressure is

used to measure the intermediary pressure between low and high pressure. The oil pressure is subtracted from

this pressure to determine the oil differential pressure for oil pressure safety purpose.

Carrier part: OP12DA040

Voltage (VDC)

20

40

60

80

138

276

414

552

120

100

689

828

Pressure

140

160

965

1103

180

1241

200

1379

PSI

kPa

Low pressure transducer curve

3.3 - THERMISTORS

All thermistor, excepted the reset sensor, have similar characteristics (see next page).

They have Carrier Part No. HH 79 NZ 047

3.3.1 - Discharge gas temperature

This is installed on the discharge pipe of each compressor. It is used to control the discharge superheat. The

discharge gas temperature (lowest discharge compressor temperature or average discharge temperature of both

compressors) is subtracted to the saturated condensing temperature to determine the discharge superheat.

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

USER'S GUIDE FOR

ECG-UG-02-002

Rev: original

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

Page: 19/98

5K Resistor: Resistance vs Temperature Curve

Temp.

(C)

-32,0

-31,5

-31,0

-30,5

-30,0

-29,5

-29,0

-28,5

-28,0

-27,5

-27,0

-26,5

-26,0

-25,5

-25,0

-24,5

-24,0

-23,5

-23,0

-22,5

-22,0

-21,5

-21,0

-20,5

-20,0

-19,5

-19,0

-18,5

-18,0

-17,5

-17,0

-16,5

-16,0

-15,5

-15,0

-14,5

-14,0

-13,5

-13,0

-12,5

-12,0

-11,5

-11,0

-10,5

-10,0

-9,5

-9,0

-8,5

-8,0

-7,5

-7,0

-6,5

-6,0

-5,5

-5,0

-4,5

-4,0

Resistanc

e

(OHMS)

100 049,0

97 006,4

94 060,8

91 209,3

88 449,0

85 777,0

83 190,7

80 687,1

78 263,9

75 918,3

73 648,0

71 450,6

69 323,7

67 265,0

65 272,4

63 343,7

61 476,9

59 670,0

57 920,9

56 227,9

54 589,1

53 002,7

51 467,0

49 980,4

48 541,1

47 147,7

45 798,6

44 492,4

43 227,6

42 002,9

40 816,9

39 668,3

38 555,9

37 478,4

36 434,7

35 423,7

34 444,2

33 495,2

32 575,6

31 684,6

30 821,0

29 984,0

29 172,7

28 386,3

27 623,8

26 884,4

26 167,5

25 472,2

24 797,8

24 143,6

23 509,0

22 893,2

22 295,6

21 715,7

21 152,6

20 606,4

20 075,9

Temp.

(C)

-3,5

-3,5

-3,0

-2,5

-2,0

-1,5

-1,0

-0,5

0,0

0,5

1,0

1.5

2,0

2.5

3.0

3,5

4,0

4.5

5,0

5,5

6,0

6.5

7.0

7,5

8,0

8,5

9.0

9.5

10,0

10,5

11,0

11,5

12,0

12,5

13,0

13,5

14,0

14,5

15,0

15,5

16,0

16,5

17,0

17,5

18,0

18,5

19,0

19,5

20,0

20,5

21,0

21,5

22,0

22,5

23,0

23,5

24,0

Resistanc

e

(OHMS)

20 075,9

19 560,8

19 060,6

18 574,8

18 102,9

17 644,5

17 199,1

16 766,3

16 345,7

15 936,9

15 539,5

15 153,1

14 777,5

14 412,2

14 056,9

13 711,4

13 375,3

13 048,3

12 730,1

12 420,5

12 119,2

11 826,0

11 540,5

11 262,7

10 992,1

10 728,8

10 472,3

10 222,6

9979.3

9742.5

9 511,7

9287.0

9068.0

8854.7

8 469,9

8 444,5

8 247,2

8 055,0

7 867,7

7 685,1

7 507,2

7 333,9

7164.9

7 000,3

6 839,8

6 683,4

6 530,9

6 382,3

6 237,5

6 096,3

5 958,7

5 824,6

5 693,9

5 566,4

5 442,2

5 321,2

5 203,2

Temp.

(C)

24,0

24,5

25,0

25,5

26,0

26,5

27,0

27,5

28,0

28,5

29,0

29,5

30,0

30,5

31,0

31,5

32,0

32,5

33,0

33,5

34,0

34,5

35,0

35,5

36,0

36,5

37,0

37,5

38,0

38,5

39,0

39,5

40,0

40,5

41,0

41,5

42,0

42,5

43,0

43,5

44,0

44,5

45,0

45,5

46,0

46,5

47,0

47,5

48,0

48,5

49,0

49,5

50,0

50,5

51,0

51,5

52,0

Resistanc

e

(OHMS)

5 203,2

5 088,1

4 976,0

4 866,8

4 760,2

4 656,4

4 555,2

4 456,6

4 630,4

4 266,7

4 175,4

4 086,3

3 999,6

3 915,0

3 832,5

3 752,1

3 673,7

3 597,3

3 522,9

3 450,2

3 379,4

3 310,4

3 243,1

3 177,5

3 113,4

3 051,0

2 990,1

2 930,7

2 872,8

2 816,2

2 761,1

2 707,2

2 654,7

2 603,4

2 553,3

2 504,4

2 456,6

2 410,0

2 364,4

2 319,9

2 276,3

2 233,8

2 192,2

2 151,5

2 111,7

2 072,8

2 034,7

1 997,4

1 960,9

1 925,1

1 890,1

1 855,7

1 822,1

1 789,1

1 756,8

1 725,1

1 694,0

Temp.

(C)

52,0

52,5

53,0

53,5

54,0

54,5

55,0

55,5

56,0

56,5

57,0

57,5

58,0

58,5

59,0

59,5

60,0

60,5

61,0

61,5

62,0

62,5

63,0

63,5

64,0

64,5

65,0

65,5

66,0

66,5

67,0

67,5

68,0

68,5

69,0

69,5

70,0

70,5

71,0

71,5

72,0

72,5

73,0

73,5

74,0

74,5

75,0

75,5

76,0

76,5

77,0

77,5

78,0

78,5

79,0

79,5

80,0

Resistanc

e

(OHMS)

1 694,0

1 663,5

1 633,5

1 604,1

1 575,2

1 546,9

1 519,0

1 491,6

1 464,7

1 438,3

1 412,3

1 386,8

1 361,6

1 336,9

1 312,6

1 288,7

1 265,2

1 242,1

1 219,3

1 196,9

1 174,8

1 153,2

1 131,8

1 110,9

1 090,2

1 069,9

1 050,0

1 030,3

1 011,0

992,1

973,4

955,1

937,1

919,4

902,1

885,1

868,4

952,0

836,0

820,2

804,8

789,8

775,0

760,6

746,5

732,6

719,2

706,1

693,3

680,8

668,6

656,8

645,2

634,0

623,2

612,6

602,4

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

Temp.

(C)

80,0

80,5

81,0

81,5

82,0

82,5

83,0

83,5

84,0

84,5

85,0

85,5

86,0

86,5

87,0

87,5

88,0

88,5

89,0

89,5

90,0

90,5

91,0

91,5

92,0

92,5

93,0

93,5

94,0

94,5

95,0

95,5

96,0

96,5

97,0

97,5

98,0

98,5

99,0

99,5

100,0

100,5

101,0

101,5

102,0

102,5

103,0

103,5

104,0

104,5

105,0

105,5

106,0

106,5

107,0

Resistanc

e

(OHMS)

602,4

592,4

582,8

573,4

564,4

555,7

547,2

539,1

531,2

523,6

516,2

509,2

502,3

495,7

489,4

483,2

477,4

571,6

466,1

460,8

455,6

450,6

445,7

440,9

436,3

431,8

427,4

423,0

418,8

414,5

410,3

406,0

401,8

397,6

393,3

389,0

384,7

380,3

375,8

371,1

366,5

361,6

356,7

351,5

346,3

341,1

335,3

329,7

323,8

317,9

311,6

305,3

298,6

292,1

285,2

USER'S GUIDE FOR

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

ECG - UG - 02 - 02

Rev: Original

Page: 20 /98

4.2 - CONFIGURATION

4.2.1 - General

Four types of configuration are available:

w The factory configuration. It describes the "hardware" structure of the unit (e.g. the number of compressors,

valve...). This configuration is accessible through the Main Interface Factory menu Menus or the Network

Service Tool and can be done by Carrier factory or service only.

w The Service configuration. It allows to modify operating parameters. This configuration is accessible

through the Main Interface Service Menus or the Network Service Tool and can be done by Carrier

factory or service only.

w The User configuration. It allows to modify a limited number of simple parameters (i.e. loading sequence,

start-up delay, cooler pumps control, reset select...). This configuration can be done through the Main

Interface or through the Network Service Tool. This configuration can be modified by the customer.

w The network configuration. It allows to modify parameters used by network functions (i.e. Alarm POC,

Broadcast ...). This is accessible through the Building Supervisor or the Network Service Tool.

4.2.2 -Main interface configuration sub menu tree structure

CONFIGURATION SUB MENUS

USER

I

T

E

M

S

SERVICE

FACTORY

USEr MEnu

SErViCE MEnu

"FACtorY MEnu"

USEr 1

SErViCE 1

"FACtorY 1 MEnu"

USEr 2

SErViCE 2

"FACtorY 2 MEnu"

dAtE

SErViCE 3

SCHEduLE 1

MAStEr SLAvE

SCHEduLE 2

HoLidAY

broAdCASt

MAIN INTERFACE FACTORY CONFIGURATION SUB MENU TREE STRUCTURE

FACTORY CONFIGURATION SUB-SUB MENUS

FACTORY 1

0

I

T

E

M

S

"FACtorY1 MEnu"

unit_typ (idem version 1.x)

nb fan a (idem version 1.x)

nb fan b (idem version 1.x)

hd selec (idem version 1.x)

econ sel (idem version 1.x)

oil_sel (idem version 1.x)

cpa1_mta (idem version 1.x)

cpa2 mta (idem version 1.x)

cpb1 mta (idem version 1.x)

10

cpb2 mta (idem version 1.x)

11

hr temp (idem version 1.x)

12

recl_opt (idem version 1.x)

13

evap_pas (idem version 1.x)

14

cira lwt (idem version 1.x)

15

heat sel (idem version 1.x)

16

exva max (1500)

17

exvb max (1500)

18

pd4_aux (aux board select)

19

TQ_r_fbk (TQ valve feeddback)

FACTORY 2

"FACtorY2 MEnu"

fac_pass

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

USER'S GUIDE FOR

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

ECG - UG - 02 - 02

Rev: Original

Page: 21 /98

4.2.3 - Factory configuration

4.2.3.1 - Factory configuration from Service Tool

The Network Service tool allows to view and modify the factory configuration (table FACTORY in 'Modify

Controller').

TABLE NAME: FACTORY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

PIC TABLE TYPE : 10H, instance 1

DESCRIPTION

STATUS

DEFAULT UNITS

POINT

Chiller Type

Circuit A Fan Stages Num

Circuit B Fan Stages Num

Varifan or W. Valves Sel

Economizer Select

Large Bd Oil Transducers

Comp A1 Must Trip Amps

Comp A2 Must Trip Amps

Comp B1 Must Trip Amps

Comp B2 Must Trip Amps

Reclaim Sensor Select

Air Cooled Reclaim Sel

Evaporator Number Pass

Cooler LWT On Circuit A

Cooler Heater Select

Factory Password

EXV A Maximum Steps Numb

EXV B Maximum Steps Numb

Motor Cool. TQ Feedback

PD4 Aux Boards Select

1,2,31

0 to 82

0 to 82

0/1/2/3/4

Yes/No3

Yes/No4

0 to 5605

0 to 5605

0 to 5605

0 to 5605

Yes/No6

Yes/No7

1 to 38

Yes/No9

Yes/No10

0 to 15011

1500/1500012

1500/1500012

Yes/No13

Yes/No14

1

0

0

0

No

No

0

0

0

0

No

No

3

Yes

No

113

1500

1500

No

No

unit_typ

nb_fan_a

nb_fan_b

hd_selec

econ_sel

oil_sel

mta_cpa1

mta_cpa2

mta_cpb1

mta_cpb2

hr_tmp

recl_opt

evap_pas

cira_lwt

heat_sel

fac_pass

exva_max

exvb_max

TQ_r_fbk

pd4_aux

Parameters from 1 to 16 in version 1.x are the same than those in the new version 2.X.

For Retrofit from verson 1.x to the new 2.x, it is better to write down in a paper, configuration items

from 1 to 16. Use Service Tool to upload all the configuration from version 1 (example address 1).

Then use address search function to change the address to 2 before downloading the new software

version 2.x. Use Service Tool to add a new controller with a different addresse (example address 1 for

version 1 and address 2 for version 2). Once Upload configuration is done, fill factory configuration in

FACTORY table and then download this.

1.

2.

1 = air cooled. 2 = water cooled . 3 = heat machine

0 = no fan

< 4 = each DO output of the 4xDO board support 1 fan .

> 5 = DO # 1 and DO # 2 support 1 fan each.

DO # 3 support 2 fans

DO # 4 support 1 fan if circuit has 5 fans max

DO # 4 support 2 fans if circuit has 6 fans max

DO # 4 support 3 fans if circuit has 7 fans max

DO # 4 support 4 fans if circuit has 8 fans max

nb : these fans are not controlled by a varifan.

For pro_dialog 4 Auxiliary board select, each DO output of the Auxiliary board support 1 fan

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

USER'S GUIDE FOR

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

ECG - UG - 02 - 02

Rev: Original

Page: 22 /98

13.

Yes = Use Pro_dialog 4 auxiliary boards instead of old 4xAO-2xAO board and 4xDO board

No = Use old 4xAO-2xAO board & 4x DO board (shall be set to no for version 1 retrofit)

3.

When this item is selected, both compressor use the common economizer transducer in the economizer.

Otherwise, each compressor uses it own economizer transducer, located in the refrigerant injection pipe

line, near the motor cooling valve. Economizer pressure represents the intermediary pressure between

high pressure and low pressure. It is used to determine the oil differential pressure (oil pressure economizer pressure).

4.

The use of large band oil pressure transducer is required for low ambient application and is only applied on

oil pressure transducers since high pressure range transducer can not read pressure lower than 2.4 bars,

Calibration is automatically determined each time the control is in OFF mode and both suction and

discharge pressures are equalized. Differences between oil pressures and suction pressure are then

stored as offset (if less than 0.4 bar).

5.

MTA configuration is required for capacity calculation, motor current measurement and protection. This

value shall match the one read from MTA header configuration on screw compressor board, if not an alarm

will be generated.

6.

If only reclaim sensor is selected and reclaim option is not, an 4xAI-2xAO board is required, and reclaim

temperature sensor are used for information only.

Reclaim option requires an Aquasnap Basic board for reclaim entering and leaving temperatures,

solenoids, an analogue output to control the reclaim condenser water valve, 2 transducers for reclaim

pumpdown injection pressure.

This items indicates the number of pass the cooler fluid goes through the cooler. For example, if cooler

enters from circuit A and goes out by circuit A and only 1 time, then a number of 2 shall be entered. This

item is used for exv control when caculating cooler pinch.

This items indicates if cooler leaving temperature sensor is in the circuit A or not. If cooler leaving pipe line

is on side A, then Yes shall be entered, otherwise, no shall be required. This item is used for exv control

when caculating cooler pinch.

Cooler heater option requires an Aquasnap Basic board for refrigerant isolation solenoids and heater

output.

Factory password is required when accessing the main interface factory menu. Factory password can be

used to access to service and user configuration sub menus.

7.

8.

9.

10.

11.

12.

1500 = For Muller valve, Unipolar, 1500 steps, 33 steps/s (1500 steps shall be kept !!!)

15000 = For Muller valve phase 3, Bipolar, 15300 steps, 300 steps/s (for future use,)

Note: schemes are described in appendix C.

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

USER'S GUIDE FOR

ECG - UG - 02 - 02

Rev: Original

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

Page: 23 /98

4.2.3.2- Factory configuration from main interface

ITEM #

VARIABLE

FORMAT

UNITS

COMMENTS

"FACTORY

MEnu"

When selected this item shall allow to return to the Configuration

main menu.

unit typ

1/2,3,4

Chiller type select

2[1]

nb fan a

0 to 8

Number of fans on circuit A not controlled by a varifan

3[1]

nb fan b

0 to 8

Number of fans on circuit B not controlled by a varifan

hd_selec

0,1,2,3,4

Varifan or Water valve select

econ_sel

yes/no

Economizer select

oil sel

yes/no

Large Band Oil transducer select

cpa1 mta

0 to 560

amps Compressor A1 Must Trip Amps

8[1]

cpa2 mta

0 to 560

amps Compressor A2 Must Trip Amps.

9[1]

cpb1 mta

0 to 560

amps Compressor B1 Must Trip Amps.

10[1]

cpb2_mta

0 to 560

amps Compressor B2 Must Trip Amps.

11[1]

hr_temp

yes/no

Reclaim sensors select

12[1]

recl opt

yes/no

Heat reclaim option select

13

evap pas

1 to 3

Cooler number of pass select

14

cira lwt

yes/no

Cooler leaving sensor on circuit A select

15[1]

heat sel

yes/no

Cooler heater select displayed on air cooled chiller only

16

exva_max

1500 to 15000

EXV A Maximum Steps Number (Shall be left 1500)

17

exva_max

1500 to 15000

EXV A Maximum Steps Number (Shall be left 1500)

18

pd4 aux

yes/no

Pro dialog 4 Aux boards select

19

tq r fbk

yes/no

Economizer units with TQ feedback signal sensor

ITEM #

VARIABLE

FORMAT

UNITS

COMMENTS

"FACTORY 2

MEnu"

When selected this item shall allow to return to the Configuration

main menu.

fac_pass

0 to 150

Factory password

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

USER'S GUIDE FOR

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

ECG - UG - 02 - 02

Rev: Original

Page: 24 /98

Economizer Tq valve Feedback Signal Control Wiring

SCPM A1

TQ output (done)

THA

Connexion to be done (tq_r_fbk = yes)

THB

EXV BOARD

TQ output (done)

SCPM B1

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

USER'S GUIDE FOR

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2

ECG - UG - 02 - 02

Rev: Original

Page: 25 /98

4.2.4 - Service configuration

4.2.4.1 - Service1 configuration table from Service Tool

The Network Service tool allows to view and modify the service configuration table SERVICE1. Unit shall be

stopped and under CCN Operating Type control.

TABLE NAME: SERVICE1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

PIC TABLE TYPE : 13H, instance 1

DESCRIPTION

STATUS

DEFAULT

Cooler Fluid Type

Head Pressure Diff Timer

Head Pressure Diff

Prop PID Gain Varifan/Wv

Int PID Gain Varifan/Wv

Deri PID Gain Varifan/Wv

Cir A Superheat Setpoint

Cir B Superheat Setpoint

Cir A Cooler Pinch Setpt

Cir B Cooler Pinch Setpt

Maximum Condensing Temp

Max Condensing Temp Diff

Maximum Current Setpoint

Maximum Current Diff

Close Capacity Ctrl Sel

Auto Z Multiplier Setpt

Maximum Z Multiplier

Entering Fluid Control

1/2/31

10 to 1202

3.8 to 223

-20.0 to 20.04

-5.0 to 5.04

-20.0 to 20.04

8.3 to 225

8.3 to 225

0.5 to 2.66

0.5 to 2.66

48.8 to 71.17

5.5 to 117

50 to 858

5 to 208

Dsable/Enable9

4 to 610

1.0 to 6.011

Yes/No12

1

90

5

1.0

1.0

1.0

11

11

1.0

1.0

68

6.7

80

10

Dsable

6

6.0

No

UNITS

sec

^C

^C

^C

^C

^C

C

^C

%

%

-

POINT

flui_typ

head_tim

head_dif

hd_pg

hd_ig

hd_dg

dsh_sp_a

dsh_sp_b

pinc_p_a

pinc_p_b

mct_sp

mct_diff

curr_max

curr_dif

cls_ctrl

zm_spt

hc_zm

ewt_opt

Note: this table canl be downloadable at any time. However, modified value shall not be used by tasks until the

unit is in off state . This shall not apply to the Varifan/water valves gains that shall be modified at any time and

used immediately by the head pressure control tasks even if the unit is in operation.

1. >

1 = Water

2 = Brine

3 = Low Brine

Warning: This decision affects the freeze protection threshold.

w water: 1.1C

w brine & low brine: coldest setpoint - 4.4C

2.

Used to set fan cycling. Decreasing this value will increase fan cycling. This timer can be reduced since the

unit is fitted with an important number of fan stages, as to increase the condensing control accuracy. But in

certain cases, notably on units with few fan stages, at too small value can causes superheat hunting

problems.

3.

Used to set fan cycling. Default value is 5 ^C, 11.1^C or higher value are recommanded if unit has varifan.

This value can be increased on units with few fan stages to avoid superheat hunting problems.

CARRIER S.A

NOT TO BE DISCLOSED TO PERSONS OUTSIDE CARRIER ORGANIZATION

USER'S GUIDE FOR

CARRIER SA

30GX&HX PRO_DIALOG 4 V.2