Professional Documents

Culture Documents

Nicholas Melvin Professional Resume

Nicholas Melvin Professional Resume

Uploaded by

api-307963619Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nicholas Melvin Professional Resume

Nicholas Melvin Professional Resume

Uploaded by

api-307963619Copyright:

Available Formats

Nicholas

Melvin

28 Hearthstone Drive | Bethel, CT 06801 | (203) 788-2648

nmelvin19@gmail.com | nmelvin.weebly.com

Summary

A driven, hands-on and personable engineer with a significant passion for the aerospace and robotics industries, specifically in

new product design. Multi-faceted and have a strong attention to detail. Work well under pressure and can prioritize work as it

comes in to ensure on time delivery and satisfaction. Proven ability to take complete ownership of projects in order to solve

engineering challenges.

Education

Northeastern University | Boston, MA

May 2017

Bachelor of Science in Mechanical Engineering | Cumulative GPA: 3.62

Honors: Deans List | 2015 Elite Flight Services Scholarship | 2016 Alphonse Joseph Scholarship

Activities: American Society of Mechanical Engineers (ASME) | Club Inline Hockey Assistant Captain | Intramural Sports

Relevant Skills

Design Software

SolidWorks CSWP

PTC Creo 2.0

CATIA V5

AutoCAD

Other Software

Matlab

Microsoft Excel VBA

C++

MasterCAM

ANSYS

Manufacturing

FDM 3D Printing

3-Axis Mill

Band Saw

Drill Press

Professional Experience

QinetiQ North America | Waltham, MA

July 2016 Current

Unmanned Systems Engineering Co-op

Designed and prototyped components for a robot fiber optic attachment package to enhance user-friendliness, and

transitioned into production

Wrote procedure and process documents outlining installation and use of the fiber optic attachment package

Conducted radio frequency range testing in order to evaluate robot antenna configuration limitations and documented

results and recommendations for the customer

Created several proof of concepts for different methods for mounting an attachment to a robot with several critical,

customer driven constraints

Assisted in production level builds for an attachment kit to meet contractual delivery dates

Sikorsky Aircraft A Lockheed Martin Company | Stratford, CT

July 2015 January 2016

Propulsion Design Co-op

Designed and prototyped an avionics cooling solution to exhaust heat from the multifunction displays out of the aircraft

skin with a manufacturability scope

Modeled propulsion systems on the top deck of a Black Hawk in a conversion from Mylar to 3D models

Designed solutions to assembly line impacting issues for the Black Hawk, Sea Hawk and Med-Evac helicopters

Developed and maintained an earned value tool that tracked cost, schedule and performance for all major programs,

saving the time of the Vice President and providing data in concise charts

Created 3D models of avionics hardware to assist in computational fluid dynamics (CFD) analysis and mesh creation

Performed tolerance stack-ups per GD&T standards for legacy Black Hawk component interference

UTC Aerospace Systems ISR and Space Systems | Danbury, CT

May 2014 January 2015

Optical Manufacturing Engineering Co-op

Created solid models and engineering drawings for diamond tooling, optic blanks, assembly fixtures and test equipment

mounting hardware

Executed dimensional analysis and assigned geometric tolerances to part and assembly drawings per the Machinerys

Handbook

Wrote Manufacturing Process Documents (MPD) for processes including machine refurbishments, equipment testing,

proof loading hardware and machine safety guarding

Acted as a designer on a team in support of major spreader bar proof load for a high priority contract

Wrote Manufacturing Operation Sheets (MOS) to rework optics after defects were identified

You might also like

- I Recently Visited KennedyDocument2 pagesI Recently Visited KennedyPamNo ratings yet

- Tejas ShettyDocument1 pageTejas Shettysamarth tubachiNo ratings yet

- @ SANTHOSH GAUTHAM RESUME - Santhosh GouthamDocument3 pages@ SANTHOSH GAUTHAM RESUME - Santhosh GouthamposttopictomotiveNo ratings yet

- Mechanical Engineering Student Resume TemplateDocument2 pagesMechanical Engineering Student Resume TemplateRavi TyagiNo ratings yet

- Meche Sample ResumesDocument5 pagesMeche Sample ResumesShyam Ramanath ThillainathanNo ratings yet

- 2017-07-24 ResumeDocument1 page2017-07-24 Resumeapi-365474033No ratings yet

- B ResumeDocument2 pagesB ResumeTunde KarimuNo ratings yet

- Resume April 2020Document1 pageResume April 2020api-509647787No ratings yet

- Cerier 090918Document1 pageCerier 090918api-332195824No ratings yet

- Sample Resume Mechanical Engineer Entry LevelDocument2 pagesSample Resume Mechanical Engineer Entry LeveltarunNo ratings yet

- Career Fair Resume ResumeDocument1 pageCareer Fair Resume ResumemattNo ratings yet

- David Driscoll: Career ObjectiveDocument1 pageDavid Driscoll: Career ObjectiveDavid DriscollNo ratings yet

- Abhishek Balaji: ObjectiveDocument2 pagesAbhishek Balaji: ObjectiveSakthi GaneshNo ratings yet

- Creating Your Resume: Joyce Donahue BY 310 480 965-2966 For An Appt. Joyce - Donahue@asu - EduDocument30 pagesCreating Your Resume: Joyce Donahue BY 310 480 965-2966 For An Appt. Joyce - Donahue@asu - EduCesar PaloneNo ratings yet

- Ravi Kaninde ResumeDocument2 pagesRavi Kaninde Resumeapi-357519222No ratings yet

- Miriam Glickman - Resume 2024Document2 pagesMiriam Glickman - Resume 2024api-483695163No ratings yet

- Nisnisan Mark ResumeDocument2 pagesNisnisan Mark Resumeapi-346239636No ratings yet

- Ashish Sonawane CV-1Document2 pagesAshish Sonawane CV-1ashish853097No ratings yet

- David A. Smith: University of Cincinnati, Cincinnati, OhioDocument1 pageDavid A. Smith: University of Cincinnati, Cincinnati, OhioDavid SmithyNo ratings yet

- E Technologist DesignerDocument2 pagesE Technologist DesignerBahia GazaliNo ratings yet

- Michael Kenneth Tuttle: University of West GeorgiaDocument1 pageMichael Kenneth Tuttle: University of West Georgiaapi-265393976No ratings yet

- New Text DocumentDocument4 pagesNew Text DocumentKaLvz FontamiLlas MarQuezNo ratings yet

- Banty Singh ResumeDocument2 pagesBanty Singh ResumeManoj SharmaNo ratings yet

- Mechanical Engineer ResumeDocument1 pageMechanical Engineer ResumeSARTHAKNo ratings yet

- Jackson Quedenfeld Resume Fall2020Document1 pageJackson Quedenfeld Resume Fall2020api-527215374No ratings yet

- Resume - ENC3246 PDFDocument1 pageResume - ENC3246 PDFAnonymous m1kQes7No ratings yet

- Shirleylu ResumeDocument1 pageShirleylu Resumeapi-466559975No ratings yet

- Nirajkumar Mehta, PH.D.: Professional SummaryDocument2 pagesNirajkumar Mehta, PH.D.: Professional SummaryNirajkumar MehtaNo ratings yet

- Unit 1 - ScriptDocument4 pagesUnit 1 - Scriptapi-491388679No ratings yet

- Dinesh CV June 2012 - UpdatedDocument4 pagesDinesh CV June 2012 - UpdatedJimmy JoseNo ratings yet

- Mattmcdermottresume Careerfairfall2017Document1 pageMattmcdermottresume Careerfairfall2017api-371835526No ratings yet

- Marc StapletonDocument3 pagesMarc StapletonDjobrane LinkerzNo ratings yet

- Eet102 ResumeDocument2 pagesEet102 Resumeapi-244958549No ratings yet

- Mechanical Engineer CV SampleDocument8 pagesMechanical Engineer CV SampleAndrew NelsonNo ratings yet

- Oscar Chen ResumeDocument1 pageOscar Chen ResumeOscar ChenNo ratings yet

- Choi Nicholas ResumeDocument1 pageChoi Nicholas Resumeapi-376444733No ratings yet

- What Is MMEDocument15 pagesWhat Is MMEsbmallurNo ratings yet

- 001 Civil Engineering IIT Pune PDFDocument35 pages001 Civil Engineering IIT Pune PDFNehal AhmedNo ratings yet

- Mechanical EngineeringDocument15 pagesMechanical EngineeringASHISH ANAND50% (2)

- Yash Kshatriya - Mechanical EngineeringDocument1 pageYash Kshatriya - Mechanical Engineeringyashkshatriya108No ratings yet

- Introduction To EngineeringDocument16 pagesIntroduction To EngineeringLuis NunesNo ratings yet

- AbhinavDocument3 pagesAbhinavAbhinav VermaNo ratings yet

- Introduction To Mechanical EngineeringDocument16 pagesIntroduction To Mechanical EngineeringHafiezul HassanNo ratings yet

- Shreyash Ghodke CVDocument2 pagesShreyash Ghodke CVseanNo ratings yet

- Mechanical Enginering Soft and Hard Skills Course FDocument2 pagesMechanical Enginering Soft and Hard Skills Course FfatmafarahNo ratings yet

- Resume A Sadullah Uz AirDocument4 pagesResume A Sadullah Uz AirkamranNo ratings yet

- KristoferkurtinresumeDocument2 pagesKristoferkurtinresumeapi-280159290No ratings yet

- Uttam AJDocument3 pagesUttam AJmohammed rafi shaikhNo ratings yet

- Mechanical EngineeringDocument7 pagesMechanical Engineeringapi-328191955No ratings yet

- 1220.0 - ANZSCO - Australian and New Zealand Standard Classific PDFDocument3 pages1220.0 - ANZSCO - Australian and New Zealand Standard Classific PDFAjesh kumarNo ratings yet

- Wiley ResumeDocument1 pageWiley ResumeKrista SosaNo ratings yet

- Ran Lin, EIT: ObjectiveDocument1 pageRan Lin, EIT: ObjectivePalencia CharlesNo ratings yet

- Mechanical EngineeringDocument30 pagesMechanical EngineeringDeepak SharmaNo ratings yet

- Portfolio Resume2018Document1 pagePortfolio Resume2018api-427265381No ratings yet

- B.tech Me Freshers - CV SamplesDocument6 pagesB.tech Me Freshers - CV Sampleskapil kumarNo ratings yet

- #Rachit Shah ResumeDocument2 pages#Rachit Shah ResumeRachit ShahNo ratings yet

- Usman ResumeDocument2 pagesUsman ResumeMuhammad Usman BashirNo ratings yet

- Hy Hy HyDocument2 pagesHy Hy HyArvind GuptaNo ratings yet

- GF Pre Acp Eng PDFDocument626 pagesGF Pre Acp Eng PDFMessias De Oliveira SantosNo ratings yet

- ITIL® 4 Foundation Exam Full Preparation ITIL® 4 Foundation Exam, Latest Version by Daccache, GeorgioDocument52 pagesITIL® 4 Foundation Exam Full Preparation ITIL® 4 Foundation Exam, Latest Version by Daccache, GeorgioFathi AbderrahmaneNo ratings yet

- SR - No Name Roll No. Credits: (Formerly Delhi College of Engineering)Document11 pagesSR - No Name Roll No. Credits: (Formerly Delhi College of Engineering)kdash43No ratings yet

- أخلاقيات الذكاء الإصطناعي1Document24 pagesأخلاقيات الذكاء الإصطناعي1محمد سامي أبوعصرNo ratings yet

- Inverter: PowerDocument1 pageInverter: PowerMohammad Talib MaqatifNo ratings yet

- Macam2 Kompresor-1-6Document6 pagesMacam2 Kompresor-1-6nopaNo ratings yet

- Quotation For GPS Tracking/Fleet Management: Reports FeaturesDocument1 pageQuotation For GPS Tracking/Fleet Management: Reports FeaturesShiromi MarasingheNo ratings yet

- Global Position System: in This Project We Use GPSDocument9 pagesGlobal Position System: in This Project We Use GPSGarima JainNo ratings yet

- Speech Emotions Recognition Using Machine LearningDocument5 pagesSpeech Emotions Recognition Using Machine LearningAditya KumarNo ratings yet

- SND 6084r Spec SheetDocument2 pagesSND 6084r Spec Sheetalecandro_90No ratings yet

- Alcon Boardband Outdoor SolutionsDocument2 pagesAlcon Boardband Outdoor SolutionsBobanNo ratings yet

- Personal: 1. What DBA Activities Did You To Do Today?Document7 pagesPersonal: 1. What DBA Activities Did You To Do Today?dbareddyNo ratings yet

- B11 - Overload Relays (Ref) ENDocument20 pagesB11 - Overload Relays (Ref) ENAhmed AbazaNo ratings yet

- A Digital Humanities Project ConceptDocument2 pagesA Digital Humanities Project ConceptJo ManjiNo ratings yet

- SSRN Id3274917Document7 pagesSSRN Id3274917Mahesh routNo ratings yet

- Pressure Sensors QBE2002-P.. - enDocument6 pagesPressure Sensors QBE2002-P.. - entarek.amirecheNo ratings yet

- Strengths and Weaknesses of Railway TransportDocument41 pagesStrengths and Weaknesses of Railway Transportbakute12367% (3)

- Datasheet - Seal Oil PumpDocument57 pagesDatasheet - Seal Oil Pumpanıl eyüpoğluNo ratings yet

- CDMA Signaling and Data ServicesDocument90 pagesCDMA Signaling and Data ServicesMohammed GhalebNo ratings yet

- Roland A880 Owner ManualDocument9 pagesRoland A880 Owner ManualSteven ClementsNo ratings yet

- Carbon Footprint of Spam Email Report - McAfeeDocument28 pagesCarbon Footprint of Spam Email Report - McAfeeGerardoRodríguezVázquezNo ratings yet

- Vf160 Owners ManualDocument154 pagesVf160 Owners ManualQiuvoNo ratings yet

- FAQs - ICICI Multi Wallet CardDocument3 pagesFAQs - ICICI Multi Wallet CardAbhishek ShatagopachariNo ratings yet

- Gated Recurrent Unit: Master Sidsd - S2Document23 pagesGated Recurrent Unit: Master Sidsd - S2radNo ratings yet

- Learning Continuity Plan During Covid-19 S.Y. 2020-2021: Department of EducationDocument17 pagesLearning Continuity Plan During Covid-19 S.Y. 2020-2021: Department of EducationMark-Christopher Roi Pelobello MontemayorNo ratings yet

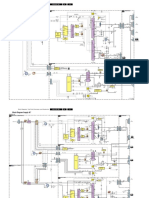

- Block Diagram Supply 37"Document37 pagesBlock Diagram Supply 37"OMARY MWAKAJE100% (1)

- Gaining Access Client Side AttacksDocument13 pagesGaining Access Client Side AttacksImtiaz AhmedNo ratings yet

- AKTA+Process Operating+InstructionsDocument180 pagesAKTA+Process Operating+InstructionsCarlos Alberto Ramirez GarciaNo ratings yet

- What It Is, What It Does, How To Protect Your StationDocument39 pagesWhat It Is, What It Does, How To Protect Your StationCarlo NiccolaiNo ratings yet

- Voltage Sag-Piller Datacentre Dynamic Dubai Piller PDFDocument54 pagesVoltage Sag-Piller Datacentre Dynamic Dubai Piller PDFNgern KlangNo ratings yet